Blacking

| Terryd | 02/01/2012 12:26:08 |

1946 forum posts 179 photos | Posted by Douglas Johnston on 02/01/2012 09:19:18: I have used rapeseed oil from the supermarket instead of motor oil for a number of years and get very satisfactory results. As mentioned just heat to dull red and plonk into a container of the oil and the steel comes out a deep black colour. Doug. Hi Doug, I haven't tried veggie oil myself but I have heard that it gives good results. The advantage of oil blacking is that one gets a nice lustrous finish and some protection against rust. One of the problems though is the relatively high temperature needed to achieve a good finish. I think that is the most important thing. When hardening tools etc it's not so bad but for vulnerable parts which may warp it could be a problem. Hi Gordon, I've tried all sorts of oil over the years and was always told to use dirty motor oil, which I did until I had none available and needed to quench some tools I was making. I was very surprised to find that I obtained better results with new oil. Also don't forget that mineral oils are all hydrocarbons so already contain large amounts of carbon in the chemical structure which would be released at high temperature I would think. Perhaps that could be confirmed or otherwise by those members of the forum with a better knowledge of the chemistry involved. Best wishes for a happy New Year, Terry |

| David Colwill | 02/01/2012 12:42:29 |

| 782 forum posts 40 photos | If you're near Nottingham I have all the cold black chemicals for steel, which does not involve heating. Dave. |

| Stub Mandrel | 02/01/2012 19:59:20 |

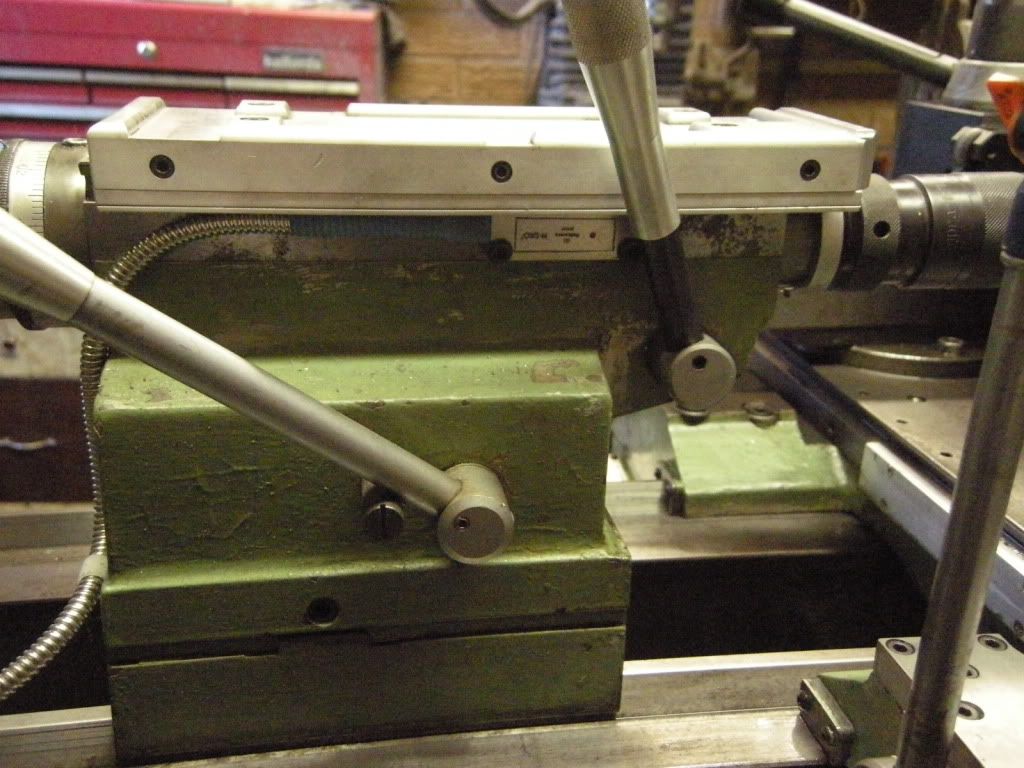

4318 forum posts 291 photos 1 articles | I have used jenolite koldblack for small components, it even blacks brass-just. I used it to disguise the brass chain on my crane. You get a more even result by quenching in oil, and you don't even need to use motor oil - I use a golden syrup tin half full of rapeseed oil for medium sized components and it gives a good, durable finish. The clamp in this picture (taken yesterday) was blacked in rapeseed oil years ago. The pale colour is an artefact caused by me photographing a black object on a black granite block. Neil |

| Jim Greethead | 02/01/2012 21:30:01 |

131 forum posts 8 photos | I prefer to avoid heating the object but if anybody wants some suitably dirty oil from a Fergie, I am prepared to swap a sump full for some clean stuff.

