Whats going on with this drill?

| Rainbows | 04/05/2015 09:48:23 |

| 658 forum posts 236 photos | So I bought a corded drill of ebay attracted by its low RPM but now I look at it I realise something is off. Thats the entire drill, notice the 3 pin plug. Thre is the information on it, notice the 110V.

Did I just buy a dud 99p drill? Seller said it probably works but it was his granddads and he doesn't have a transformer to test it. If it has been run off 240V what are tha chances the insides are baked? |

| FMES | 04/05/2015 09:58:46 |

| 608 forum posts 2 photos | Hi Rainbows, A lot of American tooling is 110 volt and will need a transformer in order to be used on UK supplies. What is worrying is the presence of a 13amp plug being fitted, giving suspicion that it has been used on a 240v system. It would be prudent to have it tested properly before use as it is obviously getting on in years. |

| Rainbows | 04/05/2015 10:14:11 |

| 658 forum posts 236 photos | I was going to open it up to check if it needed new bearings, brushes and grease and such anyway. Assuming it isn't already burnt out would one of those yellow transformers you get for construction sites be suitable? I know the voltage is right but I don't know if the frequency is right too. |

| paul 1950 | 04/05/2015 10:32:10 |

| 143 forum posts 32 photos | just had the same problem myself with a bench grinder, plugged it in worked fine then I noticed the label. no damage done put on correct plug and its working ok on 110v. the original owner may have been running it off his own bodged up 110v circuit. what you need is a yellow site transformer. if it has been burnt out it will smell. i buy lots of these old drills and they are very tuff. |

| Roger Hart | 04/05/2015 11:00:38 |

| 157 forum posts 31 photos | As said smell it. A transformer will cost a lot more than 99p, so donate it to local junk seller. I could suggest a bodge to test but that will have H&S howling. |

| John Olsen | 04/05/2015 11:19:32 |

| 1294 forum posts 108 photos 1 articles | The guys are right about the smell, if it has been cooked it will leave you in no doubt. There is actually a reasonable chance that it might survive being plugged into 240V for a short time. I have a 110V fine feed unit on my mill drill that was given to me because it had been plugged into the 240V mains and gone pop. The only thing that had actually blown was an interference suppression capacitor, so it was an easy fix. The frequency does not matter too much for this type of motor. The speed is not determined by the frequency. If you do get it going with a step down transformer, make sure that the transformer is a double wound type, not an autotransformer. The difference is that with a double wound type, the secondary is isolated from the primary, which gives you an extra degree of protection with an old unit like this. With the autotransformer type, depending which way around the primary ends up connected, you can end up with 240 V between one end of the motor and the earthed case, which is not ideal on a machine only intended for 110V. John |

| Rainbows | 04/05/2015 11:24:41 |

| 658 forum posts 236 photos | It is a good thing I kept that 110v tranformer from that auction lot I got a while back. No idea if that is double or auto though. Its the yellow box type. |

| Muzzer | 04/05/2015 11:38:56 |

2904 forum posts 448 photos | Looks as if it's from The Ark. Whether or not it's been damaged by being used on 230V, I'd suggest you run it from an isolation transformer or an RCD at the very least, given that it seems to have had a tough life. I've no idea what the internal insulation requirements were back in those days. When you dismantle it, make sure it has a solid ground / earth connection to the case, at least as heavy as the L and N connections, all the way back to the (120V) plug. |

| Gordon W | 04/05/2015 12:10:50 |

| 2011 forum posts | The yellow transformer will be a site transformer so will have all the safety features. My mate tried a 110V saw on the 240 mains 'cos it would not work on 110V, ,found that his mains was only about 180V instead of 240, no harm done. |

| Capstan Speaking | 04/05/2015 13:20:59 |

177 forum posts 14 photos | Posted by Rainbows on 04/05/2015 11:24:41:

It is a good thing I kept that 110v tranformer from that auction lot I got a while back. No idea if that is double or auto though. Its the yellow box type.

