55 Degree dovetail cutter, Where from?

| Vic | 23/09/2014 09:09:13 |

| 3453 forum posts 23 photos |

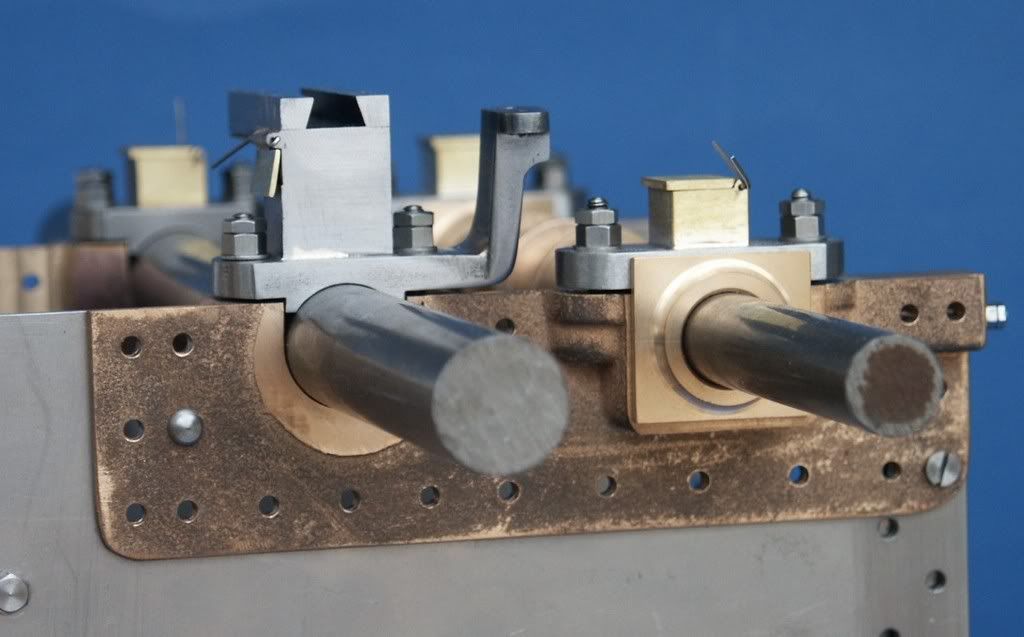

Good find Michael. This pic makes it nice and clear. Edited By Vic on 23/09/2014 09:09:44 |

| Ian P | 23/09/2014 09:29:37 |

2747 forum posts 123 photos | The range of (all types of) cutters from Harvey Tool is brilliant, but look justifiably expensive. I don't know of a UK supplier that offers a similar range. Their site does give a good plain English explanation of cutter angles and how they are specified, the image Vic posted clearly shows the dovetails as included angles, but that is a less common way of expressing dovetails as seen and used by the ME fraternity. As it happens they don't show one for the 55 degrees I need! Ian P |

| Vic | 23/09/2014 09:36:18 |

| 3453 forum posts 23 photos | It's an interesting subject for a photographer so I did a quick google. Seems there's no standard for photographic dovetail mounts. Arca Swiss use 45°, Bogen and Manfrotto use 60°. These are included angles as per the Harvey picture. Edit: No, I'm not sure they are included angles! How frustrating someone didn't come up with a standard for expressing dovetail angles! Edited By Vic on 23/09/2014 09:41:57 |

| Ian P | 23/09/2014 09:52:57 |

2747 forum posts 123 photos | Vic My definition of 'photographic equipment' was a bit vague. The actual thing I am interfacing to, is a DJI 'Ronin' stabilised camera mount. It is a beautifully made bit of kit and I think incredibly cheap after having seen and examined one. I milled a series of little test gauges at different angles in order to check what dovetail angle they used as my original very careful measurements seemed to show different angles for the male and female part (but they proved to be the same) Ian P |

| Vic | 23/09/2014 10:20:27 |

| 3453 forum posts 23 photos | What about cutting the dovetail to the full width required with a 45° cutter then angling the cutter at 10° and taking a cut on both sides to make it 55°? |

| Ian P | 23/09/2014 10:41:33 |

2747 forum posts 123 photos | Posted by Vic on 23/09/2014 10:20:27:

What about cutting the dovetail to the full width required with a 45° cutter then angling the cutter at 10° and taking a cut on both sides to make it 55°? Apart from the fact that its an extra operation that I would need to do twice on each part, the main reason is that I do not want to ever disturb the swivelling head on my mill. I have it absolutely square in both planes by means of trial and error shimming in places not meant to have shims. Ian P |

| Michael Gilligan | 23/09/2014 11:06:40 |

23121 forum posts 1360 photos | Posted by Ian Phillips on 23/09/2014 09:52:57:

The actual thing I am interfacing to, is a DJI 'Ronin' stabilised camera mount. It is a beautifully made bit of kit and I think incredibly cheap after having seen and examined one. . Looks very interesting, Ian. MichaelG. Edited By Michael Gilligan on 23/09/2014 11:07:06 |

| David Clark 1 | 23/09/2014 11:24:38 |

3357 forum posts 112 photos 10 articles | You could get a standard 60 degree cutter reground. Should not cost too much or you could regrind it yourself in the lathe. Not that difficult. |

| Vic | 23/09/2014 11:29:13 |

| 3453 forum posts 23 photos | Posted by Ian Phillips on 23/09/2014 10:41:33:

Posted by Vic on 23/09/2014 10:20:27:

What about cutting the dovetail to the full width required with a 45° cutter then angling the cutter at 10° and taking a cut on both sides to make it 55°? Apart from the fact that its an extra operation that I would need to do twice on each part, the main reason is that I do not want to ever disturb the swivelling head on my mill. I have it absolutely square in both planes by means of trial and error shimming in places not meant to have shims. Ian P Yes agreed, it is extra work. What mill do you have out of interest? |

| Ian P | 23/09/2014 11:39:24 |

2747 forum posts 123 photos | Posted by David Clark 1 on 23/09/2014 11:24:38:

You could get a standard 60 degree cutter reground. Should not cost too much or you could regrind it yourself in the lathe. Not that difficult. Well I'm not keen on grinding in the lathe and it would be unlikely I could grip the cutter shank accurately without having a collet of the correct size. I wonder whether it would be better to start with a 45 rather than a 60 degree cutter as the change in angle is less? Ian P |

| Ian S C | 23/09/2014 11:56:11 |

7468 forum posts 230 photos | Could you set it up and cut the angle in the slot with a slitting saw? Ian S C |

| Ian P | 23/09/2014 15:02:58 |

2747 forum posts 123 photos | Posted by Ian S C on 23/09/2014 11:56:11:

Could you set it up and cut the angle in the slot with a slitting saw? Ian S C An interesting concept, but how would one machine the bottom of the dovetail so that is flat and continuous into the corners? (in other words after the slitting saw had done its job there would be triangle of metal to remove) I want to avoid tilting the mill head

Vic, its an Emco Mentor (4 speed head) Ian P |

| Keith Long | 23/09/2014 15:08:24 |

| 883 forum posts 11 photos | Posted by Ian Phillips on 23/09/2014 15:02:58

An interesting concept, but how would one machine the bottom of the dovetail so that is flat and continuous into the corners? (in other words after the slitting saw had done its job there would be triangle of metal to remove) Use a cutter with a shallower angle than the dovetail side and you should be able to take out the bottom right into the corner Edited By Keith Long on 23/09/2014 15:09:42 |

| JasonB | 23/09/2014 15:12:54 |

25215 forum posts 3105 photos 1 articles | Can't you just set the work at an angle in the vice, one of the little digital angle boxes will set it to 0.1 degree. If you use a saw for the sides then small flycutter like I showed above will flatten teh bottom & get into the corners. Does it even have to be cut from one piece, you could fix two strips with a 55deg angled edge to main part, thats how I did this one

J Edited By JasonB on 23/09/2014 15:14:03 |

| Ian P | 23/09/2014 15:13:04 |

2747 forum posts 123 photos | Posted by Keith Long on 23/09/2014 15:08:24:

Use a cutter with a shallower angle than the dovetail side and you should be able to take out the bottom right into the corner Edited By Keith Long on 23/09/2014 15:09:42 Well that is basically what I am trying to do! With a cutter of the correct angle its just one operation Ian P |

| Keith Long | 23/09/2014 15:21:18 |

| 883 forum posts 11 photos | Ian - I quite agree - but you don't seem to be able to get a cutter with the correct angle so you're looking for a way round. Now you CAN get a cutter with an angle that will get into the corner IF you cut the sides with a slitting saw. Otherwise it might be time to bite the bullet and order the cutter from the USA if it will do the job, or get a standard cutter modified. For one or two off, the fiddly approach might be acceptable. If you're comtemplating a "production run" then the custom cutter wins hands down in time saving alone. |

| Ian P | 23/09/2014 15:51:56 |

2747 forum posts 123 photos | Keith As you say its a trade off between getting a cutter made or getting the same result with a series of machining operations. In this case I am looking to make six or ten identical parts so the correct cutter is appealing. Ian P

|

| Vic | 23/09/2014 16:40:29 |

| 3453 forum posts 23 photos | I'd probably bite the bullet and buy a 55° cutter. Only place I've found is this one, £44 for a one inch: http://www.mr-tools.co.uk/catalogue/42.php |

| KWIL | 23/09/2014 17:03:46 |

| 3681 forum posts 70 photos | Sussextools.co.uk sell 55 degree cutters, I have bought from them. Not a problem. Edited By KWIL on 23/09/2014 17:04:09 |

| Ian P | 23/09/2014 18:01:38 |

2747 forum posts 123 photos | Posted by Vic on 23/09/2014 16:40:29:

I'd probably bite the bullet and buy a 55° cutter. Only place I've found is this one, £44 for a one inch: http://www.mr-tools.co.uk/catalogue/42.php I did not find that one when I started looking. I would probably not started this thread if I had! I presume the price shown on their website does not include VAT but I could not find their T&Cs anywhere. Actually the Sussex tools that Kwil mention have one that is quite a bit cheaper so tomorrow I will contact both potential suppliers and place an order. Thanks to all for all the suggestions. Ian P

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in