Gauge Plate for Form Tools

| James Hall 3 | 01/01/2023 20:16:46 |

| 92 forum posts 12 photos | I'm aiming to produce some finials/ball shaped ends around 3/16" diameter and proportionate length - also some half-round mouldings of around the same size to decorate stanchions. This seems a good opportunity to develop my skills as a machinist into making and using small form tools. However, I can't find any guidance on the thickness of gauge plate to use - presumably there's a trade-off between robustness of the tool and the amount of work required to produce an accurate profile with appropriate clearance angle (i.e would obviously be ridiculous to make a tool of this size from 1" thick plate, but 1/8" might not be rigid enough). As usual, advice from those with experience would be much appreciated. |

| JasonB | 01/01/2023 20:28:40 |

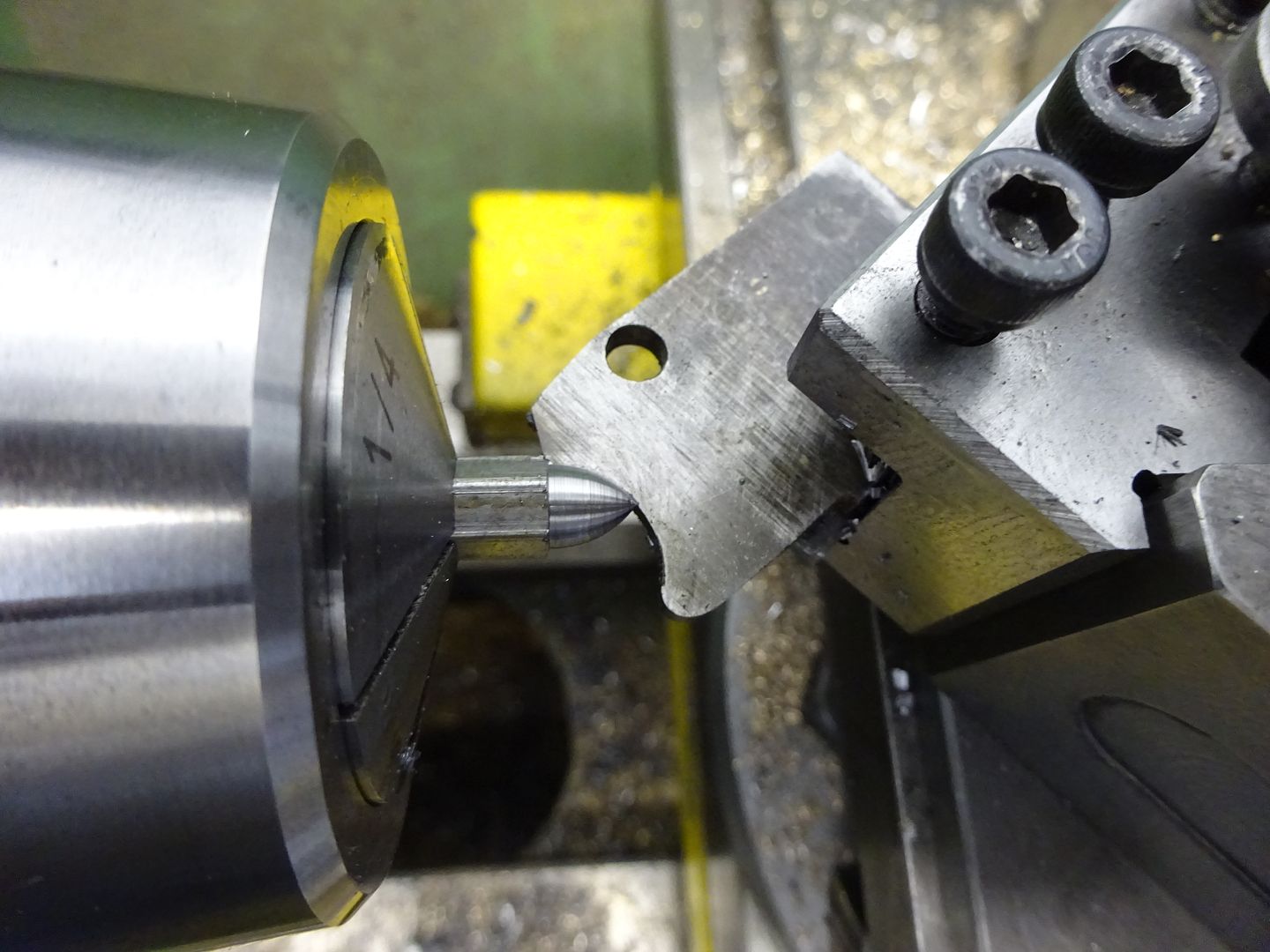

25215 forum posts 3105 photos 1 articles | I would say 1/8" will be OK for that, just avoid too much overhang from the toolpost. These 9/16" dia valve bodies are being cut with 1/8" plate. Same tool doing these steel acorn nuts

|

| Neil Wyatt | 01/01/2023 20:32:01 |

19226 forum posts 749 photos 86 articles | 1/8" works well for me too. One piece 6" long can make a dozen tools. Neil |

| Jeff Dayman | 01/01/2023 20:52:24 |

| 2356 forum posts 47 photos | Another way to make "insert style" form tools from .093 or .125" gauge plate is shown in the pics. |

| Bazyle | 01/01/2023 21:14:42 |

6956 forum posts 229 photos | You can go quite thin for brass, eg using hacksaw blade but with a bit of thicker steel underneath, set back a bit. Since brass doesn't need the top rake the hard bit doesn't need to be thick. Another possibility when needing thicker stock is old wood chisels from a boot sale. You can pick up the mangled and broken handle ones once they realise no serious buyer would want them, |

| Nick Hughes | 01/01/2023 21:19:32 |

307 forum posts 150 photos | Old worn out files are also another good source of material Edit:- Suppose I should mention (before the pedants start) anneal first, file or grind away the teeth, produce the form required, then re- harden and temper. Edited By Nick Hughes on 01/01/2023 21:25:14 |

| Martin Connelly | 02/01/2023 08:28:49 |

