Knurling Tools

How to ensure a good quality knurl

| Bob Jepp | 09/07/2016 17:26:30 |

| 42 forum posts | I've just come in from the workshop where I tried making a couple of small thumbscrews in brass - 9mm od. I turned the outside diameter and applied the medium diamond knurl using a proprietary clamp type knurling tool. The first thumbscrew knurl was pretty good, so I finished the screw and parted off. When applying the knurl to the second screw ( making sure that the diameters were the same within 0.01mm, without altering the setting of the knurling tool and using the same speed of 150 rpm ), the knurl as terrible. I did clean the knurling wheels between screws but I didn't use any lubricant either time - maybe I should have ? I notice that the knurling wheels don't line up - the top arm as skewed relative to the bottom arm by about 1/2 a knurling wheels width and the fit between the pivots and the arms seem very loose. Any thoughts ? Bob |

| daveb | 09/07/2016 17:35:09 |

| 631 forum posts 14 photos | I always knurl the bar before making the screws. Knurling (Gnarling when I do it) only fails if you try to do it on a finished part. |

| Vic | 09/07/2016 19:20:18 |

| 3453 forum posts 23 photos | I bought a knurling tool and had the same problem, very wobbly arms. I made my own in the end which works fine.

|

| Ajohnw | 09/07/2016 19:52:28 |

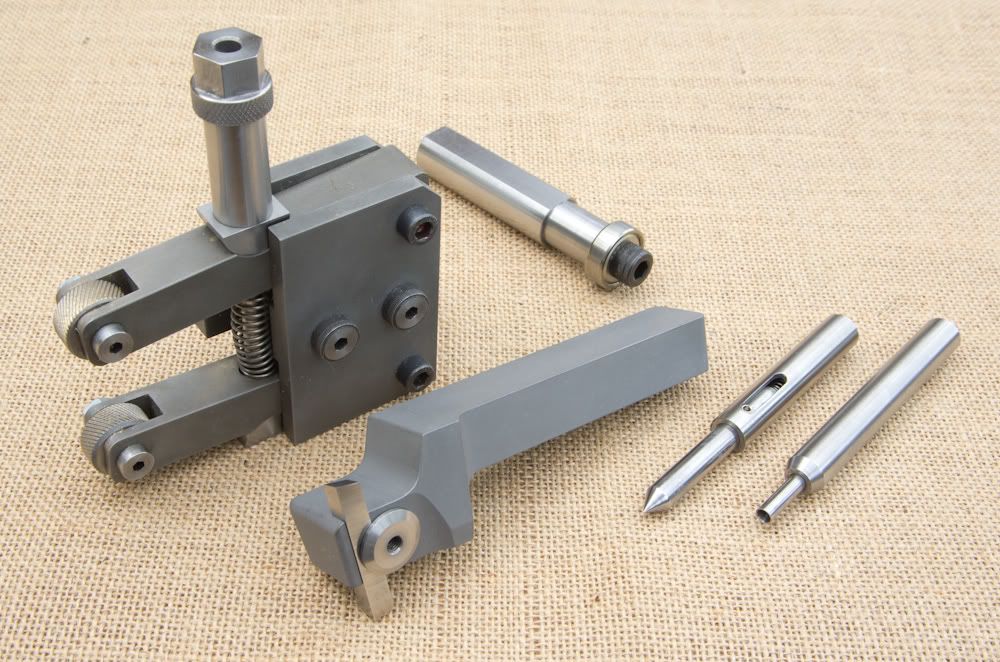

| 3631 forum posts 160 photos | These are a photo's of 2 designs in my main album. Th best one by far has plates on the side as per Vic's. There are some none clamp on types about that will work well but they may bend small parts. John - |

| Vic | 09/07/2016 19:56:56 |

| 3453 forum posts 23 photos | The best of course are cut knurlers if you can afford to buy one or know how to make one. |

| John Hinkley | 09/07/2016 20:30:36 |

1545 forum posts 484 photos | Graham Meek has a nice design of knurling tool in his book "Projects for your Workshop" I made one but altered the mounting to attach it directly to my QCTP. It works very well with a capacity of up to 60mm diameter, although I have used it in "push" mode to knurl the feed ring on my boring/facing head (78mm diameter). All the joints need to be a good fit with no sloppiness and the knurls themselves should be parallel and in alignment, wherein I suspect a lot of your problems lie. Good luck. John Edited By John Hinkley on 09/07/2016 20:31:20 Edited By John Hinkley on 09/07/2016 20:33:02 |

| pgk pgk | 09/07/2016 20:47:57 |

| 2661 forum posts 294 photos | I made the 'tom's techniques' knurling tool as a beginner project. Nice and rigid. |

| Neil Wyatt | 09/07/2016 22:20:14 |

19226 forum posts 749 photos 86 articles |

I don't buy the need for rigidity, this is my scrappy knurling tool and it does a first class job every time (including the brass knob in the photo and the aluminium parts in the image below).

|

| Michael Gilligan | 09/07/2016 22:44:47 |

23121 forum posts 1360 photos | Posted by Neil Wyatt on 09/07/2016 22:20:14:

