It's a thread Jim, but...

| not done it yet | 20/11/2018 10:01:17 |

| 7517 forum posts 20 photos | He is a diyer, we think? Cheap lightweight machines are not as rigid as a good heavyweight examples. As a diyer, he does not need to finish every job inside a minute! HSS cutters will last more than 15 seconds (based on a minute per job and the suggestion of needing regrinding after only a 1/4 of the job is completed). But they do need to be used at lower cutting speeds and depths than carbide. “Horses for courses”, I think? |

| JasonB | 20/11/2018 10:16:44 |

25215 forum posts 3105 photos 1 articles | So when does a lathe transition from a lightweight to a heavyweight? I would not have said the OP's lathe was a lightweight at some 600kg which is the same sort of weight as a M300. The poundland inserts don't help, go out and get a single one of decent parentage Edited By JasonB on 20/11/2018 10:20:36 |

| Neil Lickfold | 20/11/2018 18:57:09 |

| 1025 forum posts 204 photos | Not many people can screw cut a thread of 2mm pitch at more than 100 rpm or so . I don't think it matters if the threading tool is HSS, or a ground carbide insert. Some materials definitely tear and don't cut as well as others. I have a Myford S7 and my choice is a ground threading insert. It is sharp like hss but lasts longer. At the end of the threaded area, I make a thread relief, so am not trying to withdraw the tool at the end of the cut. on a M16, I make the relief diameter 13.75 to 13.8mm and normally I make the relief length about 5mm long. This gives about 1 second to stop at 150 rpm. Keeping the tool holder over hang to a minimum makes a huge difference , especially with a 0 Dickson holder on a deep thread like a 2mm pitch. If the material is difficult to cut, I will put on a cut with the compound, but take some of it off,by 0.05mm with the cross slide. Then retake the cut again, with the cross slide at the zero point. This makes then leading face cut not all in 1 pass. It reduces the total cutting volume and reduces the front length being cut by the tool. It is also called the zigzag screw cutting method. This is good when threads get deeper than 0.8mm deep , so like for M12 and courser pitch threads. It works for internal threads as well. Neil |

