The Workshop Progress Thread 2020

| Colin Heseltine | 30/03/2020 18:05:42 |

| 744 forum posts 375 photos | Finally managed to get some silver soldering to actually work. Third attempt at making burner assembly for CHUK2 flame gulper. Just have to stain and polish the plinth, unfortunately I have no stain or dark hole filler so this is likely to have to wait for several months in the current lockdown climate. The flame gulper ran quite well with big Sievert Burner as a heat source, but does not run as fast on small gas burner. Think I will need a few more flame holes in the burner bar. Colin https://youtu.be/_gwCVr1dBA8 Edited By Colin Heseltine on 30/03/2020 18:08:36 |

| Mark Rand | 31/03/2020 00:40:46 |

| 1505 forum posts 56 photos | Having melted many, many disassembled hard disks, plus a couple of decent sized castings last week, I've now got 75kg of aluminium ingots in three different alloys. Spent today starting to make wooden patterns for some bits I'd like to cast. It would be far cheaper and quicker to buy some large lumps of aluminium and mill the bits from solid, rather than making close-to-size castings and cleaning them up. But where's the fun in that?

|

| Nick Wheeler | 05/04/2020 12:36:16 |

| 1227 forum posts 101 photos | A loose tailstock on my WM250 meant I finally had to do something about it. So I removed and dismantled it, scraped the paint and a couple of burrs out of the joints, loctited the barrel-screw bush back in the correct place, reassembled and adjusted. Now it locks in place/releases with about a 10° movement of the lever, drills on centre(which it did before) and ejects the tooling correctly fixing a problem that's been getting worse.

While I was at it, I made a small knob for the topslide lock and a captive lever for the carriage lock. Now they're usable without tools, so will get used a lot more.

Then, using an aircraft bolt, I made new studs for the change gears that screw into the T-nuts properly(one of the originals was almost stripped), and allow the gears to float rather than undoing the stud in the middle of a job. This has also stopped the gears rubbing together and making an awful howling noise. I'm now thinking of making new linking bushes, as the current ones are a bit crumbly on their edges.

A bit of cleaning and lubricating, and it ought to be good for another five years of use.

|

| SillyOldDuffer | 05/04/2020 13:53:04 |

| 10668 forum posts 2415 photos | Posted by Mark Rand on 31/03/2020 00:40:46:

Having melted many, many disassembled hard disks, plus a couple of decent sized castings last week, I've now got 75kg of aluminium ingots in three different alloys. ...

Are you sure the cases were all Aluminium? Some hard drive cases are Magnesium, as are many laptop bodies. Magnesium and Aluminium look similar and melt at about the same temperature (650C vs 660C). The easiest way to tell them apart is to measure their density; Magnesium at 2.7g per cc is heavier than Aluminium at 1.7g per cc. Whilst Aluminium is safe to machine, Magnesium swarf is rather too easy to ignite. It burns with an intense bright white flame and the fire explodes when water is poured on it. Great fun! Magnesium is used because it casts and machines better than Aluminium and is stronger, but it has to be handled with care. Magnesium and Aluminium alloy together usefully. Commercial alloys go up to 15% Magnesium, which casts well and is strong. Alloys with less Magnesium machine better but aren't quite so good for casting. On the down side swarf from Magnesium/Aluminium alloys catches fire much more easily than ordinary Aluminium alloy swarf. It's not as bad as pure Magnesium, but still risky. Once started metal fires are more dangerous than ordinary fires, chances are an ordinary workshop extinguisher will make them worse. Magnesium is top metal for machinability - it's easy to cut, dimensionally stable, and gives excellent finish with no bother. Better than all other metals. Not used as much as it might be because the fire hazard always has to be managed, both whilst cutting and then handling and storing the swarf. This Youtube Video shows what to expect. I'd cheerfully work with it, but would take care to clear swarf often and have the right sort of fire extinguisher ready to go. Dave |

| KEITH BEAUMONT | 05/04/2020 14:00:33 |

| 213 forum posts 54 photos | Jason help please. I am trying to insert a thread with photos to i/c engines and nothing happens when I press add posting. Keith |

