Member postings for Zebethyal

Here is a list of all the postings Zebethyal has made in our forums. Click on a thread name to jump to the thread.

| Thread: Can you recommend a UK supplier for good quality "mill board"? |

| 16/06/2021 13:49:49 |

Just a thought - have you considered Dibond or one of its off-brand alternatives? very strong (used for shop front signage) even thickness of 3mm, 0.15mm aluminium skins on both sides one of which also has a coloured wipe clean coating, around £30.00 for an 8'x4' sheet, could be machined for the thinner areas of your design. I used it for the skins of my laser cutter and also recently made a box from the offcuts for housing the electronics of my World of Ward Division Controller. |

| Thread: SX2P Gas Strut Modification Issue? |

| 03/03/2021 11:53:34 |

Posted by Ron Laden on 03/03/2021 11:16:36:

Posted by Zebethyal on 03/03/2021 10:45:44:

I watched your video and then went out and checked my SX2 as I was concerned that my mill may be suffering the same as yours and I simply hadn't noticed it. I have a 150N (15Kg) gas spring and wherever I position the head, it will sit there with no pressure on the gib lock, head weight (15Kg) and spring pressure equal each other out, upwards or downwards movement, from any location, require equal degrees of effort. If I engage the fine feed, then there is about half a turn of worm backlash, but once that has been taken up I cannot move the head either up or down. I perform milling operations with the Z axis locked, boring operations with the fine feed and some drag on the gib lock and drilling operations with the gib lock loose. Any machining issues I may have had have always been down to incorrect feeds and speeds rather than any movement in the mill. I believe based on your newer motor that your head weighs the same as mine and therefore a 150N gas spring is the correct size, also gas springs offer a constant level of resistance, across their entire range of travel, in either direction (unlike the original spring). The issue on your mill appears to be with the relationship between the rack and the worm. "therefore 150N gas spring is the correct size" Is it..? I fitted my SX2 with a 120N it is equally balanced and I have never had any machining issues with it. Edited By Ron Laden on 03/03/2021 11:18:06 'within the acceptable range' then. There were comments that the OP should use a 120N spring instead of a 150N, someone else (with an older heavier motor) is using 2 x 100N, so there is obviously a fairly wide range that works, in which case multiple individuals are equally amiss claiming/implying that their spring force may be the 'correct' one, potentially yourself included. Regardless of spring force used, the root cause, as just stated by the OP, is with the rack/pinion interaction, something I do not appear to be experiencing on my mill. Maybe I have slightly better engagement between my rack and pinion - would a new pinion gear possibly reduce/remove the issue? |

| 03/03/2021 10:45:44 |

I watched your video and then went out and checked my SX2 as I was concerned that my mill may be suffering the same as yours and I simply hadn't noticed it. I have a 150N (15Kg) gas spring and wherever I position the head, it will sit there with no pressure on the gib lock, head weight (15Kg) and spring pressure equal each other out, upwards or downwards movement, from any location, require equal degrees of effort. If I engage the fine feed, then there is about half a turn of worm backlash, but once that has been taken up I cannot move the head either up or down. I perform milling operations with the Z axis locked, boring operations with the fine feed and some drag on the gib lock and drilling operations with the gib lock loose. Any machining issues I may have had have always been down to incorrect feeds and speeds rather than any movement in the mill. I believe based on your newer motor that your head weighs the same as mine and therefore a 150N gas spring is the correct size, also gas springs offer a constant level of resistance, across their entire range of travel, in either direction (unlike the original spring). The issue on your mill appears to be with the relationship between the rack and the worm. |

| Thread: Have You considered getting a 3D printer |

| 25/02/2021 15:18:13 |

I built my first printer (a modified Prusa i3) from a set of printed parts and a shelf for less than £100.00 back in 2012, after giving up on my Prusa Mendel and a set of cast parts that I started in 2011. For me it was more about the learning experience and fun of building it than simply buying one and using it - I think it was another 2 years before it was completed and actually printed something.

