Simple test to distinguish mild steel rod from silver steel rod.

| Andrew Tinsley | 16/04/2021 10:57:18 |

| 1817 forum posts 2 photos | My stock of silver steel and bright mild steel rod have become mixed. I have sorted out the lengths of silver steel (usually 330 mm long or so) Some of the other material has been sawn down and I really can't tell the difference by eye. I suppose I can mike up the diameters, which should sort out the high tolerance silver steel. I am just curious if there is another method? Regards, Andrew. |

| Emgee | 16/04/2021 11:02:31 |

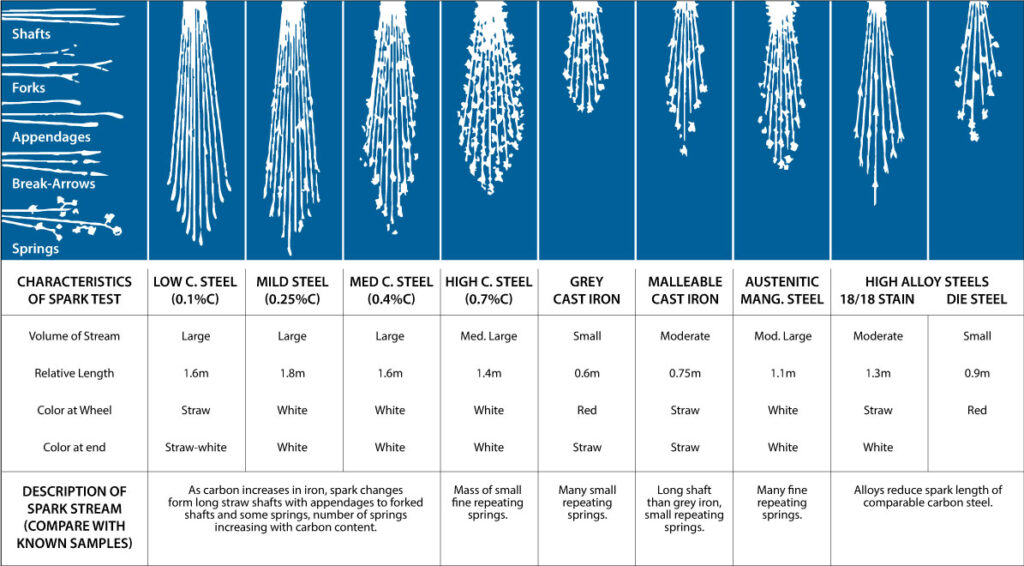

| 2610 forum posts 312 photos | Turning some and/or a spark test may reveal the silver steel. Emgee |

| Bo'sun | 16/04/2021 11:05:19 |

| 754 forum posts 2 photos | Hi Andrew, I think you might be able to tell by the colour of the sparks from a grinder, but can't remember which is which. Alternatively, look at the surface finish, with a magnifying glass if necessary. The silver steel should show grinding marks from centreless grinding. |

| Andrew Tinsley | 16/04/2021 11:08:34 |

| 1817 forum posts 2 photos | Thanks Emgee, I suppose turning the samples would be a good way. Not too sure about a spark test, I didn't think there was much difference between the two. Just my memory and I stand to be corrected! Andrew. |

| Emgee | 16/04/2021 11:35:31 |

| 2610 forum posts 312 photos | Andrew You could cut a short length off and harden in the usual way, file test should provide an answer. Emgee

|

| Mick B1 | 16/04/2021 11:42:36 |

| 2444 forum posts 139 photos | Posted by Bo'sun on 16/04/2021 11:05:19:

Hi Andrew, I think you might be able to tell by the colour of the sparks from a grinder, but can't remember which is which. Alternatively, look at the surface finish, with a magnifying glass if necessary. The silver steel should show grinding marks from centreless grinding. That's what I do. The difference between a drawn and ground finish is generally pretty obvious. I've come across PGMS, which would be a lot more difficult to distinguish, but I've only ever seen that in industrial situations - where it was worth paying for - never hobby. |

| Roderick Jenkins | 16/04/2021 11:45:50 |

2376 forum posts 800 photos | The spark test does work - best tested by comparing with 2 known specimens. Measurement is pretty good as well since most mild steel bars are a couple of thou under the nominal diameter whereas silver steel is usually less than half a thou under. HTH, Rod |

| Andrew Tinsley | 16/04/2021 11:50:35 |

| 1817 forum posts 2 photos | Hello Mick, A good magnifying glass should have been the obvious answer! It just never crossed my mind. Hardening and then filing is proof positive, but I wanted a less involved answer (being lazy!).Mind you if I was going to use it for a complex turning job, then I would go the hardening route. Too lazy to do the job twice if I got the wrong material! Thanks everyone for putting me straight, Andrew. |

| SillyOldDuffer | 16/04/2021 11:52:02 |

| 10668 forum posts 2415 photos | Spark test, plenty of advice on the web, like this example:

Dave

|

| Ady1 | 16/04/2021 13:34:40 |

6137 forum posts 893 photos | Silver steel makes a different much higher noise than ordinary metal, a different "ting" |

| Mike Poole | 16/04/2021 14:10:32 |

3676 forum posts 82 photos | The ground finish is an easy check, if it’s not ground it’s not silver steel, the ground finish does not definitively make it silver steel as some stainless and PGMS can easily be mistaken for SS, if it hardens and measures very close to size then it is a very good chance it is SS, that will leave the problem of what the rest is. When stubs were a major SS producer they stamped their name on rods that were big enough but there are plenty of manufacturers who don’t. It’s worth having a paint or notch or dot code to Mark stuff up when it comes into the shop but if you are like me you will have a pile of unknown stuff that looked handy which can sometimes be a win and sometimes not worth the trouble. Mike |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Takes a bit of practice. Grind and watch known examples of various steels to see the difference before tackling an unknown metal. Silver steel sparkles more than mild-steel, but the difference is easier to see by comparison.

Takes a bit of practice. Grind and watch known examples of various steels to see the difference before tackling an unknown metal. Silver steel sparkles more than mild-steel, but the difference is easier to see by comparison.

Register

Register Log-in

Log-in