cleaning brass after soldering

| geoff adams | 09/07/2017 15:37:29 |

| 214 forum posts 207 photos | fabricated cylinder and slide out of brass and soldered what do you use to clean before painting is there a chemical to clean off flux

many thanks Geoff |

| Thor 🇳🇴 | 09/07/2017 15:49:24 |

1766 forum posts 46 photos | Hi Geoff, If soft solder I use warm soap water and a brush. For silver (hard) solder I use citric acid and then fine emery or steel wool. Thor |

| Tim Stevens | 09/07/2017 16:03:49 |

1779 forum posts 1 photos | It all depends, Geoff, on what sort of solder and what sort of flux. If you used hard solder (such as silver solder, braze, etc - fairly high temperature (almost red-hot)) the flux is likely to include borax, and it will form hard glassy (but brown) blobs. This might be soluble in water (depending on the recipe used) so try the effect of an overnight soak - perhaps starting with very hot water. If this doesn't help, there are acids which will work. Citric acid is popular, fairly safe and easy to handle. It generally comes as a powder, so mix a couple of teaspoonsful in a tumbler of water*. This will have very little effect on the brass. Alternatively, sulphuric acid is the traditional silversmith's method. Battery acid from a proper old-fashioned garage will do - add acid to about the same amount of water, and keep it in a polythene or glass container - not metal or enamel. But do be careful, as this acid, even when diluted, will attack all sorts of household things. Cotton jeans, for example, will crumble to dust where you have spilt acid. And while citric acid can be tipped down the sink - its only like strong lemon juice - sulphuric needs looking after carefully, or diluting with lots of water before you tip it away. Mop up any spillages with a cloth soaked in washing soda (sodium Carbonate solution) which will neutralise it. If you have used soft solder (with lead or tin or both as the major constituent, and melting at around 200 C) the flux is usually a resin (which looks rather like borax residue but can be crumbled with a fingernail) or an acid such as 'killed spirit'. Other inorganic chemicals are also used. To remove resin residues, use a solvent such as alcohol (ethyl or methyl) or acetone. Or even petrol (gasoline) as long as you do it outside and carefully. The acid products are generally water-soluble, so a good soak in hot water should serve well. Again, some washing soda in the water will help with neutralising and will do no harm to the brass. And I do hope you used hard solder on your live steam parts, as otherwise the running temperature might cause failure. Steam under pressure can be much hotter than 100C. * Please note these units - my attempt to avoid conversion factors which can cause pages and pages of responses for and against different systems ... Regards, Tim |