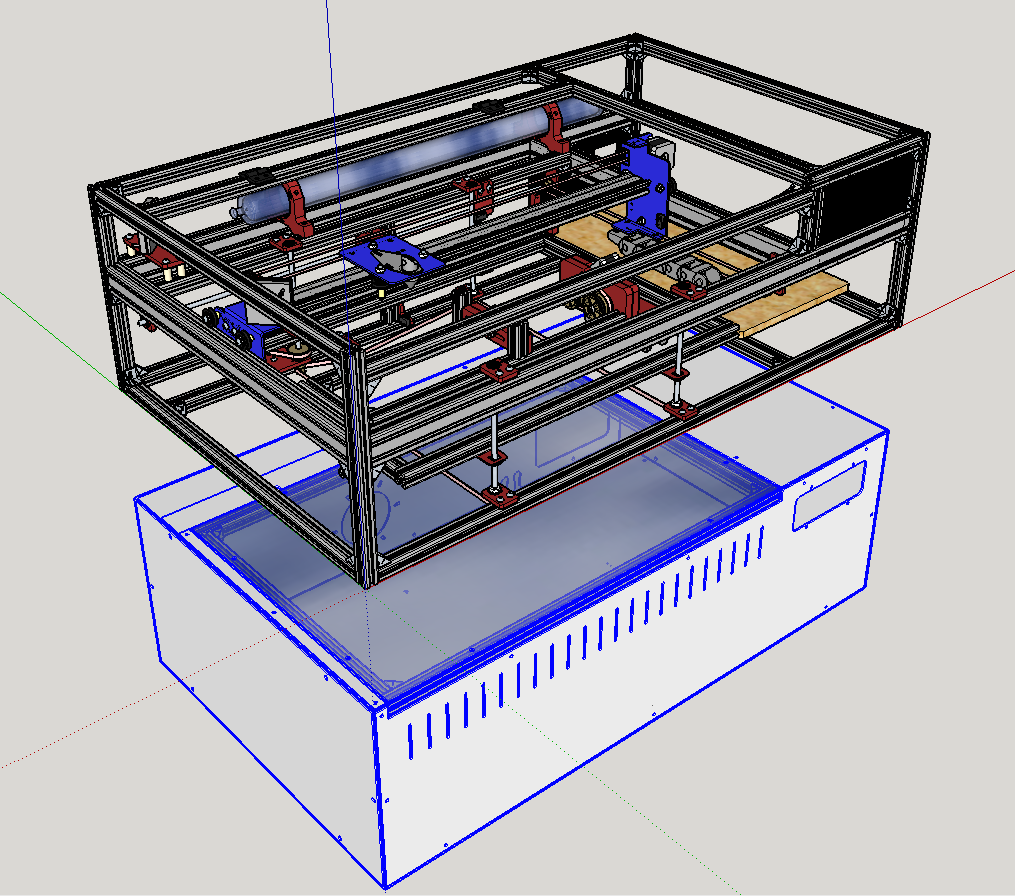

I also heavily modified it over the next few years, using it to print all of the upgrades, as well as many replacement parts when some of the original ones failed (praying the machine would hold together long enough to complete the print). I used it to print all of the parts for my Buildlog 2.x laser cutter, I could have purchased these parts for $75.00 +P&P, I could have machined them from HDPE, or cut them from acrylic with a raw material cost of around £20-30, instead I modelled and printed them for a total cost of around £3.00! I drew the entire laser cutter in Google Sketchup, such that I could guarantee that any additional parts I decided I needed could be designed and known to fit before printing. (I also posted the STL and Sketchup files on GitHub should anyone else want to use them).

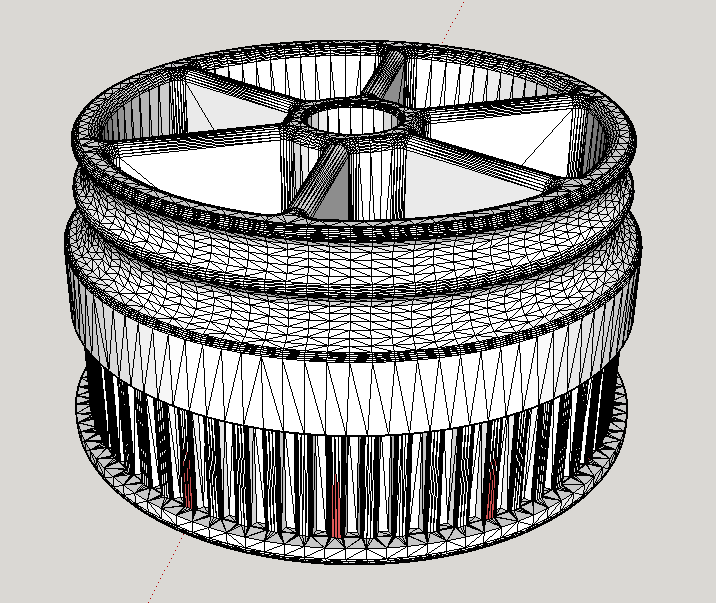

The parts for the rotating axis could mostly have been machined from 12mm HDPE or Acrylic at around £12.00 a sheet, but again I chose to print them for less than £5.00. One of the parts here was a pair of gears that had grooves for a pair of rubber grommets and also a 60 tooth GT2 profile - good luck making these parts by hand or on some manual machinery.

