how to machine an internal curve

| Sam Longley 1 | 06/09/2018 08:04:22 |

| 965 forum posts 34 photos | I want to make some friction rings in stainless steel similar to the one in the picture ( the second picture shows it in a typical use instead of a pulley) . I know I can buy them ( very expensive) but that is not the point of my question. Can someone tell me how they would go about making one please. I have the stainless steel bar. the hole in the middle is no more than 15mm diam( prefer 10-12) so I can drill that. But how do I form the inner curve but what shape is the cutter to get the clearance? If the cutter is made as a full form tool I am pretty certain my Warco 250MV will have too much chatter. Once I have the inner curve I suppose I can grip the item in a shaped mandrel & then deal with the outer internal curve but once again the curve does pose a problem as any form tool will be rather large. It has to be very smooth to allow ropes to pass through under high load without any damage Any ideas please

Edited By Sam Longley 1 on 06/09/2018 08:16:10 |

| JasonB | 06/09/2018 08:20:38 |

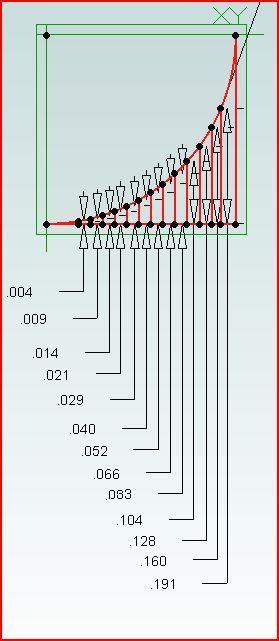

25215 forum posts 3105 photos 1 articles | Any odd shape is quite easy to machine if you draw it up and then produce a set of co-ordinates, machine in a series of steps to these co-ordinates and then blend them in by freehand turning and handwork From this

