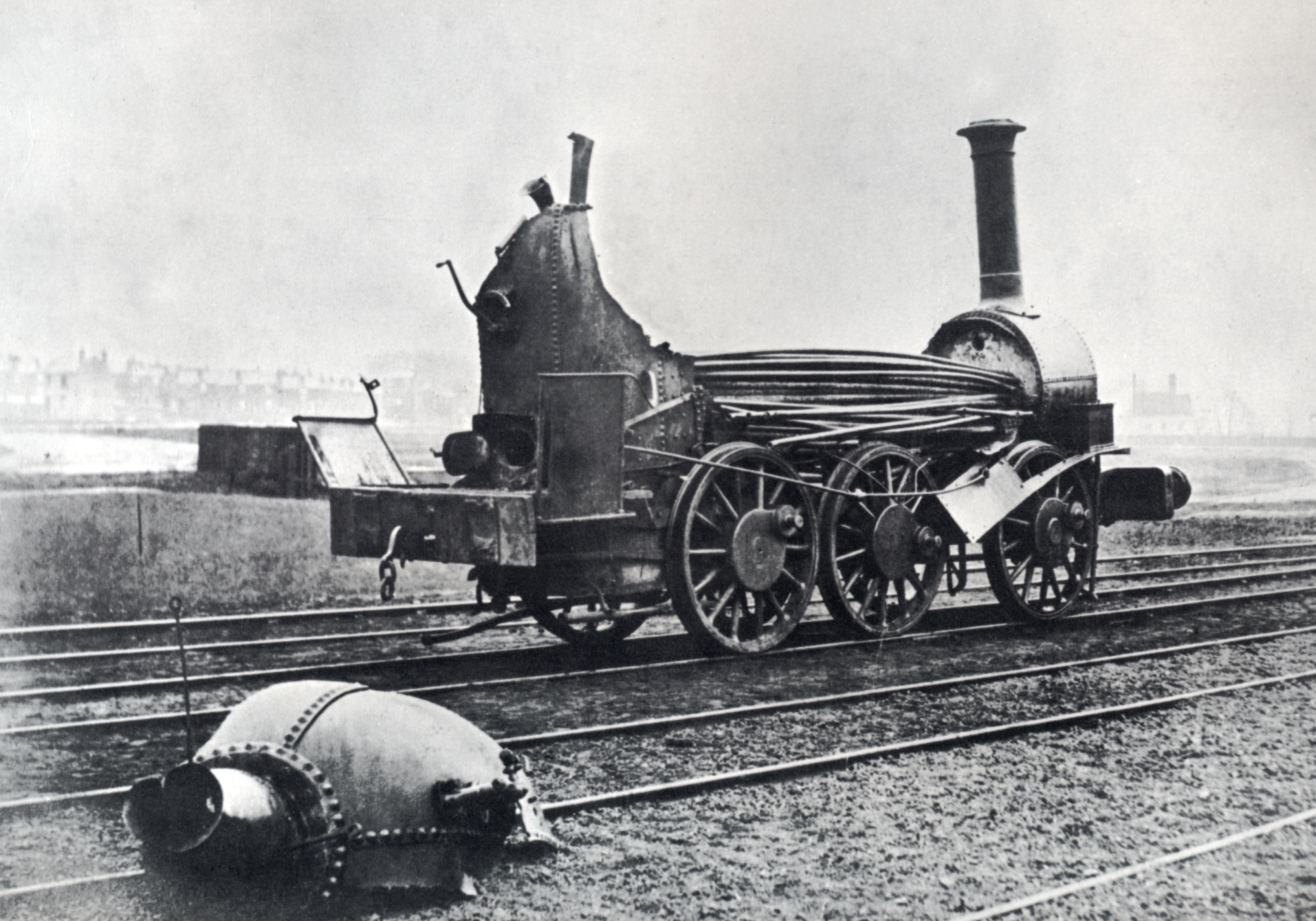

Boiler Explosion

Fascinating 19th century picture

| Neil Wyatt | 01/10/2014 18:45:33 |

19226 forum posts 749 photos 86 articles | I found this image on Wikipedia.

It's worth viewing it fullsize at: LINK if clicking the image doesn't work. Neil |

| "Bill Hancox" | 01/10/2014 19:09:13 |

257 forum posts 77 photos | Wow!! I hope the engineer and fireman were in the local pub having a cuppa when that happened. I think that boiler inspector just retired recently. Bill |

| Stovepipe | 01/10/2014 20:55:44 |

| 196 forum posts | Apparently, it was not unknown for a bucket of spanners to be hung on the safety valve lever in that era, to expedite the crew's entry to heaven ! Dennis |

| fizzy | 01/10/2014 20:58:38 |

1860 forum posts 121 photos | Hi Neil, ive got that and loads more in a book dedicated to boiler explosions....was not uncommon by all accounts!

|

| Boiler Bri | 01/10/2014 21:45:00 |

856 forum posts 212 photos | Low water, screwed down safety valve, wrought iron, neglect, decay, boom.

