New Member intro - with a bowed ME beam aluminum bedplate question

| Les Wilder | 21/02/2018 01:27:02 |

| 3 forum posts | Hello all! I’m a mechanical engineer in the US, and new to this forum. As an introduction, about 45 years ago, I became interested in model steam engines and discovered and subscribed to Model Engineer for a few years. However with a family to support, and a house to take care of, there was no time for this hobby. The solution? Purchase the Stuart No. 9 castings from Stuart, and the ME Beam castings from Reeves. And promise my wife that I would not start on them until retirement. Retirement has now arrived! Many years ago I acquired a circa 1942 7-inch Rivett “speed” lathe - (no power feeds) but very solid and precise - and happily used it off and on for miscellaneous tasks. Also acquired a small Clausing milling machine. So I felt ready for a real project! I dug out the kits and looked them over. In examining the kits, I saw that the Stuart has a 7-inch flywheel, and the beam engine a 91/4-inch flywheel. Advice on the web pointed to the beam engine as a better first model. So decided to start with it and worry about finding a way to handle the too-large flywheel later. I then noticed that its cast aluminum (or aluminum alloy) bedplate is bowed upward about 1/8-inch along its length, like an inverted rocker of a rocking chair, with a slightly sharper bend upward near one end. Because the bottom flange is only about 1/8, machining it flat is not feasible. Searching the web for ways to bend cast aluminum led to many contradictory opinions. Anneal to 400 degrees Fahrenheit, then bend while hot. Don’t bend while hot. Don’t heat at all. Use a hammer to rapidly reshape. Bend slowly. And: Don’t even try - it will crack. So I emailed Reeves about this 45 year-old defective part. In response I was sent a current price list with the info that they were not the same company as the previous AJ Reeves. A new bedplate would cost close to or more than what I paid for the entire set of castings. And the 90 tooth gear which also had never shipped was much more expensive. So - should I try to flatten it? If so, how to approach the task. Should I purchase a new one, hoping it would arrive flat? Brunell offers castings, drawings and construction notes - are they all interchangeable with Reeves items? Do both companies provide the same drawings, or do I need the Reeves drawings to match their castings. Do they use different foundries? Is their quality and service comparable? Should I assume a new bedplate might also be distorted, and I’d be better off fabricating one from one or two pieces of flat stock aluminum? Not sure where to post this, but as a newbie, perhaps I can be excused as this also serves as an intro. Les

|

| Ian S C | 21/02/2018 08:51:45 |

7468 forum posts 230 photos | Welcome to the forum Les, I'm not too sure on straightening your casting, someone will have an idea on that. Don't a afraid to post pictures, they help people decide on what path to take in a remedy for something like this. Ian S C |

| John Haine | 21/02/2018 09:02:42 |

| 5563 forum posts 322 photos | I think you might as well try straightening it - not sure how though! - with a view that if that fails you can always make a new one from flat stock. There's a member here - JasonB I think? - who makes a lot of very impressive models from stock materials. |