| Robin Graham | 21/11/2018 00:08:28 |

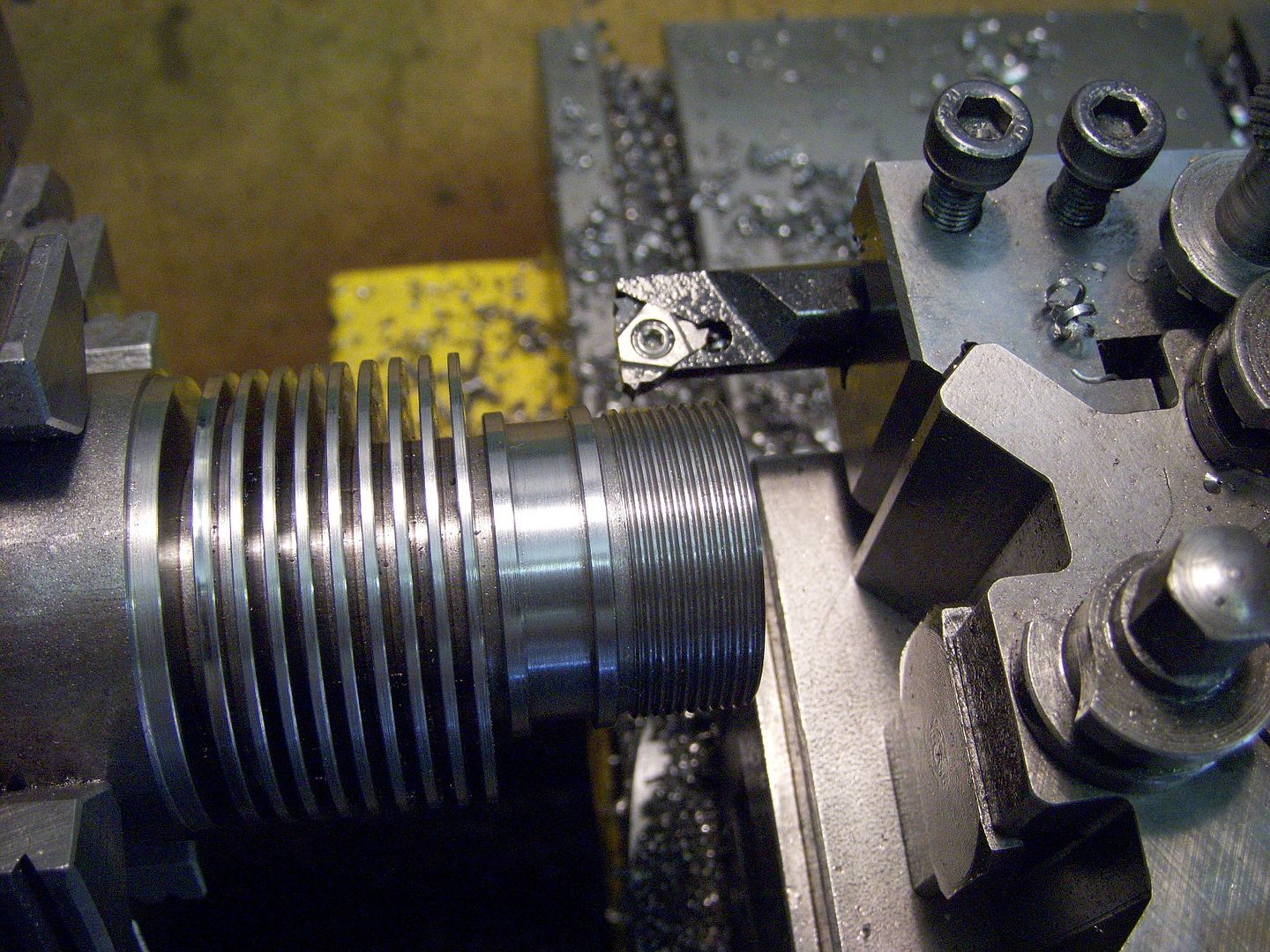

| 1089 forum posts 345 photos | Thanks for further comments. For my experiment at 65 RPM I'd actually cut a 4mm relief to leave me plenty of room to stop. In the event I found that I I could stop within perhaps 0.5mm from the headstock end of the thread, so about half a second to snap the feed lever - the lathe has the luxury of a thread indicator, unlike my first one on which I had to leave space for the chuck to wind down before reversing. So I think I can go faster without danger. I guess I need to experiment with feeds/speeds and see what's best, perhaps get nowhere, then buy some better inserts. Maybe I'll hit a 'sweet spot' :

These turnings came off EN1A, 2mm DOC, can't remember feed, but it was lovely watching them peel off. Some are 2m long! I may weld them to a brake disc and sell as industrial art. Got to be worth 400 quid. Robin

|

| JasonB | 21/11/2018 07:06:19 |

25215 forum posts 3105 photos 1 articles | As has been mentioned earlier if you want to run at speed and don't think you can stop in time work at the rear of the work with the lathe running in reverse and you have got until you hit the tailstock to stop the machine. Think I diod this at 4-500rpm

|

| Circlip | 21/11/2018 10:22:15 |

| 1723 forum posts | Please assist and advise what I'm doing wrong. 50mm long M42x4mm pitch thread using HSS tool ground once? Set over topslide, 4 way toolpost with shimmed tool and slide dials.

Do I need to change to CNC and carbides?

Regards Ian. |

| Neil Wyatt | 21/11/2018 11:05:28 |

19226 forum posts 749 photos 86 articles | Posted by Circlip on 21/11/2018 10:22:15:

Please assist and advise what I'm doing wrong. 50mm long M42x4mm pitch thread using HSS tool ground once? Set over topslide, 4 way toolpost with shimmed tool and slide dials.

Do I need to change to CNC and carbides?

Regards Ian. Depends what problems you are having. Can you give more detail? Historically, people used to cut far larger threads than that with HSS, if your tools are blunting or failing just reduce the rpm and don't try and remove too much material in one go. Carbide will work faster and with longer tool life if you have a lot of threads to cut, but if you only need a few threads you can get the results you need with HSS, if you take things steadily. Neil |

| Alan Vos | 21/11/2018 18:37:32 |

| 162 forum posts 7 photos | Posted by JasonB on 21/11/2018 07:06:19:

As has been mentioned earlier if you want to run at speed and don't think you can stop in time work at the rear of the work with the lathe running in reverse and you have got until you hit the tailstock to stop the machine. Think I diod this at 4-500rpm

Is that a standard internal right hand threading tool, or a special for external right hand threading running in reverse ? |

| JasonB | 21/11/2018 18:39:37 |

25215 forum posts 3105 photos 1 articles | Standard Internal. Neil, I think Circlips question was directed towards Jon who said HSS would not do the job. |

| Michael Gilligan | 21/11/2018 19:27:48 |

23121 forum posts 1360 photos | Posted by JasonB on 21/11/2018 18:39:37:

Standard Internal. . Please forgive my naivety on this matter, but how do you accommodate the difference in truncation? P/4 vs P/8 MichaelG.