| JasonB | 05/04/2020 15:07:57 |

25215 forum posts 3105 photos 1 articles | Looks like you have it sorted as I can see your post and the photos. |

| Jim Nic | 05/04/2020 16:31:31 |

406 forum posts 235 photos | Having completed the Muncaster Double Acting Oscillator I had no next project lined up. Looking at my collection of engines I saw that I did not have a horizontal mill engine other than trunk guide crosshead type. Soooo I thought that Stew Hart's Dad's and Lad's Mill engine would be a fairly straightforward job for me and I could add some of my own "enhancements" to it along the way. I gathered together some materials from the come-in-handy bin: and set to. First stop is the cylinder: and already there a couple of enhancements, the cylinder base having visible mounting feet and the piston rod gland, and a upcock which is trickier to see. I have made the cylinder with the inlet ports on the wrong side. Putting the cylinder head on the other end would correct it but I'm not too sure about the concentricity of the piston rod to bore if I did that so it is staying as is. Jim |

| John MC | 05/04/2020 16:44:09 |

464 forum posts 72 photos | Magnesium and Aluminium look similar and melt at about the same temperature (650C vs 660C). The easiest way to tell them apart is to measure their density; Magnesium at 2.7g per cc is heavier than Aluminium at 1.7g per cc. You have that the wrong way around, Mg is lighter than Al. John |

| thaiguzzi | 05/04/2020 17:00:40 |

704 forum posts 131 photos | Posted by John MC on 05/04/2020 16:44:09:

Magnesium and Aluminium look similar and melt at about the same temperature (650C vs 660C). The easiest way to tell them apart is to measure their density; Magnesium at 2.7g per cc is heavier than Aluminium at 1.7g per cc. You have that the wrong way around, Mg is lighter than Al. John Concur. Unbelievably lighter. |

| Mark Rand | 05/04/2020 17:59:36 |

| 1505 forum posts 56 photos | To Dave, John MC and thaiguzzi:- Yes, I'm certain that they are an aluminium die-casting alloy. The density is approximately 2.7. Coincidentally, Compac server disks used a magnesium alloy caddy for some unknown reason. I've quite a few of those as well. They (unlike the other bits) corrode quickly if left out in the weather. I have milled enough of one of them to make a respectable pile of fine swarf and tested it on an insulating firebrick with a torch. In that form, it oxidises readily rather than melting, but it will not burn unlike purer magnesium. In bulk, it melts in the furnace well and produces clean ingots. I just haven't got any projects for it in the pipeline.

I've spent the week making patterns for five different castings, varying from simple to adventurous and have spent the last couple of days making flasks. There's vastly more woodwork in this casting game than anything else. Edited By Mark Rand on 05/04/2020 18:00:54 |

| Iain Downs | 06/04/2020 20:23:41 |

| 976 forum posts 805 photos | I've just finished what I'm calling a 'half vice' for my mill.

The immediate use is to square up a piece of 10 inch aluminium plate which will for the bases of a saw table for my femi band saw (slightly cheaper in parts than the real table and much much more expensive in labour!). The Big square blocks sit in the t slots and are a rattle fit owning to the 3 slots all being different widths.The grey thing in front is an accurate T square made by milling across the bed with the backplate (hard to see in this photo) hard against the back of the table. I wanted to see how accurate it was at an earlier stage of the build so squared it up with a big Angle and took seem readings with an indicator On my second set of measures (after tapping it to properly square it), I found it to be within 0.05mm across the height and depth (which I was rather pleased with). Since then I've skimmed it (and got rid of the bolts sticking out), so I'm hoping it's even more accurate - especially with the new 'precision' T. Tomorrow, I will measure it in the final version - I don't like to do so at the end of a job so I can retain my confidence in quality overnight! Iain |

| Robert Butler | 17/04/2020 20:01:06 |

| 511 forum posts 6 photos | Is everyone on strike! No postings for ages. I am working from home but over the last couple of weekends I have managed to make some real progress with the components for fitting the Z axis encoder and head to the Quill on my Chester Lux milling machine. This will enable connection to the third axis on the Machine DRO console. I will then be able to dispense with the scale and remote readout. The components will fit to the front of the head and utilise linear bearings to guide the rail to which the encoder head is fitted. The project commenced in 2017 - how is it the warranty on everything I buy has long expired before its fitted or I use it? Robert Butler |

| JasonB | 18/04/2020 13:24:07 |

25215 forum posts 3105 photos 1 articles | Posted by Robert Butler on 17/04/2020 20:01:06:

