The Workshop Progress thread 2018

| Jim Nic | 30/06/2018 10:47:13 |

406 forum posts 235 photos | Good work George, well done. The problem you have now is what to do next! JIm |

| Jim Nic | 30/06/2018 10:54:35 |

406 forum posts 235 photos | Geoff I think that model engines at this scale running at representative speeds don't need balancing weights on the crank. However, for appearance sake sometimes they are included. Here is my Potty Vertical Cross with a balancing extension because the piece of steel I made it from was big enough to do it and the cut off excess would just have ended up in the waste bin. Jim

Edited By Jim Nic on 30/06/2018 10:56:42 |

| mechman48 | 30/06/2018 11:00:11 |

2947 forum posts 468 photos | Posted by JasonB on 30/06/2018 07:01:07:

Looking good George but does sound like you are leaking air which would be one reason your compressor is kicking in so soon.

J

|

| mechman48 | 30/06/2018 11:13:42 |

2947 forum posts 468 photos | Posted by Jim Nic on 30/06/2018 10:47:13:

Good work George, well done. The problem you have now is what to do next! Jim

|

| geoff walker 1 | 30/06/2018 14:29:04 |

| 521 forum posts 217 photos | Could I ask a general question here. A lot of "older" designs have a crank arm which is very simple and not balanced with a web the opposite side to the crank pin. Why is that, do some engines just not need it? Geoff I think that model engines at this scale running at representative speeds don't need balancing weights on the crank. However, for appearance sake sometimes they are included. Thanks for your reply Jim. From what I have observed I get the impression that the longer stroke engines with a larger flywheel and a slower speed are less in need of a balanced crank than a high speed short stroke engine. The Muncaster I am currently making (slowly) has an unbalanced crank, large flywheel and a long stroke. I'll try it and see how it runs. Thanks again Geoff |

| mechman48 | 03/07/2018 17:56:52 |

2947 forum posts 468 photos | So, I have been keeping a build record with dates & hrs spent in the man cave on this build & I've totted up the number of hrs on this, taking into account rehashes & redo's, setting up equip't etc. came to ... 228 hrs, spread over weeks from June 2017 when I started it off. It's amazing how much time is spent on projects innit!. I've also costed it out in man hours, at a very conservative rate of £10 ph... £2280.... expensive toy if I were to buy it, but it's the fun in building something... I keep telling myself ! |

| Neil Wyatt | 03/07/2018 18:09:25 |

19226 forum posts 749 photos 86 articles | While it's interesting to put a price on time spent on making something like your model, I look at it the other way around. Hobbies, pastimes and leisure are among the things that make life worth living, along with family, friends and perhaps community action etc. We don't need to price them, because they are priceless; they are our own time and whatever we put in in terms of time and money doesn't really matter, because the quality of our lives and what we choose to do with them is what really measures our riches and fills the hours with time well spent.

|

| Mark Rand | 12/07/2018 23:59:17 |

| 1505 forum posts 56 photos | I've got a bit of woodspoiling to do in making a housing for the dust extractor and a secondary filter, so I converted the bench back from welding mode to woodspoiling mode. This involves unbolting and lifting off the 5' by 20" by 8mm plate that overhangs the front of the bench (so I can sit on a chair with my legs tucked under while TIG welding), cleaning everything up and then bolting the chipboard+formica top back on the bench.

After that, for no sensible reason, I decided that all of my woodspoiling chisels needed resharpening. To be fair, some of them have been in the family for more than 50 years and have been used as wood splitting mauls as much as joinery tools. Also, neither Father or I were all that good at sharpening chisels evenly. As a result of which, some of them need a couple of mm taking off the length to get to a flat relief...

I have cheated and set up the universal vice on the surface grinder and am starting off by putting a 25° primary angle on all of them. After that, they'll get the secondary relief, if any, added at an appropriate angle for their intended use. Thus far I've done four, with fourteen more to do, but most of the effort was with setting up and doing the first one.