Edited By Michael Gilligan on 21/11/2018 19:28:34 |

| JasonB | 21/11/2018 20:21:03 |

25215 forum posts 3105 photos 1 articles | It's a partial form insert so does not create the true crests and valleys, think of a HSS tool ground to a point. Needle file over the crests to ease them and make the other part to fit. This would apply to using a external partial form insert as well as the external. |

| Neil Wyatt | 21/11/2018 20:28:42 |

19226 forum posts 749 photos 86 articles | Tip radius is a maximum not a minimum, and is actually the width - a flat is allowable.. To quote the article: "In an external (male) thread (e.g., on a bolt), the major diameter Dmaj and the minor diameter Dmin define maximum dimensions of the thread. This means that the external thread must end flat at Dmaj, but can be rounded out below the minor diameter Dmin. Conversely, in an internal (female) thread (e.g., in a nut), the major and minor diameters are minimum dimensions; therefore the thread profile must end flat at Dmin but may be rounded out beyond Dmaj." Neil

|

| Michael Gilligan | 21/11/2018 21:54:40 |

23121 forum posts 1360 photos | Posted by JasonB on 21/11/2018 20:21:03:

It's a partial form insert so does not create the true crests and valleys, think of a HSS tool ground to a point. Needle file over the crests to ease them and make the other part to fit. This would apply to using a external partial form insert as well as the external. . That's O.K. then, Jason ... Sorry, I thought it was full-form MichaelG. |

| Michael Gilligan | 21/11/2018 22:00:32 |

23121 forum posts 1360 photos | Posted by Neil Wyatt on 21/11/2018 20:28:42:

Tip radius is a maximum not a minimum, and is actually the width - a flat is allowable.. To quote the article: "In an external (male) thread (e.g., on a bolt), the major diameter Dmaj and the minor diameter Dmin define maximum dimensions of the thread. This means that the external thread must end flat at Dmaj, but can be rounded out below the minor diameter Dmin. Conversely, in an internal (female) thread (e.g., in a nut), the major and minor diameters are minimum dimensions; therefore the thread profile must end flat at Dmin but may be rounded out beyond Dmaj." Neil . Quite so, Neil ... That's why [*] I was struggling. MichaelG. . [*] when I wrongly assumed that Jason was showing a full-form insert |

| Alan Vos | 22/11/2018 18:44:37 |

| 162 forum posts 7 photos | Posted by JasonB on 21/11/2018 18:39:37:

Standard Internal. Which means, when I came to cut a simillarly proportioned blind internal thread, I could have used my existing external tool, under power, in reverse, rather than buying an internal tool and turning the chuck by hand to avoid a crash. Every day is a school day. As for inserts and high rpm, that was a hand turned chuck, with an insert threading tool, cutting (probably) EN1A. The thread came out fine. New sharp tool. Free machining material.

|

| Martin Connelly | 22/11/2018 19:43:30 |

2549 forum posts 235 photos | Might not be enough bottom rake on an external tool to do an internal thread. Martin C |

| JasonB | 22/11/2018 19:47:34 |

25215 forum posts 3105 photos 1 articles | Posted by Alan Vos on 22/11/2018 18:44:37:

Posted by JasonB on 21/11/2018 18:39:37:

Standard Internal. Which means, when I came to cut a simillarly proportioned blind internal thread, I could have used my existing external tool, under power, in reverse, rather than buying an internal tool and turning the chuck by hand to avoid a crash. Every day is a school day. As for inserts and high rpm, that was a hand turned chuck, with an insert threading tool, cutting (probably) EN1A. The thread came out fine. New sharp tool. Free machining material.

Don't know how you would get the usual external holder inside the hole as they tend to be at right angles to the lathes axis |

| Robin Graham | 22/11/2018 23:41:34 |

| 1089 forum posts 345 photos | Well, to report back on suggestions, I've now tried upping the speed (250 rpm instead of 65), using EN1A instead of EN3B and taking spring cuts. Still in badger's ar*e territory. I'm reluctantly forced to think that it must be the 'poundland' inserts - **LINK** I don't understand the codes for inserts - can anyone point me to a source of decent inserts which would fit this holder? Robin

|

| Emgee | 23/11/2018 00:44:05 |

| 2610 forum posts 312 photos | Robin, measure the side of the insert, it will be 16, 11 or 8mm, the tip code will have that dimension included in the code number along with an E for external, an I for internal and R or L for right hand or left hand threads. Emgee |

| John Reese | 23/11/2018 02:18:09 |

1071 forum posts | Another weapon in your arsenal: sulfurized cutting oil. It is almost universally used by plumbers when threading pipe. I prevents tearing in really gummy steel. I am not going to get in the debate of HSS vs carbide. I use both. HSS does give you the option of varying the top and side rake to suit the material. Flank feed is preferred to plunge cutting. When plunging there adr chip impinging from two directions and tending to jam on top of the tool. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in