Cylinder bore surface?

| Malc | 27/02/2017 17:44:18 |

| 113 forum posts 6 photos | Hi folks, I am in the process of building my first engine ( the Julian De Waal beam engine) and am about to start the cylinder and valve chamber. I am wondering how to finish the bores of the cylinder and valve chambers. I suspect that internal boring will not leave the surface smooth enough. Will I need to buy a “Cylinder Hone” to get a decent finish, and if so how much metal do I leave for the Hone to remove? Any info. would be appreciated. Thanks, Malc. |

| NJH | 27/02/2017 17:50:47 |

2314 forum posts 139 photos |

Malc I think that, for a steam engine, a finely bored finish should be quite OK Norman

|

| HOWARDT | 27/02/2017 18:10:33 |

| 1081 forum posts 39 photos | Honing primarily removes the tops of the ridges from previous machining marks. Whilst it is possible to remove some measurable amount of metal I think this unlikely from a model engineers point of view. Think of it as a surface finish conditioning process, use were a non metallic sliding seal is used at high pressure. |

| Nick_G | 27/02/2017 18:26:38 |

1808 forum posts 744 photos | . Depends on how good the bored finish is if you need to hone or not. - But in short a honed finish will always be better. If the boring has done a reasonable job leaving 1/2 - 1 thou I would say would be enough. It would also depend on if you were using a cast iron or an O ring. A rougher surface would chew up the rubber / viton ring, while a cast iron ring would eventually hone the bore this might take a long time and still run the risk of the bore and ring ending up scratched. Most people want a nice slow running engine on a wiff of air for demonstration purposes and not one running uber fast. Again a nice smooth bore will assist in this. So in short I would hone which is going to give a better finish than even the best bored out cylinder. Especially if the cast iron is not 100% good as some is nicer to machine than others. Nick Edited By Nick_G on 27/02/2017 18:28:04 |

| JasonB | 27/02/2017 18:30:57 |

25215 forum posts 3105 photos 1 articles | I like to give my cylinders a quick lick with a brake cylinder hone particularly if using O rings or in the case of Jan's beam teflon rings. Not quite as critical with iron rings Amount to allow will really depend on how high the "crests" are from your machining but something liek 0.001" -0.002" would be about right. Its not dead critical as you will make the piston and teflon ring to suit the bore. The piston valve hole is too small to fit a hone into so ream that which should give a good enough finish, you can always lap the valve spool into place with some lapping powder or even metal polish. |

| Malc | 27/02/2017 20:37:04 |

| 113 forum posts 6 photos | Hi folks, Many thanks for the advice. Malc.

|

| vintagengineer | 27/02/2017 20:56:45 |

469 forum posts 6 photos | I used to burnish small cylinder bores on hydraulic cylinders. Basicly a tool similar to an internal knurling tool but with a roller bearing running on the cylinder wall.

|

| John Reese | 27/02/2017 21:40:19 |

1071 forum posts | "Ballizing" is pressing a hardened steel or carbide ball through the bore to improve the finish. |