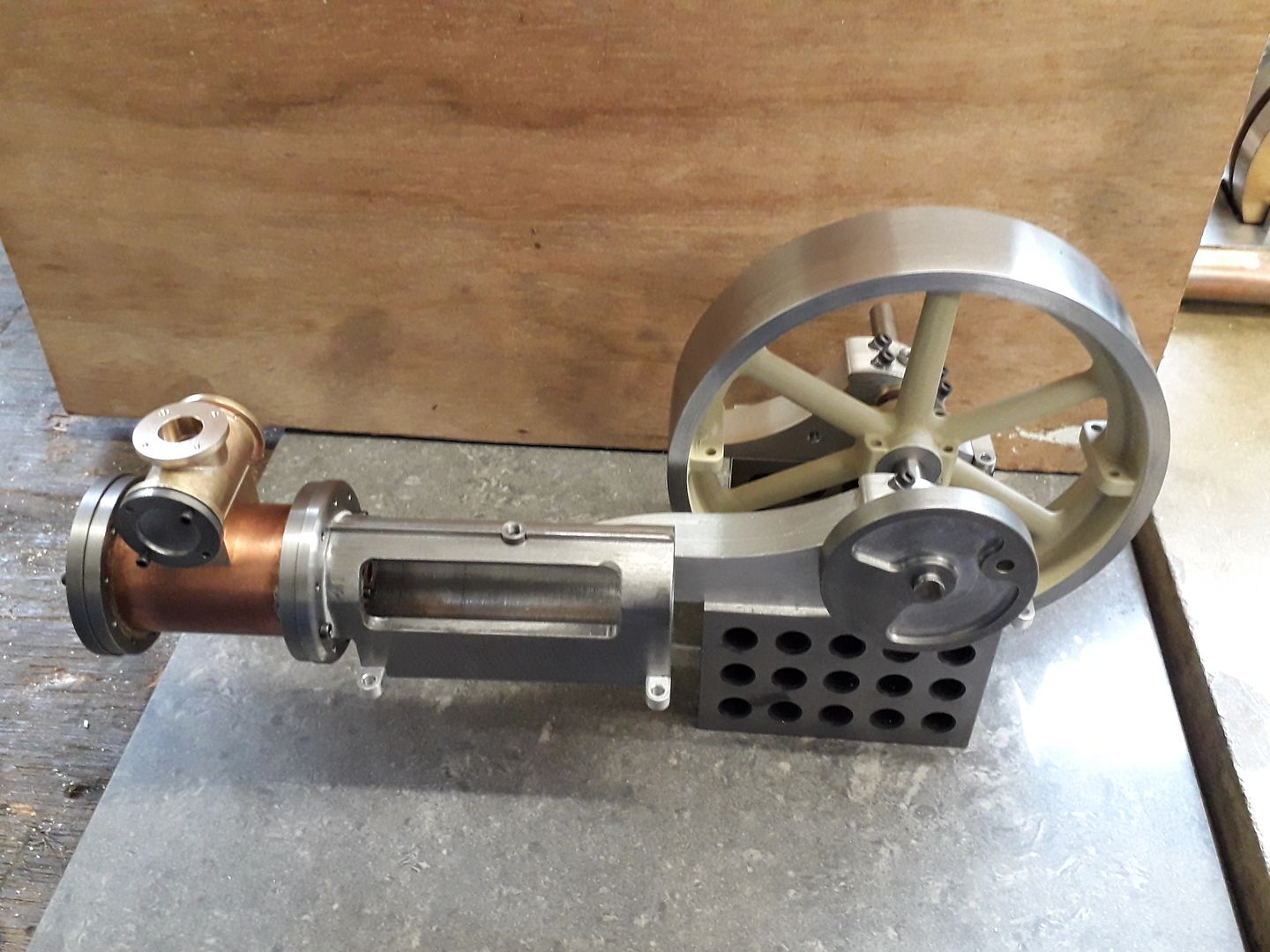

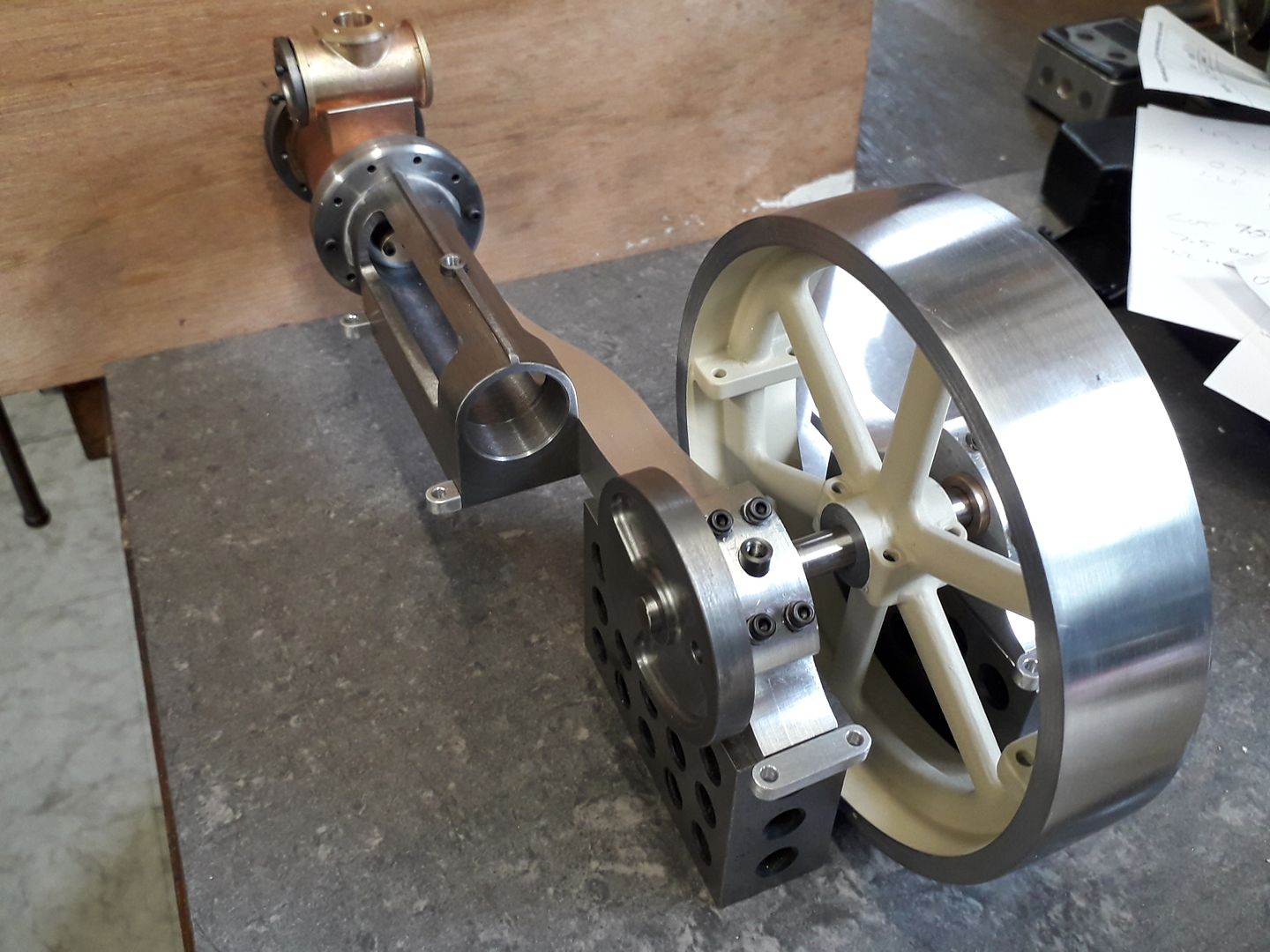

Is everyone on strike! No postings for ages. Well I can't speak for the rest of the membership but in my defence I have been posting in the KX3 CNC thread lately as several of the bits I've been doing have used that machine but here are a couple of shots of my latest effort a rocking valve engine based on a Filer & Stowell.

