TAPS, spiral or std

| Andrew Johnston | 01/05/2017 14:28:37 |

7061 forum posts 719 photos | Posted by petro1head on 01/05/2017 13:57:59:

So have I wasted my money now Not necessarily. The key phrase is "decent quality". Fifty plus years ago commercial tap manufacturers made both carbon steel and HSS taps. Carbon steel taps would have been cut, HSS steel ones ground. I don't think any commercial tap manufacturer makes carbon steel taps now. So if you want good taps from a commercial manufacturer you need to go for HSS. Andrew |

| SillyOldDuffer | 01/05/2017 15:11:59 |

| 10668 forum posts 2415 photos | Posted by petro1head on 01/05/2017 13:57:59:

So have I wasted my money now

Not at all - I learned a few things too. (Thanks chaps) Don't be surprised to break small taps, it's not that unusual. How to remove a broken tap from the hole is a popular forum topic too! Painful experience has taught me that a gallon of patience is needed for every teaspoon full of cutting fluid. I'm not a natural in the workshop and find that the problem is often me rather than the tool. I improve slowly with practice. I'd suggest starting with inexpensive new taps (provided they're sharp) on brass. M4 is big enough to take a bit of abuse: if you break one it's probably bad technique. My taps mostly come from Tracy Tools and have met my hobby requirements well. It's useful to experiment with different sized holes. Unless it's critical I usually drill tap holes a tad bigger than recommended in the tables, e.g 3.5mm rather than 3.3 for M4. This weakens the fastening slightly, but reduces the strain on the tap enormously. A trick learned on this forum. The metal being tapped makes a big difference too. Tapping M4 in a 3.5mm hole is brass is easy. Tapping M4 in a 3.2mm hole in steel is much harder. Aluminium is deceptively soft but the swarf tends to stay in the hole and jam the tap, snap! Copper is horrible - it tears. Take care to remove swarf and always apply lashings of cutting fluid, CT90 works for me. Dave Edited By SillyOldDuffer on 01/05/2017 15:14:27 |

| richardandtracy | 01/05/2017 15:54:49 |

943 forum posts 10 photos | I have used Bergen taps without problems in the past. Rarely use anything smaller than M6, and when I do, it'll be M4. I always drill M4 at 3.5mm and use cutting paste. So far (firmly touching my head as there's a fair bit of wood in there) I've not broken an M4 tap. Will say I tend to get Bergen for some of the odder sizes I use, like 3/8 BS Cycle (26 tpi), as they are cheap enough for rarely used sizes to be viable and not break the bank. Regards Richard.

|

| JasonB | 01/05/2017 16:05:36 |

25215 forum posts 3105 photos 1 articles | Posted by petro1head on 01/05/2017 13:57:59:

So have I wasted my money now

No, you will have a set of 3 good quality M2.5 taps that will cut well. Given that the hole you intend to use them for is to take a Torx screw for an insert I would not go larger than 2.1mm for the tapping drill as there is not much length to these screws and we tend to wind them in quite tight. You will also be able to use them in situations where you cant assure there is support for the other end directly above the work which is where a taper tap will be easier to start true into the hole. |