printed part:

Complete rotating axis:

My Prusa i3 eventually fell apart last year (it was mainly made from a sheet of chip board) and I have replaced it with an Ord Bot Hadron, built from a set of aluminium plates and some Makerslide with a total build cost of less than £150.00. The stepper motors I bought for my SX2 CNC conversion had a different screw pattern on the back, so I could not use any of the existing models for covers, so again I designed my own and then added axis information as well.

|

| Thread: Yuriy's Toys DIY DRO |

| 27/04/2020 13:52:41 |

One piece of software I find very useful for vero, perf, strip board type layouts is DIY Layout Creator it is a free piece of software, available for PC and MAC, aimed at people with minimal electronics knowledge. I regularly use it for laying out this type of circuit . Here is the layout I created for the above board using this software: I then use this to create the circuit on the perfboard (view from back of board):

The wire traces shown are stripped solid cores from an old piece of ethernet cable. I am also too cheap to buy sets of jumper wires to use on bread boards so also use various lengths of ethernet solid core wire for this (just the ends stripped). Edited By Zebethyal on 27/04/2020 14:02:56 |

| 27/04/2020 12:19:16 |

Mine cost under £5.00 half of which was for the bluetooth module, and could have cost £0.87 less if I had used a 5V supply or a couple of extra resistors for a voltage divider from my free 7V wallwart supply instead of a buck converter.

Edited By Zebethyal on 27/04/2020 12:22:28 |

| 27/04/2020 11:22:30 |

I built mine using perfboard and an ATtiny85 (an 8 pin microcontroller) as seen here, which also shows a much reduced schematic. I used Igaging scales from Taylor Toolworks, a US ebay supplier, that even after shipping, taxes, etc was still cheaper than any UK supplier, and the cheapest Android tablet I could find. The scales, while they use USB cables are not USB compatible, they use a +ve, -ve, clock and data for pins 1-4, the first 3 can be joined together across all axes to common pins, then you just need the data pin from each axis to go to a separate pin on your microcontroller. A real USB connection uses +ve, D+, D-, -ve for pins 1-4, the 5th connection is for the ID which is floating in the case of a B device, or tied to ground for an A device. As mentioned above, the scales do not use true USB and even mess with where +ve and -ve are connected. It is also worth changing the cables for shielded ones as the original ones can cause resets if they see EMI spikes from motors or similar - I had this happen quite often while I was still using the original readouts. Be aware that the scales may also need to be calibrated, and while you can use a feedback calculation based on a reading and distance measures, the correct cpi value for Igaging scales is 2560 - found on the Schumatec OpenDRO website (the default cpi value in TouchDRO is 10,000 which is way too high). |

| Thread: Coal being phased out |

| 26/02/2020 10:35:42 |

Posted by Bill Davies 2 on 25/02/2020 20:05:19:

Zebethyal, 65000 BTUs, that's a lot of energy. But I'm not familiar with the comment from the Matrix. However, it's a quantity of energy and not a rate of doing work. Assuming it is used up over a day, that's about 800 watts, over a horsepower, continuously, so no-one could keep that up for long! You'd have to eat quite a few steaks, so more bovine farting. You have some nice projects, by the way. Bill Hi Bill, Turns out the Matrix style numbers may be a bit off, however the population spike graph still follows the same trend as the geological temperature spike graph shown by Martin. I found another article that recons (based on some actual scientific calculations) that the human body radiates about 100W of energy per day as heat from consuming around 2000 calories. This is still an increase of around 570 billion Watts per day comparing between 1920 and today (2 billion - 7.7 billion people) and over 750 billion Watts per day between 1700 and today and predicted to rise by another 220 billion Watts per day by 2100. Historically the population has been held in check by disease, famine, wars, ability to produce enough to sustain a village, etc, these days people live longer, hygene levels have improved, medical science has made huge advances and we have all but eradicated many diseases that previously would wipe out entire villages (cholera, typhoid, etc, etc), wars that previously involved 100s of thousands of individuals fighting hand to hand now only use thousands largely fighting long range and food production is managed country wide or globaly . Together the lack of constraints means that population growth is largely unchecked. If the human population was likened to deer in the north of the UK, or Kangaroos in Australia, where there is no apex predator keeping the population in check, there would be some form of cull to reduce the numbers - reminds me of Logan's Run with enforced euthenasia at 30. Many thanks for the comments about my projects. Edited By Zebethyal on 26/02/2020 10:41:41 |

