Setting up my Myford ML 10

| Robert St-Louis | 21/04/2018 19:18:20 |

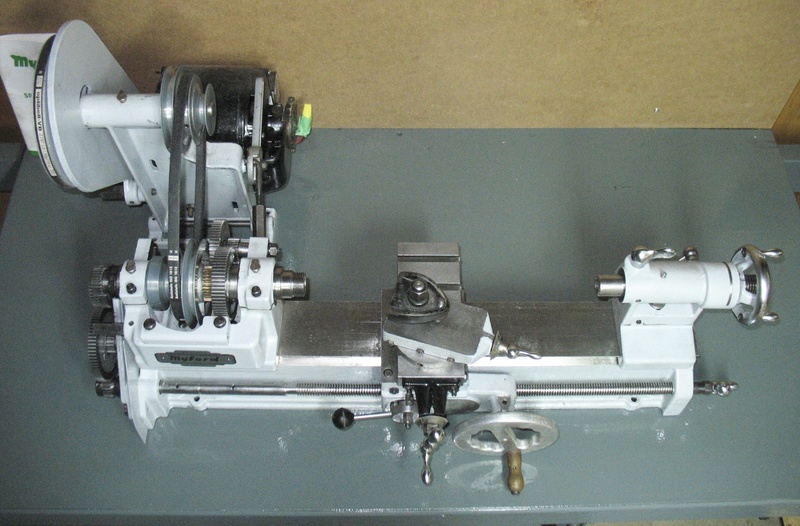

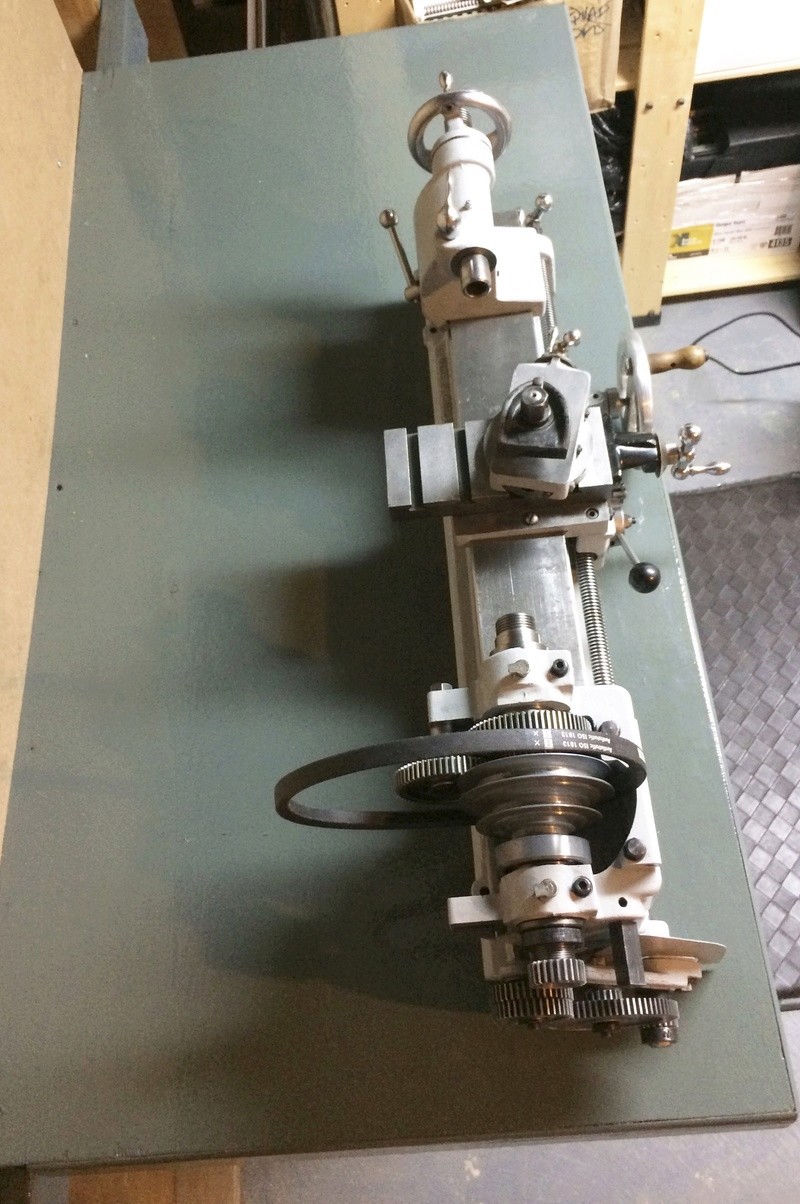

| 14 forum posts | Hello all, I am setting up my first ME lathe, a restored Myford ML 10 which I bought locally a few weeks ago. I saw it run at the seller's house, but it was just sitting loosely on a bench, so it was a quick demo without any actual turning. First order of business was building myself a bench for it in my basement, which is now complete. Top is two sheets of 3/4 plywood glued and screwed together, with some reinforcing 1x4" pine boards underneath to prevent warping. The bench is screwed at the back into a 2x4 screwed level into the wall studs. The front of the bench is supported by two heavy duty Ikea adjustable legs. The top was painted grey and covered with 3 coats of polyurethane to make it oil proof. I levelled the bench and just put the lathe and motor stand on it to line things up. Some people put stands under the 4 mounting holes of the bed to do some fine tuning of the lathe levelling, but I figured that for my amateur use the lathe can sit on its flat bottom right on the bench, and secure it with a bolt in each mounting hole. Likewise I will secure the motor stand when I have figured out where to position it. I've centered it, and placed it above the two table legs to minimize any sagging it could generate. That means the cross slide handles are over the top and not sticking out the front if the lathe was moved further forward. I've also centered the lathe left to right, not presently having any plans to attach anything else to the bench (maybe a small temporary bench vise at one end). I would appreciate any advice on how to best position the lathe on the benchtop, before actually drilling any holes. I attach a few pictures to show you my setup so far. Thank you.

|

| Jim C | 21/04/2018 20:28:49 |

76 forum posts 4 photos | Hi Robert. It looks like it has had a replacement carriage handwheel fitted and in the position shown in your photos your knuckles will certainly foul the top of the bench. Bring it forward or obtain the original handwheel. Otherwise things look fine. |