| JasonB | 09/07/2017 16:52:58 |

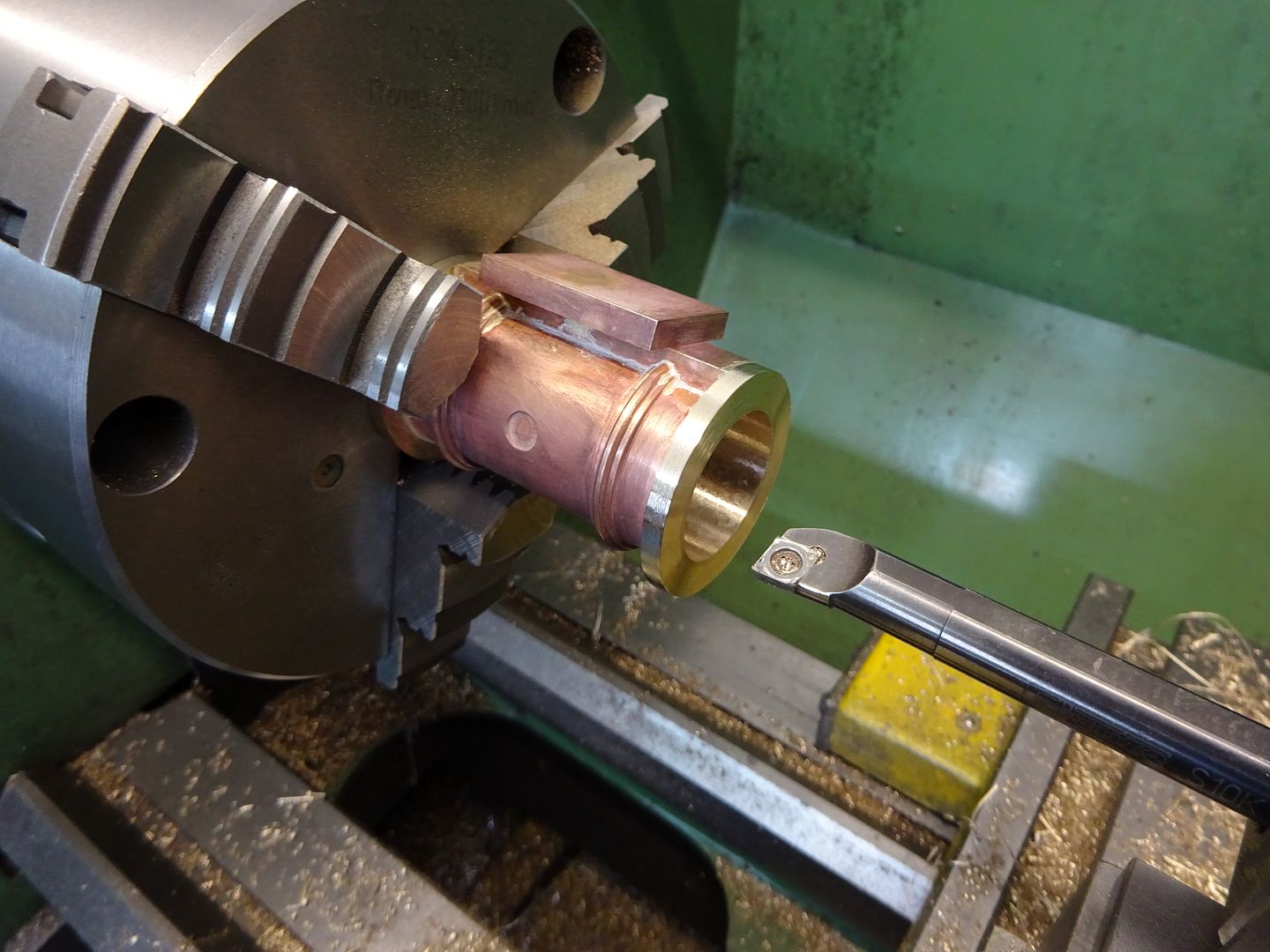

25215 forum posts 3105 photos 1 articles | For silver soldered joint I have moved away from citric acid as it takes quite a while and won't shift some of the fluxes such as HT5. I now use brick cleaner available from your local builders merchant or large DIY shed. Takes about 1/2hr to remove flux and discolouration for example From this gunmetal & bronze fabrication

To this in 1/2hr

Fumes can be a bit corrosive so use it outside. Also just the job for removing the black scale from hot rolled steel. |

| richardandtracy | 09/07/2017 17:14:35 |

943 forum posts 10 photos | Brick cleaner usually contains hydrochloric acid. It would work pretty well. Regards Richard. |

| Neil Wyatt | 09/07/2017 17:45:04 |

19226 forum posts 749 photos 86 articles | > sulphuric needs looking after carefully, or diluting with lots of water before you tip it away For avoidance of doubt, always add acid to water, not the other way around, less likely to be nasty fizzing and popping and any splashes are mostly water, not acid. Neil |

| IanT | 09/07/2017 17:46:41 |

| 2147 forum posts 222 photos | Just as a comment on Tim's advice above (with regards to cleaning flux off after soft soldering) & mainly because it's still fresh in my mind! I was reading an article about painting (and lining) in old issue of MRJ (No 76) this morning and the Author (Alan Brackenborough) - a professional model loco painter - strongly recommended not using "paste" flux at all when soft soldering brass kits. He stated it was extremely difficult to completely remove paste flux and that he'd had problems with it causing paint blisters to "bubble-up" months after painting. Although he was referring to his work on 7mm finescale locomotives, it seemed useful advice where brass parts are being soft soldered and painted afterwards. He advised the use of a liquid flux instead. Regards,

