Small saw. Proxxon or something else

| John Smith 47 | 21/04/2021 01:18:36 |

| 393 forum posts 12 photos | Hello

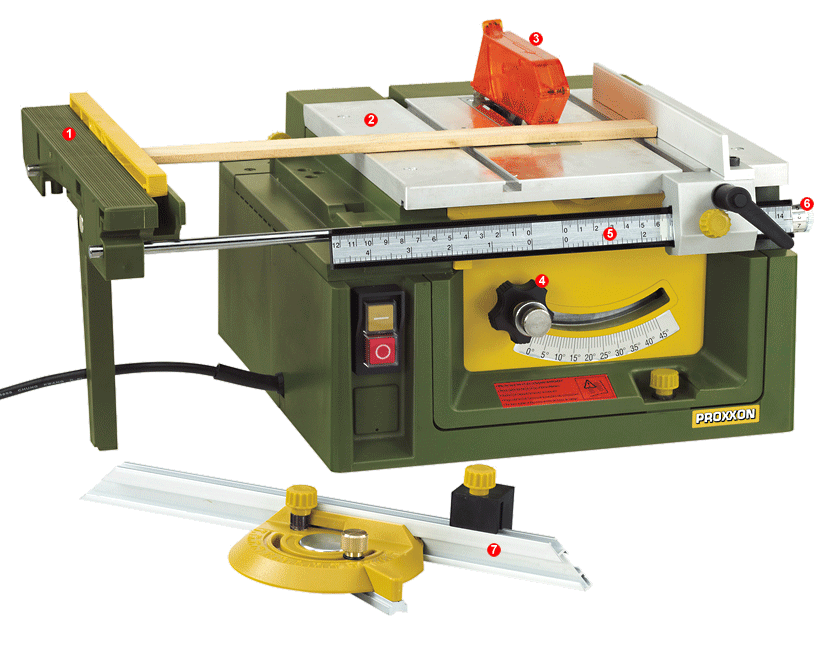

If not can you recommend any other alternative? PS Or what about the Proxxon FET Table Saw?

|

| Pete. | 21/04/2021 02:30:36 |

910 forum posts 303 photos | Hi John, those are for woodwork, even if the machine did possess the power to cut steel, I don't think you'd find an 80mm blade capable of cutting steel, I've never seen one. A good hacksaw with a high tension ability would be better, or a horizontal Bandsaw with table to use vertically. |

| John Smith 47 | 21/04/2021 02:56:24 |

| 393 forum posts 12 photos | I need to cut straighter lines and more accurately placed lines and faster than is possible with a good hacksaw. I recently needed to cut some 0.10mm steel, which I needed to keep perfectly flat. The metal was way too thin for a hacksaw - the teeth just made total mess. I tried a nibbler and even a pair of scissor but they both made a mess of the flat surface. |

| John Smith 47 | 21/04/2021 03:34:39 |

| 393 forum posts 12 photos | Another circular saw option would be this: "NovelLife Mini Hobby Table Saw with Miter Gauge,3 Inch HSS Circular Saw Blade,96W Power Supply for DIY Handmade Wooden Model Crafts, Printed Circuit Board Cutting"

But like I say, I am currently favouring abrasion, rather than any kind of cutting for if and when I next need to cut very thin (0.1mm) steel plate. Mostly I shall be cutting 1.0mm mild or stainless steel.

PS Is there any way to edit the title of the post after you have started a thread? Also the animated GIF on the right are a nightmare of a distraction! I need to find an extension that stops all GIF images from animating. Edited By John Smith 47 on 21/04/2021 03:39:28 |

| Pete. | 21/04/2021 04:48:02 |

910 forum posts 303 photos | As already said, I doubt you'll find any 80mm steel cutting blades, sawing steel is generally not a process used for finished edges where high standards of straightness is required. None of those woodwork hobby tools will meet your very high requirement standards, or were you planning on milling the edges after? Have you considered a bench shear like this? This is a tool commonly used for cutting straight lines in sheet metal. If you keep the work left of the blade during cuts, it should be possible to keep it flat. |