| David George 1 | 21/04/2018 20:51:09 |

2110 forum posts 565 photos | Hi Robert looking at your lathe it needs a couple of spacers under the bed and then bringing forward nearer to the front face of the bench. If you look at the web site www.lathes.co.uk and look for lathes then Myford and then ML10 it will give you a few ideas what it looks like with the spacers. You could make some from a couple of blocks of steel or try and buy some on the internet. David Edited By David George 1 on 21/04/2018 20:54:15 Edited By David George 1 on 21/04/2018 20:54:34 |

| Robert St-Louis | 21/04/2018 21:18:12 |

| 14 forum posts | Hi Jim and David, thank you for your replies. I do have the original carriage handwheel, the previous owner had made up that bigger one for some reason. I would prefer keeping it a bit further back from the front face of the bench, which gives room for some hand tools measuring tools etc in front of it. Yes, I am aware that some/most place those spacers under the bed holes at head and foot of the lathe. And I gather these spacers help with fine-tuning the levelling of the lathe, but the lathe as it sits is the optimal height for me, and I'm not sure I'll be needing the absolute precision for the kinds of work I am envisioning, in the short term anyway. Anyway, it's good for me to mull over these issues before I drill any holes in my new bench! Cheers, --Robert |

| Robert St-Louis | 21/04/2018 21:26:51 |

| 14 forum posts | I looked at the ML10 pictures on lathes.co.uk. I see what you mean David about those spacers at the head and foot. And I can see that one such set was made from a block of steel as you suggested. Maybe I misunderstood that those spacers were there for levelling the lathe, and are really needed to elevate the bottom of the bed from the bench-top? The bottom of the bed seems well machined and flat, so I presumed it could just sit on top of the bench top, but maybe I'm wrong. Also, I can see it would be much easier to clean cuttings and oil from under the lathe, if it's sitting on those spacers. Mind you, without the spacers, no cuttings could get underneath it... |

