Emco 8.6 - Tumble Reverse Position for Screwcutting?

Question Regarding Correct Position of Tumble Reverse for Screwcutting

| Avery Neaman | 03/09/2020 16:21:56 |

| 4 forum posts | New Member here, my name is Avery, Hello. I reside in the US, Los Angeles. I have an Emco 8.6. Restoring it now. Can't find any serial number on the old girl, so I don't know how old she is. So sorry to bother you good folks with such a simple question. I don't have the "Operator's Manual" for this lathe. As to Screwcutting, which position should the tumble reverse be in for cutting threads? This lathe has an visual indication/guidance/reminder cast into the change gear case door. It shows when the tumble reverse is in the up position, less screw threads result. In the down position, more threads result. I've tested this, and it is in fact the case. No need to reply and question this, please. The challenge I'm facing is that the screwcutting chart inside of the change gear case, does not indicate which position the tumble reverse lever should be placed in, in order to cut screw threads based on the chart? For information, the chart has an interesting indication: It shows an arrow pointing to the right and "0.12 mm/U". Then there is an arrow pointing left, and "0.05 mm/U" An answer to my question, or any relevant information, would be greatly valued. Does anyone have an "Operator's Manual" that they could refer me to (or possibly forward a copy of)? Finally, do any of you good folks know where I should find the serial number on her? She has the four speed Milling Head attached to the bed ways frame. I don't see any nameplate anywhere, except on the motor itself. Thanks a million! Avery

|

| Thor 🇳🇴 | 03/09/2020 18:24:35 |

1766 forum posts 46 photos | Hi Avery, Welcome to the forum. There is a spare parts list here. You may be able to buy a manual from lathes.co.uk. Thor Edited By Thor on 03/09/2020 18:25:56 |

| JasonB | 03/09/2020 18:28:30 |

25215 forum posts 3105 photos 1 articles | Have you tried the Emco user group? used to be a yahoo one but that has changed to groups.io now. Unfortunately I did not have the change gears for my 8.6 so never tried it and the manual went with the machien when I sold it. |

| Oldiron | 03/09/2020 19:30:33 |

| 1193 forum posts 59 photos | Hi Avery. Try here >>> EMCO parts lists available so they may also have the manuals. Always worth an email to the supplier with questions. UK I know but there may be a US equivalent site. regards |

| JohnF | 03/09/2020 20:32:31 |

1243 forum posts 202 photos | Hi Avery, there is an Emco section on groups.io but seems to be little regarding the 8 series but I would suggest you join and ask the question. However if you terminology is the same as this side of the pond the tumbler reverse normally only changes the direction of travel of the carriage and thus whether you are cutting left or right hand threads. There is more detail but thats the basics. John |

| Versaboss | 03/09/2020 22:58:40 |

| 512 forum posts 77 photos | I'm quite sure what Avery mentions is the push-pull knob which changes between the coarse (0.12 mm) and the fine (0-05 mm) feed . Many years ago I owned a Emcomat 8.6, and I am absolutely sure the tumbler gear didn't change the pitch of a thread. I would be interested to see that >>visual indication/guidance/reminder cast into the change gear case door. It shows when the tumble reverse is in the up position, less screw threads result.<< Regards, |

| Avery Neaman | 04/09/2020 00:14:20 |

| 4 forum posts | Thanks to all for every cogent and germane reply to my novice question. Everyone is so generous with their time and information! It seems like the EMCO yahoo group has now taking place at groups.io, indeed. Furthermore, the group is called EMCOV10lathe. The group is not limited to the V10 machines, but rather is for all EMCO machines. That is my initial take, but don't take is as any gospel, please. The EMCOMACHINETOOLS.CO.UK website refers to having operational manuals, oh boy Han ("Versaboss" So as Hans mentions, this gives the lathe more capability (rather ingenious I think) because when simply using the change gears to drive the power feed, the operator has at his or her disposal, two feed speeds, as Hans refers to them as "coarse" and "fine." This being then coupled with the change in direction (that's why it's called "Tumble REVERSE, afterall), and the number of screw pitches that can be cut with this "vocational" machine is doubled! The practicality of that is not understood by me, but initially, I think that the pitches generated with the lever in the "alternative" position would be of no value, unless they coincidentally happen to be Module or Diametral!! But this doesn't answer my question: Is the tumble reverse lever supposed to be in the up or down ("coarse" or "fine" If I had the manual (which emcomachinetoos.co.uk apparently doesn't carry, it might answer my question. So without that, I'll just have to knuckle under and get some experience. I'll cut some test screw pitches with the tumble reverse in the up position, and then the down position, and simply count the threads! Thanks again to all, you gentlemen are valued and appreciated! You gentlemen are kind. Avery

|

| Michael Gilligan | 04/09/2020 06:53:05 |

23121 forum posts 1360 photos | Here’s a German version, Avery : **LINK** https://dokumen.tips/documents/emcomat-84-86-manual.html .... probably not convenient, but worth a look. MichaelG. . Edit: German PDF freely downloadable here: Edited By Michael Gilligan on 04/09/2020 06:57:49 |