That would be perfect. Frequency can't change through one and the difference between UK 50Hz and US 60 HZ won't matter. Some, if not all, of the yellow boxes are CTE or centre tapped for extra safety too. |

| old Al | 04/05/2015 13:24:54 |

| 187 forum posts | I wouldn't put my hands round it and turn it on..It is probably well made, but I have better things to waste my time on than something that might electrocute me. |

| Neil Wyatt | 04/05/2015 14:38:43 |

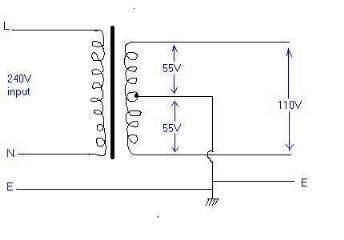

19226 forum posts 749 photos 86 articles | If a 110V transformer is correctly wired (and the sealed units should be) the earth will be wired to the centre tap of the 110V. this means that no live part of the drill will be more than 55V from earth. Though the Americans need thicker conductors than us (for higher current) their system is a fair bit safer than ours! Neil

|

| Russell Eberhardt | 04/05/2015 15:42:10 |

2785 forum posts 87 photos | Posted by Neil Wyatt on 04/05/2015 14:38:43:

If a 110V transformer is correctly wired (and the sealed units should be) the earth will be wired to the centre tap of the 110V. this means that no live part of the drill will be more than 55V from earth. Though the Americans need thicker conductors than us (for higher current) their system is a fair bit safer than ours! We used to use 55 Vac to line power cable TV amplifiers on the basis that 55 Vac was the highest safe voltage. I thought that the domestic electricity supply in the US was two phase with 110 V at most outlets having one side earthed and 220 V for things like cookers with centre tap earthed. So it is still potentially lethal. Russell. |

| Rainbows | 04/05/2015 15:49:26 |

| 658 forum posts 236 photos | I can never trust a electrical system that uses such feeble and fragile plugs. |

| paul 1950 | 04/05/2015 16:00:19 |

| 143 forum posts 32 photos | with things like that i put a cable tie around the switch then turn the thing on at the wall. |

| Nicholas Farr | 04/05/2015 16:16:59 |

3988 forum posts 1799 photos | Hi, a 110v yellow site transformer will be OK as they are just as Neil has pointed out centre tapped, so that your are only ever likely to be exposed to 55v, which is deemed to be a safe level in industrial and outdoor situations. The majority if not all of them will have a built in thermal overload so that if you start drawing more power than the unit is designed for, for any length of time, the output will be cut off until the unit cools down enough to be reset. This drill you have is an old style one which would not be allowed to be used in an industrial environment because it is not double insulated and an earth wire must be used with it even though it is only 110v. All yellow site transformers have a three pin socket outlet with the thickest pin hole connected to earth, but of course the power lead going to the transformer must be earthed in the first place, because the site transformers are themselves double insulated. Regards Nick. P.S. the one at the top of this list would be suitable http://www.machinemart.co.uk/shop/range/guid/C1C63496-8E8F-4533-A0D9-BF9A15436A24?da=1&TC=SRC-110v%20transformer Edited By Nicholas Farr on 04/05/2015 16:24:15 |

| John Stevenson | 04/05/2015 16:49:13 |

5068 forum posts 3 photos | Rainbows. What with this post and the home made arc furnace post can you supply a post code where you live please ?

Reason is I want to check I'm at least 3 counties away from you. |

| Rainbows | 04/05/2015 17:03:35 |

| 658 forum posts 236 photos | I haven't even tried my electrical arc ignition system for a waste oil furnace though!

Also out of curiosity is it possible to make it double insulated? I'm wondering is there is some sort of insulating spray that could be applied to the inside of the drill casing. |

| paul 1950 | 04/05/2015 17:32:31 |

| 143 forum posts 32 photos | all you need to do with it is check the wires from the switch to the windings are ok by covering them with heat shrink sleeving, i fix these things up all the time. just do not use it in the rain in bare feet. |

| Capstan Speaking | 04/05/2015 17:50:43 |

177 forum posts 14 photos | Know a friendly PAT tester? |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in