Head or quill feed when slotting

| Mike Donnerstag | 08/12/2021 17:26:05 |

231 forum posts 53 photos | I have a Sieg SX3. I need to run a slot along the side of some mild steel (a finger clamp) to allow it to be bolted to the mill table. I am using a 6mm 2-flute slot drill and I'm not too bothered about the finish or the exact size, so I'm using this to mill a 6mm slot. My question is, should I lock the quill and use the head feed (Z-feed) and the three axis DRO that I fitted, or should I lock the head and use the quill feed? Which is best? I tried the former (locking the quill and using the Z-feed) and the mill started to shake. Is this due to movement on the pillar dovetail? I had more success with the quill feed, milling the slot in about 0.5mm increments. Many thanks in advance, Mike |

| Nigel Graham 2 | 08/12/2021 17:46:44 |

| 3293 forum posts 112 photos | I don't know the particular machine but as a general rule for work like that, for maximum rigidity I would lock the spindle fully home, and feed by the knee instead (analogously, the head on that form of mill). Unless the quill has a graduated fine feed, the knee or head feed is more accurate anyway. The quill is better left for drilling. |

| JasonB | 08/12/2021 18:15:58 |

25215 forum posts 3105 photos 1 articles | I tend to use the head to put on a cut, the less you have the quill sticking out the more rigid the setup. Lock the head during the cut I would also have thought you could go a bit deeper per pass 1 to 1.5mm should be possible with a half decent cutter that is sharp Video I did some time ago on the X3 which is not a lot different to yours doing a 12mm wide by 2.5mm deep per pass slot. Quill remains retracted and locked and you can see me unlock the head to put on the cut then lock it again before cutting Edited By JasonB on 08/12/2021 18:26:23 |

| Dave Halford | 08/12/2021 19:36:46 |

| 2536 forum posts 24 photos | Posted by Mike Donnerstag on 08/12/2021 17:26:05:

My question is, should I lock the quill and use the head feed (Z-feed) and the three axis DRO that I fitted, or should I lock the head and use the quill feed? Which is best? I tried the former (locking the quill and using the Z-feed) and the mill started to shake. Is this due to movement on the pillar dovetail? I had more success with the quill feed, milling the slot in about 0.5mm increments. Many thanks in advance, Mike Yes, this might imply that your head feed dovetail is looser than you thought it was. |

| Clive Foster | 08/12/2021 22:42:14 |

| 3630 forum posts 128 photos | Agree with Dave that your Z gib may be looser than ideal. Dunno how much it applies to the smaller Sieg but back in the day I found that the overhung weight of the head on my bigger, Chester supplied, vertical column mill gave a false impression of gib tightness. I ended up winding the head down onto a block of wood sat on the table whilst resting my finger on the top of the head body to feel for fore and aft rock when moving onto and off the block. Didn't help that the gib on that machine was somewhat insensitive to adjustments needing winding up and down a few times after each tweak to get it settled. With the benefits of 20 years of hindsight I suspect that some of the preservative grease had gotten around it almost gluing it into place. Probably rather less than 5 thou per foot of tilt movement to start with but once eliminated it made the mill behaviour much more predictable with reliably good finish. As delivered with that slight slackness I was never sure of how to get a good finish. Some days were good mill days and some bad mill days with no difference that I could discern in conditions or technique. Clive |

| not done it yet | 09/12/2021 08:21:15 |

| 7517 forum posts 20 photos | As I see it in very simple terms, machining metal requires a combination of factors. Feed rates, cut depth, sharp cutters and cutter type all need attention. Also, with hobby machines, rigidity is paramount. Smaller machines cannot be as rigid as machines with far greater mass. As Jason points out, he locks the adjusted axis. I go further and say both unused axes should be clamped, with all cuts, for maximum rigidity. The other factor of quill v. head movement is also a simple rigidity consideration. Is the (even locked) quill more rigid with zero stick-out or with 72mm stick-out? No contest in my view. My mills both have knees, so the table is easily raised. One of them has no other option than raising/lowering the table. I always use the table for setting the depth of cut, if practicable. Sometimes axes might not be clamped, but even so, as I see it, cuts may well be OK, sufficiently accurate (for the job in hand) but it will eventually mean increased wear in the unused axes - it will not show up today, tomorrow or even next year, but over the life of the machine it will. Machine life, without clamped axes, will wear out sooner. |

