Milling machine enclosure

| David Keil 1 | 26/01/2021 16:05:11 |

| 24 forum posts 7 photos | Has anyone any suggestions for an enclosure for a tabletop milling machine for example taig or sherline size. Something to be able to keep surrounding areas free from chips etc. |

| Steviegtr | 26/01/2021 16:34:34 |

2668 forum posts 352 photos | Some i have seen, have made perspex side windows that are hinged. My mill just throws swarf everywhere. Have a look on youtube at the cnc mills, most of them have enclosures around them. Steve. |

| David Keil 1 | 26/01/2021 16:40:54 |

| 24 forum posts 7 photos | Perspex seems a good idea. |

| Bo'sun | 26/01/2021 17:06:53 |

| 754 forum posts 2 photos | Have a look at Frank Hoose on You Tube, "mini mill chip enclosure". He also makes a plastic sheet bender to assist construction. |

| Mike Poole | 26/01/2021 17:20:46 |

3676 forum posts 82 photos | Enclosure James Clough constructed this enclosure for his CNC mill, it’s quite large but maybe some ideas could be useful. Mike |

| Rod Renshaw | 26/01/2021 17:29:48 |

| 438 forum posts 2 photos | Perspex/ Plexiglas sounds like a good idea but I remember reading in one of the Tubal Cain's (Tom Walshaw) workshop books that he made a splash guard for his Myford to contain cutting oil splashes from the chuck. This was after he had fitted a pumped cutting oil system to his lathe. He commented wryly in the book that after some years the Perspex he had used had gone opaque and he might as well have made the guard from aluminium. Rod |

| John Haine | 26/01/2021 17:31:40 |

| 5563 forum posts 322 photos | You can buy sheets of plastic and edging from B&Q and other places, with that and the bench for support you could make a 3-sided box, open at the front. Add a separate front door from a sheet of polycarbonate to close it off and you're done.

|

| Joseph Noci 1 | 26/01/2021 17:37:25 |

| 1323 forum posts 1431 photos | what I did..

no help for full frontal chips though.. Joe |

| Nick Wheeler | 26/01/2021 18:13:02 |

| 1227 forum posts 101 photos | Cardboard and duct tape prototypes until you've designed something that works and doesn't get in the way of working |

