Some beginner questions regarding knurling tools

| Sherlock | 06/08/2018 15:28:58 |

| 52 forum posts 11 photos |

Hi guys, sorry for another thread. There is so much I don't know, yet trying to get my head round, despite searching for the answers myself. So I am looking for a knurling tool for my Cowells ME90, The manufacturer sells their own single wheel type with 6mm shank that fit their tool holders. I have also seen these double wheel types on eBay that I thought might be a bit better and cheaper, but they have a 10mm shank which is too big for the tool holders I own.

Do I buy that and try file the shank down a few mm? (if my files can handle that type of steel?) Buy a tool holder that accepts slightly larger tooling? If I can I even do that, are all the dovetails on those tool posts universal and interchangeable? Just buy a single wheel type from Cowells?

or something else? Not really in a position to make my own just yet which I assume will be a good option down the road at some point when I have more experience and tools. Thanks Edited By Steve Sherlock on 06/08/2018 15:29:38 Edited By Steve Sherlock on 06/08/2018 15:30:30 |

| Frances IoM | 06/08/2018 15:57:52 |

| 1395 forum posts 30 photos | I'd be surprised if the single wheel is really suitable for a cowells unless uses a very small wheel - there was a two part article by Maral in MEW about 2 years ago that used a cutting rather than a compression technique - will need some special holder made + a knurling wheel without a bevel but Maral claims low force required Personally I would just concentrate on getting used to the lathe + grinding/sharpening the small HSS tools it really needs |

| Tim Stevens | 06/08/2018 16:04:48 |

1779 forum posts 1 photos | You may find that a small lathe with a small tool-holder is not up to the job of knurling steel. Light alloy, yes, brass, yes, but even then only with a narrow knurl and with patience. Cheers, Tim |

| Sherlock | 06/08/2018 16:08:28 |

| 52 forum posts 11 photos | Thanks Guys, I'm only working with brass and ally. I bought the lathe predominantly to make control knobs so would really love a knurling tool of some sort. I should add that I would probably only be using fine straight knurls any way.

|

| Vic | 06/08/2018 16:19:12 |

| 3453 forum posts 23 photos | With care I think one of the scissor type knurlers may work on your Lathe provided you can get one to fit your tool post. I made one to suit my lathe. |

| Vic | 06/08/2018 16:22:05 |

| 3453 forum posts 23 photos | How about this. It says: “Shank Size is 10 mm x 10 mm x 50 mm Long. This could easily be removed / modified if you needed a smaller shank” |

| John Haine | 06/08/2018 16:42:32 |

| 5563 forum posts 322 photos | This one claims to fit a Unimat so should work on the Cowells. I would not even try a single wheel knurl on a cowells. |

| Sherlock | 06/08/2018 16:45:35 |

| 52 forum posts 11 photos | Posted by Vic on 06/08/2018 16:22:05:

How about this. It says: “Shank Size is 10 mm x 10 mm x 50 mm Long. This could easily be removed / modified if you needed a smaller shank” Thanks Vic that's actually the one I linked to initially, but just realised the link wasn't working, Will I be able to bring that down with a hand file? |

| Sherlock | 06/08/2018 16:47:03 |

| 52 forum posts 11 photos | Posted by John Haine on 06/08/2018 16:42:32:

This one claims to fit a Unimat so should work on the Cowells. I would not even try a single wheel knurl on a cowells. Thanks John, Seems we are all finding the same one! |

| Vic | 06/08/2018 17:03:27 |

| 3453 forum posts 23 photos | You may be able to file it Steve but why not give us your general location, someone on here local to you may be able to mill it down for you. |

| Sherlock | 06/08/2018 17:06:44 |

| 52 forum posts 11 photos | Thanks Vic, I'm in London. |

| John Reese | 06/08/2018 19:24:03 |

1071 forum posts | On my South Bend 10K I can use bump type knurls without damaging the machine. For smaller machines I would definitely choose the clamp (scissor) type knurls as shown in several of the posts. |

| JasonB | 06/08/2018 19:34:04 |

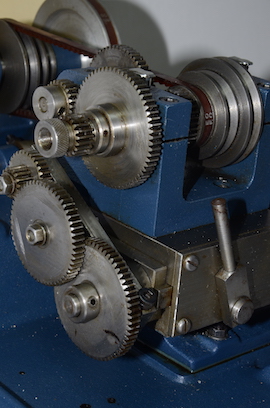

25215 forum posts 3105 photos 1 articles | For a straight "knurl" on brass you don't even need a knurling tool. Just mount a Vee shaped tool on it's side and traverse along the work. Simple gear on the spindle to index. Top of this lubricator was done in a similar way.