2549 forum posts 235 photos | There is a recent thread about making a faceplate for watchmaking that links to a YouTube video. In it there is a short segment where a tool of the style you are after is shown being made. Thread 184361 so it is probably worth a look if you have not already watched it. It is nearer the end of the video than the beginning if you don't want to watch the whole thing. Martin C |

| DC31k | 02/01/2023 10:43:51 |

| 1186 forum posts 11 photos | I think it was during a discussion of making button tools for gear cutting that John Stevenson mentioned using a cone drill to form the shape as then it is truely circular (not elliptical) and the clearance/relief is built in. Clearly, you have the finished tool upside down when you drill it and do a test so that you know how deep to plunge so that the underside is your 3/16" diameter. A better quality version of the smallest of this set might do: https://www.screwfix.com/p/erbauer-cone-drill-bit-set-3-14-8-20-16-30mm-3-piece-set/9031V |

| Roderick Jenkins | 02/01/2023 13:00:47 |

2376 forum posts 800 photos | Posted by Nick Hughes on 01/01/2023 21:19:32:

Old worn out files are also another good source of material There are rumours on the knife making forums that some files are case hardened mild steel rather than solid tool steel. Rod |

| Tony Pratt 1 | 02/01/2023 13:06:27 |

| 2319 forum posts 13 photos | Posted by Roderick Jenkins on 02/01/2023 13:00:47:

Posted by Nick Hughes on 01/01/2023 21:19:32:

Old worn out files are also another good source of material There are rumours on the knife making forums that some files are case hardened mild steel rather than solid tool steel. Rod The old properly made ones are/would be solid carbon steel but god knows what crap some things are made of these days? Tony |

| Nigel Graham 2 | 04/01/2023 20:16:13 |

| 3293 forum posts 112 photos | Good tip, the cone drill, but it is intended for cutting mild-steel and non-ferrous metals. I'd suggest low speed, cutting fluid / paste and avoid rubbing. Both these and step drills are excellent for their intended use, holes in thin sheet material without grief. The shank of a standard twist-drill is as good a gauge as any for testing the hole diameter. |

| Dave S | 05/01/2023 16:56:20 |

| 433 forum posts 95 photos | The reason for using a cone drill was the size of the curve could be got correct by the correct depth of drilling, *and* the cone automatically adds the required relief to the cutter. Made a few that way. Dave |

| SillyOldDuffer | 05/01/2023 19:10:46 |

| 10668 forum posts 2415 photos | Posted by Roderick Jenkins on 02/01/2023 13:00:47:

Posted by Nick Hughes on 01/01/2023 21:19:32:

Old worn out files are also another good source of material There are rumours on the knife making forums that some files are case hardened mild steel rather than solid tool steel. Rod Maybe, or at least something like it. Modern engineering looks to make affordable files, disposable, and not intended to provide home metal-workers with cheap metal. The ideal file has hard teeth and a tough backing. Old files were entirely made of hardenable steel, which is brittle. A smarter file is made from two steels. like bimetallic saw blades. One steel is optimised to provide a cutting edge whilst the other to backs it with a strong bendy metal to resist snapping. Knife makers should know all about this: it's often desirable to forge knife blades with a soft tough back welded to hardenable strip that takes an edge. Such blades take a pounding better than those made from hardenable steel throughout. Blades for cutting soft materials can be made from a single hard steel, but they tend to break whilst hacking into hard woods, ice, bamboo, bone, and oil drums! My perception is the people who complain most about the poor 'quality' of modern metals are amateurs. I put this down to us repurposing metal rather than buying to a specification. We risk making a poor choice, perhaps assuming files are made in a particular way when they're not. Car makers would scream blue murder if modern steel was poor stuff. Instead it seems industries using millions of tons of metal per year rarely have any bother with it, whilst the tiny quantities used by men in sheds cause endless trouble. Dave

|

| Nigel Graham 2 | 05/01/2023 21:05:57 |

| 3293 forum posts 112 photos | Good point about specifications. I think we can trust the new steel from "our" suppliers, who probably buy from the same trade-retailers who supply the precision-engineering contractors on the same trading-estates. Contractors usually given tight materials specifications too. So if we ask for EN1A or EN24T (or by whatever are their modern descriptions) that is what we get. How many of us though, including me, also use "pre-loved" materials, as you say? Always chancy unless the original use is clear, such as a scrapped machine part. That does not tell us the specification but is a guide to its suitability at least for such components. It might be very high-quality stuff too, but prove hopelessly un-machinable to us, even if not hardened. Or buy the sort of rather rough stuff sold in the DIY supermarkets? That steel is not the best for the motion work on a fine-scale miniature locomotive, but is fine for its expected purposes: parts for buildings and garden-gates. So we can use it, but for those parts for which its characteristics are better suited, like the strap-work on railway-wagons. |

| James Hall 3 | 10/01/2023 17:13:20 |

| 92 forum posts 12 photos | Thanks to everybody for some helpful responses. Got some 1/8" gauge plate and had a go - cleaning up the column mouldings for my Stuart beam. I started small with just the bead and then on to the rest. First attempt failed as the iron machined my tool - insufficient heat when hardening - judged by eye, next attempt used a magnet and all was well. Pic shows the result, which I'm pleased with as the casting was very poor quality, very oval, ill-defined, and full of sand pits (some of which remain, but it will be painted) - at least it's round now and the mouldings are properly formed. I'm now confident to further make and use form tools as and when required. Seems difficult to find cones - almost all people selling step drills advertised as cones, but not at all what is required. I eventually purchased a taper end mill (half as much again as a cheap cone but has already done more work than the only cone I ever owned and which blunted at the mere sight of steel), which easily produced relieved holes and allows very fine control of the hole size for beads etc. |

| DiogenesII | 10/01/2023 17:24:06 |

| 859 forum posts 268 photos | Try 'Conecut Taper Drill' as a search term. Edited By DiogenesII on 10/01/2023 17:25:22 |

| Michael Gilligan | 10/01/2023 18:15:04 |

23121 forum posts 1360 photos | Just out of interest … does anybody know : Are Conecut drills ‘relieved’ or do they somehow rely upon the taper to make the cutting edge work ? Yes, I know I could have a look … but it’s easier if someone knows the answer ! MichaelG. . Ref. https://bonthron-ewing.se/wp-content/uploads/2019/11/G-J-HALL-komplett-katalog1.pdf Catalogue page 19 et seq. Edited By Michael Gilligan on 10/01/2023 18:25:55 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in