Edited By JasonB on 18/04/2020 13:24:32 |

| duncan webster | 20/04/2020 13:31:01 |

| 5307 forum posts 83 photos | I put up some photos of my ELS some time ago saying I would get round to fitting a belt guard. Here it is. Once I can get it to a fellow club member to get the curved bit tack welded with his TIG it will get a coat of paint. Anyone know what rattle can car paint matches Myford green? |

| Anthony Knights | 20/04/2020 15:32:50 |

| 681 forum posts 260 photos | I finally got round to fitting a scale I can read on the tail stock of my CL300 lathe. Edited By Anthony Knights on 20/04/2020 15:33:46 |

| Nick Clarke 3 | 20/04/2020 16:35:41 |

1607 forum posts 69 photos | Posted by duncan webster on 20/04/2020 13:31:01:

I put up some photos of my ELS some time ago saying I would get round to fitting a belt guard. Here it is. Once I can get it to a fellow club member to get the curved bit tack welded with his TIG it will get a coat of paint. Anyone know what rattle can car paint matches Myford green? It is 40 years since I was in the paint game but if you want a standard colour you can buy off the internet I would start looking at Ford Highland green from the late 1950s and reintroduce in the late 1970s After that there was a green used on Moggie thou's and Farina bodied BMC cars that was close as well. If you can wait until we are past our present troubles Jawel Paints **LINK** will mix car and also BS and RAL colours in a number of different paints and put them into a rattle can. Just before the shutdown I bought a can of RAL 5004 Black/Blue to repaint my Drummond Round Bed - an ongoing project! BS 4000 14E53 Irish Green looks close to the green on your lathe. You would need to match the car colour to your machine and as for any of these suggestions you need to match your lathe to the paint 'in the flesh' so to speak so take a bit in to the paint supplier - a gear guard perhaps. No doubt there are other paint suppliers but Jawel are just down the road from me and I have happily used them on and off for years. |

| Nigel McBurney 1 | 20/04/2020 18:19:51 |

1101 forum posts 3 photos | In my time in the business,hard drive body castings were gravity or pressure die cast aluminium,the arm thar held the reading heads and swung across the disc surface were cast in magnesium from the early days of hard drives,I would avoid using or machining magnesium, I have seen the results of a fire in a machining contractors premises ,it took a lot of effort to get production going again,not adviseable to machine magnesium if your work shop is integral to the dwelling or garage,plus buildings insurance might be problem. When evaluatng a foundry for investment cast,i saw the whole premises and they had a large foundry for magnesium casting including magnesium wheels for racing cars,did not stay in there long as sulphur was liberally spread on the floor to reduce the fire risk,most unpleasant smell. Very good casting supplier but I have heard that it was all flattened and is now a housing estate, |

| Henry Brown | 20/04/2020 18:57:47 |

618 forum posts 122 photos | Have a look for the Myford green here Duncan: |

| duncan webster | 20/04/2020 23:46:41 |

| 5307 forum posts 83 photos | Posted by Henry Brown on 20/04/2020 18:57:47:

Have a look for the Myford green here Duncan: Thanks, as soon as post starts working again I'll get some ordered. I seem to get one delivery of letters a week, but no packages, at least from Royal Mail |

| Henry Brown | 21/04/2020 08:07:59 |

618 forum posts 122 photos | Posted by duncan webster on 20/04/2020 23:46:41:

Posted by Henry Brown on 20/04/2020 18:57:47:

Have a look for the Myford green here Duncan: Thanks, as soon as post starts working again I'll get some ordered. I seem to get one delivery of letters a week, but no packages, at least from Royal Mail That's a bind, I guess we're lucky here, all as normal at this end though I suspect there are some hold-ups at the senders sorting office as I'm waiting for an M2 die to arrive from Rochester. Incidentally, they do sell sample pots. I got one to paint a Record vise, about £6 if I remember correctly... |

This thread is closed.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in