IanT |

| Tim Stevens | 09/07/2017 19:46:05 |

1779 forum posts 1 photos | Can we please not make a silly situation worse? There are already concerns about 'never adding water to acid' - but this advice applies to only one acid, which we have here - sulphuric acid. BUT - and it is an important BUT - the advice applies to CONCENTRATED SULPHURIC ACID. ONLY. If we follow the advice offered by Neil, we would never be able to top up an overcharged battery - because that is adding water to acid. My advice, as stated above, is to start with 'Battery Acid'. This is nothing like concentrated acid, and concentrated acid is NOT available from your local (or any other) garage. And for the benefit of others, it is not because we are talking about acid that is the problem. The particular property of Conc Sulphuric is that it reacts violently with water. It gets very hot, and the mixture boils. Not because it is acid, and the problem does not occur with other concentrated acids. And I am obliged to IanT for his advice about paste and liquid flux. I do wish I could be sure which of these is resin-based and which includes zinc chloride or other corrosive chemicals. I'm not saying he is wrong, it is just that the advice regarding resin and killed spirit followed by advice to use liquid and not paste will not make sense to everyone. There. I feel better now. Regards, Tim

|

| vintagengineer | 10/07/2017 01:07:33 |

469 forum posts 6 photos | Oneshot drain cleaner is 91% pure sulphuric acid and is available in most hardware stores!

Edited By vintagengineer on 10/07/2017 01:08:51 |

| Colin Whittaker | 10/07/2017 01:39:38 |

| 155 forum posts 18 photos | Can we please not make a silly situation worse? There are already concerns about 'never adding water to acid' - but this advice applies to only one acid, which we have here - sulphuric acid. BUT - and it is an important BUT - the advice applies to CONCENTRATED SULPHURIC ACID. ONLY. Based on my experiences with concentrated hydrochloric acid with a pH of -1 I would remove the word Sulphuric from the above advice, i.e. any concentrated acid should be added to water and not vica versa. |

| IanT | 10/07/2017 09:17:15 |

| 2147 forum posts 222 photos | Hi Tim, I'm afraid I'm not an expert on the chemistry of these things. Apart from resin-cored solders used for electrical work in the past, I've used Fry's 'Fluxite' paste when required for soft soldering my modelling work. However, I generally prefer to silver solder (non-ferrous) and Sifbronze/braze (ferrous) parts whenever possible, mainly for strength quite apart from any issues of heat. So my soft soldering experience has not been really that extensive, although I do find solder 'chucks' quite useful in some circumstances. I am currently trying to get back into electronics (which will involve some SMD work) as well as having some etched parts to assemble (which I've been putting off and putting off for some reason) - and it seems I will need to start using some form of liquid (acid?) flux in both of these areas. Regards, IanT |

| roy entwistle | 10/07/2017 09:32:40 |

| 1716 forum posts | Tim , I've often wondered how you wash an acid container after emptying if you don't add water to acid Roy |

| Sandgrounder | 10/07/2017 09:38:46 |

| 256 forum posts 6 photos | Posted by Colin Whittaker on 10/07/2017 01:39:38:

Can we please not make a silly situation worse? There are already concerns about 'never adding water to acid' - but this advice applies to only one acid, which we have here - sulphuric acid. BUT - and it is an important BUT - the advice applies to CONCENTRATED SULPHURIC ACID. ONLY. Based on my experiences with concentrated hydrochloric acid with a pH of -1 I would remove the word Sulphuric from the above advice, i.e. any concentrated acid should be added to water and not vica versa. I've just been reading a safety fact sheet on Sodium Hydroxide and the advice is "Never add water to a corrosive. Always add corrosives slowly to COLD water." so it's safest to assume it applies to all, acids and alkalis. John |

