The Workshop Progress thread 2018

| mechman48 | 23/05/2018 23:22:11 |

2947 forum posts 468 photos | Posted by Meunier on 23/05/2018 20:39:40:

Posted by V8Eng on 23/05/2018 14:26:05:

Posted by mechman48 on 23/05/2018 09:36:53:

Posted by JES on 22/05/2018 12:05:05:

Chantilly ?

Tasted just like horrible oily paint to me...

You’ve been eating oily painted Lace? painted Lace ? Oh baby that's what I like. ... & a purty face, a wiggle & a walk, a giggle & a talk that makes the world go round, a black eyed honey that takes my money, plays real loose like a long necked goose, hey baby that's what I like.... J.T Richardson ( Big bopper ), Richie Valance, Buddy Holly, all sadly died in plane crash Feb 14 1959... yes I am of that age... |

| HOWARDT | 24/05/2018 15:04:22 |

| 1081 forum posts 39 photos | While doing some light finishing off to the edges of my loco frames at the weekend my Dremel drill stopped. On investigation the motor still ran but the chuck spindle didn't. Split the casing and found that the motor and spindle were joined by a bit of splined polythene tube which had disintegrated over the last twenty years, yes the drill plate said 1997, this was my second unit in 40+ years. Looked at the Dremel supplier site in Derby and lo and behold you can get a spare. So duly ordered Monday, arrived in post Tuesday and back up and running. |

| JasonB | 26/05/2018 10:18:52 |

25215 forum posts 3105 photos 1 articles | Started the weekend off on a good note with getting the Robinson X-Type to run for the first time. Still need to play with the hot tube burner as it needs a bit of extra heat at the moment but at least I know everything else is working OK. Bit of a poor video as I only grabbed the phone and that was in my left hand.

|

| mechman48 | 26/05/2018 10:35:20 |

2947 forum posts 468 photos | Very nice Jason, I like the sound... chuff, chuff |

| Mark Rand | 26/05/2018 11:49:42 |

| 1505 forum posts 56 photos | Are you permitted to make a heat retaining cowl around the hot tube? Just a bit of sheet to guide the flame so that all of the tube is heated and less heat is radiated away from the tube? |

| JasonB | 26/05/2018 13:16:32 |

25215 forum posts 3105 photos 1 articles | Mark it does have a shroud but it was making it hard to get the extra flame into the right spot so I took it off, did not get hot enough with it in place. Height of where the heat is applied will advance or retard ignition.

|

| Mark Rand | 26/05/2018 14:16:04 |

| 1505 forum posts 56 photos | maybe a ring shaped burner? |

| JasonB | 26/05/2018 14:27:54 |

25215 forum posts 3105 photos 1 articles | Yes that is a possibility, the strange thing is a few of us over on MEM have all been building at the same time and use the same burner but mine is the only one not getting hot, Graham has suggested reducing the OD of the tube so will try that first. |

| Ian S C | 27/05/2018 12:29:29 |

7468 forum posts 230 photos | With my hot air motors I use the valve, jet, and bunsen section of Primus gas camp stoves, and fit a ring burner . The burners that I use have three rows of holes, and a 60 mm inside dia on has 15 holes (1.5 mm) per row, this is for a motor with a 35 mm hot cap. A gap of 10 mm to 15 mm around your hot tube, 12 holes per row is probably all you can fit in.. I make my burners by using two concentric bits of tube (drill all the burner holes on the inner tube, then braze end plates on. Early on in my time of building these motor I got some old truck drive shafts, a great source of steel tube, and that's what I use. Your motor runs great, but I was (as you were)disappointed when it needed assistance from another torch. You will soon get it sorted. Ian S C |

| mechman48 | 27/05/2018 18:55:24 |

2947 forum posts 468 photos | Decided to do a bit of decorative machining on the entablature of my VS Cross, thanks to an idea from Jim Nic... |

| mechman48 | 27/05/2018 18:59:36 |

2947 forum posts 468 photos |

|

| JasonB | 27/05/2018 19:03:51 |

25215 forum posts 3105 photos 1 articles | Is it set to public? |

| Jim Nic | 28/05/2018 10:15:38 |

406 forum posts 235 photos | That looks good George (but then, I would say that wouldn't I?) How is it running now? Jim |

| mechman48 | 28/05/2018 11:15:13 |

2947 forum posts 468 photos | Thanks Jim; it was running not too bad on trials ( see video ) have a couple of air leaks top & bottom cylinder covers, can be sorted with paper joints. Have started stripping it down for titivating here & there, cylinder cladding to do, looking at combining exhausts into single manifold ( similar to yours ) plus other bits 'n' pieces, as one does so... |

| JasonB | 29/05/2018 15:12:30 |

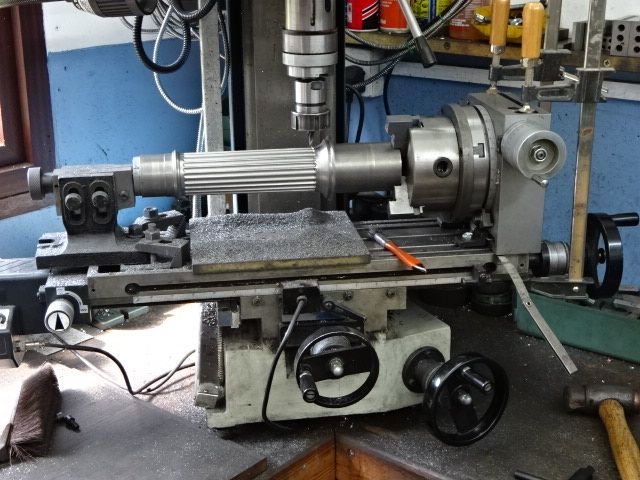

25215 forum posts 3105 photos 1 articles | Just managed to get the Otto cylinder onto the mill table without too much hanging off each end to mill the 24 flutes. Bit of a difficult one to set he as the section to be fluted is tapered and the depth of the cut needs to decrease as it goes up the column to get classic Ionic column proportions. Its good enough but could have done with being about 0.2mm higher at the left hand end. I used the Rotary Table from ARC as it is 72:1 which makes it easy to do 24 divisions as it is just 3 turns of the handle. Quite like using this one and it did not even give me an odd spacing on the last flute

Edited By JasonB on 29/05/2018 15:15:12 |

| mechman48 | 29/05/2018 15:54:10 |

2947 forum posts 468 photos | Nice one Jason, superb bit of machining, must put set up into memory banks for future ref... if I can find where they are |

| Neil Wyatt | 29/05/2018 16:31:35 |

19226 forum posts 749 photos 86 articles | NBice work Jason, a bit more ambitious than my fluted pillars... |

| richardandtracy | 29/05/2018 16:43:46 |

943 forum posts 10 photos | What, preparing early for this year's candlestick challenge? Regards, Richard |

| Jim Nic | 29/05/2018 16:48:18 |

406 forum posts 235 photos | George You may have to do a bit of head scratching to combine the exhaust ports on your Vertical Cross because looking back I see you have done them to plan and put them on the side of the valve chest. I had planned to combine them from the off and so put mine in the face of the chest so that a simple cover plate and some longer studs made it easy. The additional cover plate has a shallow groove in the back covering the 2 ports and then a hole through from the groove to the front with a connector flange silver soldered in. Jim |

| mechman48 | 29/05/2018 18:57:40 |

2947 forum posts 468 photos | Noted already Jim thanks, churning the grey matter over as to which way to go also considering that it would be awkward to fit cladding banding on as well... ho hum, never mind, there's always an answer somewhere, just arriving at it takes a fair bit longer these days... |

This thread is closed.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in