Putting on a fine cut..

| jon hill 3 | 25/06/2023 14:15:55 |

| 166 forum posts 40 photos | Having always wanted to build a small single cylinder aero engine I thought it would be a good time to get some opinion on putting on fine cuts, say working to 5/10000" in steel or aliminium. As my ml10 is graduated in 'thou' what are the remedies to get finer cuts?

|

| Martin Kyte | 25/06/2023 14:42:37 |

3445 forum posts 62 photos | Angle the compound slide to 6 degrees and put on the cut using that. 10 thou on the dial is 1 thou infeed. regards Martin |

| Buffer | 25/06/2023 14:56:22 |

| 430 forum posts 171 photos | Spareys the amateur lathe tells you all about this. |

| John Haine | 25/06/2023 14:58:26 |

| 5563 forum posts 322 photos | But you need to have a really sharp tool and well adjusted slides. |

| noel shelley | 25/06/2023 14:59:44 |

| 2308 forum posts 33 photos | For the final sizing lap or use a cylinder hone. Good luck Noel. |

| martin haysom | 25/06/2023 15:08:20 |

165 forum posts | working to those limits you will also need a tempture controlled workshop and some very high end machine's. as for measuring equipment i don't know. but i do know it will need calibrating professionally. i have never worked to those limits, however i do work in the aerospace industry where such equipment is the norm. |

| noel shelley | 25/06/2023 15:33:32 |

| 2308 forum posts 33 photos | Hi Martin, as an apprentice I was given a Harrison 10 and a 1" mike and told to make 400 pins in silver steel, to a tolerance of 1/4 thou, the lathe was worn and there was no temp control, but I got the job done - it was for RR. Noel |

| bernard towers | 25/06/2023 16:11:22 |

| 1221 forum posts 161 photos | Model aero is machine to within a thou and hone /lap the rest, just finished a 0.1 dragonflea but its a tad too small for me ,working on a glow humbug at the moment hope you have success with yours. somewhere around 1.5 to 2.5cc is a nice manageable size. |

| JasonB | 25/06/2023 16:51:47 |

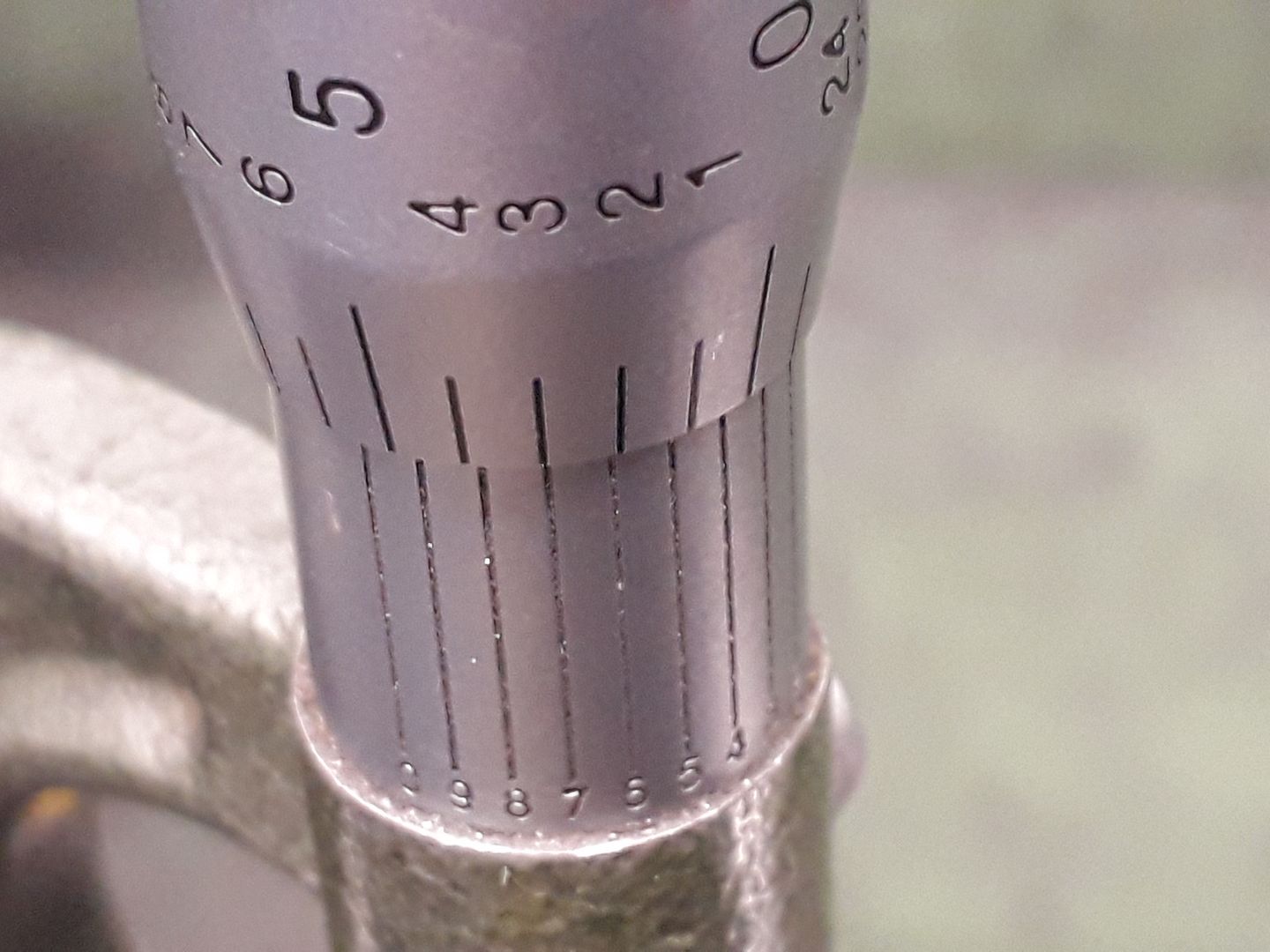

25215 forum posts 3105 photos 1 articles | I've never bothered to do anything special when making aero engines even the ones with no rings just split the divisions by eye. Final fit is by feel not measurement. So long as both parts you are working on are at similar ambient temp you don't need to control the workshop temp Here is the old chinaman taking a 1 though cut to get to 0.3937" (10mm in new money) Insert tool and cross slide set parallel to lathe axis which is a lot easier when working to a shoulder like here than having the slide set over as that also moves the tool sideways as well as a little way in.