|

| Sherlock | 06/08/2018 19:46:05 |

| 52 forum posts 11 photos | That Looks Great Jason I shall definitely like to try that. When you say a simple gear on the spindle to index please would you mind elaborating on that? or if you could link to a picture maybe that would be great so I can visualise it. Does it go behind the chuck, like a division plate? then something I'm guessing gets fastened somewhere else to index to those teeth?

I went an ordered a scissor type knurled anyway for the sake of £14 and after realising the tool shaft is removable so I can just unscrew and take my angle grinder to it in a pinch. Edited By Steve Sherlock on 06/08/2018 19:46:18 |

| JasonB | 06/08/2018 20:04:25 |

25215 forum posts 3105 photos 1 articles | You should be able to use the large gear on the left of your spindle under the cover, a simple detent of some form to engage between two teeth will allow you to divide work into quite a few numbers |

| Ian S C | 07/08/2018 12:35:58 |

7468 forum posts 230 photos | As sujested by Stan Bray in his book "Introducing The Lathe", I made this knurling tool, it's rough, put together in about an hour, it consists of a bit of scrap steel about 3/8"/10 mm square by 3"/75 mm long with a fork in the end, cut wit a hacksaw. The wheel is from a disposable lighter, this is fitted with a bronze bush, the spindle is a needle roller. It produces a fine, straight knurl, not requiring a great amount of pressure. Ian S C |

| Howard Lewis | 08/08/2018 19:04:04 |

| 7227 forum posts 21 photos | F W I W, my preference is for the clamp type knurling tool. If you cannot find a set of drawings, or a tool, to suit your lathe, how about making one at a reduced scale? Perhaps Hemingway would sell you a set of drawings that you could "downsize" for your needs? Howard |

| Sherlock | 10/08/2018 16:33:07 |

| 52 forum posts 11 photos |

Ok guys, I went with one of the scissor types. Had a little play with it today.... Now, After everything I have gleamed from the subject of knurling, I wasn't expecting things things to go smoothly and I was correct. Trouble is I seem to get knurls on the edges and not in the middle, like rail tracks. I know there are other problems on there such as double lines etc, but been trying to save on wasting stock so using the bar more than once to practice on to see if I can get it to cut in the centre to no avail. I tried changing the wheels from diamond to straight. Tried the bar stock rough, then tried after turning it to size. tried with and without cutting oil. Clamping directly on centre and a little off centre. clamping down quickly to gain a bite. All to avail.. Any ideas where I might be going wrong, Do a pair of 'rail tracks' with no knurl in the middle suggest I am doing something obviously wrong?

|

| Roderick Jenkins | 10/08/2018 16:54:15 |

2376 forum posts 800 photos | The first thing I would do with a small lathe is to put it into back gear, you will need lots of torque. My usual technique with a scissor knurl is to start with only a third of the tool width clamping on the job. I introduce the tool to the job and adjust the wheels so that they are finger tight on the diameter of the job. I then withdraw the tool and tighten the tool by about a quarter turn. Switch on the lathe and then advance the tool with the cross slide. This should produce a good pattern. Once the pattern is set then the tool can be advanced towards the headstock with the leadscrew. HTH, Rod |

| Andrew Johnston | 10/08/2018 16:57:31 |

7061 forum posts 719 photos | Start at one end, with the knurls just overlapping the work. Once they've started to form a good depth of knurl you can move the knurling tool along the rest of the knurl. Trying to form the knurl full width will probably require more force than the tool can provide, unless you have a friendly gorilla in residence. Andrew |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in