Bed stop clamp

| brian jones 11 | 19/07/2021 23:49:50 |

| 347 forum posts 62 photos | has anyone ever come across an official bed stop clamp used to stop saddle movement towards the chuck and provide turning to a fixed should Yes there is a multi position indexable type as used in capstan work for example very expensive £140 but way above my simple requirements Any ideas anyone? |

| Grindstone Cowboy | 20/07/2021 00:01:01 |

| 1160 forum posts 73 photos | Well, there's been quite a few described on this forum, see here Links to https://www.model-engineer.co.uk/forums/searchresults.asp?Search=carriage+stop&t=0 Rob |

| brian jones 11 | 20/07/2021 00:28:46 |

| 347 forum posts 62 photos | thnx GC for the link, many brave souls with superior milling power have knocked up suitable robust clamps some have the dovetail bed shape maybe clamping is easier and a DTI clamp might do the job if used with care. The ML7 bed is two flat strips someone even suggested a g cramp - perish the thought. those beds are soft like putty and the outer edges define bed accuracy. I thought a clamp type as used in the wood workers tool rest it uses the tee nut and bolt down the centre channel same as used by the fixed steady Anyone know where you can get the special Tee nut and bolt for this (Myford dont sell it when the sell the Wood tool rest - believe it or not they say you should use your own clamp nut) Making this Tee nut is not trivial and should be 1/2" thick, same as for the clamp plate, so more serious milling

Well I thought I must be missing something, but I have a cunning plan

|

| Grindstone Cowboy | 20/07/2021 00:55:52 |

| 1160 forum posts 73 photos | Now we know what machine it's for, you could do worse than something like this - and no need to clamp anything to the bed. Links to http://www.hemingwaykits.com/acatalog/Multi_Position_Saddle_Stop___Myford_7_Series.html Rob |

| Nigel Graham 2 | 20/07/2021 00:58:45 |

| 3293 forum posts 112 photos | Owning an ML7... all I found necessary was to cut a piece of 25mm X 6mm steel flat the width of the bed, and drill a hole through the middle. I secure it to the ways with the clamp and bolt borrowed from the fixed steady. I did not need make any T-nuts etc as I use existing fittings. Yes, it's a slightly crude set-up and gives only one stop position at a time but has amply repaid itself many times. Actually, thinking about it, I did not make the bar specially for that. It is really a clamp-plate I made for holding one of my milling-vices to the table. Why make two items when you can make one item perform two duties? |

| not done it yet | 20/07/2021 07:06:31 |

| 7517 forum posts 20 photos | Yet another waste of a thread. I would expect that lathe beds of differing shapes and sizes, so there is never going to “a bed stop clamp” that would ‘fit all’. Dunno what the OP thinks by “official” but my lathe does not need a ‘stop’. It has a long travel trip which, when set, automatically removes the power feed at that precise point. It was supplied with the lathe at purchase, so was an obviously ‘official’ part of the machine. Simple requirements are often simple to arrange. I suggest the OP makes a stop for his particular lathe. BTW, the auto-trip on my lathe only works while turning towards the chuck; simple stops can be made for turning away from the chuck as well. I doubt many “official” stops would be supplied as ‘standard’ on lathes with a power feed due to the likelihood of some users causing a crash. |