Jim

|

| Nicholas Farr | 02/01/2012 21:32:38 |

3988 forum posts 1799 photos | Posted by Jim Greethead on 02/01/2012 21:30:01:

I prefer to avoid heating the object but if anybody wants some suitably dirty oil from a Fergie, I am prepared to swap a sump full for some clean stuff.

Jim

Hi Jim, that must be a fair trade for someone. Regards Nick |

| Wolfie | 02/01/2012 21:38:13 |

502 forum posts | If I heat up some steel and then quench it in oil, is this not the same as the hardening process. Would I then have to temper it again? Hardening and tempering is not something I have done as yet. |

| ANDY CAWLEY | 02/01/2012 21:46:45 |

| 190 forum posts 50 photos | No, cos you are only heating to about 500 C to harden you have to go to above 750C. Long explanation could follow but I suggest you read it up when the time is appropriate.. |

| Terryd | 02/01/2012 21:47:25 |

1946 forum posts 179 photos | Hi Wolfie, You can only harden high carbon steels. If your part is made from mild steel you cannot harden it, but you can black it by that method. Do some experiments on scrap parts or odd bits of materials. That is how we learn. If you are using high carbon steels than that is a good way to harden it and then you need to temper it by heating to a lower temperature and quenching. Try a few samples. Regards Terry |

| Jon | 03/01/2012 00:02:00 |

| 1001 forum posts 49 photos | Another alternative for steels inc stainless is to heat up either by friction or with a blow lamp between 230 and 280 degrees, the colour spectrum. 265 ish looks quite nice but be quick heat rises cool quick. |

| Jim Greethead | 03/01/2012 01:39:48 |

131 forum posts 8 photos | Incidentally, all the blacking on this engine: http://www.youtube.com/watch?v=o-zo52flDbI&feature=related

was done with the Blackfast.

Jim

|

| Tel | 03/01/2012 03:20:36 |

157 forum posts 28 photos | There's no need to run your piece up to red heat at all - just heat it until it reaches the colour you want, then quench in oil. As others have said, the type of oil is not too critical, you can even set the colour in water and then oil it, but it won't be as long lasting. |

| Terryd | 03/01/2012 07:14:15 |

1946 forum posts 179 photos | Hi Jon, For smallish parts you can use a domestic oven for that. An electric one is best as the temperature is very constant. My own at home has a maximum temperature of just over 300º C. However teh temperature scale on the average control knob is not very accurate so some experimentation is necessary. if you have an oven thermometer that might help. Using an oven in this way is much more controllable than using a flame it is also easy to observe colour changes - which are much slower than with a flame - if the oven has a glass door. This tapered dot punch shows the consistency of the colour which is sometimes difficult to achieve on such a part with a torch Edited By Terryd on 03/01/2012 07:22:11 |

| Stub Mandrel | 03/01/2012 21:27:30 |

4318 forum posts 291 photos 1 articles | I find that the heat colours usually darken with age - a 'dark straw' becomes a real rich bronzy brown in time. If you get it right (and it can be done) you can get the lovely 'blue steel' colour. Neil |

| Jon | 03/01/2012 21:48:48 |

| 1001 forum posts 49 photos | Yes Terry have tried it in a Bosch fan assisted oven and cant quite get there, translucent brown. This suggests around 230 degrees. Darkist blue would be 275 degrees prior to that purple. 280 degrees it out. The trick is to let the part heat up slowwwww often revolving, its a lot more contollable then. Best i ever did and took 13 attempts i went through the colour spectrum brown to light blue like a rainbow down the length of 18" tubing, took some doing but used the lathe to revolve. Most of the time i use a propane blow lamp but a brick or any method to induce heat will do the trick including friction. Screws dead easy to do and add that hand made sort of look with pure quality. Terrys above not quite for a beginner, try something smaller to get the hang of it. Decent job by the way - blow lamp held vertical and part upright can tell where it tapers = less heat?  |