To This

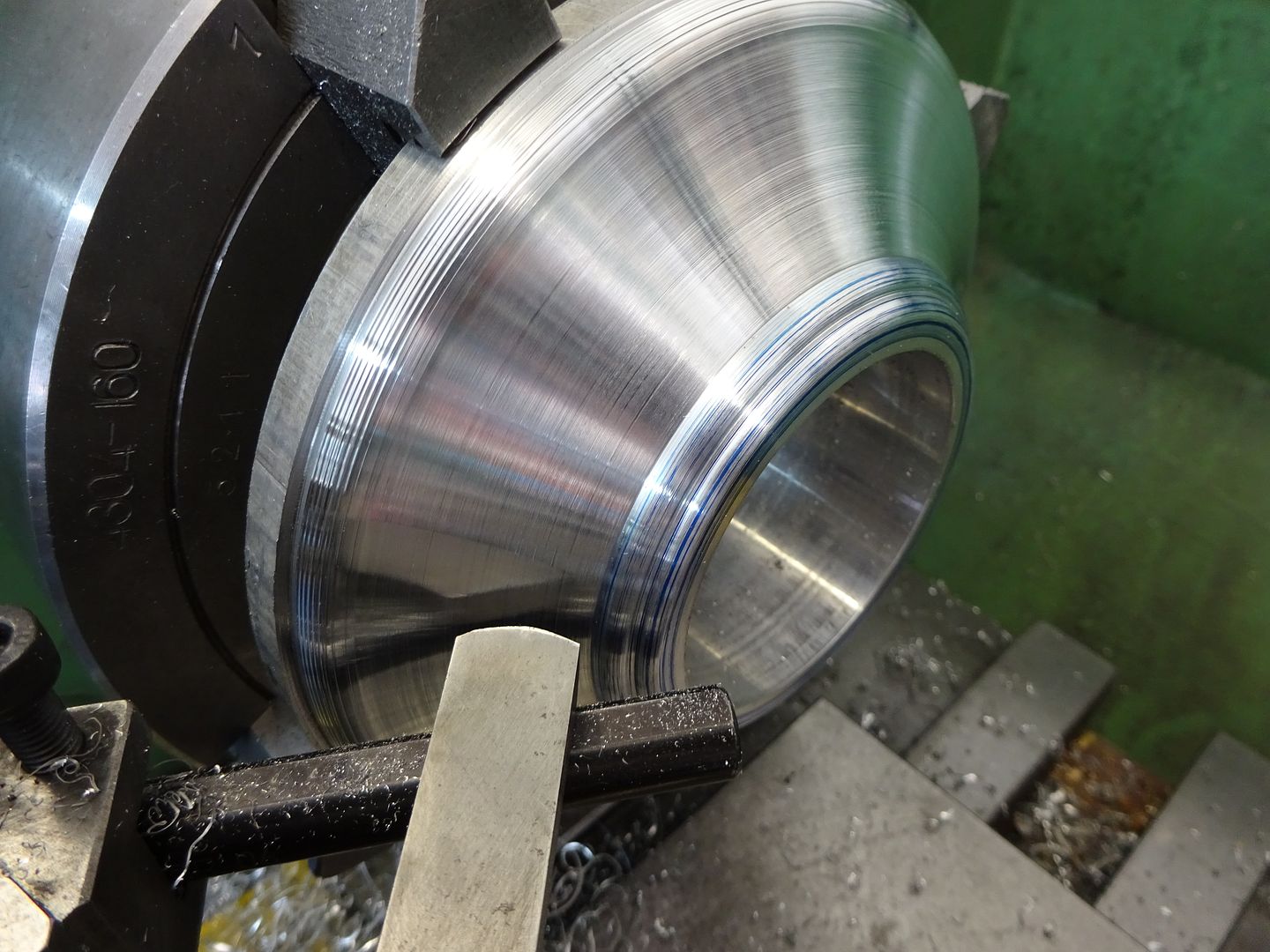

And another one showing teh stepped cuts

Blending

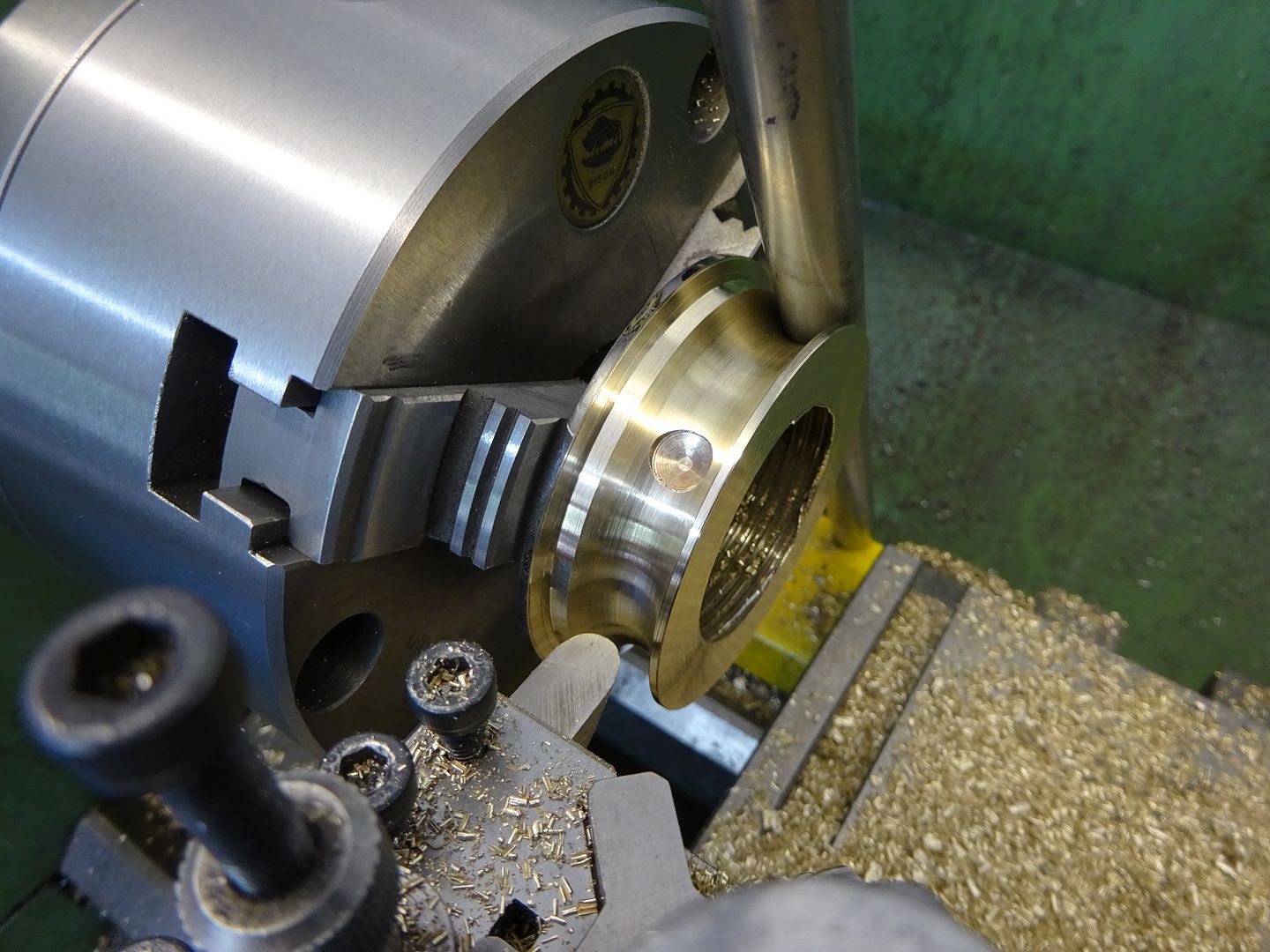

The external groove can be done with a narrower half round tool so you don't have a large area of contact to cause chatter use a bit of rod to gauge the shape, this was 3/8" cutter for 1/2" groove

Edited By JasonB on 06/09/2018 08:24:11 |

| Alan Waddington 2 | 06/09/2018 08:35:51 |

| 537 forum posts 88 photos | Do you have access to a mill ?...... Easy enough to do with an end mill and dividing head. You could probably do the same using the lathe, but it might take a bit of ingenuity to set up. |

| Paul Lousick | 06/09/2018 08:54:17 |

| 2276 forum posts 801 photos | Have not tried this but looks like a ball turning attachment on a lathe could be adapted to cut the inside curves by moving the pivot centre to be in front of the axis. Cut one side of the inner curve and reverse the material to cut the second side. Then cut the outer groove with a shaped mandrel as you have described. Paul. |

| Chris Evans 6 | 06/09/2018 09:22:01 |

2156 forum posts | Go with Jason's method, I spent 50 years as a mould and die toolmaker and that is how we did it before CNC. |

| KWIL | 06/09/2018 09:27:46 |

| 3681 forum posts 70 photos | Alternatively, mark out and make a template of the required shape, set up a follower and machine using "copying lathe" approach. Often seen in Andrew Johnstone's photos. |

| John Hinkley | 06/09/2018 09:39:27 |

