Belt Up

| Martyn Nutland 1 | 31/05/2020 15:45:28 |

| 32 forum posts 2 photos | Hello In the days when showman's engines drove electric generators to drive the gallopers and traction engines drove threshing machines in the fields, I'm told by the wise that the belt didn't come off the pulley because the circumference of the pulley is convex. I know this to be true but I've never really understood the physics. I need to make Austin Seven crankshaft pulleys that carry the fan belt. The originals do have flanges about 3-4mm deep on each side but the belt track is also convex. Do I need to make a convex track, given, I would have thought (probably in ignorance) the flanges will keep the belt on? If I do need to make a convex track, how is the best way? I tried a 'form tool' but it wasn't a great success, someone suggested using a wood-turner's gouge, but I strongly object to that approach! How do you do it, please? Keep safe in these difficult times. Martyn |

| Speedy Builder5 | 31/05/2020 15:55:04 |

| 2878 forum posts 248 photos | Yes you do Martyn, If you don't, then the edges of the A7 flat belt WILL chafe on the pulley flanges. Crowning the pulley also helps when pulleys are misaligned. You will find plenty of A7 camshaft pulleys with chips in the flanges - still doing sterling service without chafing the belt. As for the crown profile, you could use a small round nosed tool and guess it by eye, clean up with a file. Unless you have a big heavy lathe, a form tool is out of the question. BobH. 1932 RN |

