3 Phase Motor HP?

| _Paul_ | 11/09/2012 01:53:39 |

543 forum posts 31 photos | I have a 3 phase motor looks like an older squirrel cage Brooks/Crompton sadly it's missing it's information plate. What is the most accurate method of calculating it's KW or HP? The motor is wired Delta and has an across the terminals resistance of 8.2 Ω dividing this by 1.5x gives a single winding resistance of 12.3 Ω. Using Ohms law my calculations have given me this: V/R = I. therefore 230v ÷ 12.3 Ω gives 18.6992 Amps (I) 230v x 18.6992 Amps = 4.3 Kw ÷746 = 5.765 HP Looking at the size of the motor it dosen't seem big enough to be this powerful, but that said it won't run for long on my 2HP RPC before the switch trips out. Any & all help appreciated. Paul

|

| jason udall | 11/09/2012 09:29:06 |

| 2032 forum posts 41 photos | you have measured the "DC" resistance of the COLD windings.. I say cold since that value varies with temperature and rises as the motor heats up. Simpler way to power( watts or horse) would be ( 230*230/R) ( just algerbra) 1) your calculated current would be closer to the stall current (0 rpm) of the motor ( again cold but would drop as the windings heat up ..eeek!) 2 FLA is a term oftern used with motors ( full load amps ) this figure would be closer for that calculation of horse power..( and is rule of thumb about 1/10 of stall current) 3 You say delta...so lets assume three phase ... thus each "phase " is doing the (230 *230)/R thing so hp would be triple what you calculate... ( but see 1 and 2) so my guess would be (3*230*230/12.3 )/10(ish !) =1290 W or1.7 hp stall/fla guess --------kW------ hp 5------------------------- 2.5 ------3.4 8 ------------------------ 1.6------ 2.2 10 ---------------------- 1.3 ----- 1.7 12 ---------------------- 1.0 ----- 1.4

hope this helps and not just fogs the matter

Indeed edited by Jason..to fix the formating decisions made for me by this PXXXXY editor

V Edited By jason udall on 11/09/2012 09:34:20 |

| Les Jones 1 | 11/09/2012 09:32:45 |

| 2292 forum posts 159 photos |

Hi Paul, Les. |

| KWIL | 11/09/2012 11:10:31 |

| 3681 forum posts 70 photos | There is a little thing called inductance that is missing from all of this, we are dealing with AC. What diameter is the main casing and the shaft diameter? |

| jason udall | 11/09/2012 11:55:14 |

| 2032 forum posts 41 photos | Indeed Kwil.. inductance and back emf and various others.. but the OP started simply and a rule of thumb type approach appeared usefull. A motor is not even a pure inductor , motors are more complex and theres phase angle to include in the V.I product.( vector vs scalar arithmatic ) I know or at least have forgotten much of my AC theory. But ..but the OP has made some sensible tests.. might suggest test motor off load measure I and work from there... |

| Russell Eberhardt | 11/09/2012 13:58:11 |

2785 forum posts 87 photos | The only real way to measure the power is to power it up and load it with a brake until the speed drops to its rated speed, usually 1440 rpm., then measure the output power. Dificult unless you have or can improvise a dynamometer. Instead you could measure the electrical power input which will be perhaps 10% higher. Again that's difficult without a power meter, amps times volts doesn't work. I really think your best approach is to see if it will do the job. If it runs slow or overheats it's not powerful enough. Russell |

| Steve Garnett | 11/09/2012 15:10:42 |

| 837 forum posts 27 photos | KWIL is asking the sensible questions, I think - give us some physical dimensions and we can make a much better guess at what the rating plate might have said... I have 2 or 3 different Brookes/Comptons to check against, and I'm sure that others do as well. |

