Help wanted solving groove for O ring cutting on lathe

| Christine Walker | 17/11/2016 09:16:59 |

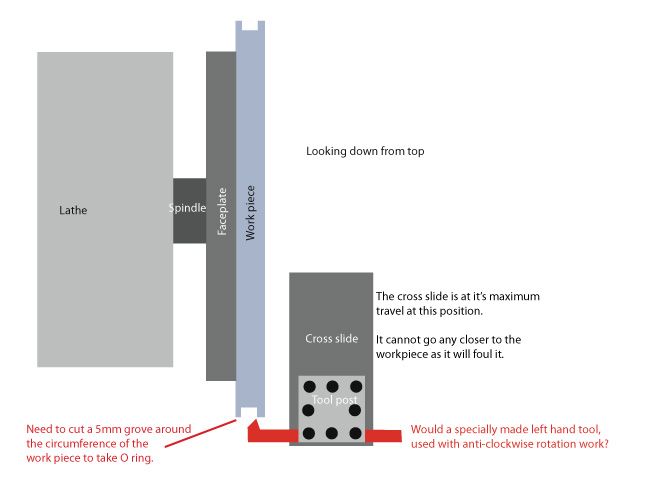

| 37 forum posts | Hello This is my first time posting here. I have a problem which I can't, for the life of me see a way around. In a nutshell, I need to cut a 5mm groove to fit an o ring seal in to the circumference of a 190mm dia workpiece (the piece is Engineering PVC). However, the cross-slide on the CJ0623B lathe won't swing out far enough to use a 'straight' cutting tool. Therefore, I need a kind of right angle too. Please see the attached diagram to se the problem. Can anyone advise what kind of tool I could purchase that might do the job, please? Thanks

|

| peak4 | 17/11/2016 16:32:42 |

2207 forum posts 210 photos | If you do a search for double ended boring bar, you will likely see images like this **LINK** I'd probably make one something similar, but with round holes and use a bit of round tool steel rather than a square length of HSS. Use the straight rather than the angled hole. Just grind your profile on the end; I guess an ideal candidate for the toolbit would be an old centre drill.

Welcome to the forum.

Regards Bill Edited By peak4 on 17/11/2016 16:33:36 |

| Les Jones 1 | 17/11/2016 16:51:04 |

| 2292 forum posts 159 photos | Is it not possible to turn the top slide (Compound slide.) so that is pointing to the front. I.E the handle will be at the back of the lathe. you may have to remove the handle and find another way to turn it. Les. |

| Les Jones 1 | 17/11/2016 17:48:17 |

| 2292 forum posts 159 photos | I have just realised I have made a wrong assumption. I was thinking that the groove was in the face of the work piece. If the groove was close to the end of the work piece you may be able to angle the top slide so that it let you get the tool tip to the larger diameter and also to the left of the cross slide to enable you to cut the groove. Les.

|

| Neil Wyatt | 17/11/2016 18:22:01 |

19226 forum posts 749 photos 86 articles | A boring bar fitted to the back of the toolpost is how I would do it. One with an inserted cutter from 1/8" HSS would be ideal and easy to grind to shape. You can do the same to skim large flywheels. Neil |

| Neil Wyatt | 17/11/2016 18:22:13 |

19226 forum posts 749 photos 86 articles | P.S. welcome to the forum. |

| Sam Longley 1 | 17/11/2016 18:37:05 |

| 965 forum posts 34 photos | So how does one view the attachment because i cannot see it !!!??? |

| Andrew Johnston | 17/11/2016 18:44:20 |

7061 forum posts 719 photos | Posted by Neil Wyatt on 17/11/2016 18:22:01:

You can do the same to skim large flywheels. Like this, using a boring bar with the cross slide fully back: Andrew |

| Frances IoM | 17/11/2016 19:47:34 |

| 1395 forum posts 30 photos | "So how does one view the attachment because i cannot see it !!!???" you can't it's only local to his computer and visible only to his web-kit based browser - yet another probably confused by the arcane image uploading of this web site |

| Christine Walker | 18/11/2016 09:26:55 |

| 37 forum posts | Hello all Thanks for taking the time to reply and welcoming me to the forum. Unfortunately, I don't think I have explained the problem well. The groove for the O Ring has to be around the outer perimeter of the circular workpiece, a little like a pulley wheel type thing. Does that make sense? Imagine two locomotive wheels stuck face to face and you get the idea? Sorry, I can't think of any other way of explaining. I have a diagram which shows the problem perfectly, but for the life of me, I cannot find a way to post it. I click on the image icon and it asks me for a URL which I don't have as it's on my desktop not in photo bucket or similar. Ditto when I click on the camera. Any advice on how to post the image would also be most gratefully received. PS: I am female

|

| Circlip | 18/11/2016 09:46:10 |

| 1723 forum posts | Sounds like a hook tool is required.

Regards Ian. |

| Christine Walker | 18/11/2016 09:48:41 |

| 37 forum posts |

http://s304.photobucket.com/user/christineanniewalker/media/OringLathe_zpsyah4beh7.jpg.html

This may work

|

| Hopper | 18/11/2016 09:51:45 |

7881 forum posts 397 photos | Posted by Christine Walker on 18/11/2016 09:26:55:

Any advice on how to post the image would also be most gratefully received. PS: I am female

Easiest way is to put the image up in Photobucket or similar. It's free and easy. Then when you click the image icon on here, copy and paste the "DIRECT" link in where it says URL. |

| Christine Walker | 18/11/2016 09:52:42 |

| 37 forum posts |

Done that but just get a question mark? See if this works

|

| Emgee | 18/11/2016 09:53:09 |

| 2610 forum posts 312 photos | Hi Christine Simplest way to upload a pic is save your sketch/drawing as a jpeg file, you can then upload it to an Album. Do this from the top line Menu, click on Albums and follow hints, when writing your message click on the camera "Insert image from Album" and follow menu. Emgee

|

| Hopper | 18/11/2016 09:54:31 |

7881 forum posts 397 photos | Here you go

No need for special tools or counter-rotation. A common boring bar will do the job. One with a removeable HSS bit will allow you to grind it to a nice square profile to make the shape groove you show. |

| HOWARDT | 18/11/2016 09:55:08 |

| 1081 forum posts 39 photos | For those that can't see the pictures. I assume it is this way for most, they don't appear in email notifications, you have to use the forum (not necessary to log in). |

| Christine Walker | 18/11/2016 09:55:40 |

| 37 forum posts | It's in photobucket now. However, when I copy the URL and try and put it in this forum's uploader, it just tells me the image source is missing. Never experienced this before.

|

| Christine Walker | 18/11/2016 09:56:14 |

| 37 forum posts | Thank you Hopper. |

| Hopper | 18/11/2016 09:57:58 |

7881 forum posts 397 photos | YOu would need a boring bar like this one, with a piece of HSS in the square hole at the lefthand end.

I's sure ArcEurotrade or other advertisers from this site can supply such a beast. You can get them do hold different sizes of HSS square bits, depending on what size groove you wish to turn. Edited By Hopper on 18/11/2016 10:00:27 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in