| Mike Donnerstag | 07/01/2022 17:31:31 |

231 forum posts 53 photos | Apologies for the very late reply! I read all of the comments (many thanks to all) and realised I had neglected to say that the slot I was milling was fully enclosed, necessitating plunging. It was the plunge that gave me trouble, resulting in the head shaking (both the milling machine's head and mine!) I stripped and reassembled the head and column using the ArcEuro Sieg SX3 dismantling and reassembly guide, ensuring everything was lubricated, adjusted and working as it should... though to no avail. Since then, I since found a similar post: https://www.model-engineer.co.uk/forums/postings.asp?th=145271&p=2, describing the same problem but with a Warco mill of a similar size. I conclude the following from the thread:

Let me know if anyone has any comments on this. I realise that a sturdier, commercial mill would be more forgiving! Many thanks and Happy 2022 to everyone. Mike |

| John Haine | 07/01/2022 17:42:38 |

| 5563 forum posts 322 photos | I'm even more puzzled now!

I would have though that the correct procedure for this is to position the cutter over one end of the slot (before it's cut) and feed down into the metal about 1 - 1.5 mm using the Z feed with the quill locked. Then lock Z and unlock X and feed along X to the end of the slot. Then repeat until you're right through. Keep Y locked throughout. |

| JasonB | 07/01/2022 18:17:58 |

25215 forum posts 3105 photos 1 articles | You can also make life easier for the milling cutter to plunge by predrilling ei ther end of the hole, for your 6mm slot a 5mm hole would be ideal. This also helps prevent the "dogbone" effect of alarger hole at each end of the slot caused by the milling cutter moving about and cutting ove size. I tend to prefer a 3-flute cutter to plunge with |

| Mike Donnerstag | 07/01/2022 18:35:39 |

231 forum posts 53 photos | John: Apologies - I didn't explain myself well. According to the 'Warco head shake' post, Old Mart posted the following: "I remember plunging a 1/4" slot drill about 1/4" deep and getting a hole 0.015" oversize. Changing the cutter resulted in a hole only 0.001" oversize, yet there didn't seem to be much difference in the sharpness." From this, I assumed that it must be the cutter geometry that is different between the two 2-flute cutters. I watched JasonB's Youtube video that showed a trouble-free plunge using the z-axis, again surmising that it was the quality of my cutters that may be at fault. Also, I should have changed the word 'lower' to 'move' as this obviously only applies to the Z-axis and not the X-axis. By 'fully enclosed' I mean that the slot starts and ends within the metal. The cut was blind (not through) and about 5mm deep overall. I took this to depth in 0.5mm passes. In a previous post, JasonB explains that ArcEuro recommend using the quill feed for plunging, rather than the Z-axis. Having tried both, at least using the poor quality bit I have, it was evident that the quill feed was more controllable. JasonB: Many thanks for your advice. That's exactly what I should have done. Can you also mill the slot using the 3-flute cutter, or would you switch to the 2-flute?

|

| Emgee | 07/01/2022 18:38:17 |

| 2610 forum posts 312 photos | Hi Mike Ramp milling is the preferred method of plunging for most materials even with over centre fluted cutters and would reduce the load on your machine spindle. If using a manual machine and the cut is in the Y axis with the work mounted in a vice I always cut towards the vice rear fixed jaw, I have found this to reduce the chance of vibration. Of course as said by others locking the axis not being used is always a good idea. Emgee |

| JasonB | 07/01/2022 19:03:47 |

25215 forum posts 3105 photos 1 articles | Posted by Mike Donnerstag on 07/01/2022 18:35:39:

. Can you also mill the slot using the 3-flute cutter, or would you switch to the 2-flute?

