Machining a curve

| Jed Martens | 16/12/2019 15:47:45 |

85 forum posts 54 photos | I'm trying to figure out how to make the part below. It's a "bell" that is used for crimping crown caps onto glass bottles. Most of it is simple turning and threading, but I'm not sure how to tackle the "bell mouth". My best guess so far so to successively approximate the curve using the compound, and then use some kind of abrasive to blend it together. I don't think the exact nature of the curve is critical, just that it is smooth and gradual, and that the minimum internal diameter is spot on. Is there a better way? |

| Tony Pratt 1 | 16/12/2019 15:55:24 |

| 2319 forum posts 13 photos | With care you can probably do it with the top slide & cut an angle then blend with a decent half round file. Tony |

| Gary Wooding | 16/12/2019 15:56:56 |

| 1074 forum posts 290 photos | I'd approximate it with a few tangents, 4 or 5 should do it, then blend them with a file. |

| Jed Martens | 16/12/2019 15:58:15 |

85 forum posts 54 photos | Ok, done. Thanks for the prompt feedback. |

| Jeff Dayman | 16/12/2019 16:04:22 |

| 2356 forum posts 47 photos | You could also use a full size filed sheetmetal template clamped to the bed of the lathe as a guide, with a follower "tooth" or stylus on the compound. The cuts are made as you would with X Y movements to do the cuts, but by aligning the tooth to a guide rather than by using the dials to approximate the curve as you mentioned. Easiest way to make such a template is to print out your section from CAD, check the print is to scale, then use spray glue or glue stick to attach the paper to the sheetmetal. Cut and file the sheetmetal to your printed line. This method can yield very accurate curves. |

| Neil Wyatt | 16/12/2019 16:23:25 |

19226 forum posts 749 photos 86 articles | I'd do it by eye, but cutting outwards so that the critical inner diameter was correct. Surely a bottle opener rather than a closer is going to be more useful this Christmas? Neil |

