Embarking on a metal planer/shaper design+build

Would be terrific to see some metal planers and shapers in person :)

| Ryan Farndon | 10/10/2017 13:56:33 |

4 forum posts | Hi All,

My name is Ryan and 20 years old. I am a 3rd Year Mechanical Engineering Student at the University of Nottingham.

For my group project, my team and I are to design and manufacture a 'desktop-sized', automated metal planer (or shaper) for under £500. Currently, we are defining the requirements with our supervisor.

It would be brilliant if we could see some metal planers and shapers in action; naturally to aid understanding, but also because they're pretty impressive!

Any help that anyone can provide would be greatly appreciated.

Best Regards,

Ryan

|

| Ady1 | 11/10/2017 00:24:36 |

6137 forum posts 893 photos | Youtube and Google videos should be your first port of call IMO Lets you see various designs in action GL |

| Speedy Builder5 | 11/10/2017 06:52:42 |

| 2878 forum posts 248 photos | As Ady1 said, but then looking at even the smallest design, they are very rigid cast iron. To reduce cost, consider concrete for the bed? roller bearings for the sliding head etc. |

| Davey J | 11/10/2017 07:53:04 |

| 26 forum posts 4 photos | Might be worth checking the "Gingery shaper". The majority of which could be easily constructed from sheet materials instead of castings That's where I am looking at the moment. Book still available from various suppliers David |

| Speedy Builder5 | 11/10/2017 08:12:30 |

| 2878 forum posts 248 photos | I don't see how the Gingery Shaper could be made for £500. The motor and pulleys would consume the first £100 and the castings for the ram, head, table etc another £200 even before you start machining. |

| Davey J | 11/10/2017 08:20:33 |

| 26 forum posts 4 photos | My suggestion was to check out the design for ideas not to copy. Kindest regards David |

| Chris Evans 6 | 11/10/2017 08:24:11 |

2156 forum posts | If you go the cast Iron route make the patterns from blocks of polystyrene glued together. OK it gets destroyed when burnt out of the sand but it costs nothing using recycled packaging. I used this method when I made a new cross slide for my lathe. Any foundries in Nottingham to talk to ? |

| Neil Wyatt | 11/10/2017 09:11:33 |

19226 forum posts 749 photos 86 articles | Personally I'd go for a planer. A large heavy bed might be OK on heavy duty linear bearings rather than dovetails. Drill and tap holes for clamps rather than t-slots. But you could do worse than fabricate a copy of the Adept No. 2? Others use a big crank wheel instead of a gear train which may turn out cheaper.

|

| dcosta | 11/10/2017 09:58:46 |

| 496 forum posts 207 photos | Hello Ryan, good morning.

|

| Clive Foster | 11/10/2017 14:48:34 |

| 3630 forum posts 128 photos | Planer would be easier and more likely to be a successful learning exercise. Looked into the idea myself as part of a potential business thing and decided re-working the common cheap desktop CNC router kit design to have a moving table was feasible. Fixed standards of reasonably thick alloy plate put sufficient stiffness in to handle metalworking loads appropriate to a desktop, A4 / A3 table, size machine. Fully supported linear guide rods on extrusion support rail with plastic bearings will carry the table loads OK. Various structural X and more complex sections to choose from for the cross rail. Main issues are how to ensure that the cross rail doesn't tilt when moved up or down and how to drive the table. Simple bull wheel, shaper style, is fine and cheap but won't permit accurate stopping positions. Screw drive is accurate but costs will add up. Grid of holes table preferable to T slots for small machine but need to consider costs. Major before you start question is how large a cut will it need to take and should it in principle be capable of setting up as a planer-mill. Everything is overhung on a shaper so you need a stiff structure. Cast iron is the simple, effective, proven way but relatively expensive to do these days. Machining set-ups are, in principle, simple. Which is why there were many hobby user priced versions around back in the day. No real room for novelty as the design issues were sorted long ago. Neils rework the Adept, or equivalent, suggestion will work fine but you aren't going to learn anything. Student projects should be edgy. Clive |

