Setting a Machine Vice Parallel on the Mill

| SillyOldDuffer | 23/08/2018 11:42:17 |

| 10668 forum posts 2415 photos | Posted by thaiguzzi on 23/08/2018 10:03:31:

Posted by Andrew Johnston on 22/08/2018 19:13:47:

...

I though this was just S.O.P? I think it was well worth sharing, not least because of the alternative suggestions it got. Besides, it's unwise to assume there's any such thing as 'standard operating practice' in the duffer workshop!

Dave |

| Vic | 23/08/2018 11:44:38 |

| 3453 forum posts 23 photos | Dave, I think sometimes it helps to be anal about some things. As I mentioned in another thread. A professional machinist I know of drilled right through his vice into the table for a couple of pins. Setting up his vice now takes no longer than bolting it down. |

| Douglas Johnston | 23/08/2018 11:45:47 |

814 forum posts 36 photos | What on earth does S.O.P mean? |

| Tony Pratt 1 | 23/08/2018 11:48:52 |

| 2319 forum posts 13 photos | Standard operating procedure? Tony |

| Andrew Johnston | 23/08/2018 11:50:00 |

7061 forum posts 719 photos | The answer is Standard Operating Procedure. I'd agree with SoD, except to say that it probably isn't SOP even in professional machne shops. Every one will have it's own ideas. Andrew |

| Circlip | 23/08/2018 11:52:39 |

| 1723 forum posts | The late Sir John (RIP) advised the "Goalpost" plate clamped in the vice yonks ago for rapid setting, but he was only working to RR standards, not NASA

Regards Ian. |

| Clive Foster | 23/08/2018 12:00:36 |

| 3630 forum posts 128 photos | Only universal SOP I know of is "verbal encouragement" in steadily rising volume and profanity. Clive |

| Hopper | 23/08/2018 12:00:39 |

7881 forum posts 397 photos | SOP in some machine shops is to clamp a length of ground square bar or similar to the table, set dead parallel to the traverse. Then flip your vice upside down and clamp it onto the square bar. Then machine a slot across the vice base the same width as the Tee slots in the table. Put a piece of neat-fitting key steel or similar in the slot and hold it in place with a couple of socket head cap screws in counter bored holes. So to set the vice up nice and straight is then just a matter of setting it on the table with the key steel in a T slot. Or if you want to set the vice at an odd angle, two screws and the key steel comes off. |

| Neil Lickfold | 23/08/2018 12:00:44 |

| 1025 forum posts 204 photos | A great topic Andrew. I have seen where some use a single (pivot) tennon to adjust the vice on. Like you say , it takes less that a few minutes to set to within 0.01mm over the length of the vice. To get better that 0.01mm over the length of the vice, it needs to be clamped with a reference of some descript.

|

| JasonB | 23/08/2018 12:01:34 |

25215 forum posts 3105 photos 1 articles | My method is in the current MEW |

| blowlamp | 23/08/2018 12:37:28 |

1885 forum posts 111 photos | Has anyone else used their DRO feature-set to adjust a vise to a precise angle? I've done it a couple of times with pretty good results. Fine setting a vise is a good case where a swivel base can be useful.

Martin. |

| JasonB | 23/08/2018 13:20:12 |

25215 forum posts 3105 photos 1 articles | I've mounted mine on the rotary table a few times when I have wanted the odd angle, just clock in the fixed jaw when table is at zero and then you can set the angle you need with the R/T and a lot more accutrate then the scale on the average swivel base.

Edited By JasonB on 23/08/2018 13:23:01 |

| Andrew Johnston | 23/08/2018 14:31:51 |

7061 forum posts 719 photos | Posted by blowlamp on 23/08/2018 12:37:28:

Has anyone else used their DRO feature-set to adjust a vise to a precise angle? Obviously not in my case, because I'm not sure what the technique involves? Andrew |

| KWIL | 23/08/2018 14:43:00 |

| 3681 forum posts 70 photos | Martin, Yes, it works fine, also useful if you want to tilt something in the vertical plane that is held in a vice. Simple right angle triangle calc of course. |

| Tony Pratt 1 | 23/08/2018 14:57:57 |

| 2319 forum posts 13 photos | Posted by Andrew Johnston on 23/08/2018 14:31:51:

Posted by blowlamp on 23/08/2018 12:37:28:

Has anyone else used their DRO feature-set to adjust a vise to a precise angle? Obviously not in my case, because I'm not sure what the technique involves? Andrew Say for example you want to set the vice at 45 degrees. Set the vice to 45 degrees approx, touch DTI stylus on vice jaw & zero dial. Move 25mm in X and 25mm in Y to contact the vice jaw again. If the DTI shows exactly zero the vice jaw is at 45 degrees. Adjust as necessary. Tony |

| JasonB | 23/08/2018 15:06:49 |

25215 forum posts 3105 photos 1 articles | When using the DRO you don't need to move 25mm by 25mm. You set the angle into the DRO and anywhere along that angled line the DRO will read 0-0 which allows the DRO to do the maths rather than you having to work out the X & Y amounts. When DTI also reads zero at any position you then have the vice at the required angle. Edited By JasonB on 23/08/2018 15:07:47 |

| John Reese | 26/08/2018 22:47:45 |

1071 forum posts | Vic pointed out that his vise had provision for dowels to align the vise o the T slots. Most vises I have seen have slots for keys to align the vise to the table slots. I think it is foolish not to take advantage of them. It may be necessary to make stepped keys to properly fit your vise and the machine table. For owners of Kurt vises or their clones Kurt sells stepped keys that only cost one arm and a leg. My vise is keyed to the table. If I need to get the vise out of the way I just loosen the bolts ans slide it to the end of the table. I can slide it back to the middle of the table and it is perfectly aligned. No clocking.