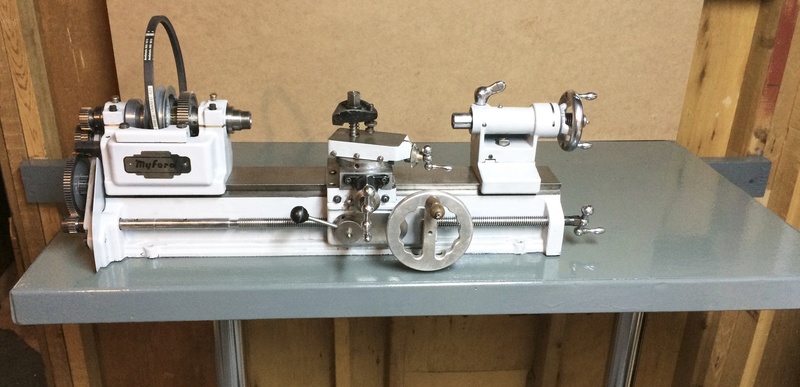

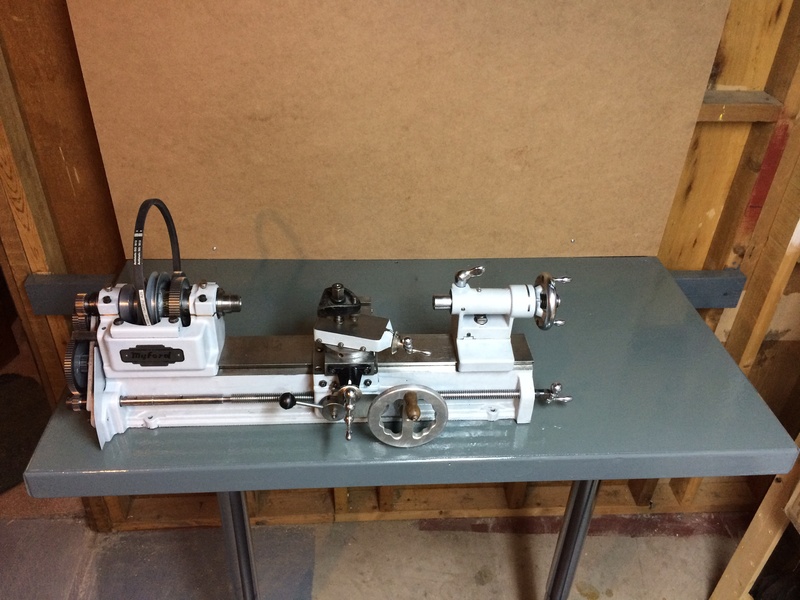

| Mick B1 | 21/04/2018 22:49:41 |

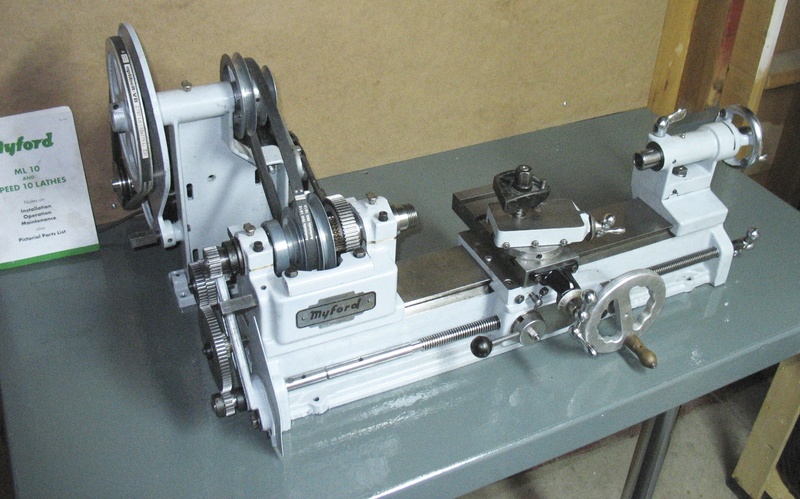

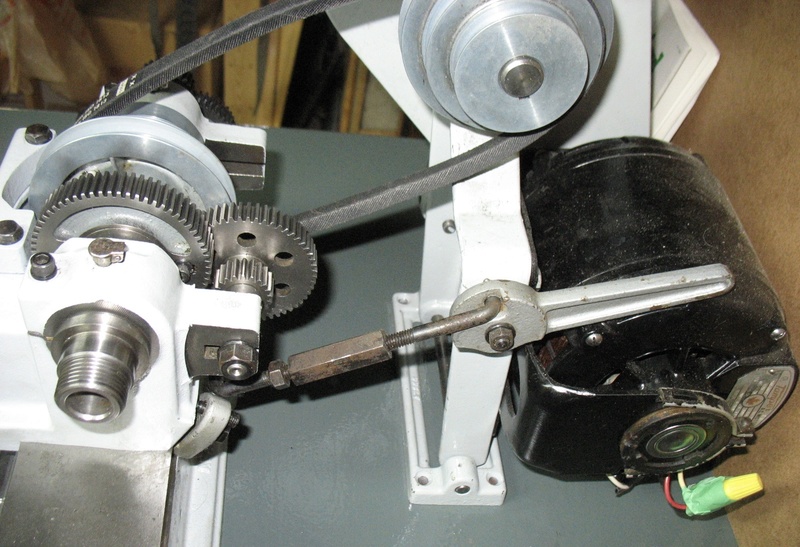

| 2444 forum posts 139 photos | Here's what my Speed 10 setup was like:- The risers made the operating height more comfortable, the 4-way toolpost gave better tooling flexibilty, and the leadscrew clutch allowed use of the leadscrew handwheel and dial for accurate length control with the geartrain disconnected. The position of the Dewhurst switch was pretty much dictated by available space and cable lengths, but worked well. I used this successfully enough for 15 years, but eventually the desire for bigger capability overcame my natural laziness and miserliness, and I bought a Warco WM250V. |

| Robert St-Louis | 21/04/2018 23:31:17 |

| 14 forum posts | Thanks for sharing the picture Mick. Sounds like you had a good run with the Myford for 15 years, hopefully I will also enjoy using mine for however long I can or want to. Looks like your lathe was mounted a bit closer to the front edge of the bench than I was initially thinking for mine, so I'll have to think that over. In my case, I had built the bench at exactly the right height so the lathe is at the ideal work height without the risers, which is one reason I would rather avoid using them if I can. I'll also need to think about installing a proper switch for the motor, it's