Getting started with CNC Machine & software choice

| Bob Rodgerson | 29/03/2014 09:06:41 |

| 612 forum posts 174 photos | I am considering purchasing a CNC milling machine with a view to light industrial use. I am reasonably conversant with AutoCad for which I have a licence. I have looked at all of the smaller machines on offer and am siding toward a Wabeco machine. Others I have considered are the Axminster and Arc Euro Seig machines. One option with the Wabeco machines is to buy them CNC ready and use controllers of your choice or to go with their own recommended software and controllers. What I would like to know is which is considered the best option of both machine and software that I can integrate with AutCad? I do not want to go down the second hand machine route preferring the guaranteed accuracy of a new machine. Another thought I have had is, has anybody fitted a headstock with chuck to the table of a milling machine and used the X & Y axis to produce cmc turned parts? I would also like to fit a CNC rotary table to the machine. Is this an easy option with the Wabeco machine? |

| blowlamp | 29/03/2014 09:28:27 |

1885 forum posts 111 photos | I would recommend CamBam as your CAM software. It will easily accept DXF output from AutoCAD and just about any other good CAD software and has functionality way, way beyond its price. As for controller software, the common good ones seem to be Mach 3, LinuxCNC (totally free and very good) as well as Edingcnc, amongst other less popular varieties. Those mentioned all work with a fourth axis too.

Martin. |

| Andrew Evans | 29/03/2014 11:14:41 |

| 366 forum posts 8 photos | I would second CamBam. I do simple stuff and don't use a dedicated CAD package and use CamBam as a simple CAD package too. CamBam is easy to understand if you are used to Windows apps because everything is basically a series of properties that you can set in standard Windows style property grids. It's a lightweight application too so you don't need a huge PC to run it. You can a great free trial period to try it out and it's excellent value. As for machines I have a Sieg KX3 which I find great (for what I do), I don't have a 4th axis but I believe it has the driver and wiring already installed and you can just plug one in. This is designed as a hobby machine so not sure how well it would fit for industrial use. Another good option for a new machine is a Tormach which look great value and I have read good things about - if I had the money I would get one imported from the States. Another good option is a 2nd hand Denford Triac, converted to work with Mach3. I have owned a couple of Denford lathes and they are well built machines. I use mach3, which always works well although the user interface is very cluttered and I find the wizards hard to understand in some cases. Andy |

| David Jupp | 29/03/2014 12:11:42 |

| 978 forum posts 26 photos | What do you mean by 'integrate with AutoCAD' ? Just accept output from it to work with, or do you want embedded CAM where changes to the CAD design can ripple through to the toolpath with little effort ? An awful lot of CAM software will accept DXF input - even controller software like Mach3 and I think Linuxcnc will accept DXF input for profiling at least, without actually needing CAM software. Will you need 3D toolpaths, or just profiling? If 3D, is your work in AutoCAD compatible with that need (many use AutoCAD solely as a 2D system)? Will you be using only your own CAD to program from, or will you be accepting files from others (perhaps originating form other CAD systems)? Once complete, will designs remain fixed for manufacture, or will they go through many iterations or variations? CAM software can be 'less than straightforward' to get to grips with - perhaps look at some trials to see which seems most natural for you. Look at user forums, discuss training options with the vendor - help to make the most of the software will probably be at least as important as its technical capabilities. Cost is likely to be a factor to consider - prices vary enormously, some charge for maintenance. It's a bit of a minefield - goo luck. |

| John Stevenson | 29/03/2014 13:59:54 |

5068 forum posts 3 photos | I can offer more advise if needed, be more specific but steer clear of Wabeco's own software, it's the pits. |

