Oil coolant pumps - which type of pump

| Martin Newbold | 21/01/2017 11:57:32 |

| 415 forum posts 240 photos | Hi everyone which type of pump is best suited to pump oil coolant on to machined item . Are there specifics about the type of pump that is most effective to pump this and material around. Can a motor drive a pump pulley as well as the lathe head? |

| David George 1 | 21/01/2017 18:06:36 |

2110 forum posts 565 photos | Hi this is the type of coolant pump which I would recommend but you would need to have a tank with lid to support said pump. They are available in various sizes depending on tank depth and volume you need to pump and they come in single and three phase electricity supply. they work regardless for many years with little attention. I personally wouldn't run a pump from a spindle motor as it is not good to run coolant at the same time if anything goes wrong i.e. forgot to turn the coolant tap off it would take your concentration off the spindle work which could be dangerous and you could get wet with coolant. You would also need a control circuit with a no volt safety built it to the circuit. David

Edited By David George 1 on 21/01/2017 18:08:45 Edited By David George 1 on 21/01/2017 19:14:19 |

| Nick Hulme | 21/01/2017 18:24:22 |

| 750 forum posts 37 photos | Most commercial coolant pumps work on the same principle as pond pumps, I suspect that pond pumps may not be compatible with all types of coolant though. |

| Brian H | 21/01/2017 19:03:25 |

2312 forum posts 112 photos | I have a Vertex pump in a self contained unit similar to this from Rotagrip: 01a) Coolant Pump Kit 1/8 HPPrice per Unit (Each): £192.30

£153.84 (including 20 % tax) You Save: 20.00%

Vertex 1/8HP Coolant Pump Kit Fully combined unit consisting of a single phase 1/8 hp pump , flexible feed pipe, bracket to secure to your machine and magnetic base with coolant hose. This unit is ideal for the small to medium size lathe or milling machine Specifications Tank : 14 x 10 x 7.5" Capacity : 27-28 l/min @ 1m / 25-26 l/min @ 2m Part Number 1026-030 Brian |

| Mark Eisen | 24/01/2017 06:27:17 |

88 forum posts 68 photos | I am going to a washing machine pump, seen some good set ups on an Aussie forum. |

| daveb | 24/01/2017 08:47:29 |

| 631 forum posts 14 photos | I bought a used surface grinder a while ago, the PO had cobbled together a coolant system with a washing machine pump, the oil had caused all of the rubber parts to disintegrate. Dave |

| Scrumpy | 24/01/2017 09:05:53 |

152 forum posts | My Mitchell lathe 8 1/2 swing X 10 ft bed has a built in pump being run from the main motor it also has a pressure valve to bypass the system some years ago it failed so we fitted a washing machine pump after adjusting the bypass it works perfect |

| Martin Newbold | 29/01/2017 11:46:37 |

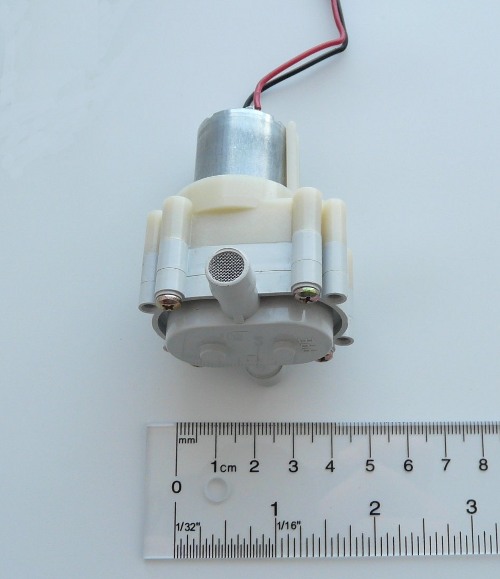

| 415 forum posts 240 photos | Hi everyone and thank you for the posts am looking for a small pump for a self build on a small lathe. My post was in relation to the types of pumps as there is a lots of types usually gears are used for oil pumps and not an impellar or propellor. I am wondering if there are any small pump motors that use gears to pump. This is a water pump but i wonder if they make metal pumps at this site . Does anyone know the viscosity of the cutting liquid please?

