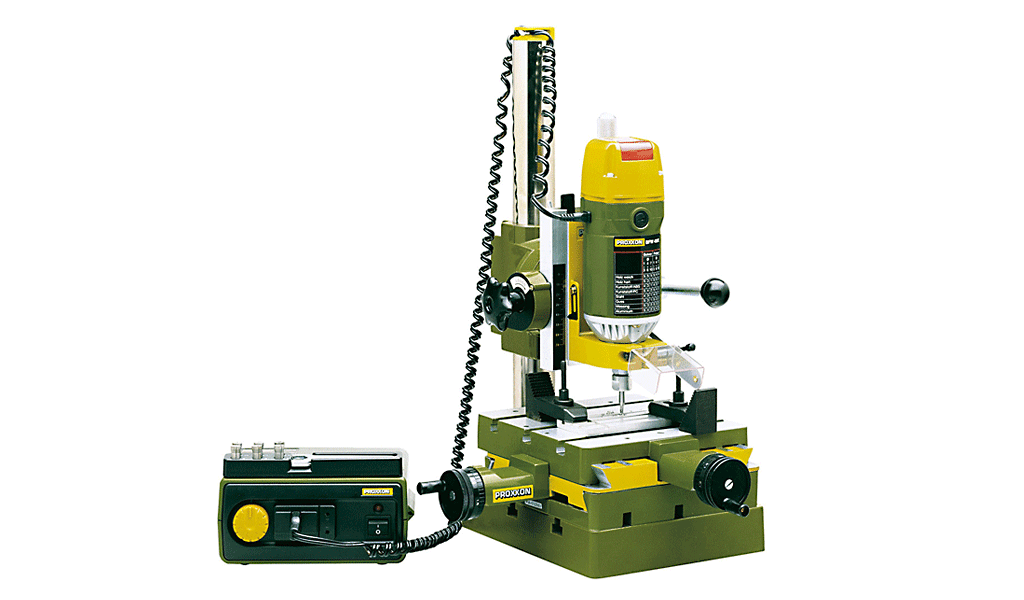

(old) Proxxon BFW 36/E vs. (new) Proxxon BFW 40/E

| Michael Gilligan | 30/09/2021 16:50:32 |

23121 forum posts 1360 photos | Posted by John Smith 47 on 30/09/2021 16:43:25: […] … I could have bought x3.4 Proxxon MF70s for £850! . … or at least a hundred bags of Compost [or whatever took your fancy] But surely you wouldn’t MichaelG.

|

| Robert Butler | 30/09/2021 17:00:13 |

| 511 forum posts 6 photos | Moderators there is no solution to this issue and respectfully suggest the topic thread is closed Robert Butler |

| John Smith 47 | 30/09/2021 17:04:51 |

| 393 forum posts 12 photos | Posted by Michael Gilligan on 30/09/2021 16:50:32:

Posted by John Smith 47 on 30/09/2021 16:43:25: […] … I could have bought x3.4 Proxxon MF70s for £850! . … or at least a hundred bags of Compost [or whatever took your fancy] But surely you wouldn’t MichaelG.

|

| John Smith 47 | 30/09/2021 17:07:52 |

| 393 forum posts 12 photos | Posted by Robert Butler on 30/09/2021 17:00:13:

Moderators there is no solution to this issue and respectfully suggest the topic thread is closed Robert Butler Up to you. Does the existence of this thread cause inconvenience? Edited By John Smith 47 on 30/09/2021 17:13:26 |

| John Smith 47 | 01/10/2021 00:03:52 |

| 393 forum posts 12 photos |

One more thing... Because the pillar is circular without a key slot of any sort, every time you loosen off the clamping screws in order to move the mill in the Z-axis (vertical), the whole thing can rotate around the pillar! >>> For anyone interested in using EMCO Unimats for any serious milling, I thought this was interesting.