| Andrew Johnston | 31/05/2020 15:55:08 |

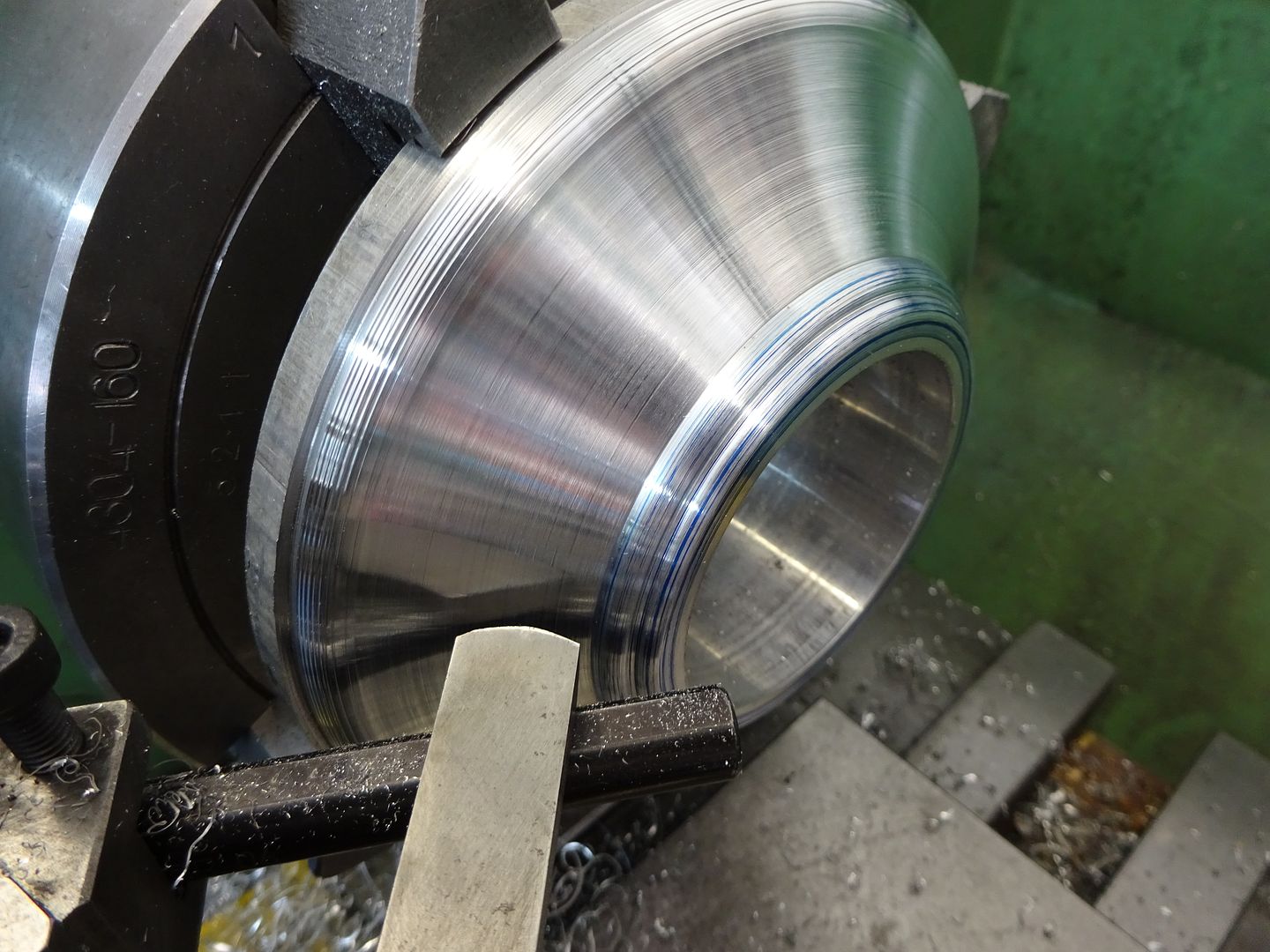

7061 forum posts 719 photos | I made these governor pulleys by forming the groove with a HSS parting style tool. I then tilted the top slide a couple of degrees each way and machined a small taper each side. Final shaping was done with needle files. The exact shape of the crowning isn't critical as long as it has a bigger diameter in the middle and is a smooth curve: Andrew |

| JasonB | 31/05/2020 16:18:24 |

25215 forum posts 3105 photos 1 articles | I do it the same way as Andrew, flat in the middle and slight angle at each side then hand blend, on wider ones I do two angles each side so total of 5 facetes

|

| Martin Kyte | 31/05/2020 16:34:46 |

3445 forum posts 62 photos | Posted by Andrew Johnston on 31/05/2020 15:55:08:

I made these governor pulleys by forming the groove with a HSS parting style tool. I then tilted the top slide a couple of degrees each way and machined a small taper each side. Final shaping was done with needle files. The exact shape of the crowning isn't critical as long as it has a bigger diameter in the middle and is a smooth curve: Andrew Do you never hand turn Andrew? regards Martin |

| John Baron | 31/05/2020 17:04:41 |

520 forum posts 194 photos | Hi Martyn, Guys, Tension will cause the belt to climb up the slope of the crown until its running centrally on top of the crown. Have a look at some of the old line shaft pulleys. The crowning was all that kept them on the pulley.

|

| not done it yet | 31/05/2020 17:13:16 |

| 7517 forum posts 20 photos | Don’t know about all of them, but the engine pulley on the Massey Harris 701 baler was flat with high side ribs at 90 degrees. I believe the main flywheel was also flat, but I seem to recall that the tensioning pulley may well have been convex. I will check the motor pulley to be sure. |

| Howard Lewis | 31/05/2020 17:26:11 |

| 7227 forum posts 21 photos | Many years ago, beyond memory, at Tech we were given a mathematical proof that a crowned pulley caused the belt to run on the top of the crown. There have been millions of pulleys confirming this. Kempes Engineers Year book, 1982 in section E9/3, referring to flat belts, calls for pulleys to be cambered, with either a smooth curve or two symmetrical smooth curves with a central flat portion not exceeding half the width of the belt. It also says that flat tapers should not be used since they introduce stresses into the belt, and decreases contact between belt and pulley. Like Jason, I would probably use two very slight tapers with a central flat portion So the transition from the slight taper needs to be blended into the central flat. It says "The effectiveness of the camber depends on the ratio of camber to pulley diameter, and is practically independent of belt width. It is affected by length of drive and by pulley diameter itself, but not to any significant extent". It also says that "If the pulleys are very different in size, it is good practice to leave the smaller pulley flat and provide all the necessary camber on the larger pulley" All the A7 fan pulleys that I have seen have been crowned HTH Howard

|

| Andrew Johnston | 31/05/2020 17:28:33 |

7061 forum posts 719 photos | Posted by Martin Kyte on 31/05/2020 16:34:46:

Do you never hand turn Andrew? What do you mean by hand turn? Andrew |

| Martyn Nutland 1 | 01/06/2020 08:39:26 |

| 32 forum posts 2 photos | Many thanks all. My understanding much improved. Didn't get on with the form tool. Obviously lathe too small. Thanks again. Keep Safe.

Martyn |

| larry phelan 1 | 01/06/2020 09:00:14 |

| 1346 forum posts 15 photos | I think very few small lathes like form tools of any kind, has been my experience anyway. |

| Martin Connelly | 01/06/2020 10:03:26 |

2549 forum posts 235 photos | I have had success with a wide form tool on plastic using back gear and the lowest speed pulley setting. It took a lot of pressure to start cutting and it would not have worked on brass, aluminium or steel. I have a video of it somewhere. Martin C |

| Hopper | 01/06/2020 10:25:46 |

7881 forum posts 397 photos | Or you could make a large radius ball turning tool. It might need to stick out several feet behind the lathe though! |

| Andrew Johnston | 01/06/2020 10:44:13 |

7061 forum posts 719 photos | I've no idea what the question regarding hand turning was about, but it can't have been important. To complete the picture the drive pulley on the crankshaft for the governor is also crowned: SInce this pulley only has one flange the crowning was machined using a hydraulic copy attachment and a marked out and hand filed pattern; the one bottom right: Does this count as hand turning? Andrew |

| Circlip | 01/06/2020 10:52:37 |

| 1723 forum posts | "I've no idea what the question regarding hand turning was about," Possibly like watch/clockmakers do, use of a graver rather than topslide etc. to generate the crown. One of the advertisers sells a fancy version.