| Bob Rodgerson | 29/03/2014 17:14:29 |

| 612 forum posts 174 photos | Hi All, thanks for the advice, plenty of food for thought there. I will do some more research on CamBam and Mach 3 the latter of which seems to be very popular. I use AutoCad as a 2d drawing/design aid and to be honest found 3d work to be a little bit too complex when I dabbled in it over 10 years ago. Most of my work will be the manufacture of such things as alloy casings and covers for small IC engines of various sizes up to about 650 cc, connecting rods in alloy and steel and general milling jobs. From what David is saying I will probably only require profiling. I like a challenge and this is being taken on as a pin money maker and a means of keeping my brain active in retirement. From what I can see it should do all of that. I will be seeing my accountant soon to see which way the wind blows with regard to the recent changes to pensions and to see if, while I still have my own company I can buy a machine on the company even though I will probably be semi retired and it will not return much profit. Even if I can't I will probably still buy a CNC mill out of my retirement fund. I will keep you posted as to how things pan out. In the mean time I might try to add some of the projects that I have used my inbuilt CNC to make for various old motorcycles. John I might just take you up on your offer and I will certainly steer clear of the Wabeco software if I go down the Wabeco route. |

| Bob Rodgerson | 29/03/2014 17:21:21 |

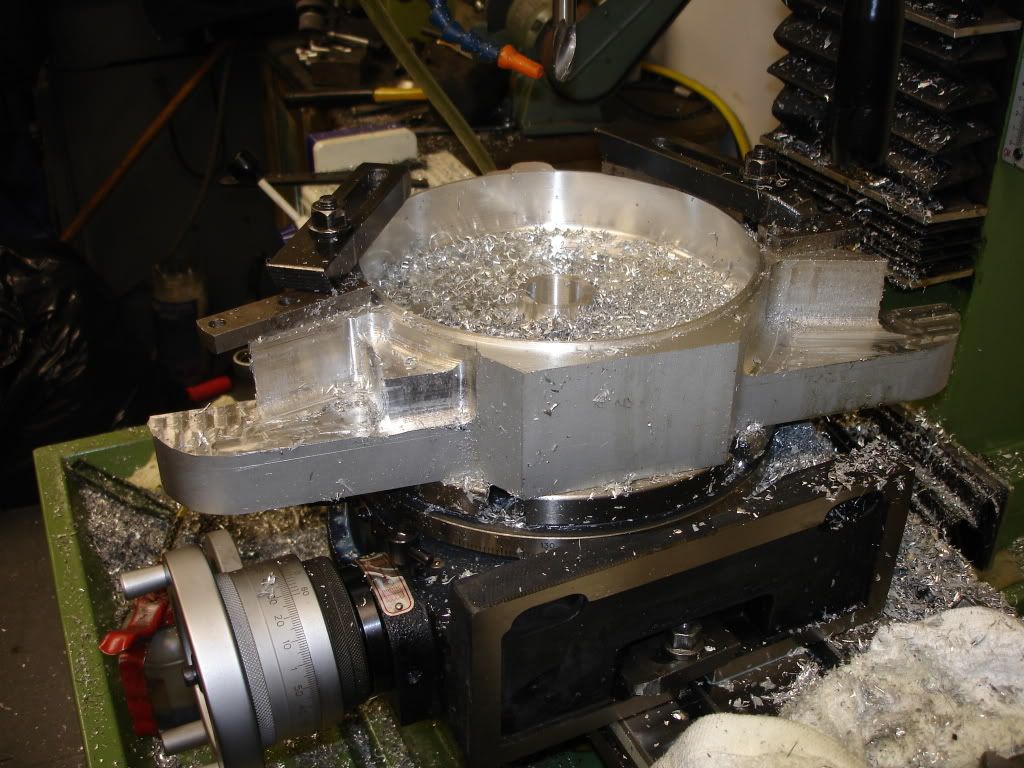

| 612 forum posts 174 photos | Here are some pictures of a 1905 Rover crank case and crank I made from the solid.