currently temporarily wired by the seller to demonstrate that it worked and that the lathe spun. I'm not sure what is meant by the leadscrew clutch but I'm sure it will all make sense in the end. A 4 way toolpost will also be in my future. |

| Sam Stones | 21/04/2018 23:53:46 |

922 forum posts 332 photos | My first reaction Robert, was one of the painful sensation when my knuckles dipped into swarf under the hand-wheel. Not enough clearance as has already been indicated by other posters. Only wish I still had one. Have fun, Sam |

| Robert St-Louis | 22/04/2018 00:10:56 |

| 14 forum posts | Point well taken Sam. I'll replace the carriage hand-wheel with the original (smaller) one, which will buy some space. But sounds like I would be advantaged to put some spacers under there, to gain some additional space off the bench. That either means living with the lathe an inch and a bit higher than I had thought optimal (elbow height), or else disassemble the bench and relocate an inch lower on the wall (don't relish that)... Cheers. |

| Jim Guthrie | 22/04/2018 00:36:28 |

| 128 forum posts 5 photos | Robert, The previous owner may have fitted the larger handwheel on the carriage to make movement of the carriage a bit easier. It's the one thing I don't like on my ML10 - that smallish handle on the saddle feed. So if you can get some risers to lift the lathe from the bench top you might find the larger handle better. Jim. |