I think I might also have a go at the cold chisels and brick bolsters while I'm at it. It's a bit slow and fiddly as a grinder job, but an order of magnitude faster than a Norton stone. |

| mechman48 | 13/07/2018 11:16:01 |

2947 forum posts 468 photos | Neil, completely at one with your comments; 'twas just an exercise out of curiosity. It certainly was a pleasure albeit at times annoying & frustrating, mainly down to my faults, to build it. Certainly didn't / won't stop me enjoying it all. |

| Jim Nic | 19/07/2018 21:23:10 |

406 forum posts 235 photos | After completing my version of Ray Hasbrouck’s No 3 Rocking Valve engine I was at a bit of a loose end because that engine seemed to finish all of a sudden and I hadn’t seriously considered “What next.” I gave a lot of thought to Julius de Waal's drawings of the Monitor engine from Model Engine Maker site. I have never been keen on his drawing layouts, I find them difficult to follow (probably due to my advancing years and retreating brain power), but downloaded them and gave them a good looking at while I spent some time cleaning my workshop and attending to machine maimtenance. I had got to the point of deciding to give it a go when I happened upon a ME forum query regarding Stew Hart’s Over Crank engine. I remembered following Stew’s build 7 or so years ago and thinking it was well beyond me, but that was then and this is now so I messaged Stew to ask for a copy of the drawings and he very kindly sent them to me. The result: Somewhere amongst this pile is an Overcrank Engine (I hope). It’s a fairly complicated twin cylinder beast so should keep me occupied for a while. I’ll do my best to do the design justice and may post random thoughts on my progress when anything significant occurs. Jim |

| geoff walker 1 | 21/07/2018 18:33:46 |

| 521 forum posts 217 photos | Looks a good choice to me Jim, keep us posted. Here is my recently completed mini muncaster oscillator. Really enjoyed this build. Here is a picture. The sizes are much the same as the principle Muncaster/ Westbury sizes Video on you tube if you want to see it working. Sorry I'm thick when it comes to loading you tube videos, perhaps Jason will oblige. Geoff Edited By JasonB on 21/07/2018 19:17:33 |

| JasonB | 21/07/2018 18:48:04 |

25215 forum posts 3105 photos 1 articles | Looks good and runs well Geoff. Edited By JasonB on 21/07/2018 19:17:57 |

| Jim Nic | 21/07/2018 20:37:50 |

406 forum posts 235 photos | That's a good looking "wobbler" Geoff, good work and a good runner too. I like the upside down look like which is a long way from the run of the mill oscillator design that I did for my first engine. Well done. Jim |

| geoff walker 1 | 22/07/2018 11:04:02 |

| 521 forum posts 217 photos | Hi Jim, Jason, Thanks for your comments. I have prepared a detailed CAD/PDF drawing of the engine to my sizes. Much the same as the Muncaster/Westbury I've just "beefed it up a little", Anyone who would like a copy P.M. me and I'll get one to you. Geoff |