| JasonB | 04/09/2020 07:09:56 |

25215 forum posts 3105 photos 1 articles | As Hans says the tumbler reverse with it's lever at the front is just that a reverse for the leadscrew and does not alter feed rate. Up or down will move the carrage in the direction you want to cut and then return it to take the next cut. There is also a push/pull knob sticking out the left side of the headstock that changes feed rate fron high to low as indicated by teh coarse and fine zigzag markings., I would expect that some screw pitched need this on one position and some in the other. EDIT having looked at the manual Michael posted I think it stays in the pushed in position for all thread cutting. When I had my 8.6 the Group answered queries I had about it despite being mainly aimed at the larger machines, should still be photos and other documents in the files and photo sections of the site showing series 7 and 8 machines. Edited By JasonB on 04/09/2020 07:24:57 |

| Avery Neaman | 04/09/2020 16:34:20 |

| 4 forum posts | Thank you all for your replies, answers and information. This has been so helpful. I think Hans had rightfully asked for pictures, but I'm having a bit of challenge finding out how to add pictures that are saved on my computer's hard drive, or my iPhone, I'll work on that next. Sorry. Note the screwcutting chart (a little out of focus, sorry). If you zoom in you can clearly see the indications of the two feed speeds (0.12 mm/U and 0.05 mm/U). It shows a right arrow next to the 0.12 mm/U and a left arrow next to the 0.05 mm/U. Here is a summary of what I've empirically observed: Tumble Reverse Lever Down; Motor Forward => Carriage feeds to right at faster speed, I assume this is the "Coarse" (0.12 mm/U) speed that Hans refers to. Tumble Reverse Lever Up; Motor Forward => Carriage feeds to left at slower speed, I assume this is the "Fine" (0.05 mm/U) speed that Hans refers to. I also noted that the spring-loaded "pull knob" which is in the center of the Tumble Reverse lever, does not change speeds from "Coarse" to "Fine." It simply is a safety interlock such that the knob must be pulled out before the lever can be changed from any position to another. You certainly don't want to accidentally move the lever with an inadvertent hand or arm motion, when the lathe is operating. That would be the end of the change gears and maybe other items. So in summary, the Tumble Reverse mechanism of this EMCO 8.6 is such that when you operate the Tumble Reverse lever, you are changing not only the direction of the feed, but also the carriage feed speed. Not reading German, I'm unable to "read up" on how EMCO designed the Tumble Reverse mechanism to work (changing both direction and speed, both at once by re-positioning the lever). But again, by observation, that is how the machine works. And finally, I assume that since screw cutting is always done at the slowest carriage feed rate, that with this particular tumble reverse design, the Tumble Reverse lever is always in the UP position when cutting threads. Thanks to all for your input!

Avery

|

| Thor 🇳🇴 | 04/09/2020 16:40:51 |

1766 forum posts 46 photos | Hi Avery, Here is an explanation on how to create Albums and post photos. Thor |