| Mick B1 | 22/04/2018 10:16:01 |

| 2444 forum posts 139 photos | I have to wonder whether that metal bench top won't "ring" a bit if you take any cuts that cause vibes or minor chatter. That was one of the factors (apart from laziness and cheapness) that made me choose a Clarke wooden bench. Still, if there's a problem, you could probably just interpose a plywood board under the lathe. |

| Hopper | 22/04/2018 11:04:36 |

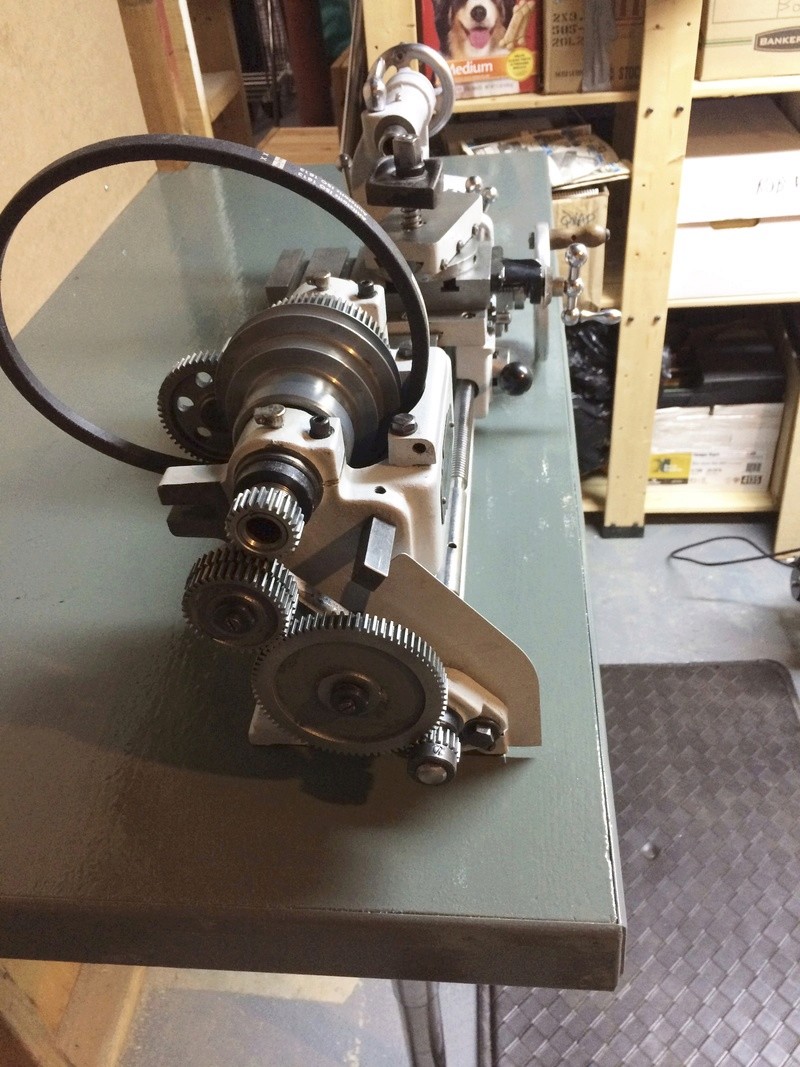

7881 forum posts 397 photos | You may need the spacers under the bed if you want to do screw cutting, or fine feed, and use a 60 or 70 tooth change gear on the end of the leadscrew? I would move your lathe to the left by six inches or more, too. This gives you handy bench space at the right hand end to put tools and materials etc, away from the thrashing change gears and belts and out of the swarf zone. |

| Clive Hartland | 22/04/2018 12:34:57 |

2929 forum posts 41 photos | The hand wheel on the ML10 is a bit course for accurate travel, hence the Leadscrew mod. that gives you an engraved drum/wheel that fits on the outer end of the Leadscrewand has a measured 3 mm travel. Easy to set up for zero by using the top slide. The other worthwhile mod is to fit the thrust and needle bearing on the Crosslide Leadscrew. |

| Michael Gilligan | 22/04/2018 14:39:43 |

23121 forum posts 1360 photos | Posted by Mick B1 on 22/04/2018 10:16:01:

I have to wonder whether that metal bench top won't "ring" a bit if you take any cuts that cause vibes or minor chatter. That was one of the factors (apart from laziness and cheapness) that made me choose a Clarke wooden bench. Still, if there's a problem, you could probably just interpose a plywood board under the lathe. . Mick, I think the photo might be a little deceptive: The text in Robert's opening post is quite clear ... [quote] Top is two sheets of 3/4 plywood glued and screwed together, with some reinforcing 1x4" pine boards underneath to prevent warping. The bench is screwed at the back into a 2x4 screwed level into the wall studs. The front of the bench is supported by two heavy duty Ikea adjustable legs. The top was painted grey and covered with 3 coats of polyurethane to make it oil proof. [/quote] MichaelG. Edited By Michael Gilligan on 22/04/2018 14:44:38 |

| Robert St-Louis | 22/04/2018 14:52:10 |

| 14 forum posts | Haha, yes, it's kind of nice that my paint job gave the plywood the look of metal! Sounds like there are enough reasons to consider adding spacer/risers under the lathe, so I will heed this advice, and hopefully it won't affect the ergonomics too much (raising my right forearm a bit when turning the hand wheels). I also like the advice of moving the lathe a bit off center to the left, to leave some bench space open at the right. So I suppose it would be better to move it to the left around 6 inches or so, and forward a few inches. Now to get a hold of some spacers... Thanks for all the advice, I appreciate it. I'll no doubt have other questions down the road... --Robert |

| Robert St-Louis | 22/04/2018 16:18:01 |

| 14 forum posts | I moved the lathe to the left and to the front a bit, and now the hand wheels are conveniently clearing the front of the bench so I think it would work well at that spot, and that height, without need for spacers. Except for the reason that Hopper indicated: "You may need the spacers under the bed if you want to do screw cutting, or fine feed, and use a 60 or 70 tooth change gear on the end of the leadscrew?" It's too early in my lathe learning to know if the above issues are some I would eventually encounter... Here's how the revised location could look like.

|

| Neil Wyatt | 22/04/2018 16:40:56 |

19226 forum posts 749 photos 86 articles | How high up is the lathe? If you use it standing up (normal) it is nice to have it so the centres are at roughly elbow height. Neil |

| Tomfilery | 22/04/2018 16:46:30 |

| 144 forum posts 4 photos | Robert, Don't agonise over spacers! For my lathe (a Super 7) I drilled the worktop then passed long coachbolts (M8 I think, or or pos M10) through it, with the heads underneath. I then used the 30 mm long hexagonal spacers you get for joining lengths of studding together as nuts. I then screwed on a normal nut followed by another hex spacer, Next you put the lathe in position (on temporary wooden blocks) and screw short bolts through the feet into the top hex spacer, which you can now use to adjust the level of the lathe. Once done, you tighten the normal nut up against the top spacer (to lock it) and screw down the short fixing bolts. My lathe had been bought with a badly drilled (in several places) deep drip/swarf tray which I replaced with an oil drip tray from Frost Automotive (meant to be slid under a vehicle to stop oil stains on the floor and approx 1200 x 600 x 15mm deep). Its a bit flimsy, but has been Ok for the last 5 years, or so ands tops most of the swarf from dropping on the floor. You might want to consider something similar. Regards Tom

|

| Robert St-Louis | 22/04/2018 17:15:07 |

| 14 forum posts | Posted by Neil Wyatt on 22/04/2018 16:40:56:

How high up is the lathe? If you use it standing up (normal) it is nice to have it so the centres are at roughly elbow height. Neil The bench height is 38.75". I had put it at that height so that with the lathe sitting flat on it the hand wheels would be in line with my elbow height. I'm glad I had read about that, it helped me to situate the bench properly. |

| Mick B1 | 22/04/2018 17:16:08 |

| 2444 forum posts 139 photos | Posted by Michael Gilligan on 22/04/2018 14:39:43:

Mick, I think the photo might be a little deceptive: The text in Robert's opening post is quite clear ... ... MichaelG.

Doh...! Serve me right fer just lookin' at the pictures... |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in