| 25/02/2020 15:53:18 |

Posted by Bill Davies 2 on 25/02/2020 14:09:55:

Martin, your link to the global temperatures over time is very revealing. I have not any compelling 'natural' explanations for the rapid rise after relative stability for the last 12,000 years since the last ice age; orientation of Earth's axis, sunspots, etc. Thanks, Bill Edited By Bill Davies 2 on 25/02/2020 14:10:28 How about this as an off the wall thought: What about global population growth? that has exploded in the last 200 years from 2 billion to a projected 10.9 billion in 2100. before 1700 it was below 600 million. if you watched the Matrix, it quoted an average human body producing around 25,000 BTUs of heat, all those billions of extra bodies are pumping out insane levels of extra heat and CO2 (breathing and farting). Source for population numbers: Our World in Data |

| Thread: magic 127 TOOTH ? |

| 15/01/2020 10:32:33 |

Another good calculator is the one at LittleMachineShop, it allows for any set of gears and any lead screw pitch and will show all possible exact combinations or closest alternatives with the gear set you listed including the error % and error in 10 pitches for each combination. It also allows you to specify min and max values for pairs of gears you can fit on your banjo, so you can restrict it to only show combinations that would actually fit for your lathe. |

| Thread: The Chocolate Fireguard as designed by Mercedes Benz |

| 13/05/2019 14:01:18 |

Having ones own home with off street parking and only a single, maybe 2 cars to charge is great, however that does not work for a significant portion of the population. According to the government 2010 housing survey, 20% of the population live in flats, no real option of charging an EV from the 3rd or 20th floor. 32% rely on street parking and 2% have no provision whatsoever for parking. With the national average being 1.3 cars per household (according to statista), with many having 4 adults and 3 or 4 cars and no off street parking, charging points at work (assuming you can park there) are going to be a necessity. If I look at one of my local roads, most of the houses have provision for off street parking for 2 cars, yet the street is also full of cars with no spare spaces. This is a residential street in greater London that is 20+ minutes walk to the nearest shop and 10 minutes from the nearest bus stop, so the spaces are being used by people who actually live in these houses, not by people wishing to pop to the shops. Go past during the day and there are hardly any cars parked on the street, proving that most of these people work elsewhere. With the current charging speeds/capabilities if any of these households suddenly swapped to EVs they would struggle to charge them in a sensible time frame. Yet supposedly London only has 0.8 cars per household (according to statista), this is a skewed statistic because a high percentage of those who live in central London tend not to own cars and just use public transport or taxis, leaving those outside the centre to boost the numbers with 3-4 cars per household.

Edited By Zebethyal on 13/05/2019 14:05:04 |

| 07/05/2019 10:45:38 |

You then have the ever expanding and multiplying Ultra Low Emission Zones that go out of their way to persecute Diesel car owners, unless your car is less than about 2 years old for a Diesel and around 10 years old for a petrol you are hit by this. Currently only a big issue for the congestion charge area in Central London, but in 2 years time, this expands to just inside the M25 and then will no doubt expand further 2-3 years after that, with similar plans for Birmingham, Liverpool, Manchester, etc on the way. Almost daily demonstrations by taxi drivers in Central London had no effect on this being brought in. I am all for cleaner air, but alternatives need to be incentivised, currently they are just filling the pockets of car manufacturers and associated new car duties for the Government along with massive carbon footprint for manufacture and the waste from scrapping the old ones. Where is the increased investment in public transport to encourage people to use that over driving. Taxes paid by road users on fuel are at least proportional to road usage and also relate to the efficiency of the vehicle being used, unlike road tax, where every owner of a particular vehicle type is taxed the same regardless of 5 mile a year or 50K miles a year usage. |

