The Workshop Progress Thread 2019

| geoff walker 1 | 13/10/2019 13:39:10 |

| 521 forum posts 217 photos | Nice work Jason, I like it a lot. Are you doing some drawings for it? I'm looking to make an i/c engine next model, preferably 4 stroke, could be an option. Is it air cooled? Geoff |

| JasonB | 13/10/2019 14:07:56 |

25215 forum posts 3105 photos 1 articles | I need to decide on the drawings, it is all done in Alibre but only modeled in 3D not working drawings. Yes air cooled, would normally have just stuck out in the wind of a tether boat or car. |

| Jim Nic | 13/10/2019 14:23:40 |

406 forum posts 235 photos | Lovely little engine Jason. What's next, a Midget twin? Jim |

| JasonB | 13/10/2019 14:27:30 |

25215 forum posts 3105 photos 1 articles | Posted by Jim Nic on 13/10/2019 14:23:40:

What's next, a Midget twin? I might just skip that stage and go straight to a radial, seven |

| martin perman | 13/10/2019 14:31:09 |

2095 forum posts 75 photos | Posted by JasonB on 13/10/2019 12:24:12:

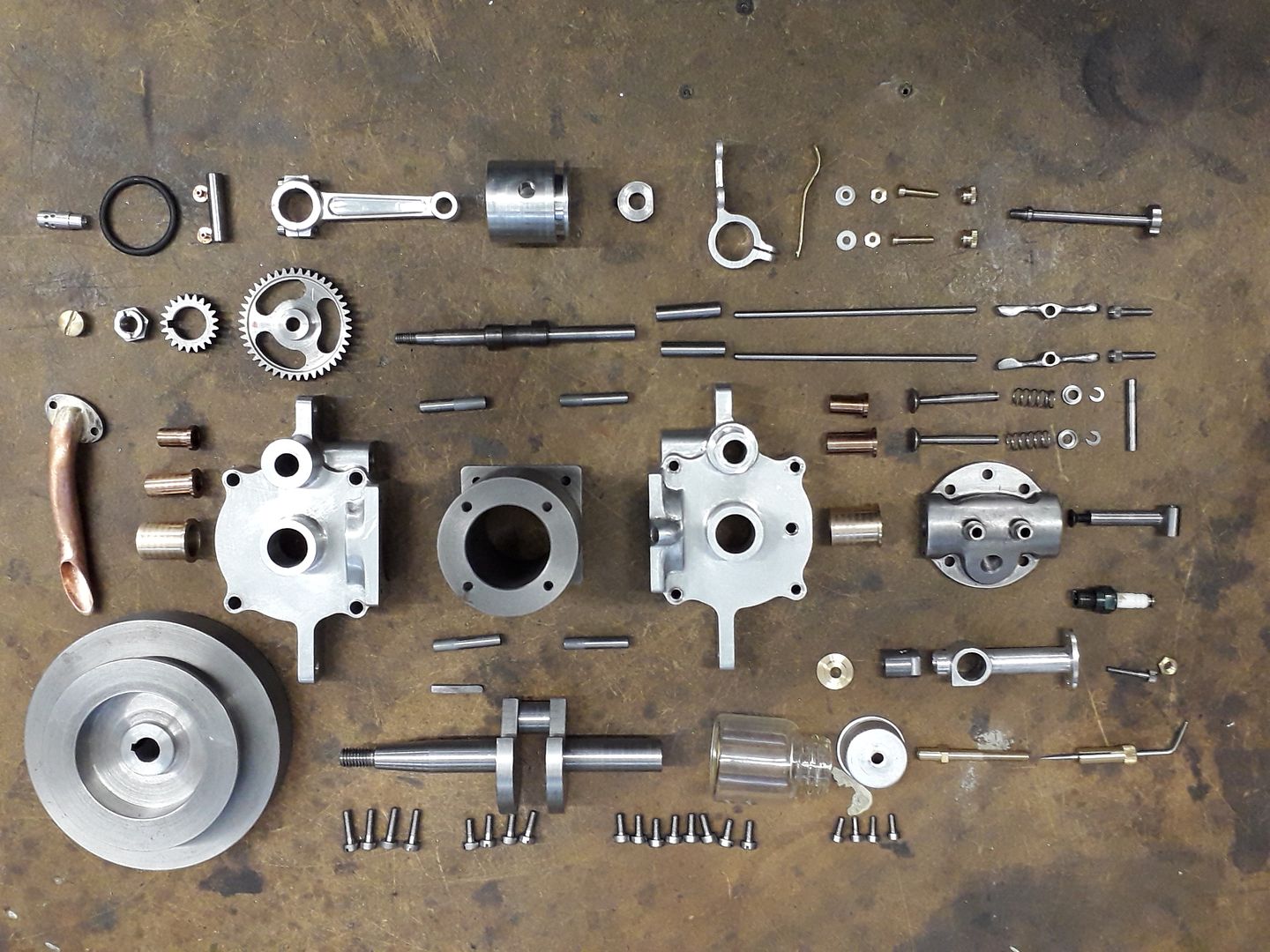

I got all the Midget parts finished, 57 individual items plus a further 30 custom made nuts, screws etc.