| David George 1 | 21/04/2021 06:27:20 |

2110 forum posts 565 photos | In the past I made thin strips of steel for a mould to make cooling channels in a ceramic turbine blade and we cut them on a surface grinder with a slitting blade perhaps you can get a small bench top surface grinder or a ceramic tile cutter which will take a slitting wheel. David |

| John Haine | 21/04/2021 06:57:51 |

| 5563 forum posts 322 photos | Good suggestion from David - see this from B&Q at £40. Alternatively, for very thin shim, I use two ways to cut 0.1mm BeCu sheet for pendulum suspension springs. One is using an office guillotine which is quite effective and hardly affects flatness. The other is to clamp the material in a machine vice with the bit you want in the jaws, and use an old wood chisel to cut off the excess. |

| Roger B | 21/04/2021 07:19:35 |

244 forum posts 105 photos | The 50mm Proxxon solid carbide blade 28 011 will certainly cut steel although the KS 230 may run a little fast. This is one slitting a steel 'taperlock' style bush. They a quite useful as small slitting blades.

|

| JasonB | 21/04/2021 07:22:57 |

25215 forum posts 3105 photos 1 articles | If you go through with buying a mill that you were asking about in your other thread then a slitting saw blade in that could be used to cut sheet, subject to overall size and holding methods. Although you can get 80mm slitting saw blades I would suggest a smaller dia on a mill the size of the Sherline. Cut off disc could also be used in the same way As for the Gifs and adverts down the side of the page, they help pay for the site, without them it may not exist and you would not have access to all this "free" information and help Edited By JasonB on 21/04/2021 07:46:38 |

| Michael Gilligan | 21/04/2021 07:52:36 |

23121 forum posts 1360 photos | Posted by Roger B on 21/04/2021 07:19:35:

The 50mm Proxxon solid carbide blade 28 011 will certainly cut steel […] . That’s useful to know, Roger ... The description does not claim that ability, but I see that you are using it on a more appropriate spindle than that of the KS230 Thanks MichaelG. . Ref. Solid carbide saw blade |

| Stuart Munro 1 | 21/04/2021 08:45:29 |

| 108 forum posts | Hi John, I model in wood and metal and faced this same dilemma. I bought the Proxxon FET which is (mostly) great for fine wood cutting but useless for any metals. Even the non ferrous one that I mostly work with. I have to compliment Michael on being able to cut steel with the solid carbide blade - I found with my Proxxon FET, whilst the cut was good, the FET overheated and cut out. My solution was a guided handsaw such as the Stanley 1-20-800 Adjustable Mechanical mitre box - sorry don't know how to paste a picture here but it retails on Amazon for £37.99. Its a long suspended saw with changeable blades in a metal adjustable frame. (you need to look on amazon to see what I mean). I've had mine for many years and its not a Stanley but looks the same, so check first that it has the option for fine tooth blades. Mine cuts very accurately through most materials. But if you are looking to cut heavy pieces you do need something powered, unless you have very strong arms! Stuart

|

| Michael Gilligan | 21/04/2021 08:51:20 |

23121 forum posts 1360 photos | Posted by Stuart Munro 1 on 21/04/2021 08:45:29:

[…] I have to compliment Michael on being able to cut steel with the solid carbide blade - . I think Roger deserves the compliment MichaelG. |

| Stuart Munro 1 | 21/04/2021 08:59:29 |

| 108 forum posts | Michael, Roger, Mia cupla!

I also use a slitting saw for fine work but obviously this can not cope with cutting off stock neatly of removing large pieces from an object before milling the rest. The 'Adjustable Mitre Box/Saw' works well for that purpose. Stuart |

| Martin Kyte | 21/04/2021 11:39:32 |

3445 forum posts 62 photos | It's more expensive but you could consider the Proxxon Micromot MBS 240/E Bandsaw. It's small but with a sled you can cut wood and metal in straight lines. They do mention diamond bands which will deal with glass and ceramics too. I have a freind who bought one and he was very happy with it for brass and steel for clocks and small model engines. It's a genuine all rounder although as I said small. regards Martin Edited By Martin Kyte on 21/04/2021 11:40:01 Edited By Martin Kyte on 21/04/2021 11:40:20 |

