Bandsaw - wood and metal ?

| gerry madden | 11/04/2021 11:29:00 |

| 331 forum posts 156 photos | Finally after years of ridiculous hand sawing I've decided to get myself a bandsaw. I'm erring towards the tall standing type that are usually described as being for woodworking. However half the time I need to cut bits of metal, which in the worst case would be a 5 inch diameter bar of aluminium or steel plate up 1 inch thick. Even with the right kind of blade fitted I can see an issue with this type of saw is that the table doesn't move so one would have to constantly push the workpiece towards the blade. With heavy lumps of metal this could be challenging and depending on how one chooses to do it, possibly dangerous too. My question is therefore: Am I 'barking up the wrong tree' in thinking that a woodworking saw would do for lumps of metal ? If so, what would you recommend ? Gerry

|

| Clive Brown 1 | 11/04/2021 11:48:19 |

| 1050 forum posts 56 photos | Woodworking bandsaws run too fast for metal cutting, particularly ferrous. The blades will be quickly ruined. My small bandsaw is geared down to a speed of about 200ft/min and that seems fairly good. Also you would find that attempting to cut large diameter round bar held by hand on the saw table is NOT advisable. The bar will rotate and you will not be able to grip it. Can't help with a suggestion of a bandsaw for taking work of the size that you mention, but it will be big. I use an old Rapidor hacksaw which will take bar up to 6". Edited By Clive Brown 1 on 11/04/2021 11:53:20 |

| David George 1 | 11/04/2021 11:49:38 |

2110 forum posts 565 photos | Hi Gerry I think you would be much better of with a horizontal type band saw than a vertical saw. You can get a horizontal saw which can be configured to be used as a vertical saw and that gives you options. If you were to try and cut a 5 inch diamiter bar on a vertical saw it would be challenging but thin plate is better on a vertical saw. I have a small horizontal saw from Chester machine tools and a vertical saw from Machine Mart and I use the horizontal saw most of the time but the vertical saw is used to cut wood, plastics, and non-ferrous metals and eavan with the correct blade is useless for steel etc. David |

| Georgineer | 11/04/2021 12:40:18 |

| 652 forum posts 33 photos | Gerry, At the last school where I worked we had a floor-standing bandsaw which could take either wood- or metal-cutting blades. In the pedestal was a series of v-belts and pulleys to select the appropriate cutting speed, which was much slower for metal and required a different blade. Unfortunately I can't remember the make or model. I did once witness a colleague cutting metal with the woodworking blade. The sparks were quite impressive, and the technician had to replace the blade afterwards... George B. |

| Jeff Dayman | 11/04/2021 12:44:44 |

| 2356 forum posts 47 photos | For many years now I have been using a steel framed woodworking bandsaw modified for blade speed of 150 fpm an using an HSS bimetal blade. This saw cuts steel or other metals as well as wood with excellent results. Typically woodwork machines run many times faster than 150 fpm and have lighter blades and lighter frames, not suitable for metal cutting. However If you can find a woodworking saw that can be modified to run at 150 fpm and having a steel frame, it may work fine. Otherwise look for a metalworking saw. You may also be able to find an inexpensive Chinese import handheld portable metalworking bandsaw, which you could use handheld of course but it could be mounted to a bench frame and a table fitted to it if need be. Edited By Jeff Dayman on 11/04/2021 12:45:54 |

| HOWARDT | 11/04/2021 12:46:36 |

| 1081 forum posts 39 photos | As all said the speed is one factor, but 1 inch steel and 5 inch diameter aluminium you would need some serious holding fixture that slides easily supporting the work both sides of the blade. If you don’t there could be some snatch as the part gets close to cut off. Also the time taken to stand there feeding the material through. Better to get the steel plate flame cut. |

| Douglas Johnston | 11/04/2021 12:51:11 |

814 forum posts 36 photos | In the past I wondered if I could get away with one bandsaw for wood and metal but it is not really a good option. The speeds are different and so are the blades. You would be forever changing the blades and that can be a real pain. I ended up with one of the 6 by 4" horizontal bandsaws for the metal and a vertical one for wood. A wood one will cut aluminium at a pinch but not large chunks of the stuff.