1545 forum posts 484 photos | In order to acheive a similar result for one of my projects, I used a radius milling cutter held in a boring bar holder on the lathe. By carefully adjusting the cutter such that the cutting edge was tipped a fraction below horizontal and just at or below centre height, I managed to get a pretty reasonable finish. Probably not "accepted" engineering practice, but, hey, it worked for me. But then, I'm not an "accepted" engineer, either! John |

| JasonB | 06/09/2018 10:09:28 |

25215 forum posts 3105 photos 1 articles | Sam what is the radius on the internal edge? As John says you may be able to use a roundover bit but my only worry is as you said about a form tool in that the width of cut becomes quite wide and you may get chatter or work hardening on the stainless, OK if it were ali or brass as even router cutters will work on that if held in the tool post. |

| John Hinkley | 06/09/2018 10:24:29 |

1545 forum posts 484 photos | Jason, Unless Sam has really massive thumbs or that's his big toe in his first picture, I estimated that the internal radius was around 5mm. That and the pulley carries the figure "30" on it indicated to me that it was 30mm diameter. That's why I suggested what I did. It obviously negates the suggestion if it's a lot bigger or smaller. John |

| Andrew Johnston | 06/09/2018 10:28:00 |

7061 forum posts 719 photos | The grade of stainless steel is important too. Grade 303 is lovely to machine, 316 is nice to machine too, but work hardens at the drop of a hat, don't even think about peck drilling! And 304 is horrible. Andrew |