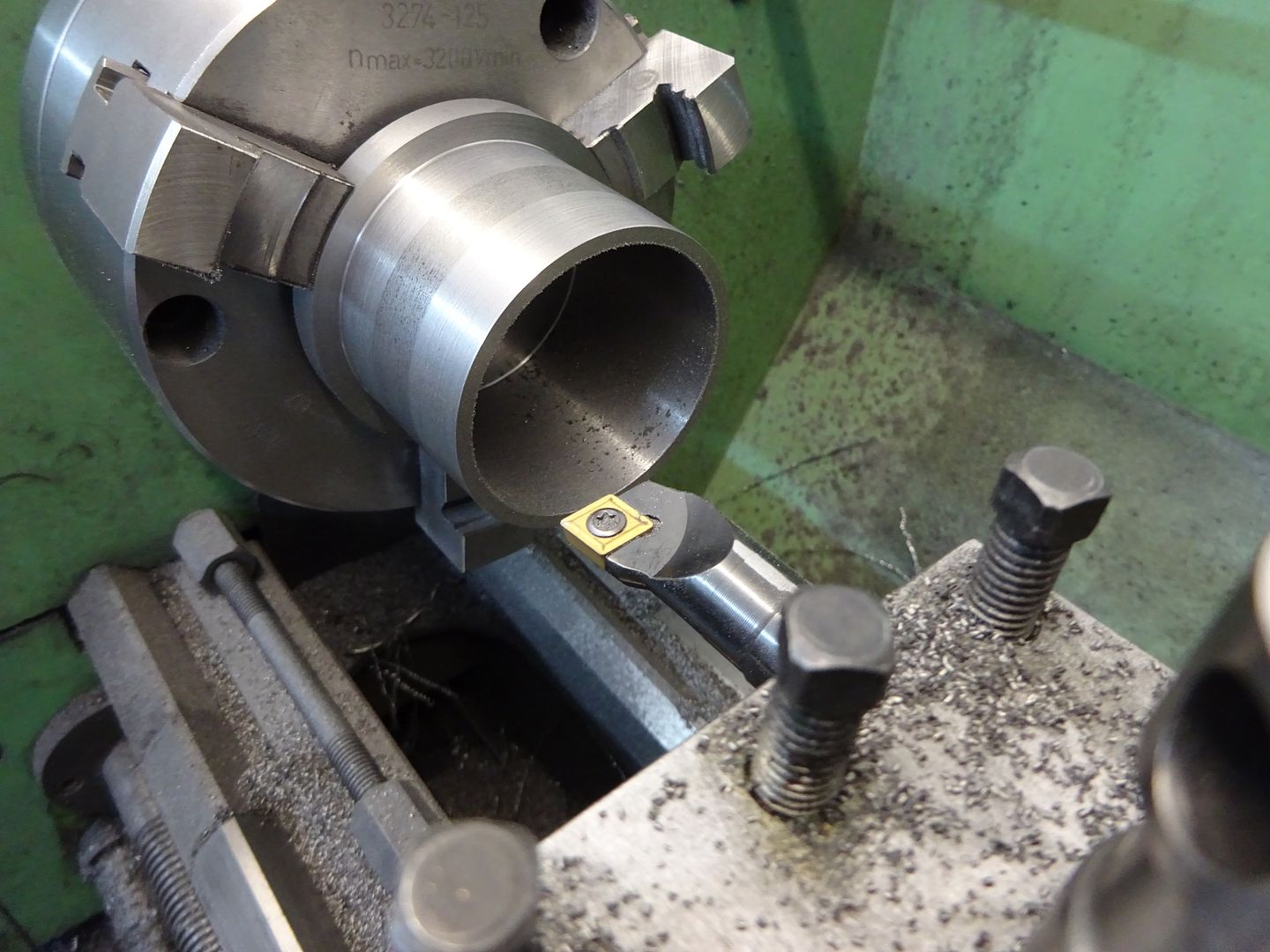

| DiogenesII | 20/07/2021 07:29:32 |

| 859 forum posts 268 photos | If you are working close to the chuck, or with collets / faceplate, there's nothing but 'gap' to clamp a stop across.. ..fairly sure the mounting holes were there already..

Edited By DiogenesII on 20/07/2021 07:31:17 |

| JasonB | 20/07/2021 07:34:48 |

25215 forum posts 3105 photos 1 articles | If you want a solution to your "simple requirement" then this works for me, couple of nuts and a bit of studding laid on the bed.

If you want a tee nut like the Myford wood turning rest then one it does not really need to be a tee nut just a short length of bar will do. If you do want a Tee then your Dore Westbury should be more than capable of machining a rebate on each end of some 1/2 x 2 bar, it's probably being let down by the user if it won't Downside of a clamp like that on the Myford is that the gap bed may mean you have to work with excess tool overhang as carriage can't get as close to the headstock, plus gets in the way for larger dia work.

Edited By JasonB on 20/07/2021 07:53:32 |

| Howard Lewis | 20/07/2021 08:25:38 |

| 7227 forum posts 21 photos | With so many different sized and shaped beds, there cannot be a "One size fits all" stop. So the only way in most cases will be make a bespoke stop for your particular machine. For owners of mini lathes clamps are / were available to buy, but for everyone else it is D I Y, ranging from simple flat strip clamp ons, to ones to fit a dovetail or a Vee bed. It can be a simple dead stop, incorporate a Micrometer barrel, or a DTI, or whatever takes your fancy and can be produced with the facilities available. Howard

|

| Nick Wheeler | 20/07/2021 09:05:14 |

| 1227 forum posts 101 photos | Posted by brian jones 11 on 20/07/2021 00:28:46:

I thought a clamp type as used in the wood workers tool rest it uses the tee nut and bolt down the centre channel same as used by the fixed steady Anyone know where you can get the special Tee nut and bolt for this (Myford dont sell it when the sell the Wood tool rest - believe it or not they say you should use your own clamp nut) Making this Tee nut is not trivial and should be 1/2" thick, same as for the clamp plate, so more serious milling

Making a T-nut to clamp in the centre channel is as trivial as some simple marking out cutting the edges with a hacksaw and finishing with a file. It's a part that needs to fit well, but precision isn't important. No mill needed. A small benchtop mill probably wouldn't be any quicker than doing it by hand either. |

| Clive Brown 1 | 20/07/2021 09:07:07 |

| 1050 forum posts 56 photos | Agree with most of the above comments. My Boxford has the maker's micrometer carriage stop. Sturdy and quick to deploy. It's a most useful addition. The clamp lever is a modified allen key. The micrometer feature is sturdy to resist the occasional thump from the saddle and making one wouldn't be too difficullt. A plain version was available and would be even easier to make |

| Anthony Kendall | 20/07/2021 09:13:24 |

| 178 forum posts | Posted by not done it yet on 20/07/2021 07:06:31:

Yet another waste of a thread. Snip Presume you are having a bad day, or it's early. Not a waste for me - I saw an option I had not thought of. Therefore valuable. It's what forums are all about. Edited By Anthony Kendall on 20/07/2021 09:19:09 |

| Michael Gilligan | 20/07/2021 10:39:58 |

23121 forum posts 1360 photos | Posted by Anthony Kendall on 20/07/2021 09:13:24:

It's what forums are all about.