Regards Ian. |

| JasonB | 01/06/2020 13:24:09 |

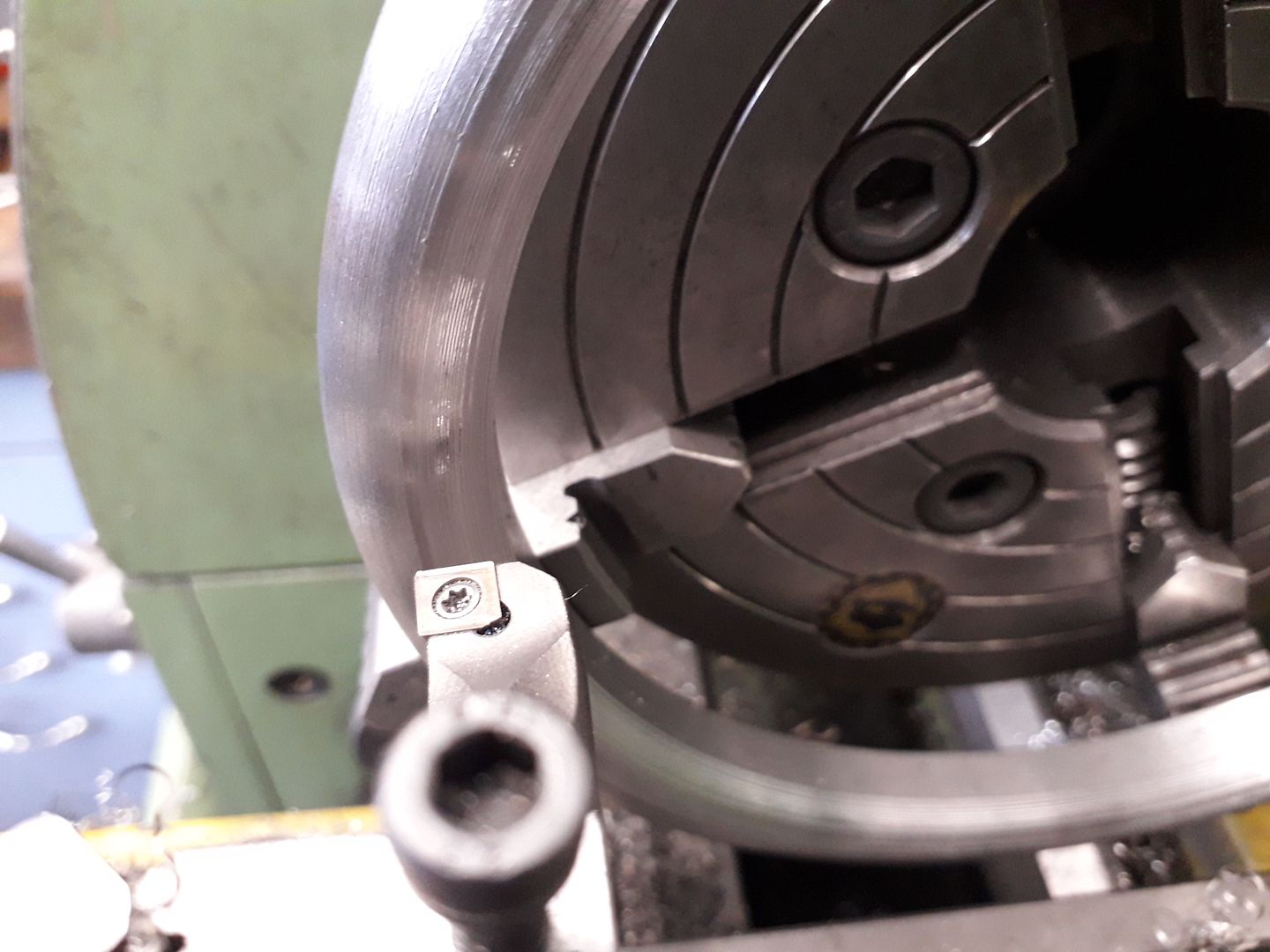

25215 forum posts 3105 photos 1 articles | Although the OP said he did not fancy doing it by hand it is not too hard, even if you opt to do the blending by file similar methods can be used. Draw out the profile and work out a set of co-ordinates so the work can be roughed with teh handwheels or DRO and simply blend which is much like dot to dot. 0.020" increments

Woodturning scraper with boring bar used as a rest

Works on steel too

|

| Mick B1 | 01/06/2020 13:43:16 |

| 2444 forum posts 139 photos | Why not turn a shallow taper each side away from the middle, parallel-turn a narrow flat on top , then file and emery to blend to a curved crown? |

| Speedy Builder5 | 02/06/2020 08:10:29 |

| 2878 forum posts 248 photos | Found this on the net, although it seems a very small amount for small pulleys :-

Crowned pulley dimensions A convex crowned pulley usually has an increase of +/- 1/16” per foot of pulley width. Therefore, an 18” face width pulley (4” in diameter), could either have a 4” diameter measurement in the center with 3-13/16” diameter edges or a 4-3/32” diameter measurement in the center with 4” diameter edges. |

| Martin Connelly | 02/06/2020 08:31:25 |

2549 forum posts 235 photos | Thinking about this it seems to me that a small amount makes sense. Think in terms of moving a belt 0.001" towards the centre of the pulley per rev. It would not take many revs of the pulley to get it into position. I don't think it wants to move too fast otherwise the belt could start to overshoot and start oscillating from side to side. Martin C |

| Mike London | 02/06/2020 09:30:06 |

| 33 forum posts 1 photos | If you look at any belt sander / linisher you will see a crowned pulley. It can give you an idea of scale and shape. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in