| Andrew Johnston | 01/05/2017 16:25:54 |

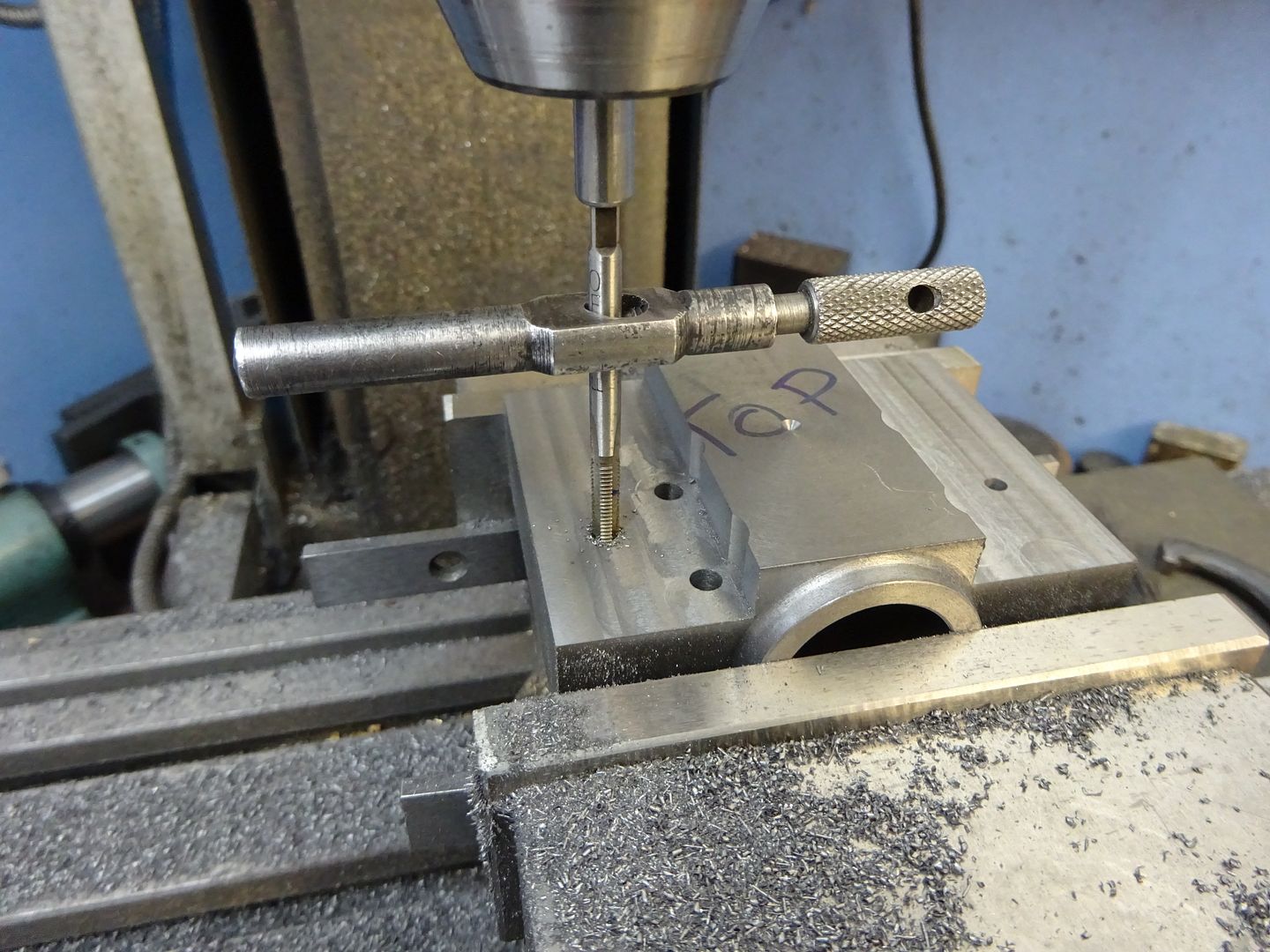

7061 forum posts 719 photos | This is the swarf you get from a spiral flute tap in a ductile material (low carbon steel): The steel offcut will be a gauge for the screwcut external threads on the brass pipe connectors. The drilled hole is a little small at 17.5mm, but that's the nearest drill I could find. Note the name stamped on the tap wrench; made by my father as part of his apprenticeship at RAE Farnborough, probably around 1940/41. Andrew |

| Bob Murray | 01/05/2017 16:38:30 |

| 24 forum posts | Use a tap guide to start and keep the tap vertical. For your tap, a 2.6mm hole through a 6mm piece of steel that can be clamped to the work should be sufficient. Harold Hall's book of workshop projects has a couple of more elegant solutions.

Regards, Bob |

| petro1head | 01/05/2017 17:05:02 |

984 forum posts 207 photos | Posted by JasonB on 01/05/2017 16:05:36:

Posted by petro1head on 01/05/2017 13:57:59:

So have I wasted my money now

No, you will have a set of 3 good quality M2.5 taps that will cut well. Given that the hole you intend to use them for is to take a Torx screw for an insert I would not go larger than 2.1mm for the tapping drill as there is not much length to these screws and we tend to wind them in quite tight. You will also be able to use them in situations where you cant assure there is support for the other end directly above the work which is where a taper tap will be easier to start true into the hole. Jason, I was refering to buying a full set of Volkel taps not the 2.5 ones Cheers for all the tips guys, they will be put to good use

Edited By petro1head on 01/05/2017 17:06:08 |

| Antony Powell | 01/05/2017 17:53:45 |

147 forum posts 19 photos | No you have bought decent kit There is a big difference between opinions - but there is also a big difference between using something daily and using it once in a blue moon, using it on a bit of copper or brass and using it on harder metals you will never get a perfect answer only individual opinion..... Tony |

| JasonB | 01/05/2017 18:05:07 |

25215 forum posts 3105 photos 1 articles | On other way to protect small taps is to hold them by the shank, that way if thighs should tighten up hopefully the tap wrench will slip before the tap goes ping! These are M2.5 Volkel ones like I linked to this morning doing blind holes in 2.5mm thick brass