| Stub Mandrel | 11/09/2012 21:34:03 |

4318 forum posts 291 photos 1 articles | DC resistance will only tell you the approximate stall current of the motor, which will, in practice, still be a bit less due to inductive effects on AC. It is, indeed, the physical size of the motor which is the best guide to its power as this limits how much heat it can dissipate. Also, the diameter of the copper wire in the windings should give a clue as to the maximum working current. Follow some of these links: **LINK** Neil |

| _Paul_ | 11/09/2012 22:25:04 |

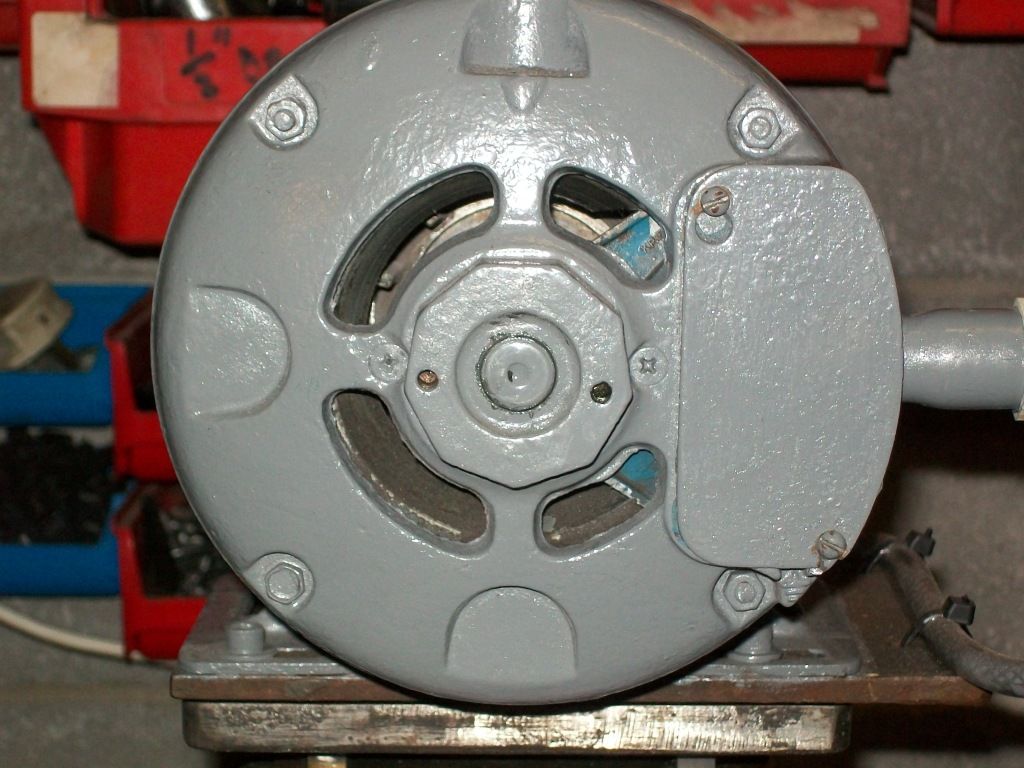

543 forum posts 31 photos | Thank you gentlemen some very good food for thought. Some more information: Dimensions: Length bell to bell 10" Diameter 6-3/8" Shaft Diameter 5/8" Running (unloaded) RPM 2970 (difficult to load up as it's a T&C grinder) Voltages: L1 - L2 = 250v L2 - L3 = 230v L1 - L3 = 240v Voltage mismatch is down to the homebrew 2HP RPC it is running from. Amperages: L1 = 1.5 L2 = 1.1 L3 = 0.7 Above measurements taken with motor running @ 28 degrees C And as they say a picture paints a thousand words....