| Terryd | 03/01/2012 21:51:55 |

1946 forum posts 179 photos | Posted by Stub Mandrel on 03/01/2012 21:27:30: I find that the heat colours usually darken with age - a 'dark straw' becomes a real rich bronzy brown in time. If you get it right (and it can be done) you can get the lovely 'blue steel' colour. Neil Hi Neil, I quite agree with you, some lovely colours are possible. The real trick is getting the temperature right and letting the work soak for a considerable while which is why I suggest using a proper temperature controlled furnace, or failing that the domestic oven!! By doing it properly the rush to quench at the right time and the fluster etc involved with a torch is eliminated. Best regards Terry |

| Terryd | 03/01/2012 22:01:55 |

1946 forum posts 179 photos | Posted by Jon on 03/01/2012 21:48:48: Yes Terry have tried it in a Bosch fan assisted oven and cant quite get there, translucent brown. This suggests around 230 degrees. Darkist blue would be 275 degrees prior to that purple. 280 degrees it out. The trick is to let the part heat up slowwwww often revolving, its a lot more contollable then. Best i ever did and took 13 attempts i went through the colour spectrum brown to light blue like a rainbow down the length of 18" tubing, took some doing but used the lathe to revolve. Most of the time i use a propane blow lamp but a brick or any method to induce heat will do the trick including friction. Screws dead easy to do and add that hand made sort of look with pure quality. Terrys above not quite for a beginner, try something smaller to get the hang of it. Decent job by the way - blow lamp held vertical and part upright can tell where it tapers = less heat?  Hi Jon, I wouldn't achieve that easily with a blow torch, except by indirect heating on a plate, in sand bed or salt bath, but it was done easily in my domestic oven set at about 290º C You are right though about using heat properly, it is a skill same as any other, and is also one of the secrets of successful silver soldering (and welding), it's not just a case of simply using a great big heat supply , but more importantly knowing how to focus it correctly. It's the mistake most folks make in the beginning. Best regards Terry |

| Jon | 03/01/2012 22:19:22 |

| 1001 forum posts 49 photos | I love doing that sort of colouring, i'll be doin a couple of screws tomorrow. Me and my photography wont show it though. An even colour that length would be very very hard to do, might take me two attempts with a lamp. Steady hand and watching the colour either side of the flame expecting it to rise. Stainless is weird you have to get it bordering red then it cools off to show purple to blue. Done some of the fittings on me M300 last year, the quill lock is done thats about 2 1/2" up to the aluminium. No other piccies sorry. Whilst on this heat colouring i would say its the preparation that counts, polish like chrome and it will have the depth just like a dark blue mirror. Might try bead blast and colour next time, see what that does. At work we used to back temper on a steel block that had been in the forge. Edited By Jon on 03/01/2012 22:20:57 |

| Gordon W | 04/01/2012 10:07:36 |

| 2011 forum posts | What is the Nevil Shute book where the hero makes toy eggs and colours them, all different, by heating ? |

| Terryd | 04/01/2012 10:29:59 |

1946 forum posts 179 photos | Posted by Gordon W on 04/01/2012 10:07:36: What is the Nevil Shute book where the hero makes toy eggs and colours them, all different, by heating ? Hi Gordon, He wrote a novel about the adventures of a mild mannered model engineer who also wrote articles for magazine concerned with model engineering (no prizes for correct guesses!). He had to collect a legacy from the South Seas when his sibling and wife were killed in a boating accident. It's a while since I read it and can't remember the 'eggs' but it could well have been in there as there are many references to model (and full size) engineering. The book was called "Trustee From The Toolroom" Nevil Shute Norway to give him his full name was also a distinguished Aeronautics engineer and I think he had something to do with airship design before the project was abandoned, if I recall correctly. He dropped the 'Norway' for his novel writing. Hope that helps, Best regards, Terry |

| Springbok | 04/01/2012 10:41:41 |

879 forum posts 34 photos | Thanks doug will use that method next time

Bob |

Please login to post a reply.

Magazine Locator

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our Newsletter

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

Latest Forum Posts

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

Shopping Partners

Latest "For Sale" Ads

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

Latest "Wanted" Ads

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Get In Touch!

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

All Forum Topics > Beginners questions > Blacking

Register

Register Log-in

Log-in