Also has the benifit of making it easier to support the end of the tap with a female ctr as someone mentioned earlier

|

| John Reese | 01/05/2017 18:05:27 |

1071 forum posts | I have a question about the 3 tap sets: Are they serial taps where each tap in the set cuts slightly larger than the previous tap, the last one finishing the hole? Or are they taper, plug. and bottoming? I much prefer the spiral point or spiral flute taps over conventional taps. |

| JasonB | 01/05/2017 18:56:56 |

25215 forum posts 3105 photos 1 articles | T, P & B |

| Jelly | 01/05/2017 23:36:57 |

474 forum posts 103 photos | HSS taps are a "nice to have", so I wouldn't call it a waste of money. I tend to get CS taps or dies for one-off tasks because they're inexpensive, and HSS if I foresee using them lots (either repeatively on one job or over time). Best advice I ever got on tapping was to get a piece of scrap steel and practice tapping holes in it until I got the feel of it. I was told to start with worn taps out of the scrap tooling tub (this is a luxury you may not have, but buying a dubiously cheap set off the net would substitute), and not worry too much about breaking them then buy myself a sharp set once I had a feel for how much force would cause breakage. |

| Enough! | 02/05/2017 01:20:46 |

| 1719 forum posts 1 photos | One of the best small tools I bought for my shop was a tap holder like this. Haven't broken a tap since. They can be used in the mill or drill or lathe and fully support the end of the tap-wrench. You don't have to worry about tap alignment and can concentrate on the "feel" of the tap (when in doubt, back it out). You can still use the tap-wrench freehand if you wish (I avoid that like the plague). I bought the first one but then modified all my other tap-wrenches. It's trivially easy. |

| John Reese | 02/05/2017 01:27:20 |

1071 forum posts | Bandersnatch, I agree that is a great tool. I made the mistake of buying cheap Chinese imitations that were junk. I do use spring loaded tap guides that engage the center pop in the top of the tap. They also work quite well. When I am using the T type tap wrench, not guided by the machine, I like to leave the chuck a bit loose. That way if my hands wobble a bit the slack keeps me from breaking the tap. |

| Andrew Johnston | 02/05/2017 11:06:26 |

7061 forum posts 719 photos | And at the end of the tapping process the swarf is nearly a foot long: I have a range of the T-handle tap holders and extensions, albeit from the cheaper end of the market. I used them a lot, but eventually found them rather heavy and, to me, clumsy. So I now use ordinary tap wrenches. I have a selection, custom made although not by me, ranging from 2" to 12". When hand tapping a good finish on the part has the advantage that you see a reflection of the tap in the material. If the tap and reflection are in line then carry on, if not tweak the tap angle. Personally I've never bothered with tapping guides. Either I use the mill/lathe to start the tap, or I freehand tap with no guide and judge the angle by eye. Andrew

|

| SillyOldDuffer | 02/05/2017 12:26:35 |

| 10668 forum posts 2415 photos | Posted by Andrew Johnston on 02/05/2017 11:06:26:

... When hand tapping a good finish on the part has the advantage that you see a reflection of the tap in the material. If the tap and reflection are in line then carry on, if not tweak the tap angle. ... Andrew

Good tip. I would never have thought of that! Thanks, Dave |

| JA | 02/05/2017 17:17:42 |

1605 forum posts 83 photos | Many years ago I started using tapping guides with small taps. I have happily tapped 12BA threads into mild steel and, recent, 8BA into aluminium bronze. You just keep the guide pressed against the surface using your left hand and tap with your right. Simple (or have I missed something?). JA Edited By JA on 02/05/2017 17:18:31 |

| petro1head | 02/05/2017 17:47:04 |

984 forum posts 207 photos | Posted by JA on 02/05/2017 17:17:42:

Many years ago I started using tapping guides with small taps. I have happily tapped 12BA threads into mild steel and, recent, 8BA into aluminium bronze. You just keep the guide pressed against the surface using your left hand and tap with your right. Simple (or have I missed something?). JA Edited By JA on 02/05/2017 17:18:31 Thats a good idea |

| modeng2000 | 02/05/2017 19:45:43 |

| 340 forum posts 1 photos | Is it possible to tap holes if you hold the guide with your right hand? |

| Mike Poole | 02/05/2017 19:51:31 |

3676 forum posts 82 photos | Posted by modeng2000 on 02/05/2017 19:45:43:

Is it possible to tap holes if you hold the guide with your right hand? Only if you are one of those left handed people with their brain in upside down Mike |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in