** Part 2 ** ** Part 3 ** Nice work.

Edited By John Smith 47 on 01/10/2021 00:08:40 |

| Pete. | 01/10/2021 02:28:18 |

910 forum posts 303 photos | I'd be surprised if that arrangement gave 0.5mm repeatability, you've got slop between the dog point and keyway, slop in the thread of the screw, depends what you think is acceptable for your purposes. I think if the column had been scored lightly with a pointed milling cutter of some description, or in a shaper, then a mark on the clamp for alignment, you could repeat the position by eye as well, if not better. |

| Andy Carlson | 01/10/2021 08:10:45 |

| 440 forum posts 132 photos | I'd have thought it less likely that one would run out of Z travel when milling. Drilling with progressively increasing diameters (and therefore drill lengths) on the other hand are very likely to require the head to be moved further up the column. I've found that the resulting loss of position is a pain. Likewise, drilling and then using a centre to keep a tap perpendicular will have the same issue. |

| John Smith 47 | 01/10/2021 17:23:05 |

| 393 forum posts 12 photos | Posted by Pete. on 01/10/2021 02:28:18:

I'd be surprised if that arrangement gave 0.5mm repeatability, you've got slop between the dog point and keyway, slop in the thread of the screw, depends what you think is acceptable for your purposes. I think if the column had been scored lightly with a pointed milling cutter of some description, or in a shaper, then a mark on the clamp for alignment, you could repeat the position by eye as well, if not better.

|

| JasonB | 01/10/2021 18:17:36 |

25215 forum posts 3105 photos 1 articles | With a drill chuck capacity of 8mmmax and the use of stub drills you can easily spot drill and drill upto 8mm and still get a hole the full 25mm depth of the quill travel without having to move the head. Any drilling above that diameter can be done using the lathe 3-jaw in place of the drill chuck and either stub drills with shortened shanks or plunge cutting with milling cutters upto when you start to stall the machine. |

| Neil Wyatt | 04/10/2021 16:00:37 |

19226 forum posts 749 photos 86 articles | Please can people stop mudslinging? The OP is happy to continue, but I suggest that just those making positive comments continue to participate.

As for repeatability when moving the head, a popular solution for round-column mills is a vertical line on the far side of the workshop and a laser pointer attached to the mill. A distance of several feet gives a workable level of accuracy/.

Neil |

| Ian P | 04/10/2021 20:28:46 |

2747 forum posts 123 photos | Posted by Neil Wyatt on 04/10/2021 16:00:37:

As for repeatability when moving the head, a popular solution for round-column mills is a vertical line on the far side of the workshop and a laser pointer attached to the mill. A distance of several feet gives a workable level of accuracy/. Neil I've not actually used the laser and line method and my current milling machine is already constrained by a keyway but it occurs to me that the line on the wall does not need to be vertical (in the gravity sense) but more that it should be parallel to the axis of the machine column. If the machine is just sat on a bench and has not been set up so its column is dead vertical then surely errors would be introduced. I suppose if a laser pointer (mounted sideways) in the quill could be used to 'draw' a short line on the wall which could then extended upwards and downwards, that would ensure it was inline with the machine column. Ian P |

| Andrew Johnston | 05/10/2021 08:21:19 |

7061 forum posts 719 photos | Posted by Neil Wyatt on 04/10/2021 16:00:37:

.......suggest that just those making positive comments continue to participate. I hope that applies to the OP as well; he has form for airily dismissing almost all attempts at help. Andrew |

| Grindstone Cowboy | 05/10/2021 09:47:19 |

| 1160 forum posts 73 photos | Posted by John Smith 47 on 01/10/2021 17:23:05:

..... I think he was - it would only take a very small amount of wear, or a very small loosening of a V-pointed screw to have a large effect on the possible angular movement. Whereas a dog-pointed screw would at least be consistent until it fell out altogether. Although I don't think either would be a good enough method to be relied upon for accurate positioning. I like Pete's suggestion of marking the column and clamp and aligning by eye. +1 on what Andrew said as well, people tend to respond to how they are addressed. Rob Edited By Grindstone Cowboy on 05/10/2021 09:53:16 |

| John Smith 47 | 05/10/2021 16:39:18 |

| 393 forum posts 12 photos | Posted by peak4 on 23/09/2021 22:52:26:

If it's of any interest, There's a Unimat 3 up for sale HERE This was a good suggestion. FWIW, I'm still thinking about this Unimat Milling Machine even though I definitely cant really afford it! (£850) J |

| Bill Phinn | 05/10/2021 17:14:44 |

| 1076 forum posts 129 photos | Posted by Grindstone Cowboy on 05/10/2021 09:47:19:

+1 on what Andrew said +2. I admire Andrew's tact for choosing "airily". Edited By Bill Phinn on 05/10/2021 17:23:46 |

| John Smith 47 | 05/10/2021 17:37:13 |

| 393 forum posts 12 photos | Posted by Bill Phinn on 05/10/2021 17:14:44:

Posted by Grindstone Cowboy on 05/10/2021 09:47:19:

+1 on what Andrew said +2. I admire Andrew's tact for choosing "airily". Edited By Bill Phinn on 05/10/2021 17:23:46 FFS, can we get back to workshop tools model engineering, please? |

| Hollowpoint | 05/10/2021 17:47:33 |

| 550 forum posts 77 photos | I haven't read the whole thread because frankly I can't be bothered Ok so first the Emco 3 mill is a nice little machine (I own one) but they are quite rare and rather collectable and therefore expensive. Parts and accessories are readily available second hand. However there are better alternatives. Probably the best of the lot (other than the mega expensive watchmakers machines) is the Cowells mill. Unfortunately they rarely come up for sale and prices are high. Parts and accessories are available both new and second hand but expect to pay up! The Sherline mill is the next best, they aren't particularly cheap new and can be difficult to find in the UK second hand. Parts and accessories are available new and second hand but they aren't so common in the UK. Lots available in the US if you are willing to import them. One not mentioned is the Proxxon FF230. It is very similar in a lot of ways to the Emco 3 mill and is of at least equal quality if not better. It's worth knowing that not all proxxon tools are created equally. Some are dire while others are quite good. The FF230 and PF230 are two of there better products. Again they aren't particularly cheap but parts and accessories are fairly common within the UK and Europe. Forget the rest. Those 4 are the pick of the bunch if you absolutely must have a micro mill.

|

| Andrew Johnston | 05/10/2021 20:14:33 |

7061 forum posts 719 photos | Posted by John Smith 47 on 05/10/2021 17:37:13:

.....workshop tools model engineering..... I thought I'd read most of this thread, but I seem to have missed that bit. Andrew |

| John Smith 47 | 05/10/2021 22:22:03 |

| 393 forum posts 12 photos | Hollowpoint - thanks. However in my experience it's a brave man around here that says Proxxon is as good as... well pretty well anything! And certainly EMCO Unimat seems to have a lot of fans. But you sound like you have a lot of experience. Conclusion Edited By John Smith 47 on 05/10/2021 22:25:43 |

| Hollowpoint | 06/10/2021 07:46:41 |

| 550 forum posts 77 photos | I haven't used the proxxon bfw40 but have played around with a display model. (Not running). IMO the construction of the machine is way too light for milling. It's more like an accurate drill.

The Emco 3 which is better and of slightly heavier construction is only just rigid enough for light milling. So you can see the problem.

The FF230 is about the same quality of construction as the Emco 3 but has a few small tweaks that the Emco lacks. The column although still round is slightly larger diameter and the head has a proper vertical adjustment aiding alignment.

Both of the above are less rigid than either the Cowells or Sherline and so both of the latter make better milling machines. It's true they are not so good for drilling without the quill feed. However a sensitive drilling attachment is available for the Sherline which is good for drilling small holes. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

>**LINK**

>**LINK**

Register

Register Log-in

Log-in