| 07/05/2019 09:50:11 |

As of 2017, road tax for Hybrid and fully electric cars has changed. Previously they were tax free, now they are subject to road tax based on the purchase price of the vehicle. As an example a Mitsubishi Outlander phev from 2016 or earlier, 4h or 4hs models are both tax free, however a 2017 4h attracts £135.00 and the 4hs attracts £455.00 road tax a year, both have exactly the same engine, however the purchase price of the 4hs is over the £40K threshold. As already mentioned, even fully electric vehicles over £40K purchase price (including options) will be subject to road tax after the first 2 years of ownership currently levied at £320.00 a year. Where is the incentive to buy an electric or hybrid car when you are hit for almost as much road tax as a petrol car? |

| Thread: Dividing Head for a Sieg SX2P |

| 01/05/2019 14:55:59 |

I use a Warco HV6 rotary table on my SX2, which some might argue is a bit big, I bought it at a show so it was slightly cheaper. This version includes a set of dividing plates, plus I liked the fact that it has 4 Tee slots rather than the usual 3. |

| Thread: The Chocolate Fireguard as designed by Mercedes Benz |

| 01/05/2019 08:53:14 |

One of the items not shown by the accidents by car type statistics is what car caused the accident, many times the idiot who forces their way through the traffic putting everyone's life in danger is not actually involved in the accident, yet leaves a trail of destruction behind them. Occasionally there is some poetic justice; whilst on the way to a friend's wedding, I was taking the M4 slip road off the M25, when one such idiot who had been in the outside lane of the M25 decided that he was also going to take the M4, cut straight across the 4 lanes of traffic on the M25 and the 2 lanes of the slip road to embed his car directly into the armco at the left side of the slip road. Another one who was overtaking everyone on the A41, at silly speeds, when we caught up with him several hundred yards down the road had wrapped his car around a tree on the right hand side of the road. Obviously no space to pull in for the lane he was supposed to be in and a car bearing down on him at speed from the other direction left him with no other options. As can regularly be seen on the various police related TV programmes, a high percentage of these people are repeat offenders, often having no license or insurance and a previous ban, however all they receive is a fine that they can't pay as they have no money and a further ban that has no effect either, and they are back out causing havoc again the very next day. Whilst we have people like this on the roads, no amount of safety features are going to make any difference, short of everyone being forced to use automated vehicles/public transport that is itself forced to follow the regulations. |

| Thread: Cheap DRO for Mill |

| 24/04/2019 09:32:36 |

I put some cheap iGaging scales on my Mini Mill (similar to the Warco ones linked in the second post), I had the displays mounted on the front of the spindle but had issues with them resetting, plus the magnets were not the best. I built an interface to use them with the Yuriys Toys DRO on a cheap Android tablet, replaced the USB cables with shielded ones and the interface board is powered via an old phone charger. Scales for 3 axes cost me £80.00 imported from USA, interface card and USB cables cost under £5.00 and the tablet was £35.00. I don't expect the scales to last forever, but they have worked well for me so far and are enabling me to make all of the parts for my CNC conversion, after which I will no longer require them. |

| Thread: Stainless Steel Metric Fasteners |

| 23/04/2019 15:28:31 |

I use Orbital Fasteners in Watford for 90% of my nuts, bolts, set screws, etc. Prices are listed per 100, but they will sell any number of a given item, free next day delivery in and around the Greater London area (full list of qualifying postcodes on delivery charges page) for orders over £25.00. Small online orders of less than £10 value and less than 1kg weight can be sent in a Jiffy bag via Royal Mail, (although not an option at checkout - see delivery charges page for full details). Further afield, next day delivery is a little expensive at £60.00+VAT. |

| Thread: Stainless steel lathe drip tray for £30 |

| 16/04/2019 10:17:06 |

That part number refers to the Mossby shelf ( 119 x 28cm ), which it seems is no longer available. |

| Thread: Any Recent Progress in Induction Heating ? |

| 27/03/2019 15:20:48 |

Induction coils are the go-to method for annealing ballscrews before machining: |

| Thread: R8 instead of MT3 |

| 19/03/2019 12:00:59 |

I don't think I even used the MT3 spindle in my SX2 Mini Mill before swapping it for an R8 one, I intend to use the MT3 spindle on a 4th axis at some point. I have bought the Tormach R8 collet that allows me to use/fabricate Tormach style holders, that makes swapping tooling a breeze I often just tap the drawbar with my hand after loosening (it will be even faster when I finish my power drawbar). Tormach also do an MT3 collet, but I am not convinced it releases as well as the R8 one. |

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in