| JasonB | 16/12/2019 16:26:40 |

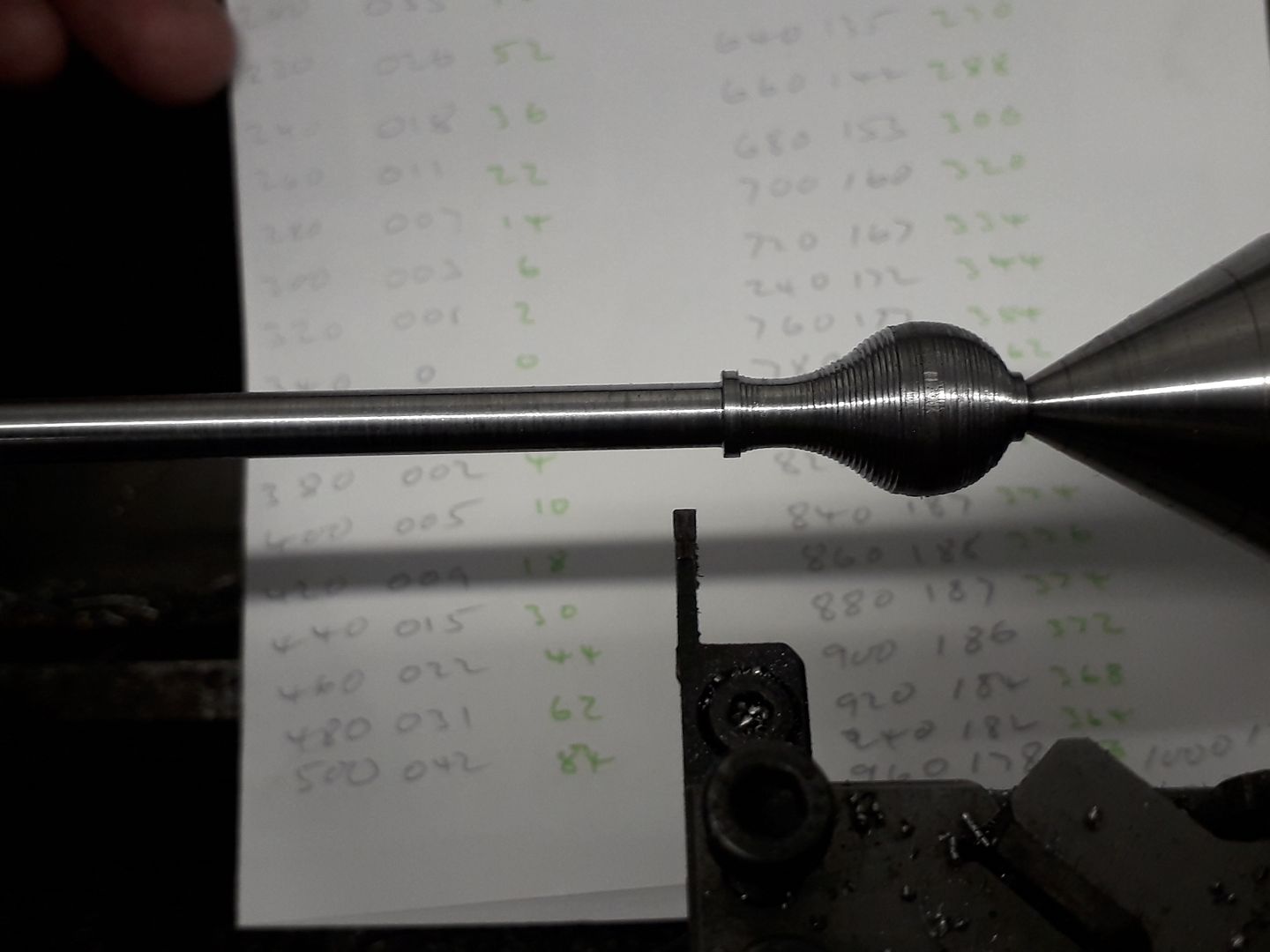

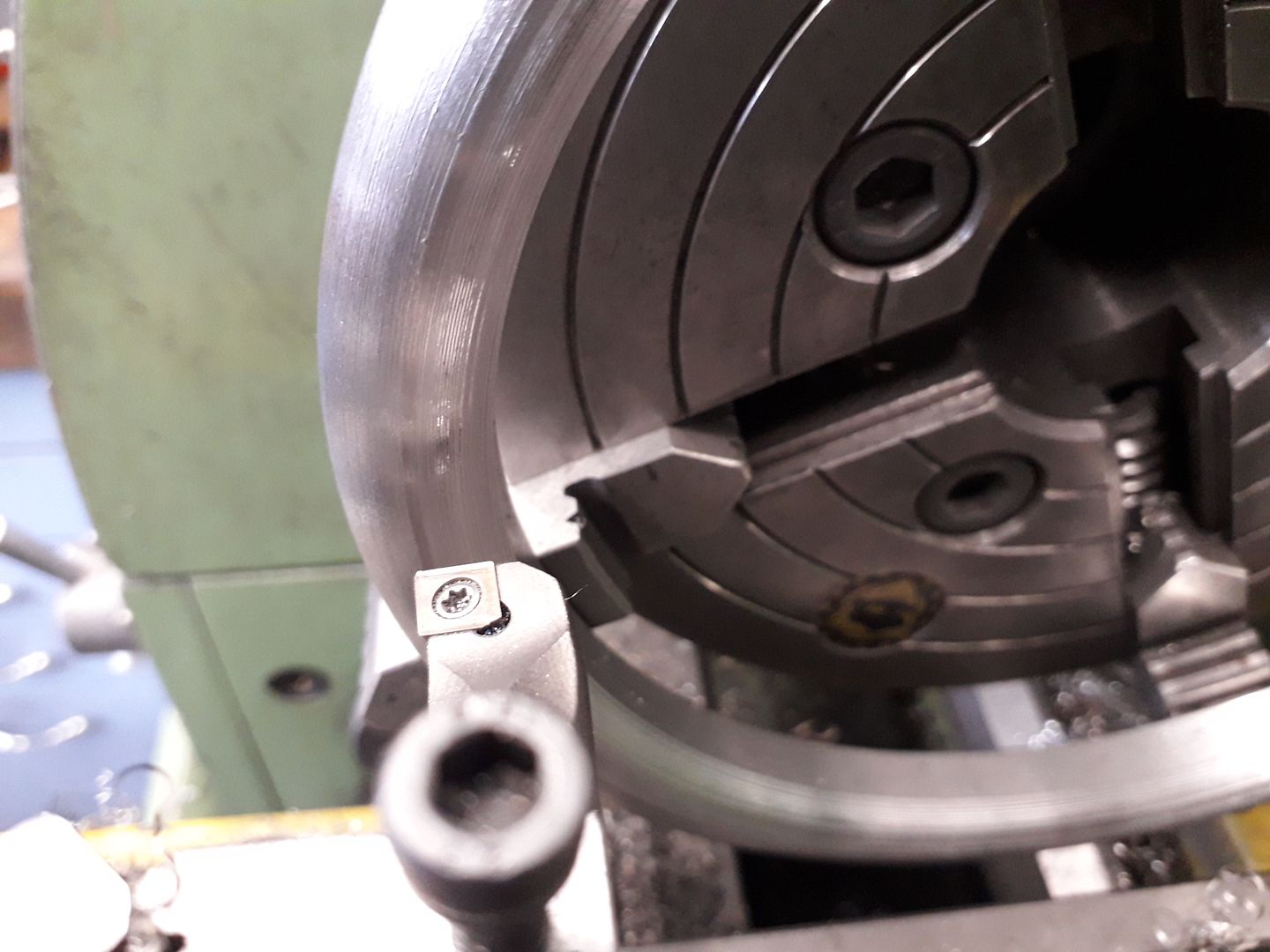

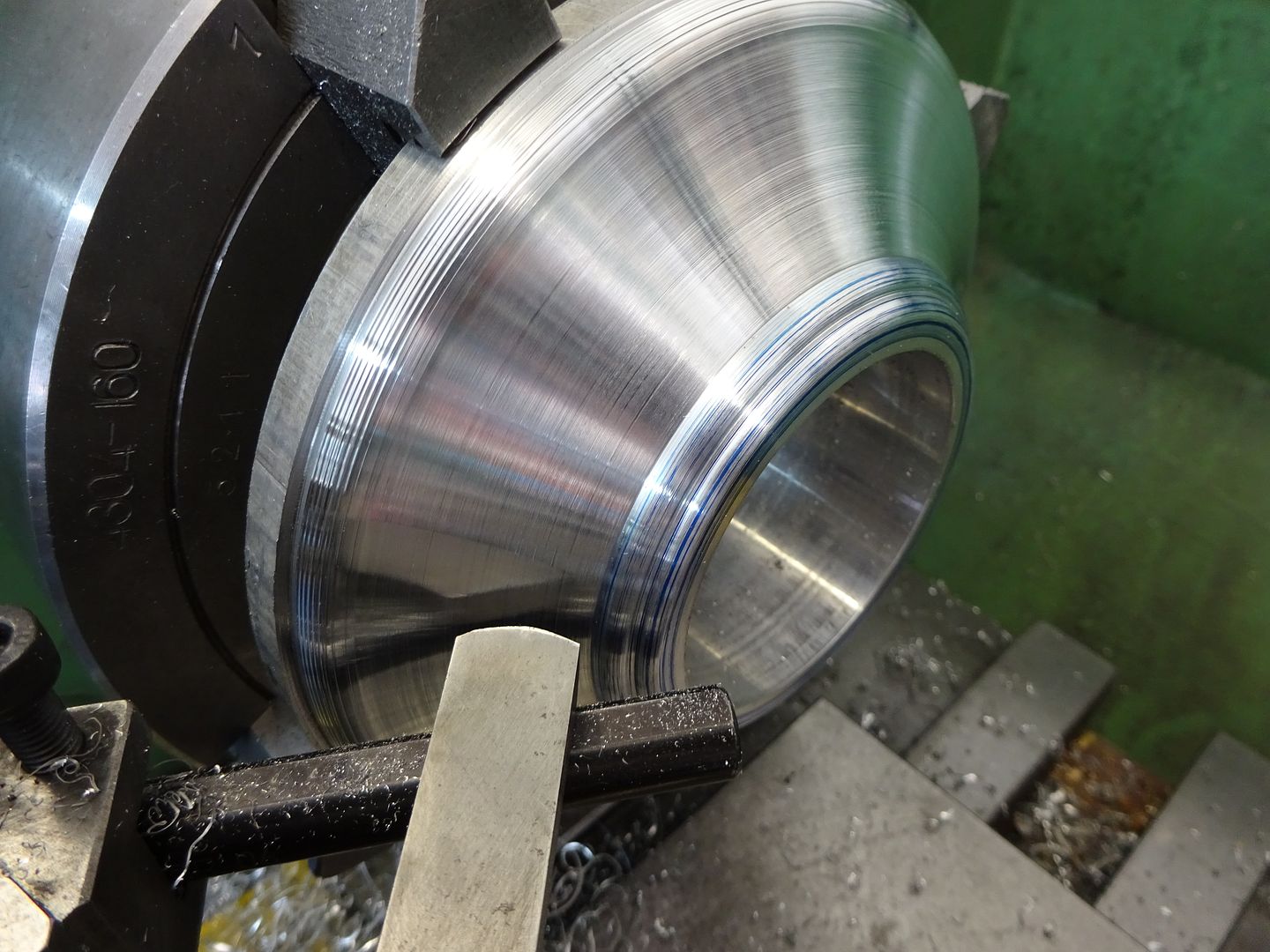

25215 forum posts 3105 photos 1 articles | I'd draw a series of lines on your CAD model at regular intervals and then measure their lengths. You then have a set of co-ordinates to cut to moving the topslide out in equal amounts and the cross slide adjusted to the measured lengths. This will give the profile ias a series of steps that can then be blended, in this case internal are best done with a hand graver and external can be done with files. This sort of thing

Bit hard to see the 10thou steps on this one

And blended

Edited By JasonB on 16/12/2019 16:28:08 |

| Emgee | 16/12/2019 19:04:01 |

| 2610 forum posts 312 photos | Not seen as such a challenge but G02 and G03 work best for me. Emgee |

| Andrew Johnston | 16/12/2019 19:30:48 |

7061 forum posts 719 photos | Don't see why it needs to be a curve. A plain taper and final parallel section would work just as well. Andrew |

| BW | 18/12/2019 06:41:20 |

| 249 forum posts 40 photos | Variation on the above answers. Not intended as a definitive answer I ask because am not sure. Could you rough it out as suggested and then use a form tool ? If too much chatter then I have read that chatter could be reduced if run the lathe backwards and tool mounted on back toolpost ? Variation on form tool - curved piece of wood with sandpaper wrapped around it ?

Bill

Bill |

| not done it yet | 18/12/2019 08:57:06 |

| 7517 forum posts 20 photos | Thread started at 15:47:45. “Ok, done. Thanks for the prompt feedback.” That post was made less than 10 1/2 minutes later at 15:58:15! So, not a difficult solution? Doing it must have been a simple operation. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in