| Dalboy | 21/04/2021 11:44:12 |

1009 forum posts 305 photos | Being a woodworker wanting to get into model engineering I would never consider using woodworking cutting type tools on metal. I have a small belt/disc sander which I use on wood but will be buying a second one for metal to avoid contamination I know it is not the same as cutting tools. I have worked with metal quite a bit in the past in my previous job as well as sell machines so am aware of the limitations of many of them. One exception may be a powered scrollsaw/fretsaw with the correct blade but only suitable really for thin metals. Getting a straight line takes a little practice and may need a false table with zero clearance if the item is small Edited By Derek Lane on 21/04/2021 11:45:56 Edited By Derek Lane on 21/04/2021 11:58:16 |

| Martin Kyte | 21/04/2021 11:47:31 |

3445 forum posts 62 photos | Posted by Derek Lane on 21/04/2021 11:44:12:

Being a woodworker wanting to get into model engineering I would never consider using woodworking cutting type tools on metal. I have a small belt/disc sander which I use on wood but will be buying a second one for metal to avoid contamination I know it is not the same as cutting tools Lovely to have the choice. Even more ideal if you can run to separate workshops. The OP seemed to want a saw that would do both. regards Martin |

| John Smith 47 | 21/04/2021 12:15:56 |

| 393 forum posts 12 photos | @Pete - I need the metal to stay absolutely flat after it has been cut. @David George 1 & John Haine So my instincts are to go for some kind of 'grinding' cut rather than a cutting blade. I am assuming that that tile-cutter does its cutting with a grinding wheel - probably with diamonds in it. That's an interesting line of thinking! Even if the build quality looks v cheap & sure enough the reviews are terrrible. Fwiw, here's another one: https://www.screwfix.com/p/performance-power-ptc450e-450w-electric-tile-cutter-230-240v/469gt I was very struck but just how well aluminium oxide & Corundum cutting disks cut steel, using my hand held highspeed drill (20,000RPM) but only once you get them up to very high speeds. Unfortunately mine is only 40watts (an old MICROMOT 50/EF) and torque suffers, but it does the job.

Precision drill/grinder FBS 240/E **LINK**

My main problem then becomes finding a circular table type housing to mount the thing on. HOWEVER the FET Table Saw is only 7000 RPM even though it is more powerful thant the hand tools (being 200watts), so I don't think it will cut very well using abrasion.

PROXXON SOLID CARBIDE SAW BLADE @Roger B - that 50mm Proxxon solid carbide blade 28 011 may cut steel but it's certainly not designed to do so "non-ferrous" only.

@Stuart Munro 1 - I thought those "Stanley 20-800 Adjustable Angle Clamping Mitre Box" IF they can cut steel then they DO look useful but they won't allow me to cut sheets of material Edited By John Smith 47 on 21/04/2021 12:22:51 Edited By John Smith 47 on 21/04/2021 12:27:13 |

| JasonB | 21/04/2021 12:22:50 |

25215 forum posts 3105 photos 1 articles | The "table saws" have a lower rpm due to the fact they take a larger diameter blade than the hand held tools. if you work out the speed at the cutting edge for both diameter cutters it will be about the same.

|

| John Smith 47 | 21/04/2021 12:28:07 |

| 393 forum posts 12 photos | Posted by JasonB on 21/04/2021 12:22:50:

The "table saws" have a lower rpm due to the fact they take a larger diameter blade than the hand held tools. if you work out the speed at the cutting edge for both diameter cutters it will be about the same.

Ah yes, good point! |

| Pete. | 21/04/2021 13:26:08 |

910 forum posts 303 photos | David's idea of of an abrasive disc in the table saw style machine is a good one, I think my 18v angle grinder runs about the speed of that proxxon saw, you could use a good quality 1mm thick slitting disk, they have a 22mm centre hole, a small ring could easily be made to take the 10mm proxxon up the correct size for 100mm 1mm slitting disc for an angle grinder. If the depth of cut is adjustable on the saw, you could slide it over in say 3 passes, about 0.3mm per pass should work. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in