Micro drilling

Drilling very small holes in brass

| Roger Hulett | 10/10/2018 14:50:39 |

| 131 forum posts 9 photos | I need to drill a wire gauge hole in a piece of brass rod. I have faced off the rod and polished with 300 emery to ensure there are no blemishes. How do I accurately "spot" the rod to ensure the drill bit drills true,and are there any other tips around. |

| Roger B | 10/10/2018 14:57:42 |

244 forum posts 105 photos | How big and how deep? I have got down to 0.2mm using a 0.5mm centre drill for spotting. |

| JasonB | 10/10/2018 15:09:10 |

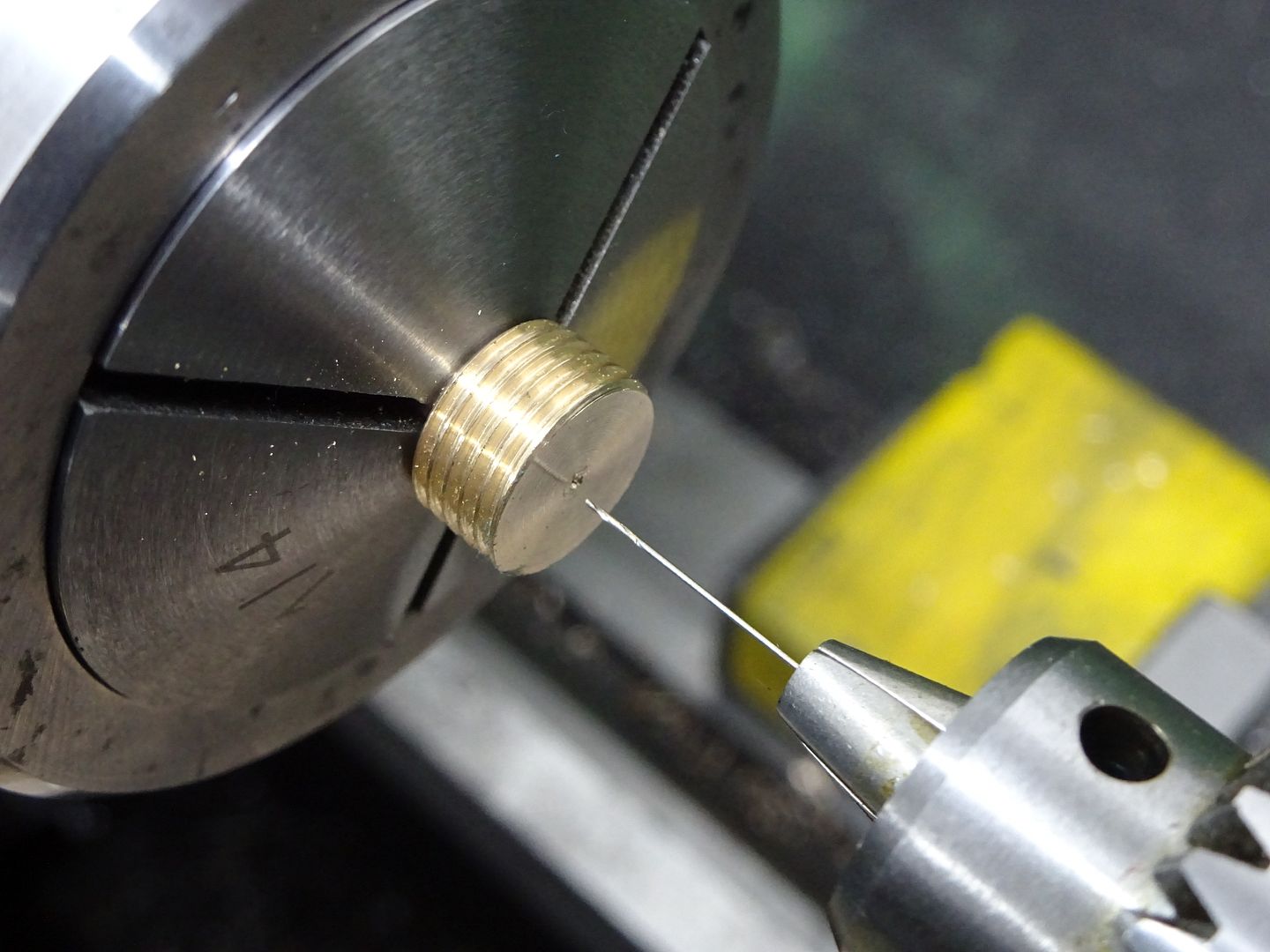

25215 forum posts 3105 photos 1 articles | What wire gauge as 10swg is not exactly small? I drilled 0.3mm the other week, faced, small spot drill and then in with the 0.3mm bit.