I don't buy the need for rigidity, this is my scrappy knurling tool and it does a first class job every time (including the brass knob in the photo and the aluminium parts in the image below). . Neil, Question ... Are all your knurlings 'less than or equal to' the width of your knurls [not conclusive from the photos], or have you traversed the tool? [I think that's where rigidity might prove beneficial]. MichaelG. |

| MW | 09/07/2016 22:52:15 |

2052 forum posts 56 photos | I think what Neil has benefited from is not the rigidity of the tool but the pressure that a clamp allows for. I've always followed the wisdom that one needs to traverse along the knurl then back it up to cut properly? Michael W |

| Clive Foster | 09/07/2016 23:28:49 |

| 3630 forum posts 128 photos | Neils scrappy little tool with its near triangular arm layout and short, central, clamp adjustment screw is inherently much stiffer than the more common design with relatively long arms. Disadvantage of Neils version is the relatively linited diameter capacity and the unbalanced forces due to the cutting points of the knurls not being directly opposite and on the centre line of the workpiece. Most clamp type designs go to inordinate lengths to put the knurls on a common diameter line through the centre of the work considering that perfectly opposed positioning is far more important than rigidity in line with the work axis. The inevitably long arms require the knurls to divine their support at considerable distance so along axis flexibility is built in. Large sideplates being, in my view, a desperate attempt to cover-up unsound design. I acquired a truely massive Marlco made knurler of this style with my P&W lathe. It flexes! Given that pretty much every writer on the subject sees fit to mention the high forces required by conventional knurls its surprising how accepted less than rigid tools are. The Graham Meek design in Johns picture is elegant but shows that even the masters among us can have an off day as inherent rigidity is conspicuous by its absence. Making one well enough to work reliably needs a high level of skill, which John clearly has. I've never been that convinced of the need for symmetric disposition of knurls. Indeed my best push style kneelers are a pair of Pratt & Whitney ones which have two knurls on an arm swinging on an offset pivot so one knurl is pushed straight in the other pushes rather upwards. Flex is minimal and they are very self stable in cut. For my money the hand held three wheel nutcracker type are by far the best on small machines. Clive. Edited By Clive Foster on 09/07/2016 23:29:23 |

| bodge | 10/07/2016 05:46:25 |

| 186 forum posts 3 photos | Posted by Michael Walters on 09/07/2016 22:52:15:

I think what Neil has benefited from is not the rigidity of the tool but the pressure that a clamp allows for. I've always followed the wisdom that one needs to traverse along the knurl then back it up to cut properly? Michael W Hi. yes thats how its done when traverse knurling keep the pressure on, if it starts to chatter which it probably will on steel tighten it up a bit till it stops chattering, continue for desired length then return back. knurl should look well defined and crisp on steel you may need to repeat again but you really do need flood suds for steel or compressed air for brass when doing traversing work to clear the chips , i`d have at guess most of us on here are only knurling small- ish components in terms of width usually the width of the knurl is enough or maybe multiple bands of knurl if a longer knurl is required. To be honest i dont remember what rpm, around 60 rpm maybe on steel 5/8 dia, maybe a bit more or a bit less. Bob if i read your post correctly " without altering the setting of the knurling tool and using the same speed of 150 rpm ), the knurl as terrible." is the part where it went wrong , i think you should have made a note of how far you applied the pressure screw, then released the knurl pressure screw then reapplied the prssure to the next piece the same amount as the first i also use clamp type knurl a marlco repetitive lever arm knurling tool so one sets the knurls so their touching the work piece tightens the locking nut, then one applies steady pressure with the lever the lever turns a cam so it will always cut to correct depth when the knurls finished cutting return lever to vertical position, repeat with next piece to be knurled, the way i read it your trying do the next piece with the knurl set to depth, rpm is something ive never thought about, just go by how it feels, at guess some where between 40-60rpm maybe a bit more, depends what metal and dia, dont think ive gone as high as 150, but ive not done anything as small as 9mm still seems a bit fast though........b PS I would`nt use coolant on brass, paraffin on ally could try using a straw to blow through, blow it clear or compressed air. Edited By bodge on 10/07/2016 06:00:25 I dont think wobbley arms are good, there is no play in the marlco knurling tool all joints are firm Edited By bodge on 10/07/2016 06:24:01 |

| Neil Wyatt | 10/07/2016 09:58:01 |

19226 forum posts 749 photos 86 articles | Posted by Michael Gilligan on 09/07/2016 22:44:47:

Posted by Neil Wyatt on 09/07/2016 22:20:14:

I don't buy the need for rigidity, this is my scrappy knurling tool and it does a first class job every time (including the brass knob in the photo and the aluminium parts in the image below). . Neil, Question ... Are all your knurlings 'less than or equal to' the width of your knurls [not conclusive from the photos], or have you traversed the tool? [I think that's where rigidity might prove beneficial]. MichaelG. The aluminium ones are about 1 1/2 knurls wide, the brass one was cut from a long bar knurled for about 2" and chopped into a set of nuts..