I hope the fireman and driver got a good send off!

Bri |

| Boiler Bri | 01/10/2014 21:47:01 |

856 forum posts 212 photos | There was a thread on here the other day that got heated about welding copper, take note on doing things that are not fully understood;(

Bri |

| Paul Lousick | 01/10/2014 22:35:27 |

| 2276 forum posts 801 photos | All boilers are dangerous ! They are a potential bomb if used by inexperienced operators. Proper training and inspections are necessary. |

| John Stevenson | 01/10/2014 22:48:11 |

5068 forum posts 3 photos | That should make cleaning the tubes easier |

| fizzy | 01/10/2014 23:35:36 |

1860 forum posts 121 photos | Hi Bri.....indeed there was, and I was called negative for pointing out what was required!

|

| Boiler Bri | 02/10/2014 05:31:20 |

856 forum posts 212 photos | There's nothing negative about sound advice. That's what most people get from this forum, although a bit drawn out sometimes. I employ very competent welders doing tig welding on stainless steel every day, however all our pressure vessels go out to specialised firms. its not the here and now, if down the years the loco goes to some unknowing person and runs it in public and it goes pop who knows who may be harmed? Then you end up with a photo like the above!

Better sticking to the tried and tested or leave it alone, but I think he had come to that decision anyway.

Bri. |

| Hopper | 02/10/2014 11:13:50 |

7881 forum posts 397 photos | Interesting pic. Looks like the riveted joints on the piece in the foreground were stronger than the boiler sheet, which looks like it split along the section that had been curved in two directions (ie domed). Wonder how far away the other bits landed? It's wonder to me there have not been more of these incidents. Over the years I worked on boilers in several places where the boiler man was out of the boiler room doing maintenance work up to a city block away more time than he was in the boiler room watching the glass. I suppose modern era safety valves and gas/oil shut-offs for low water make all the difference. Still, Murphy's law and all... |

| Ady1 | 02/10/2014 11:39:04 |

6137 forum posts 893 photos | Way back in the late 70s I was put in charge of a butterworth heater for tank cleaning on a big OBO carrier. They had a big donkey boiler for operating windlasses and turbine pumps which fed this thing and I had to keep the water level in the middle of the sight glass for 8 hours a day for about a week The water was fed in via the fire pump and everything went peachy for a couple of days until unbeknown to me the fire pump tripped out in the engine room. So I'm screwing the feed valve open and the feed water level disappears because there's no pressure and this butterworth heater starts to heat up and bang like an anti-tank gun I didn't hang about, I was off up the deck and behind the nearest hatch cover The noise, which could be heard throughout the ship alerted the 2nd engineer who got the fire pump going again and settled things down Anyway, if a boiler explosion is "imminent" I doubt that, in the majority of cases, any person in the vicinity would be unaware of the impending situation |

| Nick_G | 28/10/2014 14:41:45 |

1808 forum posts 744 photos | . This looks as if it was an 'exciting' event.!! Nick |

| Maurice | 28/10/2014 15:09:15 |

| 469 forum posts 50 photos | Earlier in this thread, "Hopper" wondered how far away the bits landed. Many years ago, I knew "Billy the steam" who used to drive a horizontal engine that drove the machinery at a brickworks near Maidenhead. He told me that at sometime in its past, the governor drive failed while the attendant was not attending. The engine ran away, The flywheel was made in two pieces, held together by bolts. These failed! One half of the flywheel went into the bottom of the wheel pit. The other half however, sliced through a roof timber at least nine inches square, exited through the roof, and landed near some workers cottages about one hundred yards away!! Billy showed me the sawn off end of the beam which was still visible. The works were out of use by the time I saw this, but it was all still there. The parts of the wheel were retrieved, undamaged, and refitted, and the engine worked untll the brick works closed. I believe that the engine is in a museum now, but I cant remember where . It is mentioned in one of George Watkins's books. Regards Maurice |

| Harry Wilkes | 28/10/2014 16:47:35 |

1613 forum posts 72 photos | Here's another "link" |

| Mike | 28/10/2014 16:51:11 |

713 forum posts 6 photos | The book I recall is "Locomotive Boiler Explosions" by Christian H. Hewison, published in 1983. I've now lost my copy. The only point I can remember is that the only British railway company never to have a boiler explosion was the LNER. There are plenty of cheap second-hand copies if students of the livelier effects of over-pressure steam on overheated metal care to look on line. |

| Neil Wyatt | 28/10/2014 19:06:54 |

19226 forum posts 749 photos 86 articles | From my Machinery's Handbook (18th ed.): The test of a very specially designed bronze and steel flywheel of built-up construction, 49" diameter and 900lbs weight. "This wheel burst at 1775 revolutions per minute at a linear speed of 372 feet per second. The hub and main spokes of the wheel remained nearly in place, but parts of the rim were found two hundred feet away."

It's worth noting that when using some small but fast lathes with cast iron faceplates it's possible to spin them at speeds that the flywheel calculations in this book suggest might be unwise. Neil |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in