The Workshop Progress Thread 2019

| mechman48 | 09/11/2019 19:13:42 |

2947 forum posts 468 photos | Posted by John Hinkley on 09/11/2019 16:55:21:

George, The site I think you're after is: You will have to supply a dxf file of the part you want cut and the owner will tell you whether your requirements are possible. I have used this service and found them excellent to deal with and very reasonably priced. John Thanks for the link John. G. |

| Brian H | 09/11/2019 20:02:11 |

2312 forum posts 112 photos | Solved the problem with the table drive gearbox on my Senior mill. I had the gear lever between slow and medium! All working properly now. Brian |

| JasonB | 09/11/2019 20:08:32 |

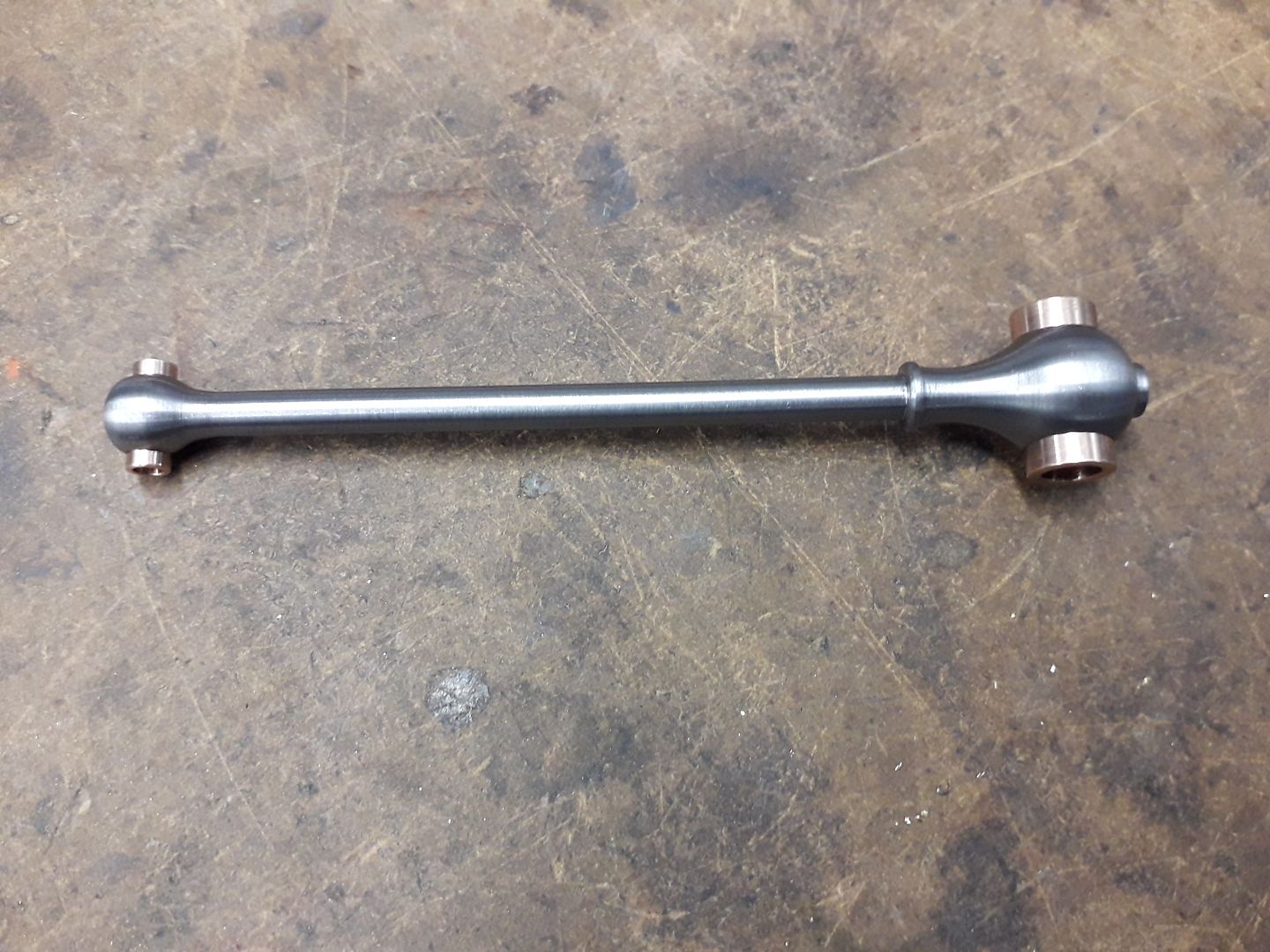

25215 forum posts 3105 photos 1 articles | I turned a 5" length of 5/8" steel into a pile of swarf and an Conrod, bit of a change from the usual designs as is most of this engine.

|

| Brian H | 09/11/2019 20:15:36 |

2312 forum posts 112 photos | VERY neat Jason. Brian |

| Jim Nic | 09/11/2019 22:04:56 |

406 forum posts 235 photos | Lovely pile of swarf, where's the conrod? Jim

|

| Ian Johnson 1 | 09/11/2019 22:41:56 |

| 381 forum posts 102 photos | Nice job Jason that's a very elegant conrod Ian |

| Mark Rand | 10/11/2019 01:08:25 |

| 1505 forum posts 56 photos | Spent a few more hours pottering around putting things away and moving stuff around. I can actually move all the way from the shed door to the far end, with only a bit of fancy footwork near the door over the pile that needs to go to the tip tomorrow. I've gained a couple of square yards of floor space that I had forgotten were there!