Doug |

| JasonB | 11/04/2021 13:02:15 |

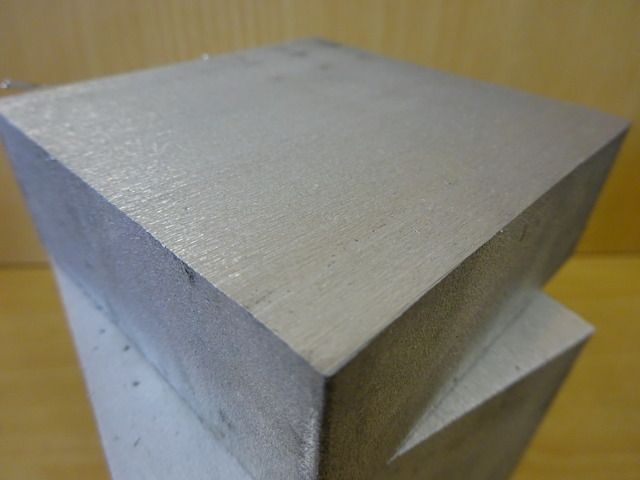

25215 forum posts 3105 photos 1 articles | With those requirements a vertical saw designed for metal will have a decent throat width for the plate and if you make up a sled then round and section can be cut safely. I use my old woodworking bandsaw for nonferrous sheet/plate and before getting the Femi it wa salso used for bar, with a bimetal HHS blade at woodworking speeds it cut OK, this is 3" square 6082 but it would be too fast for steel.

|

| John Haine | 11/04/2021 13:30:13 |

| 5563 forum posts 322 photos | I have a Femi 782 which is designed for metal and will cut up to 65 mm bar iirc. Jason has one too I think? I also have a table for it to use it in vertical mode for sheet. It will cut wood though not designed for it. Highly recommended. Stakesys is a good supplier. |

| Ian Parkin | 11/04/2021 15:16:17 |

1174 forum posts 303 photos | Many of the older startrite machines say s14,18,24 have 10 speeds with 5 belt positions and a 2 speed gearbox they will happily cut anything. but I wouldn’t want to stand there cutting 5” of steel with it

i have a s14 5 and cut alloy plate regularly on it up to 3 inch thick but mainly i use it for woodwork and a 4x6 bandsaw for metal stock |

| Martin Kyte | 11/04/2021 15:29:12 |

3445 forum posts 62 photos | Hi Gerry If you are exclusively wanting a cut off saw for metal then vertical bandsaws are not really suitable for large diameter round bar. Plate and rectangular section yes. I bought one of these from Axminster Tool a few years ago and it has saved me a lot of effort. It is arranged for a slow speed step on the drive pully with the addition of a variable speed drive. Slow speeds are a must if you are cutting metal and of course you need fast speeds for wood. I find it excellent for cutting blanks for clockwheels and frames in Brass. Steel plate up to 1" thick and large billets of aluminium. I'm not saying thats all it will do just what I have done to date. Most usefull for removing the waste from odd shaped lumps before machining. And obviously it's in it's element for wood. I hope that helps. regards Martin |

| larry phelan 1 | 11/04/2021 16:22:48 |

| 1346 forum posts 15 photos | I have a Startright upright bandsaw for wood cutting [was never happy with it, even for that ], tried cutting light sheet steel with it, learned very quickly that it did not like it and it was rather scary. Speed is much too fast and material too difficult to control, and this was even with a suitable blade. Horses for courses, I think. As regards cutting 5" round anything, you are a brave man ! |

| ega | 11/04/2021 16:35:42 |

| 2805 forum posts 219 photos | larry phelan: Sorry too hear that your Startrite bandsaw - they used to be made just down the road from me - is not performing well. I have had some success cutting sheet steel with a Rage/Evolution blade on the radial arm saw. |