| JasonB | 28/07/2018 19:56:41 |

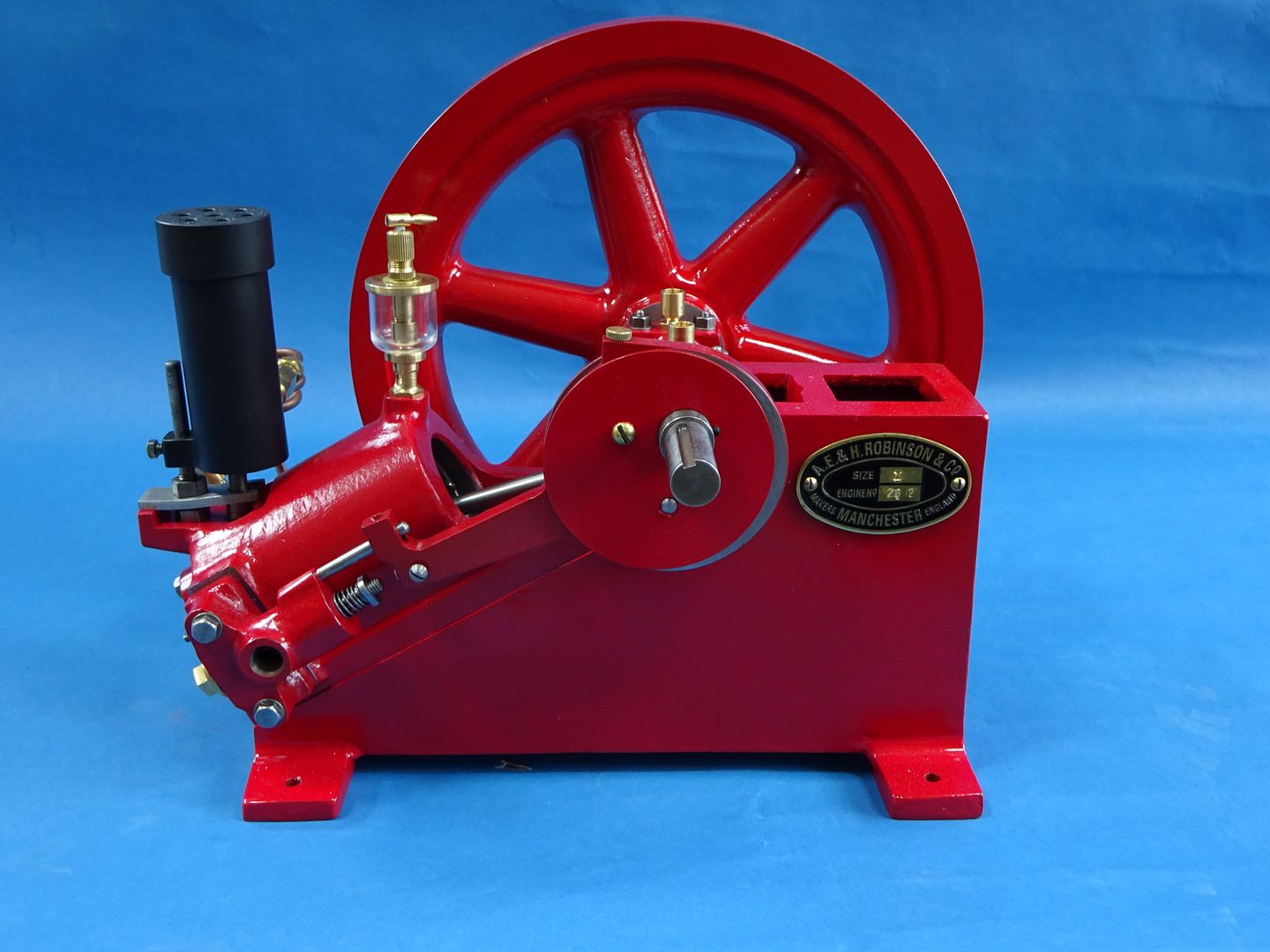

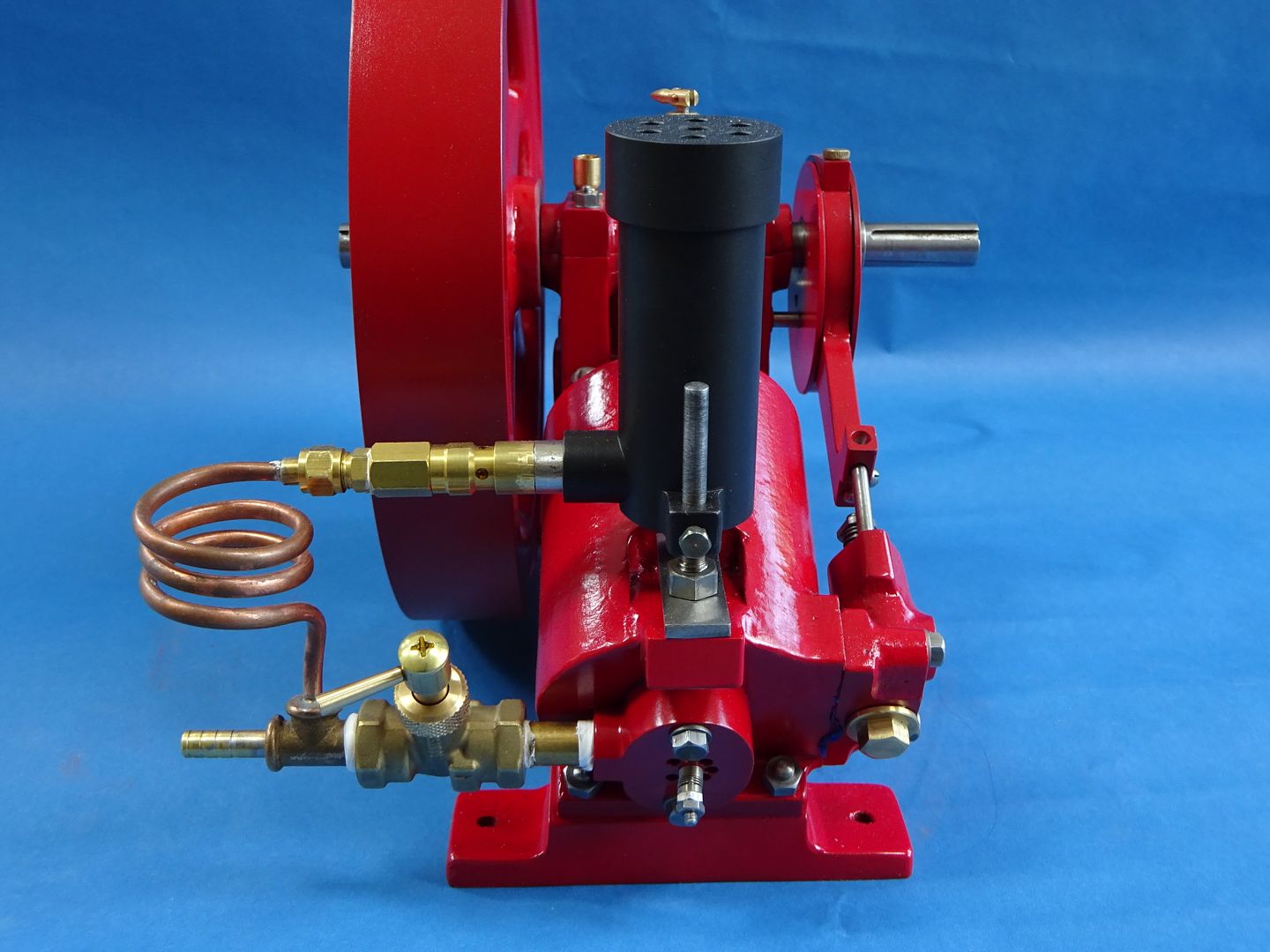

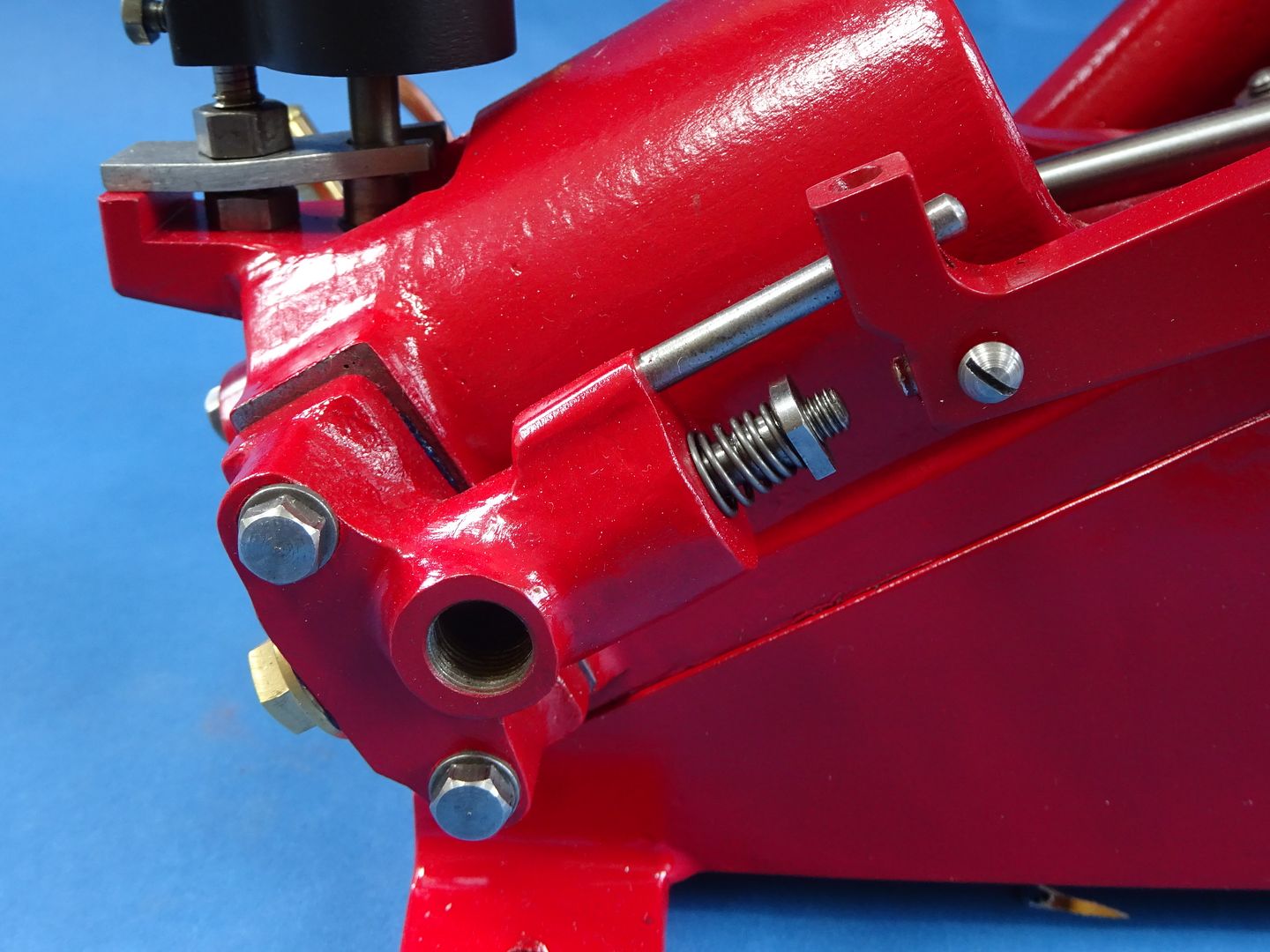

25215 forum posts 3105 photos 1 articles | The Robinson X-Type has been sitting in the workshop for the last couple of weeks in it's new shiny paint waiting for some weather that was more conducive to starting engines.

Despite what one or two may say we all know that an engine is not really finished until it has been painted and runs. So with a drop in the temperature and the prospect of more castings arriving soon it was out to the workshop early for some flywheel flicking. I'd like to say thanks to Graham Corey for making this engine possible by providing some of his rejects and the wisdom he has shared with those of us building the X-type on MEM Forum.

Edited By JasonB on 28/07/2018 19:57:20 |

| Jim Nic | 28/07/2018 22:56:27 |

406 forum posts 235 photos | As always Jason a beautiful looking model and a good runner with an interesting "beat" to the rhythm. The standard of your models gives me something to aim at even if I may never match what you produce. Jim |

| Brian H | 29/07/2018 08:07:36 |

2312 forum posts 112 photos | The Robinson engine looks and sounds good Jason. Can I just ask about the oval nameplate? was it home made or bought and if bought, where from? Brian |

| JasonB | 29/07/2018 10:14:18 |

25215 forum posts 3105 photos 1 articles | The name plate is a photo etched one that came with the castings.

|

| Brian H | 29/07/2018 10:30:58 |

2312 forum posts 112 photos | Many thanks Jason, that looks a high quality photo etch. Brian |

| Ian Hewson | 29/07/2018 16:52:18 |

| 354 forum posts 33 photos | Nice engine Jason, don’t know how you find time to fit all you do in to a day! Did you have any oil in the cups when you ran it? |

This thread is closed.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in