Now where did I put the top of the bench. |

| Anthony Knights | 10/11/2019 09:29:10 |

| 681 forum posts 260 photos |

At the beginning of July I fitted the longer table and leadscrew to my CDM10. The original table shown above has been sat on the bench annoying me, because I'm not sure what to do with it. This is my home made (some might say bodged) tool grinder, made from a cheap bench grinder mounted on a lockable turntable (made from a car brake disc) together with a cheap cross vice. Any attachments to assist with grinding specific tools are held in the vice. This is not ideal, but has worked for years. My cunning plan is to remove the actual vice and mount the table in its place. I have taken measurements and this will involve removing about 4mm from the top of the cross vice dovetail where the vice was fitted. I also need to remove a total of 13mm from width the table and vice dovetails. This could be a long job involving a lot of winding because my mini mill can only take small DOC. Edited By Anthony Knights on 10/11/2019 09:46:48 |

| Anthony Knights | 10/11/2019 09:44:02 |

| 681 forum posts 260 photos | I have removed the vice assembly from the X-Y parts and mounted it on the milling machine and begun flycutting the top of the dovetails down. After cutting the height down to what was required, I then used a dovetail cutter to widen the gap as much as I dared, hopefully without weakening it too much. I expect there will only be small stresses when grinding tools. This is the finished result. The marks on the top of the right hand dovetail are where the original gib adjusters were. I did consider filling them with epoxy resin, but as they are not a load bearing surface, I decided not to bother. I'm not sure it would stay stuck in position anyway. The next job is to machine the dovetails on the on the old table. Edited By Anthony Knights on 10/11/2019 09:48:14 |

| JasonB | 10/11/2019 17:37:23 |

25215 forum posts 3105 photos 1 articles | Made a start of the flywheel that goes with the conrod I posted yesterday

|

| Ian Johnson 1 | 10/11/2019 17:49:19 |

| 381 forum posts 102 photos | Posted by Anthony Knights on 10/11/2019 09:29:10:

At the beginning of July I fitted the longer table and leadscrew to my CDM10. The original table shown above has been sat on the bench annoying me, because I'm not sure what to do with it. That table looks familiar! I have just done the same improvement to my mill, and the old table is now sat on the bench annoying me too! Very good idea to use it like this. I think I'll hack off the dovetails on mine and make it into a mini pallet for my CNC mill. The table is big enough to drill lots of holes into it for various attachments. Ian |

| Jim Nic | 10/11/2019 21:04:47 |

406 forum posts 235 photos | Looks like Father Christmas came early Jason. Jim |

| JasonB | 11/11/2019 06:59:22 |

25215 forum posts 3105 photos 1 articles | No that's another one of his engine designs, a Type B

|

| Ron Laden | 11/11/2019 08:54:06 |

2320 forum posts 452 photos | Posted by JasonB on 09/11/2019 20:08:32:

I turned a 5" length of 5/8" steel into a pile of swarf and an Conrod, bit of a change from the usual designs as is most of this engine.

Now that is one very cool (as they say these days) conrod and a lovely piece of machining , very nice indeed. |

| Ron Laden | 11/11/2019 15:53:05 |

2320 forum posts 452 photos | That engine certainly looks different Jason, I am trying to fathom the brass ball built into the flywheel. Is it an adjustable balance for the wheel its the only thing I could come up with. p.s. or is it something to do with the timing. Edited By Ron Laden on 11/11/2019 15:58:30 |

| JasonB | 11/11/2019 16:14:41 |

25215 forum posts 3105 photos 1 articles | It's part of the governor, the other end of the bracket that the ball fixes to carries one of the ignition contacts. So as the speed goes up the ball and therefore the contact get slung outwards and this stops the spark so the engine slows and so on. |

| Ron Laden | 11/11/2019 16:22:03 |

2320 forum posts 452 photos | Thanks Jason, thats a neat idea is it unique to that engine or do others use that method. |

| martin perman | 11/11/2019 16:41:37 |

2095 forum posts 75 photos | Ron, Unless you were referring to just models, opening the points or exhaust valve were used as govenor control on full size engines for several years until the fuel throttle controlled by govenor became more reliable. Martin P |

| JasonB | 11/11/2019 16:46:11 |

25215 forum posts 3105 photos 1 articles | I don't think I have seen it on another model, the hit and miss engines tend to hold the exhaust valve open and others govern the throttle. I have done a couple of hit and miss engines that have a "battery saver" as part of the governor which also cuts the circuit so nothing gets to the spark plug when it is missing a beat but that is secondary to the exhaust being held open. |

| Anthony Knights | 12/11/2019 03:46:51 |

| 681 forum posts 260 photos |

I clamped a 12mm silver steel bar in the front T slot of the milling machine to act as a guide to clamp the old table up against, ready for machining. Checked alignment with a dial gauge and as expected, it was spot on. Milled the original dovetail off. then cut the new dovetail to the width required. Next job is to make the gib strip |

This thread is closed.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in