|

| not done it yet | 10/10/2018 15:43:24 |

| 7517 forum posts 20 photos | Is the hole to be in the centre of the rod - or somewhere else? |

| Roger Hulett | 17/10/2018 14:14:18 |

| 131 forum posts 9 photos | Yes,the hole is in the centre of the rod,similar to the set up of JasonB's photo. I don't seem able to get the spot drill to form a sharp enough recess to stop my micro drill wandering all over the place. |

| Roger Hulett | 17/10/2018 14:16:22 |

| 131 forum posts 9 photos | Having reread Roger B's post I think I need a smaller centre drill. |

| Martin Kyte | 17/10/2018 14:33:57 |

3445 forum posts 62 photos | You can get centre drills that are really small. ASA00000 has a 0.25mm pilot. However you should find that micro drills will go right down a small Jacobs chuck so you only need a couple of mm protruding. It's amazing how stiff this makes them. Usually stiff enough to form their own centre. Once this has been done the drill can be withdrawn sufficiently to drill to required depth. regards Martin |

| Roger B | 17/10/2018 15:09:38 |

244 forum posts 105 photos | Have you checked the points of your drills with a magnifying glass? The first cheap micro drills I bought had non existent points. The Titex ones I am now using are excellent. |

| Rod Renshaw | 17/10/2018 17:31:27 |

| 438 forum posts 2 photos | Hi all Centre drills are not ideal for spotting holes and they get less ideal as the hole gets smaller ( for example, the pilot gets very fragile.) Better to use spotting drills - made for the purpose, with much stronger points and they are available in a wide range of sizes down to very small. For example, "Kyocera" , a Japanese company, list them as small as 0.005" diameter (on an eighth-inch shank) and since you only need to use the point these would probably enable one to make a spot of only about 0.001" diameter if that was needed. Need good bearings in the drilling machine though! Google "Micro spotting drills" Not sure about easy availability but someone will stock small spotting drills in the UK. Rod

|

| JasonB | 17/10/2018 18:28:35 |

25215 forum posts 3105 photos 1 articles | I tend to use the Americam Keo brand spotting drills, 1/8" one started that 0.3mm drill in the pic above OK. They have a smaller "flat" than other makes. Keo in the front. I only use Ctr drills where the 60deg seat is needed. |

| Sam Stones | 17/10/2018 21:58:44 |

922 forum posts 332 photos | May be a bit late in the day Roger but ... I'd use the tool post instead of the tail stock chuck, while shaping a HSS tool bit with very acute ‘clearance’ angles. Alternatively, grind off half a (scrap) drill and fit that into the tool post. I've never used a graver, but that could produce the necessary conical concavity. Sam |

| Tim Chambers | 18/10/2018 00:15:25 |

| 89 forum posts 33 photos | This is an alternative way; |

| Michael Gilligan | 18/10/2018 08:30:21 |

23121 forum posts 1360 photos | Posted by Sam Stones on 17/10/2018 21:58:44:

I've never used a graver, but that could produce the necessary conical concavity. . Very simple process ... See the short sequence starting at 1min 30sec, here: **LINK** https://m.youtube.com/watch?v=4jTKNLjLrNM They're demonstrating carbide gravers, but a good steel one is adequate. MichaelG. |

| Michael Gilligan | 18/10/2018 08:37:26 |

23121 forum posts 1360 photos | Posted by Tim Chambers on 18/10/2018 00:15:25:

This is an alternative way; . Thanks for that link, Tim MichaelG. . I see that the price of the plan has increased somewhat

|

| Robin | 18/10/2018 14:03:12 |

678 forum posts | Posted by JasonB on 10/10/2018 15:09:10:

What wire gauge as 10swg is not exactly small? I drilled 0.3mm the other week, faced, small spot drill and then in with the 0.3mm bit.

That looks so far out it isn't true (as they say). Perhaps it is the camera angle or something |

| Sam Stones | 18/10/2018 21:49:46 |

922 forum posts 332 photos | Another gem of yours Michael! That's just how I imagined. Where do you find them? Sam A great link too Tim. Thank you. |

| Michael Gilligan | 18/10/2018 22:46:18 |

23121 forum posts 1360 photos | Posted by Sam Stones on 18/10/2018 21:49:46:

Where do you find them? . 'Eternal Tools' is a regular advertiser in the Horological Journal and I just followed my nose one day. It's a nice little demo, so I remembered it. MichaelG. |

| Roger Hulett | 19/10/2018 16:36:30 |

| 131 forum posts 9 photos | Thankyou everyone, problem now fixed. I followed Martin Kyte's instruction re spotting,worked perfectly. trued up the point on the micro drill,ensured that there was no play on the brass rod and bingo,a nice clean hole. Thanks everyone. |

| Sam Stones | 19/10/2018 21:02:03 |

922 forum posts 332 photos | Although largely intuitive to many of us, it is worth mentioning in this context (and for lathe work in general), that the stiffness (resistance to bending) of a round bar, projecting from a chuck (cantilever style) is nonlinear in relation to both its length and its diameter. Although more complex when considering for example a fluted drill, the stiffness of a round bar relates to the cube of the length and the fourth power of the diameter. Put simply … Halving the length (overhang) increases the bending resistance by eight times. Halving the diameter decreases the bending resistance by sixteen. I'm pleased to know Roger, that your drilling project was a success. Regards, Sam |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in