| Tim Stevens | 10/07/2017 10:12:24 |

1779 forum posts 1 photos | A few comments: If you are soldering wiring for electrical contact, you can normally rely on resin-cored (soft) solder. The resin, once cold, has no effect on the metal, so you do not need to remove it. Except, of course, for appearance. This is not so effective if you are re-using old wire as this tends to be brown (or even green) from age. It is true that there are a few other chemicals which have a strong affinity for water. Solid caustic soda (Sodium Hydroxide) is one of these. My comment was about acids, and caustic soda is not an acid. Anyone worried that they have some sulphuric acid but they don't know if it is concentrated? The real dangerous stuff, in this context, is thick (viscous), rather like thin honey, and noticeably heavier than water. And as regards advice never to add water to corrosives, like much of the advice offered in these oh so careful times, it is much too broad. One of the most corrosive substances is ordinary everyday 'common' salt. And every day it rains into the sea quite harmlessly. I am not saying that corrosives can be treated carelessly, they can cause serious problems. The context I was dealing with is regarding battery acid, which, as I said, will eat away even the trousers you are wearing. Finally, I am seriously concerned about some advice regarding DIY products such as brick cleaner and drain cleaner. Unless you know what is in them, in scientific terms, it is not safe to say what else they can be used for. If it doesn't say what's in it, leave it in the shop. This advice is based on the fact that some drain cleaners are mainly caustic soda, some contain strong bleach, and others, according to Vintageengineer, are strong acid. And if it isn't clear why this is a problem, leave well alone. Regards, Tim

|

| Russell Eberhardt | 10/07/2017 10:44:24 |

2785 forum posts 87 photos | Posted by IanT on 10/07/2017 09:17:15:I am currently trying to get back into electronics (which will involve some SMD work) as well as having some etched parts to assemble (which I've been putting off and putting off for some reason) - and it seems I will need to start using some form of liquid (acid?) flux in both of these areas.

Don't use liquid flux fro soldering SMD components, or any electronic components for that matter. A fine flux cored solder will do the job but best for smd is to use solder paste under the pads, place the SMDs, and then reflow on a hotplate or in an oven. Leaded components can be added after. Russell. |

| JasonB | 10/07/2017 11:54:23 |

25215 forum posts 3105 photos 1 articles | Or rather than leave it on the shop shelf look up whats in it on the makers site. This is the one I use |

| JasonB | 10/07/2017 12:19:11 |

25215 forum posts 3105 photos 1 articles | I think the last time the acid/water debate came up this got posted, have to wait until abouy 9.30 in to get a reaction and I think you would get teh same reaction at the end by addin clod water to boiling water as you would cold water to boiling acid |

| john swift 1 | 10/07/2017 13:00:45 |

318 forum posts 183 photos |

many many yeas ago I diluted some Oleum to refill an empty car battery that something you don't do in a rush https://www.youtube.com/watch?v=nHiVyesJ04U the reaction of sulfuric acid and suger is a classic I remember from school https://youtu.be/xK4z_YhtTBM

John to correct link Edited By john swift 1 on 10/07/2017 13:12:19 |

| SillyOldDuffer | 10/07/2017 13:12:11 |

| 10668 forum posts 2415 photos | That acid to water video is misleading. That bad things happen when you add water to acid is not a myth and there should be no debate about it. Concentrated Sulphuric has a strong affinity for water. When water and acid are mixed rather a lot of heat is evolved. If a small quantity of water is dropped into the acid, it is possible for the water to flash to steam. When this happens the mixture spits, which is not nice when it hits flesh. Whether or not you get a spit depends mostly on the way the two liquids happen to make contact. It doesn't always do it. The safest way to dilute Sulphuric Acid is to add small quantities of acid to a large quantity of water whilst stirring. The most dangerous way to do it it is to fling a small dollop of water into a large quantity of acid. In a lab a few drops of water into a test-tube of acid might spit dangerously. Even more fun can be had in Industry where concentrated Sulphuric Acid is used by the ton. Back in the good old days before H&S went mad, there were many accidents due to haphazard mixing. Don't forget that even small chemical burns are nasty. Quite an interesting statistic to think of when watching internet videos. Nine times out of ten it is possible to stir Nitroglycerin with a red-hot poker without causing an explosion. (We know this because Alfred Nobel did a lot research into ways of using Nitroglycerin safely, including how best to reliably set it off ). If you insist on trying it, you've got a good chance of surviving. But I sincerely hope no-one is daft enough to think it's OK to have at explosives with a red-hot poker. Dave Edited By SillyOldDuffer on 10/07/2017 13:13:25 |

| Maurice | 10/07/2017 14:34:06 |

| 469 forum posts 50 photos | MauriceIf you have soft soldered your fabrication, and there are blobs of solder where you don't want them, a glass fibre stick, as used to clean commutators, will remove the solder and not the brass. It's a slow process, but you know you are not damaging the underlying metal.

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in