Luckily I remembered how it all went back together. Valve timing was set by eye while turning the engine over slowly watching when the valves opened and closed. A little more oil than the normal running level into the crankcase, some Colemans with a drip of 2-stroke oil into the fuel jar and give it a go. I got some pops straight away and with a bit more retardation of the timing it fired into life. Throttle is by rotating the jam jar fuel tank but quite slow to react due to sizeable flywheel, advance & retard are a better way to set the speed which I had always intended was going to be for looks and noise rather than outright speed and performance. Just goes to show that you don't need to worry about working to umpteen decimal places, a micrometer was only used on the crankshaft and the 0.8 MOD gears on metric ctrs were cut with 32DP cutter but it seems to start and run . Just needs a bit of colour to finish it off Jason, Whats happened to the video. Martin P |

| JasonB | 13/10/2019 15:33:06 |

25215 forum posts 3105 photos 1 articles | Posted by martin perman on 13/10/2019 14:31:09:

Whats happened to the video. Martin P What do you see that is wrong or not see for that matter? |

| martin perman | 13/10/2019 18:40:08 |

2095 forum posts 75 photos | This morning it said unexpectedly switched off, your latest post popped up on my computer this afternoon so I've just had another look and it now says connection reset.

Martin P Edited By martin perman on 13/10/2019 18:41:07 |

| mechman48 | 16/10/2019 18:39:19 |

2947 forum posts 468 photos | Lovely job Jason, nice 'putt putt' sound. Give that man a prize off the top shelf. George. |

| Michael Gilligan | 18/10/2019 19:08:58 |

23121 forum posts 1360 photos | I don’t normally post any of my An assembly was held together with three countersunk screws, the recesses in which had been mutilated beyond recognition [they were probably JIS crosspoint]. Using a suitably sized Slocombe centre drill, I managed to pop the heads off them, and then simply unscrew the remaining thread. There was no retaining compound or corrosion present ... they were obviously just screwed-home so tightly that someone attempting to unscrew them using the wrong driver destroyed the recesses. . . . MichaelG. |

| Richard S2 | 28/10/2019 22:20:34 |

237 forum posts 135 photos | Finished the wheels for my 1" scale water cart. The old riveting tool I made 30 years ago came in handy. Added detail to hubs to reflect the casting pattern- Oil tube and cap- |

| Jeff Dayman | 29/10/2019 02:18:31 |

| 2356 forum posts 47 photos | Great work Richard! |

| mal webber | 30/10/2019 00:14:26 |

154 forum posts 309 photos | Superb job on them wheels Richard and that lettering must of taken some time but what a result and finish Mal. |

| Phil P | 30/10/2019 07:09:23 |

| 851 forum posts 206 photos | Richard Those wheels are superb, well done. Can I ask you to enlighten us on how you produced the raised lettering please. Phil |

| Richard S2 | 30/10/2019 12:16:01 |

237 forum posts 135 photos | Thank you Jeff, Mal & Phil. Lettering took about 2 hours for each wheel start to finish. Happy with the result. Phil, have a look at the bottom post on page one of this (hopeful) link below to give a description. I have more lettering challenges on the plates at each end of the tank, so I'll try and sequence some pics on here at a later stage that may help (he says without checking he has enough lettering left). Regards |

| Howard Lewis | 30/10/2019 12:32:59 |

| 7227 forum posts 21 photos | Wish that i had the skill and patience to do that sort of thing! Excellent work! Howard

|

| mechman48 | 30/10/2019 17:46:11 |

2947 forum posts 468 photos | Superb work on those wheels Richard, a lot of elbow grease gone into the finish by the looks of it. George. |

| John Hinkley | 09/11/2019 11:19:16 |

1545 forum posts 484 photos | It's been a while and slow progress, but progress it is ..... All the gear blanks for my 5-speed transaxle gearbox had been made, as have the input and ouput shafts, gear hubs and spacers. The output gears need the dogs machining and of course there is going to be a monumental gear cutting session coming up. I've been waiting until all the gear blanks were finished until setting up the rotary table. I had to alter the ratio of 3rd gear slightly as I can't obtain a 28 tooth pattern with my rotary table set up but it made little difference overall. Below are a couple of pictures from the album: The gear internals so far, with some finishing still to do: The same parts, loosely assembled. To give some idea of scale, the shafts are 201mm in length. I am awaiting delivery of some 10mm thick perspex sheet to use as the casing faces for display of the finished workings. I'll post further pictures of progress later. Much later. John

|

| mechman48 | 09/11/2019 16:45:07 |

2947 forum posts 468 photos | … Then I took delivery of the engine frames from Model Engineer’s Laser. Do you have a link for these people; I have a pair of frames that will be a long & tedious job by hand so was looking at laser cut. I have a pair that were laser cut by a friends previous work place but only in 3mm stainless; their machine will not cut small cross members ( 3mm wide ), it just blasts them away, so he says ? George. |

| John Hinkley | 09/11/2019 16:55:21 |

1545 forum posts 484 photos | George, The site I think you're after is: You will have to supply a dxf file of the part you want cut and the owner will tell you whether your requirements are possible. I have used this service and found them excellent to deal with and very reasonably priced. John |

| Brian H | 09/11/2019 18:07:37 |

2312 forum posts 112 photos | Finally got the rebuilt motor back in my Tom Senior Major Mk 2 ELT and connected to an inverter. It runs nice and quiet although it's only on a slow speed while the new and the newly packed, bearings are run in. The only problem is that, although there is drive to the table drive gearbox, there is no output. Hopefully something simple but it will have to be taken apart. I'm hoping it's just a shearpin or something. Brian |

This thread is closed.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in