| JasonB | 21/02/2018 10:32:45 |

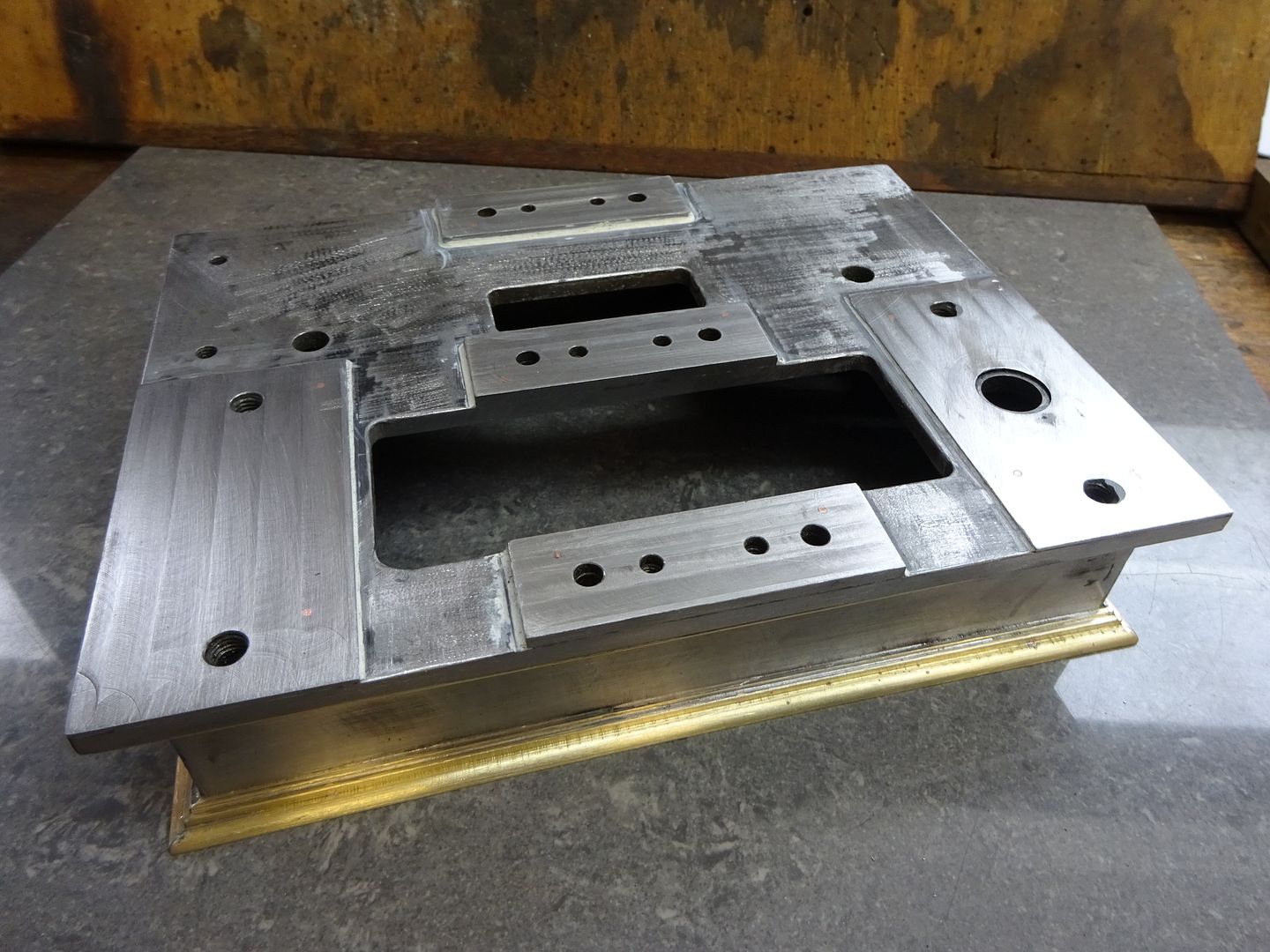

25215 forum posts 3105 photos 1 articles | You have nothing to loose by trying to straighten it, I would probably pack up under the low points and apply pressure to the high area in the middle. If that fails then think about making a base from scratch, just needs a plate with the holes milled into it and a moulding around the edge, strip of 1/8" flat bar screwed to the underside to give the bottom flange, JB Weld on the lugs for the hold down bolts around the edge and add thinner pieces of plate to form the raised areas that the parts sit on though this last item could be left off. As for the other question about the two suppliers I will just say stay with Reeves 100%. Gear does not really transmit any power so could be cut yourself and tracking down the old issues of model engineer will provide you with both the drawings and build description. These are a couple of home made bed "castings" all from plate and strip.