Edited By JasonB on 25/06/2023 17:33:57 |

| not done it yet | 26/06/2023 09:11:00 |

| 7517 forum posts 20 photos | Posted by noel shelley on 25/06/2023 14:59:44:

For the final sizing lap or use a cylinder hone. Good luck Noel. Precisely! |

| Kiwi Bloke | 26/06/2023 10:23:13 |

| 912 forum posts 3 photos | ... and it's easier to make the piston to fit the bore, rather than t'other way round. |

| SillyOldDuffer | 26/06/2023 14:43:01 |

| 10668 forum posts 2415 photos | Below about a thou, various tricky factors start causing trouble, and they get progressively worse:

What this boils down to is that lathes (and milling machines) struggle to take cuts that are both fine and accurate. Tool-room lathes and jig-borers do better, but they're elaborately engineered and maintained to hold accuracy. They have obvious limits too. The answer to high accuracy isn't a lathe. Industry are fond of grinding machines but these are expensive. Fortunately small workshops can get good accuracy and surface finish with manual abrasives, notably emery papers,and lapping. Making pistons, the lathe is used to get close to size, but turning stops a little above target. After that a succession of ever finer abrasives are used remove unwanted metal, not cutters. Unlike cutters, correctly used abrasives improve the surface as well as removing metal. The main problem with abrasives are removing metal evenly, and the amount of time it takes. Larger pistons don't go for a very tight fit: instead the seal is provided by piston rings which can expand slightly to fit. Although cylinders are bored very accurately in big engines, I've got the impression surface finish is even more important. There is no 'Running In, Please Pass'. Au contraire, I've built 5 model engines and they all needed a lot of running in! I spoiled several pistons by rushing the finishing stage. Patience in the workshop is not one of my virtues. I rarely work to better than ±0.05mm and avoid high-accuracy if I can. I stay with innocent measuring because high-accuracy is dangerously additive. 'Chasing Tenths' could easily take over my life. As Chasing Microns is even more difficult, only real men dare go metric!

Dave

|

| Martin Kyte | 26/06/2023 15:44:35 |

3445 forum posts 62 photos | However when you know you need to take 3 and a half thou off the angled top slide gets you closer to setting 1.75’ than guessing the setting of a small dial. It assumes the your tool is sharp and the last cut you made took a similar amount off. regards Martin |

| old mart | 26/06/2023 20:24:11 |

| 4655 forum posts 304 photos | Most of my imperial micrometers read in tenths of a thou, but I have never had any difficulty in splitting the 0.001" divisions by eye, so the vernier scale is redundent for my purposes. You can try tests to find how accurately you can split the divisions on your cross slide using a DTI and a piece of ground stock in the chuck, a MT socket or new drill shank. Actually cutting this finely gets difficult, which accounts for the advice on lapping. I can cut 0.0005" with steel using carbide inserts intended for aluminium. |

| Huub | 26/06/2023 22:18:11 |

| 220 forum posts 20 photos | Under CNC control, taking a 0.005 mm cut in aluminium using a CCGT060204 insert (uncoated, ground) is not a problem (do this on a daily base) even on the mini lathe. In aluminium, I could cut as shallow as 0.002 mm (stepper resolution). The biggest problem is measuring the diameter, not the turning part. For inside diameters my 2 point gauges are just not repeatable enough. That is not a gauge issue but more my ability to position the gauge the right way with the part in the chuck. Measuring a calibration ring with ground surfaces is not a problem.

|

| Neil Lickfold | 27/06/2023 10:58:19 |

| 1025 forum posts 204 photos | Posted by jon hill 3 on 25/06/2023 14:15:55:

Having always wanted to build a small single cylinder aero engine I thought it would be a good time to get some opinion on putting on fine cuts, say working to 5/10000" in steel or aliminium. As my ml10 is graduated in 'thou' what are the remedies to get finer cuts?

When I trim pistons for model engines, I set the top slide at the same angle that the taper is for the crown, about 0.7 deg. It makes my Myford top slide , 1 notch is 1um on diameter or so. The steel liners with iron pistons, the liner wants to have at the bottom below the exhaust port , about Ø0.05 to Ø0.06mm bigger than the piston diameter. Then from the exhaust port to the top dead center mark, wants about Ø0.01mm then parallel to the very top of the liner. All the liner tapers can be lapped from a parallel bore. The piston wants to be turned to fit ideally, with a slight crown taper, for about the thickness of the crown. On cast iron pistons, I recommend that the top slide be set to about 0.5 deg. Trim the piston until it just enters the bottom of the liner. Then only using the topslide to make the next cuts until it fits where you want it. To get the last little bit, you can use a light grey scotch brite on the piston. I like the Kyocera ccgt type of insert in the PR1425 grade. I have a picture in my album of the insert. As for cuts, clean the piston with break clean or any other degreaser and trim the piston dry. The amount that a lathe can cut is down to a lot of variables. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in