| Ian Parkin | 06/09/2018 10:45:44 |

1174 forum posts 303 photos | Ideal job for a turnado |

| Sam Longley 1 | 06/09/2018 10:49:33 |

| 965 forum posts 34 photos | one of my issues is the clearance on the underside of the cutter. I would use HSS tool steel & can experiment with grinding but the bevels & angles have me a bit stumped. & to answer query - yes I do have a warco 16 mill but a milling cutter with a round on it might be expensive. the curve is essentially a full semicircle inside the piece. I will look for some 303 SS to try it out or I could experiment with some aluminium first as i have a lot of that I should have put the sizes of the one in the photo Overall diam is 30mm ,Hole is 12 mm, thickness is 12mm. Outer groove is not a problem as it could possibly be square as the cordage is spliced to it & does not have much friction. The internal part has lots of friction though Edited By Sam Longley 1 on 06/09/2018 10:57:18 |

| Sam Longley 1 | 06/09/2018 11:09:23 |

| 965 forum posts 34 photos | Posted by JasonB on 06/09/2018 10:09:28:

Sam what is the radius on the internal edge? As John says you may be able to use a roundover bit but my only worry is as you said about a form tool in that the width of cut becomes quite wide and you may get chatter or work hardening on the stainless, OK if it were ali or brass as even router cutters will work on that if held in the tool post. jason Thanks I have just followed the link, I had looked on other sites & was looking for the wrong thing as I came up with something very £££'s. I could go with that though, as it is not overly expensive & I can hold the part in the mill. As an aside what RPM would you recommend as a start on 303 stainless using the one with 6mm radius cutter? Thanks Still would be interested to know how to grind a cutter for a one off though as one would not want to buy a milling cutter for a single job if one did not need to Edited By Sam Longley 1 on 06/09/2018 11:10:34 |

| Hopper | 06/09/2018 11:13:23 |

7881 forum posts 397 photos | Posted by Sam Longley 1 on 06/09/2018 10:49:33 :...I do have a warco 16 mill but a milling cutter with a round on it might be expensive. ..No. Ball nose (aka bull nose) cutters from China these days are cheap as chips and quite reasonable quality for home use. An addendum to Jason's method might be to use a hand graving tool (like the way woodworkers use a lathe) to do the final blending of the co-ordinate steps. I've never used one with stainless before so can't say how it would respond. Personally, I like the idea of using a ball-turning tool. Outside groove would be easy enough with a slender pointed tool with the tip set in front of the pivot point by the radius of the groove. The inside part might be a bit trickier, requiring one half done then turn the job around in the chuck and do the other side. Edited By Hopper on 06/09/2018 11:24:29 |

| John Baron | 06/09/2018 11:15:20 |

520 forum posts 194 photos | Hi Sam, It might help to look at carbide router bits ! Edited By John Baron on 06/09/2018 12:05:34 |

| Mick B1 | 06/09/2018 11:23:48 |

| 2444 forum posts 139 photos | Posted by John Baron on 06/09/2018 11:15:20:

Hi Sam, It might help to look at carbide router bits ! That'd be my first resort, too, held in the tailstock drill chuck if that blends correctly with the centre hole, or in the toolpost if not. |

| John Baron | 06/09/2018 12:07:27 |

520 forum posts 194 photos | Hi Guys, Its taken me nearly an hour to post a picture ! Put your own expletives in !

|

| JasonB | 06/09/2018 12:32:48 |

25215 forum posts 3105 photos 1 articles | Use about half the speed you would if cutting steel and treat it as a 20mm dia cutter. I would have thought you want 316 stainless for marine use.

Hopper that is a hand graver being used to do the blending in my 4th photo (HSS woodturning scraper actually) |

| Mick B1 | 06/09/2018 13:09:12 |

| 2444 forum posts 139 photos | Posted by John Baron on 06/09/2018 12:07:27:

Hi Guys, Its taken me nearly an hour to post a picture ! Put your own expletives in !

I use router cutters the same way - but often remove the end screw and bearing if it gets in the way. |

| Sam Longley 1 | 06/09/2018 13:24:58 |

| 965 forum posts 34 photos | Are router cutters really up to the task? In the past I found that a router cutter has only had to look at a piece of steel to shatter & stainless steel would surely be a step too far!!! I do have a few but do not want to smash them needlessly |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

.jpg)

Register

Register Log-in

Log-in