.

MichaelG. |

| steamdave | 20/07/2021 10:41:44 |

| 526 forum posts 45 photos | Here's mine. Simple and effective. I use it in combination with my indexable lathe stop, usually with longer jobs and the indexing rods can't reach the normal fixed stop. Dave Edited By steamdave on 20/07/2021 10:43:47 |

| JA | 20/07/2021 10:58:03 |

1605 forum posts 83 photos | Posted by not done it yet on 20/07/2021 07:06:31:

I doubt many “official” stops would be supplied as ‘standard’ on lathes with a power feed due to the likelihood of some users causing a crash. My new lathe has an "official" stop. It disconnects the lead screw at a point of travel set by the operator. Incredibly useful and simple. JA There have been some designs of lead screw release mechanisms for Myford ML7/S7s published over the years. Edited By JA on 20/07/2021 11:00:59 |

| ega | 20/07/2021 11:26:53 |

| 2805 forum posts 219 photos | Not official or a bed clamp but this simple device has served me well for years: The Super 7 gearbox prevents the even simpler solution shown in an earlier post. For the same reason, it is necessary to have a selection of stop rods of graduated lengths. |

| brian jones 11 | 20/07/2021 15:23:50 |

| 347 forum posts 62 photos | I think we should ignore those who belong to the flat earth society and dont like their cages rattled. I posted the question re the ML7 as I thought I had missed something and a suitable simple attachment might in fact exist. When you have to do repetitive work, a bed stop is important and one that doesnt slip like using those plastic quiick clamps do - waste of space. I wasnt looking for a universal gadget and those with a dovetail bed are better served with a DTI clamp Some other robust clamps need serious milling which auntie Doreen is not up to the mark just now. Nice work on show btw. So at the risk of a firestorm of ******* from a dizzy height here is my cunning plan I bought one of these mini vice off ykw £9 and was prepared for disappointment as usual with PRC stuff, so to my surprise when it arrived I was surprised at the quality and precision of this die cast product - so much better than the ************** CI job crude and sloppy. It complements my little xy table also v impressive then looking at it It could make a bed stop clamp Now eagled eyed guano carriers will notice from the photo that screw stick out. In fact I removed these and what I thought were soft jaws, so it was just ally surfaces. It clamped to the bed quickly and firmly, no risk of damage ******* carriers moaned that you will have a large over hang and cant get close to the chuck I have shown that you can clamp close to the gap bed and by removing the topslide clamp nut (leaving the other nut to do the clamping - this works) you can get fully close to the chuck and all that without having to cut off the vice flange, so it can still function as a table vice - double result Hope this helps - living with Mrs Myford you constantly have to be inventive

Edited By JasonB on 20/07/2021 16:38:22 |

| Jim Butler 1 | 20/07/2021 16:04:06 |

| 17 forum posts 5 photos | It looks as though I may be a little late to the party, but here goes anyway. For a very simple saddle stop I sometimes use a toolmakers clamp. This has the advantage that I have one or two, and that they can clamp close to the end of the bed, as shown below. a simple solution.

I later made something a bit more refined which would clamp to the bed of the ML7.

The body of the saddle stop is made from aluminium. All the milling was done on the ML7 itself, using a vertical slide. The threads of the clamp screw and the stop rod are both 40 TPI. This give a fine adjustment to the stop position, and in the case of the clamp screw gives a tight grip for very modest torque on the thumb wheel.

Underneath, the bit hat clamps to the bed looks like this: A brass plug on the end of the clamp screw prevents the screw from graunching the side of the bed way. Nice and simple, works for me.

JimB

|

| Sam Longley 1 | 20/07/2021 16:33:18 |

| 965 forum posts 34 photos | I am not sure if this fits the bill but i have a brand new myford multi position stop model 1483 still in its original box for sale price £ 80-00 plus postage - It is quite heavy, PM me if interested. I am based in ESSEX Uk post code CM0 |

| brian jones 11 | 20/07/2021 17:06:48 |

| 347 forum posts 62 photos | Nice piece of work JB Im glad you put that brass plug in there, had me worried for a moment but you need a miller for that solution and auntie doreen is hors de combat till I complete a dozen other unfinished works it must be remembered that both the outer and apron side sheer faces are used to guide the saddle, great care needed |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in