Thats a 6" wheel in the pics. Paul |

| Nathan Sharpe | 11/09/2012 23:30:27 |

| 175 forum posts 3 photos | Quick and dirty way of working it out from the under ower figures posted: Multiply highest voltage by highest amperage = approx watts that winding, mutiply that by 3, multiply that by 0,8 .That should be accurate enough for most purposes. I figure it at about 1.1 to 1.3 Kw. Nathan. |

| Nathan Sharpe | 11/09/2012 23:33:21 |

| 175 forum posts 3 photos | You could of course ignore my previous post and look at the obvious, it,s running on your 2hp(1100w) converter !! Why didn,t I do that? Nathan. |

| Steve Garnett | 12/09/2012 10:44:21 |

| 837 forum posts 27 photos | Hmm... not quite sure how you arrived at that exactly... Generally, we assume that 1hp is about 750W. And with that frame size, and it being a 2-pole motor (we can tell that from the unloaded speed), Brooke Compton typically made 1 and 1.5hp motors. The 2hp ones are a little bit larger - much easier to keep them cool. And they have a larger diameter shaft, as well. But from the numbers given, I'd say that by the simple expedient of multiplying the average voltage by the total current (which is the correct product!), you get a power consumtion of 792W - which, taken along with the frame dimensions, pretty firmly makes it a 1hp motor, I'd say. Edited By Steve Garnett on 12/09/2012 10:46:57 |

| Russell Eberhardt | 12/09/2012 21:20:34 |

2785 forum posts 87 photos | If it's running at 2970 rpm it is very lightly loaded indeed. Nominal no load speed will be 3000 rpm and fully loaded speed is 2880 rpm. For small degrees of slip ( the speed drop) slip is proportional to load power. Thus if you are taking about 1 hp at the moment you can take nearly 4 hp from it before the speed drops below 2880 rpm (provide of course that it doesn't overheat which would be unlikely for ittermittent loading). More than adequate for your grinder I should think! Russell |

| Steve Garnett | 12/09/2012 23:34:03 |

| 837 forum posts 27 photos |

Posted by Russell Eberhardt on 12/09/2012 21:20:34:

Thus if you are taking about 1 hp at the moment you can take nearly 4 hp from it before the speed drops below 2880 rpm (provide of course that it doesn't overheat which would be unlikely for ittermittent loading). Not from an old Brookes Crompton he won't... These are pretty lossy, and will lose power rapidly. You can get a much more sensible drive for them from a modern inverter, and with care compensate for the torque/speed characteristics somewhat. I still remember the first time I did this - something of a revelation! |

| _Paul_ | 13/09/2012 12:40:40 |

543 forum posts 31 photos | Gentlemen again thank you for some very positive advice. It seems I have by popular consensus a 1HP (or thereabouts) motor. I can appreciate the difficulties of having a mixed bag of parameters to work from with differing motor types/sizes but is there no definitive equation?, how do the motor repair workshops establish a "rogue" motors HP or do they use some kind of Dyno? Regards

Paul |

| Russell Eberhardt | 13/09/2012 17:17:56 |

2785 forum posts 87 photos |

Posted by Steve Garnett on 12/09/2012 23:34:03:Not from an old Brookes Crompton he won't... These are pretty lossy, and will lose power rapidly. You can get a much more sensible drive for them from a modern inverter, and with care compensate for the torque/speed characteristics somewhat. I still remember the first time I did this - something of a revelation!

Both the torque and the current are directly proportional to the slip up to normal working levels. Motors under 5 hp or so are designed for a slip rating of about 4% at their designed output power. Bigger motors have a lower slip rating. Without slip there is no torque developed. As I said you can load the motor until it's speed drops to about 2880 rpm and get the rated power output. I do however suspect that his input power measurement is a little off. The bottom line however is that he is currently running at a slip of only 1% so is running at about 1/4 rated power. The motor is more than adequate for the use it is put to. I must agree with you that an electronic inverter drive is the way to go. My lathe and mill are both fitted with them. Russell. |

| Steve Garnett | 13/09/2012 21:15:50 |

| 837 forum posts 27 photos |

Posted by Russell Eberhardt on 13/09/2012 17:17:56:

Both the torque and the current are directly proportional to the slip up to normal working levels. Motors under 5 hp or so are designed for a slip rating of about 4% at their designed output power. Bigger motors have a lower slip rating. Without slip there is no torque developed. As I said you can load the motor until it's speed drops to about 2880 rpm and get the rated power output. I do however suspect that his input power measurement is a little off. The bottom line however is that he is currently running at a slip of only 1% so is running at about 1/4 rated power. The motor is more than adequate for the use it is put to. You've also assumed that the rpm measured is accurate - generally it's easier to measure current accurately than speed (unless you are specifically set up to do this). And if you go back to the original post, you'll see that this motor, with its low loading, already won't run for long without tripping out the rpc that's driving it - supposedly rated at 2hp. So whilst I also suspect the current consumption, it's for a slightly different reason; there's something altogether not right about it. We know that those motors are rated, at that size, at 1.5hp max, and this one's drawing, to a first approximation, the sort of current that it should be when loaded and running at its rated speed for a 1hp. And running at 28 degrees with that light a load? Seems to be a tad warm to me, especially as this is likely to be a case reading - how warm is it inside? I think I'd be wanting to have a careful look at this before relying on it. Edited By Steve Garnett on 13/09/2012 21:17:38 |

| Nathan Sharpe | 13/09/2012 23:37:08 |

| 175 forum posts 3 photos | As an edit to my 2nd post I,ll change the wattage figure for the converter from 1100W to 1500W, apologies. The very quick calc is one I was given by an instructor at Maddon generators more years ago than I care to remember and is the one I,ve used at work to calculate the generated output required to start a motor of any size (3PH) from a mobile/portable Genset--- works for me--- for the previous 35 years. Just use Ohms law to apply it to motor Wattage. I do agree that the L1 figure is "iffy" but is probably correct given that the inverter is driving L2/L3 through capacitors. Small changes of capacitor values serving L2/L3 would give more balance to the circuit. Doing the calc L1+L2+L3 in running Watts= 776 W, so given the motor/winding temp 1100/1300 W is somewhere very close. The motor/winding temp will fall with better phase balance. Do the calc, Total V(L1+L2+L3) divided by Total A (L1+L2+L3) This also puts you somewhere close. There will always be variation due to temp and stopping/starting a motor during testing will always make it worse as the motor does not dissipate start up heat until it,s been run for a while.

Nathan.

Edited By Nathan Sharpe on 13/09/2012 23:39:34 |

| Russell Eberhardt | 14/09/2012 16:36:08 |

2785 forum posts 87 photos | Posted by Steve Garnett on 13/09/2012 21:15:50: You've also assumed that the rpm measured is accurate - generally it's easier to measure current accurately than speed (unless you are specifically set up to do this). Agreed. With the measured 1% slip an error of 0.5% in the measured speed would give a 50% error in the torque or power calculations! With an ordinary multimeter the current measurement is likely to be within about 5% but the input power is not given by I x V. Power factor must be taken into account, which is likely to be quite low at such low loading. I think the only valid conclusion from all the above posts is that the motor is adequate for the job but there is a problem with the converter. Russell. |

| Steve Garnett | 15/09/2012 10:52:37 |

| 837 forum posts 27 photos | FWIW, I looked up what Brook Crompton have to say about iron-frame motors and their overall performance, which entirely confirms what I suspect. They give a perfectly reasonable forumula which says: output hp= (V * A * Efficiency * Power Factor * 1.732)/746 If we assume that the efficiency and power factor figures are in the normal range for an unloaded three-phase motor, then the product of these * 1.732 is going to be approaching unity (I've guessed a value of around 0.9), then the end figures look like: (240 * 3.3 * 0.9)/746 = 0.955hp. That's as near to 1 as makes no odds. All the stuff about temperature will make a difference to the efficiency figure, certainly - but not a huge amount of difference to the end result. It is a 1hp motor! |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in