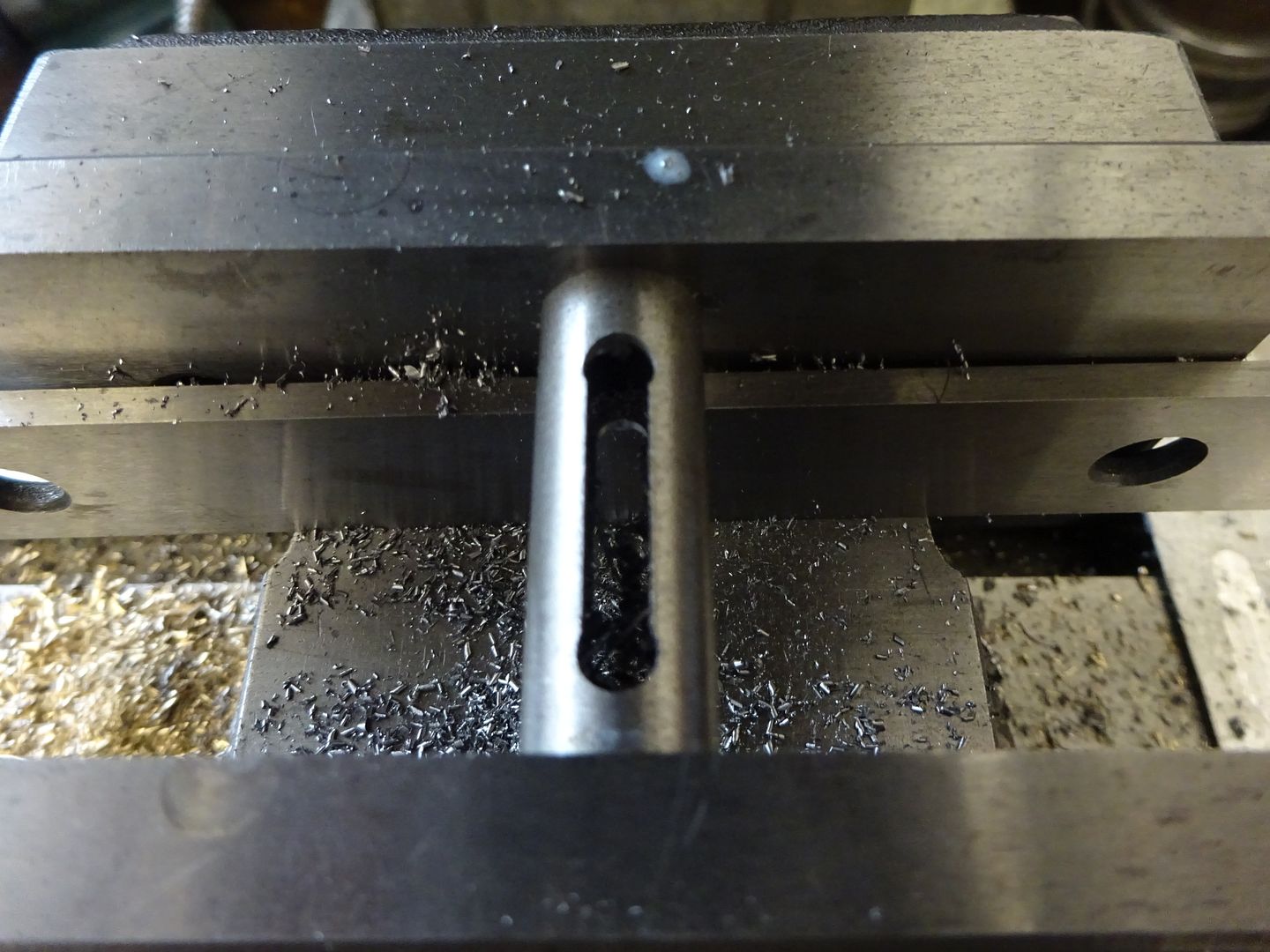

I tend to use 3-3lute most of the time just changing to a 2-flute if I have the size when I want a very accurate slot as the 2-flute should not cut over width, or you can use a slightly smaller cutter and then either move sideways to get the width you want or run down the middle of a narrower slot which is less likely to see a cutter being pulled sideways and cutting over width. This recent one was drilled 4.8, milled 4mm and then finish milled 5mm both 3-flute cutters even though it was not a critical width. Both milled in one pass each of the two 1mm thick walls