I was thinking of something like this Edited By Martin Newbold on 29/01/2017 11:57:15 |

| David Jupp | 29/01/2017 11:57:56 |

| 978 forum posts 26 photos | Big advantage of centrifugal pumps is they are contamination tolerant, and will tolerate being 'shut in' on delivery side (for a while anyway). Depending on precise detail, delivery head may be a bit low (e.g. aquarium style). Gear pump is possible, but prone to wear - quite expensive because much more difficult to manufacture. Won't be at all happy if shut in on delivery side, they are a positive displacement type and can generate high pressures. Old fashioned fuel lift pump is another possibility. Contamination may give issues with the check valves, won't mind being shut in, as diaphragm is actually pushed back by a spring not the cam. I bought a cheap mains solenoid pump to try - rather noisy, and again valves potentially prone to contamination problems. Gravity feed is effective for some people - very simple. Good luck! |

| Martin Newbold | 29/01/2017 11:59:32 |

| 415 forum posts 240 photos | Whats sort of pressure does the cooling pump ideally need to deliver?

|

| David George 1 | 29/01/2017 12:22:56 |

2110 forum posts 565 photos | If you were to get a pump with 25 litre a minute at 2 meter head you would have a reasonable pressure to flush down a drilled hole with a small bore nozzle and if you turn off the tap without turning off the pump you would be better with a centrifugal type as there will be no increase in pressure with that type of pump. David |

| RJW | 29/01/2017 12:51:42 |

| 343 forum posts 36 photos | Martin, it may be worth you looking at something similar to the parts cleaner shown in the link, you could use it as either a parts cleaner or a coolant tank and pump combined, they're designed to pump solvent as well as crap that escapes a filter, all the data you need is probably on the listing, I've saved a 'Safety Clean' parts washer pump myself for just such a job and which came as a spare with my parts cleaning tank, the intention being to make a coolant tank for the lathe, but the mill I bought last year came with a portable unit and has saved me the trouble, I'll post a photo up of the pump unit later, it came with a flexible metal hose and appears to be a dead ringer for that shown in the listing. John |

| Mark P. | 29/01/2017 13:53:01 |

634 forum posts 9 photos | A few years ago I picked up a 240 volt"vibrating" type of pump off ebay. It came with a strainer, I mounted it in a plastic 5 liter paint kettle from Wlikos. Good rate of flow and had no problems with it, works for me. Mark P. |

| David Jupp | 29/01/2017 14:19:01 |

| 978 forum posts 26 photos | Posted by Martin Newbold on 29/01/2017 11:59:32:

Whats sort of pressure does the cooling pump ideally need to deliver?

At least enough to lift the chosen fluid from bottom of your reservoir to the highest point in the pipework - plus a bit more if you want it to do more than crawl out of the end. Assume a soluble oil (so treat is as water for calculation), say 1.5m lift height (lets say 2m for luck) - that's about 0.2 bar or 3 psi. If piping is very small or fluid particularly viscous, add some more to cope with pressure drop. |

| John Reese | 29/01/2017 17:58:25 |

1071 forum posts | I have used submersible pond pumps successfully for many years in water based coolants. Not sure if they are compatible with straight oil. A lot of old machines used gear pumps. As already said, they don't tolerate particulates very well. If worn they don't prime well. If you want to go the gear pump route chjeck out carbonator pumps. |

| Martin Newbold | 01/02/2017 21:25:13 |

| 415 forum posts 240 photos | Hi RJW yep still to big though any idea what pump motor the parts washer uses please? David by centrifugal i presume you mean like a slurry pump that will cope with particles I.e a rotating disc witch is like a slinger. John are carbonator pumps this centrifugal design is there a particle size limit Thanks for all your help M |

| Muzzer | 01/02/2017 22:06:03 |

2904 forum posts 448 photos | Central heating pumps are pretty rugged and silent, and can develop a fine pressure head (~5m) and a decent flow rate. They are also very simple centrifugal pumps and don't cost a lot, particularly if you find a used one. The main problem is that they don't self prime, so you need to mount them below the fluid level. This is a typical (Grundfos) performance characteristic: |

| RJW | 01/02/2017 22:46:23 |

| 343 forum posts 36 photos | Posted by Martin Newbold on 01/02/2017 21:25:13:

Hi RJW yep still to big though any idea what pump motor the parts washer uses please? Thanks for all your help M Hi Martin, sorry I'm still looking for the spare pump for my machine, it's buried somewhere under all the clutter I've been moving into the building, I'll pull the tank off my machine and take a shot of that next time I'm in there, Something like this might do the job: John. |

| RJW | 01/02/2017 22:54:39 |

| 343 forum posts 36 photos | Martin, done a bit of digging around on the web, the pump in the link is the same as mine, there's a data spec' on the listing that should help. What about a fuel transfer pump? John. Edited By RJW on 01/02/2017 23:07:37 |

| mgnbuk | 02/02/2017 07:40:23 |

| 1394 forum posts 103 photos | Central heating pumps are pretty rugged and silent But CH pump motors have sleeve bearings that are lubricated by the pumped liquid, so would require pretty good inlet filtration to give reasonable bearing life. Nigel B |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in