Myford ML7 tailstock bore, and threading the barrel to fit a chuck

| Mike Donnerstag | 14/07/2019 10:55:31 |

231 forum posts 53 photos | I have a Myford Super 7 with the Super 7 tailstock and understand that the ML7 tailstock fits on the Super 7 bed. I wondered whether anyone can tell me the bore size for an ML7 tailstock as I'm looking into the possibility of gripping long 'bar stock' (actually violin bows) for drilling the ends. As the bow has a gentle bend, it must be held still while drilled to avoid damage. Also, to allow this to happen, there would need to be a thread and register on the tailstock barrel to fit a chuck, similar to the headstock spindle . Has anyone ever done this? Is it even possible, as in, is there enough metal in the tailstock barrel? |

| roy entwistle | 14/07/2019 11:01:45 |

| 1716 forum posts | No 2 morse taper so actual bore will be about 9/16 inch Roy |

| Mike Donnerstag | 14/07/2019 11:10:42 |

231 forum posts 53 photos | Great - that bore will definitely work for bows up to cello size, and probably most bass bows. Looking at the Super 7 headstock barrel, it seems to be big enough to accept the headstock thread, but I'd need to fit a separate 'register' so that a chuck can be threaded on. Once again, has anyone done this? I know it is possible to buy MT2 spindles with the headstock thread, but I would need to use the bore of the tailstock, so using the taper doesn't get me anywhere. |

| Brian Oldford | 14/07/2019 11:47:31 |

686 forum posts 18 photos | Methinks a specially made tailstock barrel might be your answer. Drilled through as large as possible and made with an enlarged end to accept a standard Myford chuck thread. You have the machine there to make such an item. |

| Mike Donnerstag | 14/07/2019 11:54:55 |

231 forum posts 53 photos | Brian: I like that idea. I assume that, to keep the whole drilling setup easy to attach and remove from the lathe, that it would be best to get a second tailstock casting, i.e. the hollow ML7 one? Or, would the Super 7 tailstock casting work? Also, do you know the thread of the barrel? Is it multi-start? |

| Mike Donnerstag | 14/07/2019 11:55:19 |

231 forum posts 53 photos | Also, do you know the length of the standard ML7 tailstock barrel? |

| Bazyle | 14/07/2019 12:16:40 |

6956 forum posts 229 photos | Do you need the bow to go though the chuck and down the inside of the chuck and through the bore of the tailstock barrel? As you are not using the morse taper it might be easier to use a plain bar or tube, drill a nice clearance hole then prepare for the chuck. You might make a plastic of wooden clamp instead of a chuck to avoid bruising. Again it might be easier to take off the tailstock, run the saddle down to the end and make a wooden clamp arrangement to mount on that. |

| Mike Donnerstag | 14/07/2019 12:20:38 |

231 forum posts 53 photos | Interesting, though I like the idea of using a self-centring four-jaw chuck to grip the octagon concentrically (at least within a few thou). Bruising the wood shouldn't be too much of a problem as it shouldn't need to be held tight enough to bruise, and Pernambuco wood is very hard and dense. The reason I like the idea of the tailstock is that the alignment with the headstock can be easily set and relied upon. |

| Enough! | 14/07/2019 19:12:17 |

| 1719 forum posts 1 photos | Posted by Mike Donnerstag on 14/07/2019 11:54:55:

it would be best to get a second tailstock casting, i.e. the hollow ML7 one? Or, would the Super 7 tailstock casting work?

Check the cost first. Or perhaps you're seriously rich (based on my experience to replace a broken one some years ago ..... I ended up doing a repair).