| David George 1 | 11/10/2017 15:16:18 |

2110 forum posts 565 photos | Have a look at Joseph Noci 1 ,s albums and his posts on the restoration of his shaper it is well worth looking at to give you ideas what can be done with a shaper. David |

| JasonB | 11/10/2017 15:27:07 |

25215 forum posts 3105 photos 1 articles | There was a chap over on HMEM forum that built a doubled up version of the model shaper that was in ME about a year ago worked reasonably well and that would sit on your desk and give change out of £500. Most of the build thread has fallen foul to PB but text is there and a video in post #137. Main body was a bit or ERW rect structural section with a welded on base and most other parts machined. Photos can still be found in his PB album for those that want to look.

J Edited By JasonB on 11/10/2017 15:30:21 |

| John P | 11/10/2017 18:11:20 |

| 451 forum posts 268 photos |

Posted by Might be worth checking the "Gingery shaper". The majority of which could be easily I would agree with this ,the Gingery book would be a good starting place for John |

| Rainbows | 11/10/2017 19:52:30 |

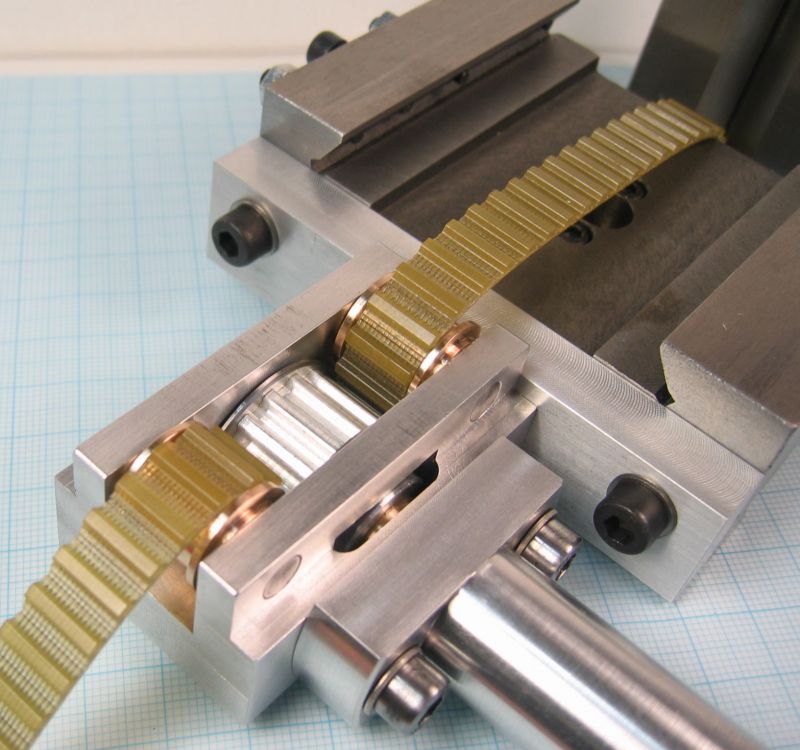

| 658 forum posts 236 photos | Most people are thinking Gingery because someone with a propane tank and a bunch of time can make it from nothing, however we are dealing with someone who I imagine has access to CNC lathes and VMCs. Re: some hints on planer construction http://metallmodellbau.de/MINI_BONELLE_II.php I would move the table using a timing belt as shown in the above link (thats for a small grinding machine). Gives fast, wear free motion. Ballscrew would be expensive, rack and pinion expensive-ish and an trapezoidal leadscrew too slow. On the input to the wheel put a medium (~200-300W for small machine, see how your budget goes) DC motor. Connect the DC motor to a H bridge and some inductance limit switches to tell it when to reverse. Use MGN linear rails to move the relatively fast and often moving table. Have the rails bolted to a chunky slab of steel, skimmed on a mill or surface ground would be best for accuracy. http://www.model-engineer.co.uk/forums/postings.asp?th=129363 <- Noci made a very nicely made automatic feed to his shaper as previously mentioned. You could do a lot worse than taking inspiration from his method. |

| Neil Wyatt | 11/10/2017 22:01:06 |

19226 forum posts 749 photos 86 articles | Posted by Clive Foster on 11/10/2017 14:48:34: Neils rework the Adept, or equivalent, suggestion will work fine but you aren't going to learn anything. Student projects should be edgy. Clive Give me credit, my first suggestion was a planer using linear bearings!