|

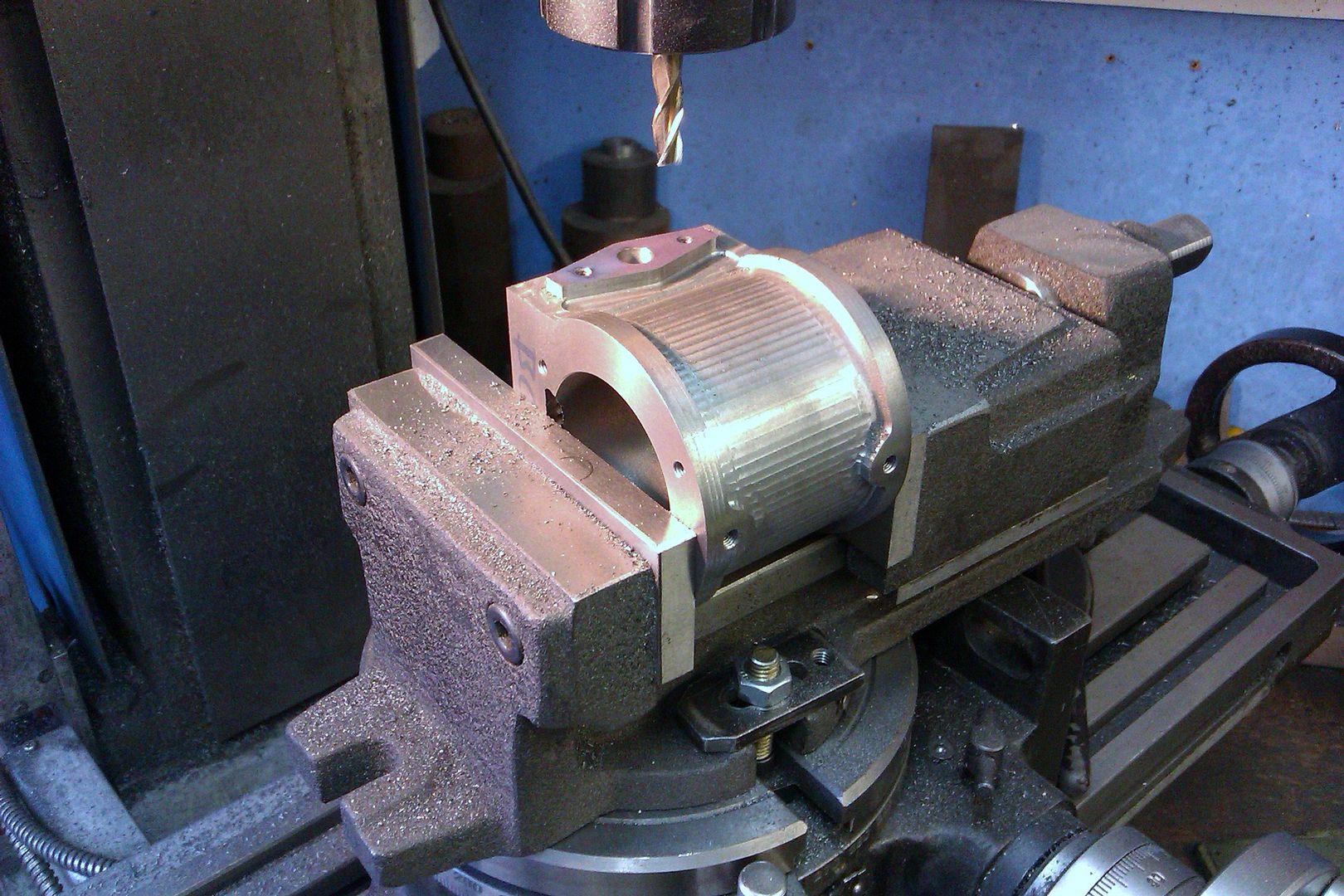

| SillyOldDuffer | 27/08/2018 09:48:07 |

| 10668 forum posts 2415 photos | My original problem (taking 40 minutes to align the vice) turned out to be caused by the idiot wielding the hammer. The vice in question is a DH-1 and its design allows jaws to be mounted in various positions. Very useful sometimes. However, unlike most vices, it is the rear jaw that moves. I wasted 40 minute by positioning the DTI on the loose rear jaw. Swivelling the vice by tapping also moves the slide. Not much, but a 0.2mm shift is massive when trying to align the vice to 0.01mm. The problem is cured by either gripping something in the vice so the moving jaw can't shift or to put the DTI on the front, which is the fixed jaw in this photo. What's curious about this fiasco is I've been successfully aligning the vice for over a year. Somehow after a week playing rotary table I forgot about the moveable jaws and tried to align it as if it were my other Kurt-style vice. Habit is a monster. Either that or I'm losing my marbles! Dave

|

| David Taylor | 27/08/2018 10:14:09 |

144 forum posts 39 photos | Well, a rear moving jaw probably would cause some confusion amongst most of us once we'd put it away for a while and forgot about it! It's a worry how long simple problems take to clarify sometimes. |

| Mike Poole | 27/08/2018 19:41:24 |

3676 forum posts 82 photos | I purchased a very large parallel to help setting up my vice, it gives a long clean face to gauge on and I find it useful. Mike |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in