Edited By John Stevenson on 29/03/2014 18:11:28 |

| Bob Rodgerson | 29/03/2014 17:22:54 |

| 612 forum posts 174 photos | I guess that doesn't work. |

| Thor 🇳🇴 | 29/03/2014 17:46:22 |

1766 forum posts 46 photos | Hi Bob, did you want to put a ***LINK*** to your photos? The link should load your first photo I think. Nice work by the way. Thor Edited By Thor on 29/03/2014 17:47:54 |

| Bob Rodgerson | 29/03/2014 18:17:02 |

| 612 forum posts 174 photos | Hi Thor, I have quite a few pictures to post but the connection I have in my hotel is so slow that I am running out of patience and time to sort out how they appear. When I get home in a few days time I might get round to posting some more. I didn't want to put a link to the photos and cancelled that half way through. |

| Neil Wyatt | 29/03/2014 19:44:44 |

19226 forum posts 749 photos 86 articles | Bob, I see the photos here. Quite an achievement, very impressive indeed. Neil. |

| Bob Rodgerson | 30/03/2014 19:44:41 |

| 612 forum posts 174 photos | I will try and add the remaining photos that I didn't manage to post yesterday.

Edited By JasonB on 30/03/2014 20:03:22 Edited By JasonB on 30/03/2014 20:07:51 |

| Bob Rodgerson | 30/03/2014 19:52:17 |

| 612 forum posts 174 photos | Still not too sure about posting pictures . I want only links to the photos URL's I have listed not the whole library in my Photobucket account. |

| JasonB | 30/03/2014 20:05:35 |

25215 forum posts 3105 photos 1 articles | Bob, the IMG code copied from Photobucket does not work on this forum, I have altered your post. Next time copy the "direct link" from Photobucket and use that as the url, you need to click the little landscape icon along the top of the reply box and paste the direct link there, also alter the width to 500 in the same window.

J Edited By JasonB on 30/03/2014 20:06:26 |

| Metalhacker | 30/03/2014 20:16:54 |

| 82 forum posts | Wasn't that the subject of some recent articles in HSM? I recognise the photographs!

Andries |

| Bob Rodgerson | 30/03/2014 22:01:42 |

| 612 forum posts 174 photos | I was looking at the Axminster offerings of milling machines and was impressed with the larger of the two milling machines and the level readiness to use. I realise that they are based on Seig machines and may not be as robust as the Wabeco machines but for the money you seem to get a lot more and a decent software package. Any thoughts anyone? By the way. The crank case half and the crankshaft were all made on machines using my own on board CNC software. It works reasonably well but occasionally makes a mistake or two. |

| Bazyle | 30/03/2014 22:17:36 |

6956 forum posts 229 photos | It looks like the Axminster one sticks the ARC one is a box and adds £3k. The software is undefined so potentially unmaintained unsupported unknown. Would what you are doing fit on one of these hobby machines? |

| John Stevenson | 30/03/2014 22:21:36 |

5068 forum posts 3 photos | Bob, The Axminster machines are Sieg based as you say but are also based on the Sieg controller hence the KX3-S suffix The ones sold by ARC are the KX3-M suffix and use the Mach 3 control software. The suffix S machines are not supported in the UK as it basically a Chinese controller with English screen. |

| Bob Rodgerson | 30/03/2014 22:27:57 |

| 612 forum posts 174 photos | Thanks for that John. I am visiting my accountant tomorrow and available budget figures for the machine will become available. The way things are looking I might just go with the Wabeco machine fully fitted with stepper motors/servo motors and ball screws but buy my own controller and software. |

| John Stevenson | 30/03/2014 22:56:11 |

5068 forum posts 3 photos | Don't quote me on this but I think they do offer one of the machines with Mach software but understand it's pricy.

What part of the country are you from Bob ? Perhaps someone local to you has a similar machine.

Depending on dosh there is always the Tormach machine, they are expensive because they come from the states and duty on equipment from the US if far higher than from China ? [ Don't ask me ? ] having said this they do have a very good spec and reputation. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in