Neil |

| Bazyle | 12/10/2017 09:06:00 |

6956 forum posts 229 photos | I trust the project report will include an explanation of the difference in use of planers and shapers and why planers never caught on in home workshops but remain in use in industry. I rather wonder if the mature and experienced engineers on here giving information and advice is rather defeating the object of the exercise for the students. |

| Muzzer | 12/10/2017 12:17:34 |

2904 forum posts 448 photos | I would be very focused on rigidity and inertia. The transient loads in the frame (all the way from the tool through the movement and back through the table to the work) are going to be critical to avoiding distortion and chatter. And the inertia that is inherent in most shaper designs (the mass of the ram itself plus the equivalent mass of the geared up moments of inertia of the bull wheel, drive gears and motor) surely plays a significant part in their operation. My understanding is that a planer has a travelling table (and work), so the inertia is also going to be pretty significant. I'm not convinced that a lightweight tool post driven by a relatively elastic drive belt is going to work in a satisfactory way. Besides, as the cost of motors and associated drive electronics will be a significant fraction of the total, I'd consider keeping the motor speeds high, where a decent power output will be possible. That would also allow you to maximise the effects of the moment of inertia of the drive train. Perhaps a geared motor and ballscrew might be a workable compromise? Murray |

| SillyOldDuffer | 12/10/2017 12:25:09 |

| 10668 forum posts 2415 photos | Posted by Bazyle on 12/10/2017 09:06:00:

... I rather wonder if the mature and experienced engineers on here giving information and advice is rather defeating the object of the exercise for the students. Especially as Ryan started by saying 'It would be brilliant if we could see some metal planers and shapers in action'. Being a 3rd Year Mechanical Engineering Student means he's hot on the theory, but as we know there's nothing like looking at a working machine. Quite often the difference between a good tool and a poor one lies in the details, like having convenient controls, and not having exposed gears that grab you by the knadgers! Is there anyone in the Nottingham area who could show Ryan a working Shaper or Planer, perhaps explaining what's good and bad about it? Dave |

| Jeff Dayman | 12/10/2017 13:44:43 |

| 2356 forum posts 47 photos | +1 on emphasizing importance of rigidity in machine tool design. If you want a planer or shaper to make flat surfaces to reasonable accuracy and with good finish, it must be rigid and must have sturdy guiding elements with miminal clearances. Drive elements should also be rigid members rather than belts. Linear guides and belts are fine for things like plotters and 3D printers where there is little or no force on the "tool head" during working, but they will not be robust enough for a shaper or planer. For shapers and planers think inches thick of cast iron for frame and guides, V gibs or L gibs for the guides, and heavy steel or iron gears and bars for drives. Lots of well oiled bronze too, at wear points. (Like they did in the 1800's onward, for same reasons as mentioned). If made well this type of construction will give reliable long lasting accurate machine tools. If built too lightly there will be all sorts of accuracy issues and harmonics issues with machine tools. Couple of video links below, in first one, skip to minute 1.00. This is a big Cincinatti shaper. Second one is a smaller Elliot. Both are great examples of good shapers. https://youtu.be/R-b8PuuH3KU https://youtu.be/hhzAWH99g6g Edited By Jeff Dayman on 12/10/2017 13:45:18 |

| duncan webster | 12/10/2017 13:50:22 |

| 5307 forum posts 83 photos | I think what's disappointing here is that a 3rd year mechanical engineering student has never seen a planer or shaper in action. How are they supposed to design things if they don’t know how they are made? Yes I know planers and shapers are old hat, but there are still plano mills out there Edited By duncan webster on 12/10/2017 13:52:05 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in