| JasonB | 04/09/2020 17:01:33 |

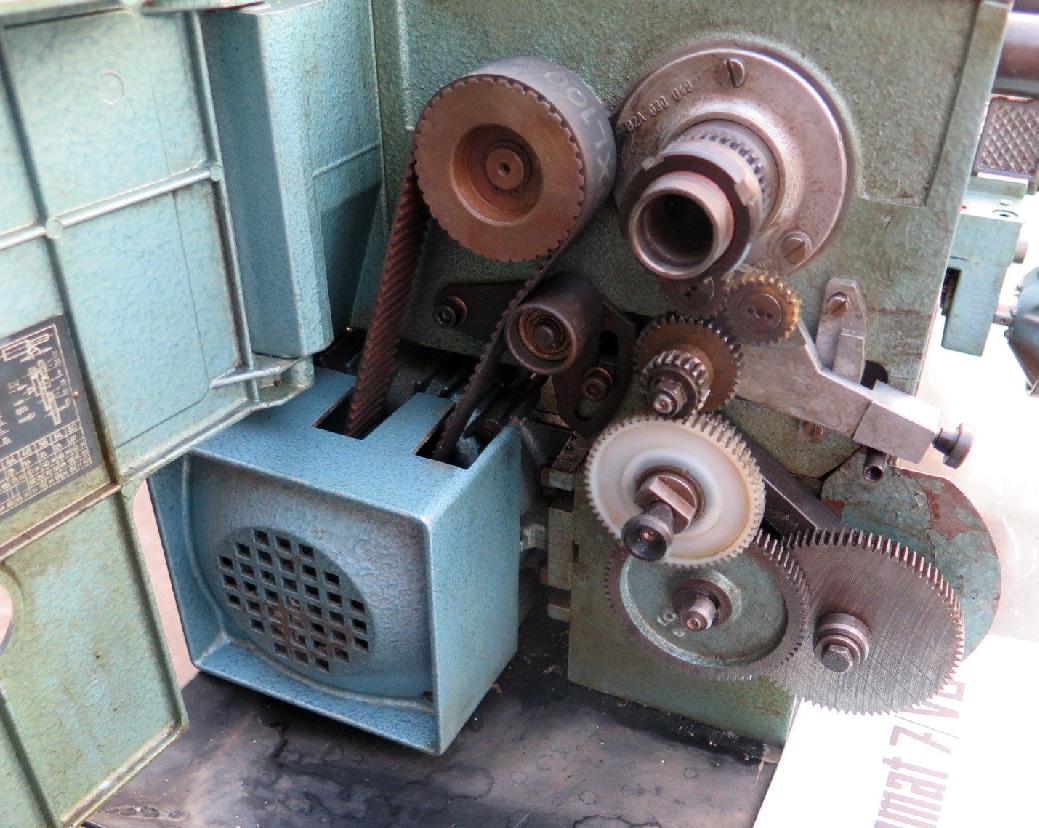

25215 forum posts 3105 photos 1 articles | Avery, you must have a machine that is not like any of the others if you look at the end of the machine where the push/pull lever is you will see a coarse and fine zig zag which represents coarse or fine feeds. The tumbler only uses one or both of two gears that are the same tooth count so only changes direction not speed. Turn the chuck slowly by hand when pulling/pushing the lever as it may not drop straight into the different gear (no syncro) and will just spring back

Phpoto below shows the two light coloured gears with a green blob on teh push/pull knob, moving this will engage one of the pair of gears marked ( or ) in green so changing the feed rate. The two small white gears on the tumbler are the same size so don't affect speeds. Images on page 32 of Michael's pdf link show the tumbler lever in the DOWN position which would be correct for the usual right hand threads. The chart in the PDF is the same as the inside cover, top left of that chart has an image of a turning tool and the two arrows with 0.12 and 0.05 are under that so apply to FEED RATES. To the left of that there is a representation of a screw thread, the gear train below that is the THREAD CUTTING one.

Edited By JasonB on 04/09/2020 17:11:57 |

| Pete Rimmer | 04/09/2020 17:10:22 |

| 1486 forum posts 105 photos | The tumbler reverse only changes the direction of the leadscrew, so it will cut a left hand or right hand thread as required. Most threads are right hand. If the spindle and leadscrew are turning the same direction you'll cut a right hand thread. If they are turning opposite directions you'll cut a left hand thread. |

| Michael Gilligan | 04/09/2020 23:06:55 |

23121 forum posts 1360 photos | Posted by Avery Neaman on 04/09/2020 16:34:20:

[…] or my iPhone […] Not reading German, I'm unable to "read up" on how EMCO designed the Tumble Reverse mechanism to work (changing both direction and speed, both at once by re-positioning the lever). But again, by observation, that is how the machine works.

. If you have the patience ... it is possible to translate that PDF using the iPhone [ it’s not set to allow selection of the text, but we can work around that ]

I have just tried it on the first section of page 19, using my iPad [quote] [/quote] Not exactly ‘vernacular’ translation, but a pretty good effort ! MichaelG. . http://aitube.doukantv.com/media/html/home/5.html |

| Versaboss | 05/09/2020 00:25:43 |

| 512 forum posts 77 photos | Reading that stuss above from Avery, (hi A. use that translator!*), I'm beginning to loose my will to live... - the knob on the tumbler reverse lever is not the one which changes the feed speeds!!! This is on the side of the cover, see Jason's picture. - I am old and cannot always trust my memory, but I am quite sure that for screwcutting that double gear is always removed, or in other words: a screwcutting setup never transmits over that double gear. The picture on p. 28 of the manual above shows the setup for normal turning., and the feeds 0.12 and 0.05 mm work only in that setup! Jason displayed all very clearly in the piccies above, so I retreat now... * ok, I do it for you: a nice word I found is balderdash... Regards |

| Avery Neaman | 05/09/2020 14:54:01 |

| 4 forum posts | Thanks to all here, this has just helped me realize that my EMCO 8.6 is missing the "push-pull" knob for changing the feed speeds. The photos provided are excellent. The explanations spectacular and so well written! I appreciate all this. I shall "experiment" with making a temporary knob, and get to know this part of "my baby" a little better. I'll also try to create an "album" so I can then begin attaching pictures to my posts. FOR THE TIME BEING, gentlemen, I do not need you assistance any longer (but I bet I will in the not to distant future!), so thank you all very much, you've been most professional and courteous, thorough, and thoughtful! Avery

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

has my partial answer to my question: EMCO used two different size tumble reverse gears, thus when both are interacting in the changegear gear train (with the lever in the up position), the leadscrew speed is indeed faster. When in the down position, only the smaller gear is in the train, and the leadscrew is slower.

has my partial answer to my question: EMCO used two different size tumble reverse gears, thus when both are interacting in the changegear gear train (with the lever in the up position), the leadscrew speed is indeed faster. When in the down position, only the smaller gear is in the train, and the leadscrew is slower.

Register

Register Log-in

Log-in