I always get the knurl running, but not cutting, then rapidly apply enough pressure to get it stared positively, then increase the pressure until I get a sharp knurl. yes capacity is limited but there is SOME play in the setup. I think that as long as the pressure is applied straight on, once cutting the embryo knurls themselves help keep everything straight. I think the main issue is why have a complex way of applying huge pressure when even the tiddly M4 screw, working at a ~1:2 mechanical disadvantage in mine is adequate? If I was making it again, I would go bigger, but as I used bronze spindles and washers for the knurls to run on (it isn't quite as skanky as it looks in the detail) it shows no signs of giving up. Elsewhere I have show a 2 1/4" straight knurl cut in EN1a using the 'plunge in method' so I have a feeling the 'small lathes can't take the forces of an unbalanced knurl' claim is a myth as well. Neil Edited By Neil Wyatt on 10/07/2016 10:06:33 |

| Michael Gilligan | 10/07/2016 10:07:51 |

23121 forum posts 1360 photos | Posted by Neil Wyatt on 10/07/2016 09:58:01:

The aluminium ones are about 1 1/2 knurls wide, the brass one was cut from a long bar knurled for about 2" and chopped into a set of nuts.. . Thanks for the clarification, Neil ... Looks like your earlier comment is demonstrated. MichaelG. |

| bodge | 10/07/2016 14:13:43 |

| 186 forum posts 3 photos | posted by Neil on 10/07/2016 09:58:01 "I always get the knurl running, but not cutting, then rapidly apply enough pressure to get it stared positively, then increase the pressure until I get a sharp knurl. yes capacity is limited but there is SOME play in the setup. I think that as long as the pressure is applied straight on, once cutting the embryo knurls themselves help keep everything straight." Yes i also get the knurls touching and running first then apply the pressure, should have said as much in my last post, going by the feed back of the lever arm on the marlco there`s very little pressure needed when knurling brass or aluminium and no problem traverse knurling , steels a good bit harder though............b

|

| Bob Jepp | 10/07/2016 17:05:26 |

| 42 forum posts | When I was in the apprentice training school in 1974, the machines were much larger than those in the usual home workshop. The standard issue knurling tool was the rotating disc with three sets of knurls, just pushed into the job with the cross-slide. Although I have a reasonable size lathe - a Warco VS1224 12" swing - I went for the clamping type knurling tool as I thought it should be best since, as we all agree, the forces are contained within the tool rather than being transferred to the machine. When knurling, I firstly set the clamping screw to make the knurls touch the diameter and for them to start rotating without making much of a mark. I withdrew the cross-slide and added a bit more to the clamp screw then fed in the cross-slid again taking the knurls just over centre. As I said, the first knurl I did was really good, but adopting the same process on the second part left me with a knurl with the peaks broken away and the knurls covered with the remnants. I took in posters suggestions on knurling speed, maybe I was over-egging it bit at 150 rpm. Maybe too much depth of knurl, maybe feeding in the cross-slide does something to the geometry of the knurl and causes it to break up, or, maybe a combination of all those things ? I have a much smaller Soba knurling tool as well - I'll try that when I get in the workshop again - it's much more rigid side-to-side than the one I used this time. There must be some logic somewhere in getting a good knurl ! |

| Ed Duffner | 10/07/2016 19:07:16 |

| 863 forum posts 104 photos | As a beginner and having a small lathe with little power, both knurling and parting off can give problems, the rigidity just isn't there, or if it is it doesn't last very long before the machine has to be tweeked back into alignment which can be a pain when your machine doesn't have gib adjustment. These operations, mostly knurling have quite a wear on small machine tools. I have found that lots of thin lubricating oil is good for evecuating displaced material, or it will be pushed into the surface. I mix motor oil and maintenance oil(duck oil) 50/50. I was thinking of doing a test to see if thinner knurls(reduced pressure) will still work. But I'm a little reluctant after just fixing my lathe following previous knurling efforts. In my own exeprience, some things to watch out for when buying cheap (e.g. ebay) knurls is: - They should have the same diameter. Ed. |

| Martin King 2 | 11/07/2016 07:23:35 |

1129 forum posts 1 photos | Hi All, I would like to buy a set of small PARALLEL knurls for some brass trammel knobs that I need to copy and cannot seem to find any? Any ideas please? Regards, Martin |

| Michael Gilligan | 11/07/2016 08:17:40 |

23121 forum posts 1360 photos | Posted by Martin King 2 on 11/07/2016 07:23:35:

I would like to buy a set of small PARALLEL knurls for some brass trammel knobs that I need to copy and cannot seem to find any? Any ideas please? . Martin [and Ajohnw for info.] These are an unusual shape [which is why I haven't used them yet ... the requisite tool is still in the 'cogitating' phase of the design process] but the quality is clearly superb, and the price is excellent. I bought a pair of each pitch a while ago, and ordered some more last night. ... Great ebay seller too !! MichaelG. |

| Martin Kyte | 11/07/2016 09:35:07 |

3445 forum posts 62 photos | Surely the narrow aspect increases the pressure for the same amount of clamping force. I agree it's a good idea. Martin

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in