| not done it yet | 11/04/2021 19:35:30 |

| 7517 forum posts 20 photos | I have a horizontal, metal-cutting bandsaw. The frame can be positioned in the vertical position, so I have made up a frame, with horizontal table, which is held in place by the vise. It needs extra vertical support, for the table, in this mode. I doubt it would cope with timber cuts as well as a vertical startrite, but that is not required as I have access to a wood sawing bandsaw. The vertical startrite (for timber) that I used a long time ago was often used for cutting curves (with narrow blades). This may be an issue. As JH says, Stakesys is a good website to check out. They actually show a lightweight table kit for the 782XL saw @ £85. The 782XL will cut 100 x 85mm ‘rectangular section’ (they quote 95mm square). |

| Speedy Builder5 | 11/04/2021 20:13:46 |

| 2878 forum posts 248 photos | Buy a second hand vertical bandsaw designed for wood. replace the motor with a small 3 phase motor controlled by a VFD. Buy some HSS toothed bandsaw blades - Happy days. Just be careful that blades don't "snatch" when cutting larger round bar / tube etc. Bob |

| Neil Wyatt | 11/04/2021 20:34:10 |

19226 forum posts 749 photos 86 articles | The ideal world is one of each - possibly cheaper than buying a VFD and less hassle blade changing Otherwise, as suggested above a metal cutting one you can put in 'upright' mode. Plus if you get stuck, it's easier to handsaw through a sleeper than through a 2" metal bar! (Voice of experience). Neil

|

| Brian G | 11/04/2021 20:35:23 |

| 912 forum posts 40 photos | Axminster sell a vertical bandsaw with a VFD offering speeds between 42 and 1000 m/min. I would love one if I had the cash and the space even though they say it can only cut 10mm mild steel plate and it costs £1,500. Realistically that would pay for an awful lot of laser cutting, and Bob's suggestion applied to a smaller machine would probably suit me more as I already have a hacksaw for thicker bar. Brian G Edit: Whoops, bandsaw speeds are not RPM Edited By Brian G on 11/04/2021 20:39:41 |

| Martin Kyte | 11/04/2021 22:21:50 |

3445 forum posts 62 photos | Posted by Brian G on 11/04/2021 20:35:23:

Axminster sell a vertical bandsaw with a VFD offering speeds between 42 and 1000 m/min. I would love one if I had the cash and the space even though they say it can only cut 10mm mild steel plate and it costs £1,500. Realistically that would pay for an awful lot of laser cutting, and Bob's suggestion applied to a smaller machine would probably suit me more as I already have a hacksaw for thicker bar. Brian G Edit: Whoops, bandsaw speeds are not RPM Edited By Brian G on 11/04/2021 20:39:41 as I said above I bought one of these from Axminster Tool a few years ago and it has saved me a lot of effort. It is arranged for a slow speed step on the drive pully with the addition of a variable speed drive. Slow speeds are a must if you are cutting metal and of course you need fast speeds for wood. I find it excellent for cutting blanks for clockwheels and frames in Brass. Steel plate up to 1" thick and large billets of aluminium. I'm not saying thats all it will do just what I have done to date. Most usefull for removing the waste from odd shaped lumps before machining. And obviously it's in it's element for wood. regards Martin |

| Brian G | 11/04/2021 23:35:00 |

| 912 forum posts 40 photos | Sorry Martin, I completely misunderstood and thought you meant a metal cut-off bandsaw. I'm reminded by your comment about odd shaped lumps of the reason I would like one of the Axminster machines, as 40 years ago part of my job as a foundry technician was cutting up alloy wheels using a bandsaw to extract large enough pieces to machine test samples. There probably isn't another tool that could do this as well as a bandsaw. Brian G |

| gerry madden | 12/04/2021 00:07:26 |

| 331 forum posts 156 photos | Thanks all for your very useful and thought provoking comments. I certainly hadn't thought much about the speed aspect ! Due to space constraints I do tend to favour one machine capable of multiple tasks, provided of course it does all of those tasks reasonably well. Martins Axminster seems to have this covered well. Strangely its just not available right now and I cant find another machine that has a similar wide range of speed. I wonder why that is ? There seem to be plenty of robust-looking machines out there for about £500 (for example the Makita) which one could feed through a £50 RS controller, which might then make it suitable for slow but steady metal cutting, albeit with appropriate work-piece holding ? Or am I missing something ? Gerry

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in