|

| Involute Curve | 21/02/2018 10:36:44 |

337 forum posts 107 photos | I straighten cast ali quite often, levers foot rest etc on motorcycles, when I or my lads fall off during trials MX racing or what ever, I use heat, I heat the metal with a flame until it just chars wood when rubbed on the surface, bend immediately whilst hot, I've heard of smearing on washing liquid again heat until it turns black, or do it with temp sticks available from welding supplies. Shaun |

| Neil Wyatt | 21/02/2018 11:09:32 |

19226 forum posts 749 photos 86 articles | Welcome to the forum Les, A Jason says, you won't lose anything by trying to straighten it. To anneal 'normal' aluminium alloys successfully, make some streaks on it with ordinary bathroom soap. Heat from the other side so you don't directly scorch the soap. When it turns dark brown, remove the heat. It will probably 'age harden' so you need to straighten it the same day, within an hour or two if possible, while it is at its most malleable. Neil |

| Hopper | 21/02/2018 11:19:44 |

7881 forum posts 397 photos | +1 on warm it up and bend it out straight. I would put it under my press, with gentle pressure, or in large vice under tension and then heat as said until soap browns up. You will almost certainly need to pack it up so you bend about 5 per cent further than the desired finished result as there is usually some spring back when tension is removed. I recently did this with the H frame on my ML7 countershaft that was twisted a lot. Came back nice and straight with no cracks. |

| Les Wilder | 22/02/2018 00:47:01 |

| 3 forum posts | What a pleasant surprise! The immediate responses from friendly and knowledgeable members are greatly appreciated. I will certainly try to straighten the aluminum casting, but I have to say that the built-up items that JasonB showed look better than what I expect my casting would look like, even if I can get it perfectly flat. Does JB Weld hold well to aluminum? Do you try to remove the resulting fillets, or is the epoxied base a hidden part? One further question - are the raised bosses on the casting necessary for engine function, or are they there to allow for machining to get a level plane for the components. If I use flat plate for a built-up base, I'd just as soon leave them off. I may try to find the recommended annealing temperature, and set and use the kitchen oven and let the part soak for a while at that temperature. Will let everyone know the result. I think I have located the relevant back issues of ME at a public library, and if so, see if they contain detailed parts drawings before ordering the Reeves set. Does anyone know if the Brunell "construction notes" are useful? Sorry for all the "newbie" questions, but I want to do this right! Now I'll post to the proper forum for thoughts as to whether to continue to look for a screwcutting lathe to replace my hand-operated carriage lathe, as I presume smoother cuts will result with powered feeds. Thanks again! Les W. |

| JasonB | 22/02/2018 07:26:44 |

25215 forum posts 3105 photos 1 articles | Les the JBWeld will hold to clean aluminium though the joint is a bit weaker than on steel but plenty strong enough for this use. As most castings tend to have fillets in all the internal corners the JB Weld that gets squeezed out can be shaped into a fillet as it starts to firm up or filed with a round needle file when dry. The raised areas were used on the full size castings as it reduced the amount of metal that needed to be machined flat but for our purposes could be left off. If you do decide to make your own there is some more detail on how I went about the ones shown above starting here and here I think the Brunell notes are just going to be photocopies of the ME article, have sent you a message click the envelope icon in the green bar at the top of the page.

J Edited By JasonB on 22/02/2018 07:32:32 Edited By JasonB on 22/02/2018 08:06:44 |

| Ian S C | 22/02/2018 10:08:19 |

7468 forum posts 230 photos | For your temperature control use the soap as suggested by Neil and Hopper. Had a friend who was rebuilding Hiller Helicopters, and he used that method when forming compound curved skins, this method approved by Hiller, and the FAA. Ian S C |

| Hopper | 22/02/2018 12:05:42 |

7881 forum posts 397 photos | Posted by Ian S C on 22/02/2018 10:08:19:

For your temperature control use the soap as suggested by Neil and Hopper. Had a friend who was rebuilding Hiller Helicopters, and he used that method when forming compound curved skins, this method approved by Hiller, and the FAA. Ian S C That's where I learned the soap trick from - a mate who is an aircraft engineer and served his time doing aluminium bodywork on old DC3s etc. |

| richardandtracy | 22/02/2018 13:35:48 |

943 forum posts 10 photos | Agree about heating. The most commonly used aluminium casting material 45 years ago for this type of little casting was LM4 to BS 1490. It has about 1% strain to failure, so is a very brittle material, and if the casting has the curvature you suggest, it'll fracture long before deforming enough. Another fun idea might be to cast your own. It isn't all that hard to do with aluminium & can be done very cheaply. I was inspired to do my own casting by a fellow countryman of yours: **LINK** I ended up with a tiny furnace that I wrote up here: **LINK** The article is quite old, but I last used it 21 days ago, and the concrete lining is just about shot after 15 years or so. Regards, Richard.

|

| Neil Wyatt | 22/02/2018 17:39:39 |

19226 forum posts 749 photos 86 articles | Posted by Hopper on 22/02/2018 12:05:42:

Posted by Ian S C on 22/02/2018 10:08:19:

For your temperature control use the soap as suggested by Neil and Hopper. Had a friend who was rebuilding Hiller Helicopters, and he used that method when forming compound curved skins, this method approved by Hiller, and the FAA. Ian S C That's where I learned the soap trick from - a mate who is an aircraft engineer and served his time doing aluminium bodywork on old DC3s etc. I learned it from the Ladybird Book of Metalworking - seriously!

Neil |

| Ian S C | 23/02/2018 10:33:16 |

7468 forum posts 230 photos | To retain the old casting, it might be better to put a number of hacksaw cuts up the sides of the base, then heat and bend and fill the gaps with JB Weld or similar filler, you still might end up with a fabrication, or some pattern making and getting a casting done. If your mad enough, you could carve it out of a block of aluminium. good luck Les. Ian S C |

| Maurice | 23/02/2018 11:10:59 |

| 469 forum posts 50 photos | Hi Les. When I built my ME beam engine, it had a bowed bed plate. It was iron. I was able to use it as it was, but you could see the thinning of the flange in the centre. I have joined this thread as you mention the missing gear. When I made my engine, I found that using gears of the size specified, there was insufficient clearance between the lay shaft and cotter remaining the big end. I overcame this by increasing the tooth count by five on each gear. Maurice |

| Hopper | 23/02/2018 11:15:19 |

7881 forum posts 397 photos | Posted by Neil Wyatt on 22/02/2018 17:39:39:

Posted by Hopper on 22/02/2018 12:05:42:

Posted by Ian S C on 22/02/2018 10:08:19:

For your temperature control use the soap as suggested by Neil and Hopper. Had a friend who was rebuilding Hiller Helicopters, and he used that method when forming compound curved skins, this method approved by Hiller, and the FAA. Ian S C That's where I learned the soap trick from - a mate who is an aircraft engineer and served his time doing aluminium bodywork on old DC3s etc. I learned it from the Ladybird Book of Metalworking - seriously!

Neil Now there's a blast from the past. I think that's where I learned most of what I know about electrickery from. |

| KWIL | 23/02/2018 11:21:16 |

| 3681 forum posts 70 photos | Always anneal Ali rivets with the soap trick before use (aviation work again) |

| Roderick Jenkins | 23/02/2018 12:14:53 |

2376 forum posts 800 photos | Posted by Hopper on 23/02/2018 11:15:19:

Posted by Neil Wyatt on 22/02/2018 17:39:39:

Posted by Hopper on 22/02/2018 12:05:42:

That's where I learned the soap trick from - a mate who is an aircraft engineer and served his time doing aluminium bodywork on old DC3s etc. I learned it from the Ladybird Book of Metalworking - seriously!

Neil Now there's a blast from the past. I think that's where I learned most of what I know about electrickery from. When I started my undergraduate physics course the Ladybird book of computers was on the book list. Rod |

| JasonB | 23/02/2018 13:16:58 |

25215 forum posts 3105 photos 1 articles | The second project we had to make in my first year of metalwork at school was a round ashtray flanged from ali and we were shown the soap method. Think the subject matter may be a bit more PC these days! |

| Mike Poole | 23/02/2018 13:43:01 |

3676 forum posts 82 photos | Ladybird have some very useful titles. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in