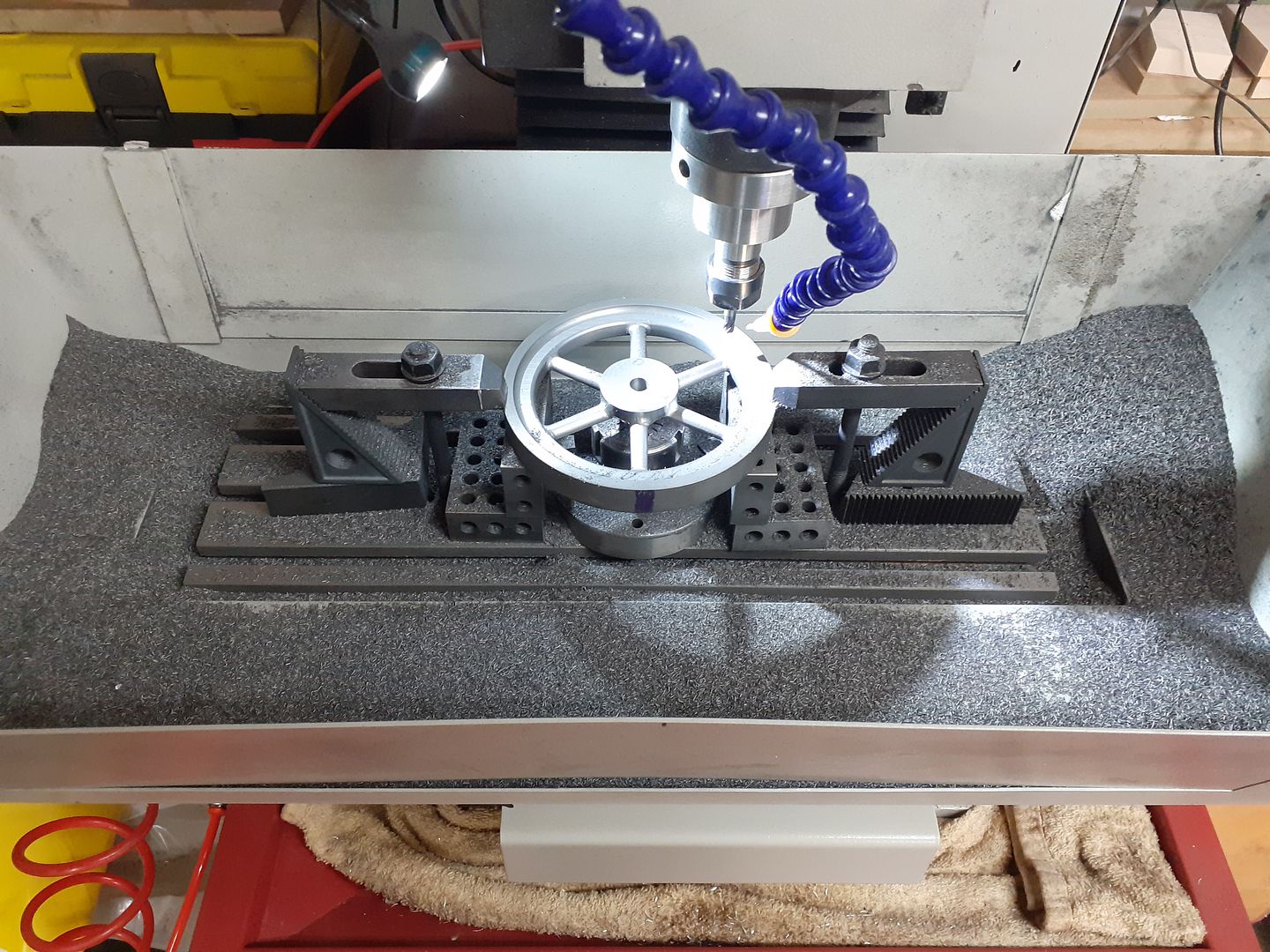

| JasonB | 26/01/2021 18:21:49 |

25215 forum posts 3105 photos 1 articles | The trough on my KX3 does quite a good job of catching the swarf, the front and rear panels can slide out easily if needed for access.

Hope those clamps are acceptable! |

| David Keil 1 | 26/01/2021 18:31:35 |

| 24 forum posts 7 photos | I think a trip to B&Q is required. Thanks for the tips and photo's, much appreciated. |

| Robert Butler | 26/01/2021 18:43:37 |

| 511 forum posts 6 photos | I have used a redundant 25 litre water carrier cut to fit and wedged into the none "T" slot - slot!!? at the rear of the table which folds round into the two troughs at the end. This catches swarf at the rear and ends - I use end mills!!? and I find little swarf exits at the front. It would not require any major repositioning if swarf from the front became an issue. Clear up mainly confined to the table. The enclosure benefits from easy removal and deflected out of the way without damage if the quill/column catches whilst concentrating on the job in hand. Robert Butler |

| Dave Halford | 26/01/2021 18:49:46 |

| 2536 forum posts 24 photos | B&Q acrylic is a swine to cut |

| Iain Downs | 27/01/2021 17:33:27 |

| 976 forum posts 805 photos | What I've done is to make some removable screens. This is a set of various sizes (determined more by available scrap, then design!). Each has a piece of perspex, and one or more mounts set with small cylindrical magnets on the base. The mounts were made with a 3D printer, but you could use a bit of wood or even Ally. I put tape on top of the magnet to make it easy to wipe away the inevitable swarf. All assembled with super glue. In fairness, they don't stop all the chips getting on the floor, though the do stop the bulk. What they do do is to keep the large majority of blue hot chips off me. Which was my intent. The nice thing is you can decide how close you want to get to the part being machined and pick a bigger or smaller screen. I might have some pictures somewhere or can take some if it ever warms up enough for this lightweight to brave the shed.

Iain |

| DC31k | 27/01/2021 18:45:21 |

| 1186 forum posts 11 photos | As this is posted in the CNC sub-forum, can we assume it is a CNC machine that you wish to enclose (i.e. it will run unattended)? I have something similar to this: https://www.christowhome.co.uk/christow-large-reinforced-walk-in-greenhouse-1.html with a CNC Taig mill inside it in a bedroom. Cheap laminate flooring inside it, with the flaps of the greenhouse, shown folding outwards in the photo, folded inwards and under the floor. Henry inside for clean up. |

| Robert Atkinson 2 | 27/01/2021 20:15:59 |

1891 forum posts 37 photos | A lot of people have mentioned "perspex" (trademrk for acrylic) This is not the best material for clear guards and shields. Polycarbonate (Lexan) is a better choice as it has much better impact resitance. It is also easier to cut without breaking. It also has better chemical resistance. The cheapest material, polystyrene, is virtually useless.

Robert G8RPI. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in