| Hopper | 28/02/2017 07:39:48 |

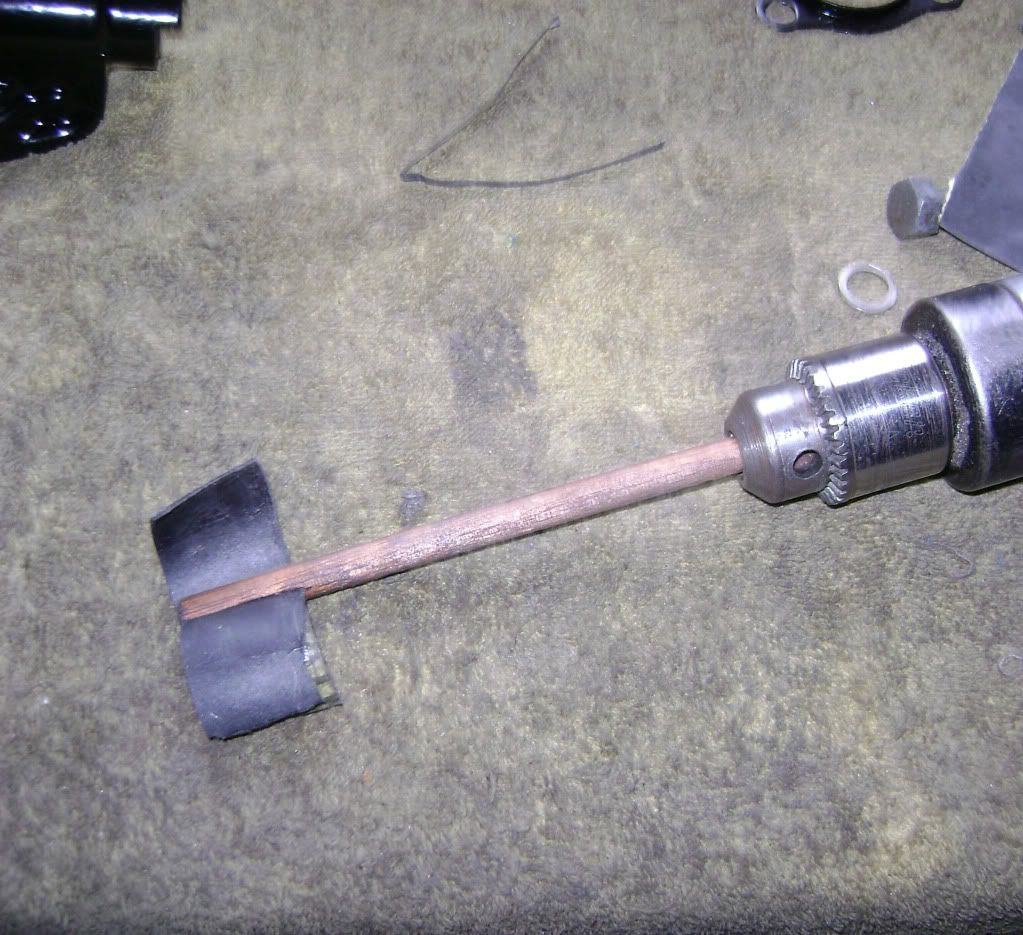

7881 forum posts 397 photos | Hillbiilly hone will do the job. Bit of dowel with a hacksaw slot in the end and a strip of emery paper or wet rub inserted. Wind the paper around the dowel a bit, insert in hole and spin with pistol drill. Works on holes smaller than a brake hone will get into too.

|

| Thomas Staubo | 28/02/2017 08:53:58 |

54 forum posts | How about using flex hones, especially for holes smaller than the normal hones do. They go down to 4mm.

|

| vintagengineer | 28/02/2017 10:29:28 |

469 forum posts 6 photos | You have to be very careful with flexi hones, as they follow and exaggerate any ovality. We banned them from our Hydraulic workshop. They are fine for a quick polish up but don't try to remove any material with them.

Posted by Thomas Staubo on 28/02/2017 08:53:58:

How about using flex hones, especially for holes smaller than the normal hones do. They go down to 4mm.

|

| Ian S C | 01/03/2017 08:14:15 |

7468 forum posts 230 photos | With my Stirling Engines I use a wooden lap, i usually finish with a fine grade of grinding paste, but I have used metal polish/Brasso, Silvo, or toothpaste, free airline toothpaste is quite fast cutting. The Stirling Engines need a polished bore, unlike a steam or IC engine with cast iron rings. Ian S C |

| Howard Lewis | 03/03/2017 16:35:30 |

| 7227 forum posts 21 photos | The other thing with Flexhones, is to CLEAN everything afterwards, I think that they advocate scrubbing with a nail brush. You cannot afford to have particles of Silicon Carbide around. That makes running out compound, not running in! Howard |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in