|

| peak4 | 14/07/2019 20:17:50 |

2207 forum posts 210 photos | As an alternative and maybe cheaper/simpler method, how about a metal block bolted to the slots on the cross slide, and machined to hold the bow. Bill |

| Mike Donnerstag | 15/07/2019 10:48:06 |

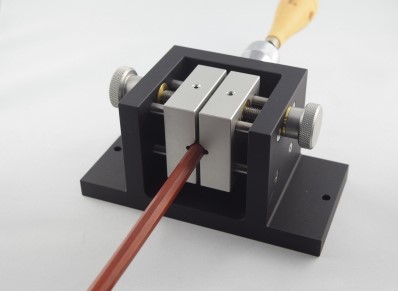

231 forum posts 53 photos | Bandersnatch: I can't say I'm seriously rich, though the £100-odd ML7 headstocks seem to be going for on eBay looks reasonable if it's a solution to the stick-drilling problem. peak4: This was my original idea, though I expect lining everything up would take some time, whereas a tailstock setup would simply slide on and off and I expect its alignment with the spindle axis would be more reliable. A commercial tool, which is basically only a self-centring vice and drill guides, costs £600-ish and has to be imported from America. It's called the Bow Badger:

And below, in use:

I'm sure there is a better and much cheaper way to do this! Edited By Mike Donnerstag on 15/07/2019 10:50:04 |

| Robert Atkinson 2 | 15/07/2019 13:09:36 |

1891 forum posts 37 photos | How about a ER32 collet chuck on the tailstock? They will grip a round or hexagonal bow end quite well. You could even make a split nylon sleeve with a hex centre hole if you needed to grip tight without marking. Possible an adaptor tube to slip over the outside of the tailstock barrel and carry the chuck to maintain the full bore clearance.

Robert G8RPI. |

| Mike Donnerstag | 15/07/2019 13:27:29 |

231 forum posts 53 photos | It's a good idea, in fact I have an ER40 collet chuck with a full set of collets, however I would prefer the self-centring four jaw chuck that I also have because it grips on the flats rather than the corners of the octagon. A split nylon sleeve with an octagon (not hex) centre seems like a solution, though there are so many variations on bow stick size that I would have to make several. |

| Mike Donnerstag | 15/07/2019 13:27:56 |

231 forum posts 53 photos | Thinking about it, I probably should have renamed this post 'Myford Hollow Tailstock Drilling Fixture'. |

| Michael Gilligan | 15/07/2019 15:42:52 |

23121 forum posts 1360 photos | Given the intended use, Mike ... I think you could get away with a slip-on/clamp-on mounting for the chuck backplate, instead of cutting a thread on the barrel. MichaelG. |

| JasonB | 15/07/2019 16:27:23 |

25215 forum posts 3105 photos 1 articles | Am I missing something as I can't see how you will be able to advance the tailstock mounted chuck towards a driven drill bit if the bow is poked down the tailstock barrel and out the back so no screw can be fitted. Or will you just slide the tailstock or it's barrel by hand? |

| mark costello 1 | 15/07/2019 17:25:34 |

800 forum posts 16 photos | Does ER 40 have a square collet available? Or could You make a square adapter to suit? Edited By mark costello 1 on 15/07/2019 17:26:16 |

| Howard Lewis | 15/07/2019 17:45:27 |

| 7227 forum posts 21 photos | As far as I know, only 5C collets can be obtained for square or hexagonal stock. I wanted some ER32 collets to hold MT shank reamers. So I made my own versions. No doubt it would be possible to make something similar for square material. Some time ago there was an article on making accessories that would fit in a round collet, or three jaw chuck, to hold square stock. Cannot recall all the details, but the finished article, was actually the raw material machined and then cut into four pieces to act as the four faces of a square collet.. No doubt, some kind soul will say which Issue of MEW it was in? Howard |

| DC31k | 15/07/2019 17:47:19 |

| 1186 forum posts 11 photos | Posted by JasonB on 15/07/2019 16:27:23:

Am I missing something as I can't see how you will be able to advance the tailstock mounted chuck towards a driven drill bit if the bow is poked down the tailstock barrel and out the back so no screw can be fitted. ML7 tailstock is hollow. Hence why it is not self-ejecting unlike Super 7 which is not and which is. 9/16" bar goes through. 5/8" bar does not. Barrel diameter is 1". Make thick washer ID 1", OD 1 1/8". Loctite ID to barrel. Loctite OD to chuck register. If force of drilling overcomes loctite, use MIG welder. |

| JasonB | 15/07/2019 18:22:56 |

25215 forum posts 3105 photos 1 articles | Thank's DC31K, I can see now that it is threaded externally so no leadscrew to get in the way of the bow. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in