Edited By JasonB on 07/01/2022 19:04:22 |

| Mike Donnerstag | 07/01/2022 19:18:02 |

231 forum posts 53 photos | Very interesting. Is a 3-flute cutter therefore a good all-rounder, or do you still use 2 and 4-flute cutters for specific purposes? Please excuse my beginner questions and feel free to point me to a thread if one already exists on the topic. Mike |

| Simon Williams 3 | 07/01/2022 19:36:17 |

| 728 forum posts 90 photos | The problem I've encountered with plunging a slot is all about re-cutting the swarf. Although it makes a mess, I've had better results by setting a compressed air jet against the cutting area to blow the chips out of the way. Jason's suggestion to drill right through at the start helps too. That way you can wash the chips down the holes and let gravity clear the cutting area. Ideally this means flooding the cutting area with plenty of suds. edit for minor but confusing typo Edited By Simon Williams 3 on 07/01/2022 19:37:00 |

| JasonB | 07/01/2022 20:05:31 |

25215 forum posts 3105 photos 1 articles | Mike, I've certainly said it a few times in the past that I feel 3-flute cutters are good all rounders, either in the "disposable" short types or regular sizes and are what I tend to use most. Expect it gets mentioned a few times in the Milling for Beginners thread 2-Flute I have some that I just use for things like keyways in shafts where you want a very good fit for the key so it does not fret. The other thing I have 2-flute cutters for are ones specifically for aluminium and non ferrous where the steeper helix angle removes the larger volumes of swarf better though I do also have 3-flute ones of these that get used on the CNC quite a lot 3-fute are my go to ones, most 6mm (& 1/4" ) and under are the FC-3 type on the manual mill or the usual 50mm O/A length for the carbides on the CNC. larger 3-flute are traditional plain or weldon shank 4-flute I have not bought many traditional ones lately preferring the 3-flute for general work though I do tend to use 4-flute ball ended cutters where most would use 2-flute one son the CNC as I can feed at twice the rate for the same given chip load. Same goes for corner radius(convex) cutter. Also a few long reach cutters which seem to be a bit more common in 4-flute. As Simon says keeping swarf out the way is good practice particularly in a slot where a bit trapped between cutter and side of slot can push it sideways and you get a wider slot. Even just blowing through a rubber tube once in a while will help. You can also drill a blind hole at each end if the slot doe snot go right through. Edited By JasonB on 08/01/2022 09:28:33 |

| DMB | 07/01/2022 21:57:16 |

| 1585 forum posts 1 photos | What an interesting thread, learned a few things here, even with several years milling experience. Never thought about drilling blind holes at the ends of a trough - slot. Also not thought about using a tube to blow swarf out. I have used a magnet to pick up swarf from slots. Never too old or too late to learn, even @70+! |

| DMB | 07/01/2022 22:00:50 |

| 1585 forum posts 1 photos | JasonB, What's a Weldon shank? Guessing it's plain with a large flat for a locking screw? John |

| JasonB | 08/01/2022 07:06:12 |

25215 forum posts 3105 photos 1 articles | Yes they are the cutters that have a flat on the side also sometimes called "sidelock". Supposed to be named after the Weldon Company in the US who first invented spiral flute milling cutters and needed a way to stop them being pulled out, prior to that they were parallel flute. |

| Michael Gilligan | 08/01/2022 09:08:28 |

23121 forum posts 1360 photos | On the subject of Weldon, etc. Just an aside … There is an interesting patent by Clare Collets, accessible here: **LINK** https://worldwide.espacenet.com/patent/search?q=pn%3DGB2138329A MichaelG. |

| AdrianR | 08/01/2022 10:04:12 |

| 613 forum posts 39 photos | I have two mills, an old Emco clone and a SX3, both shake violently when using a two flute, it's so bad I don't use two flute anymore. Three and four flute cutters are fine, and now I am only buying three flute cutters. I also found that the SX3 Z Axis gib was far too loose, I think it was about five turns on the adjustment to get it to lock. I used a wooden leaver to lift the head, and a dial gauge to measure the play between the head and column. It now has about the same play as the X and Y. It has improved the finish greatly, I must admit I have not tried a two flute cutter since adjusting it. Adrian |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in