Tangential tool holder

| Andy Sproule | 04/09/2016 09:53:33 |

| 122 forum posts 35 photos | Hi,I am going to try and make a tangential tool holder, of the ones on the net which do you think is the best design?Does anyone have step by step pictures or video of making one? |

| Martin Connelly | 04/09/2016 10:05:08 |

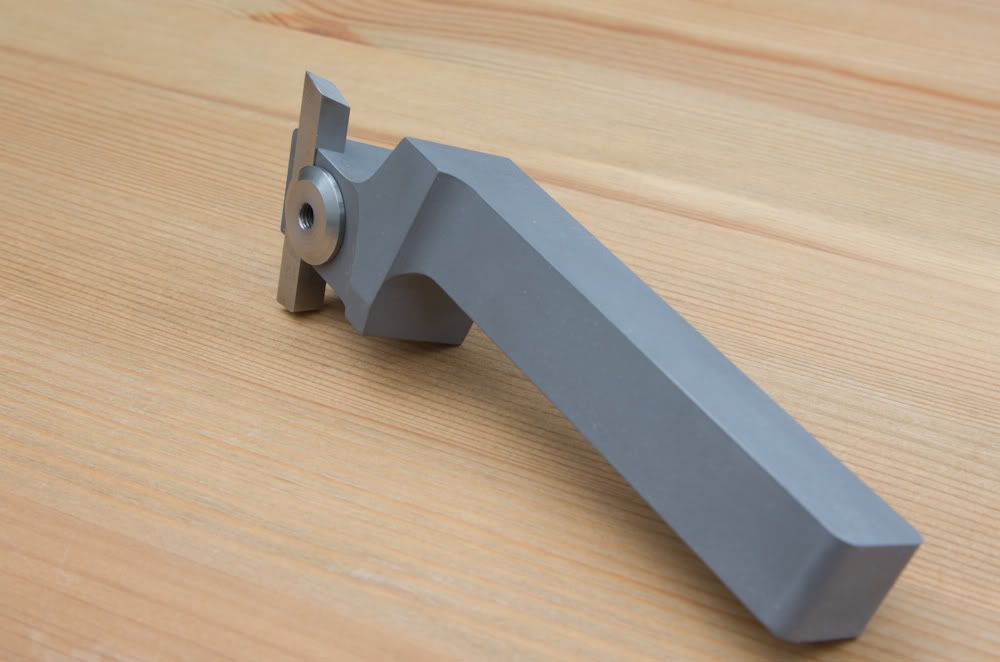

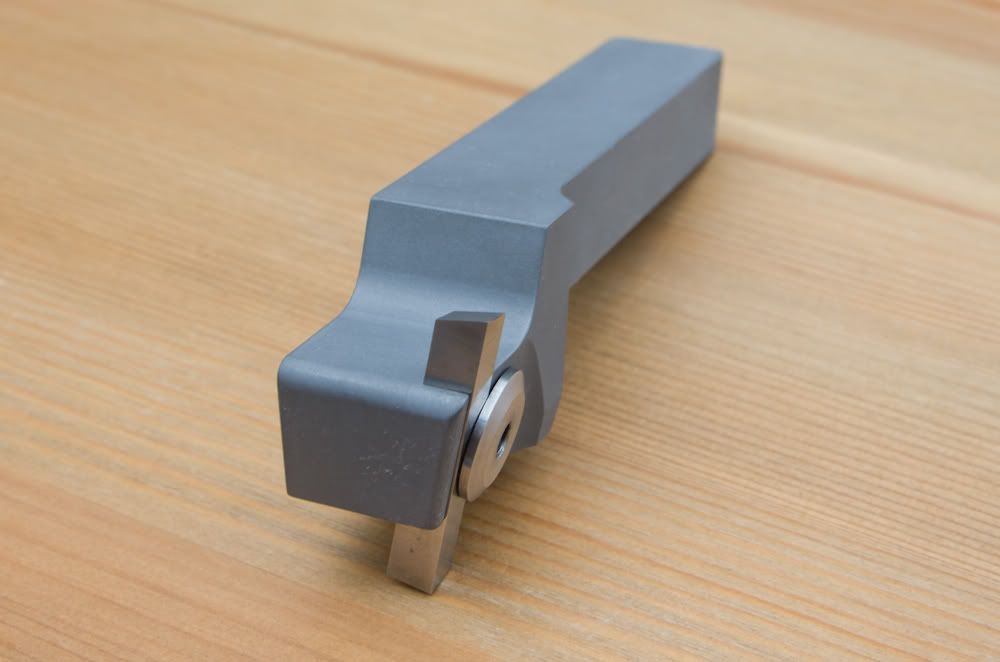

2549 forum posts 235 photos | The best one is one that you can make, fits your machine and does what you want. Only you can design this tool. Here's my own design. Martin |

| Vic | 04/09/2016 10:19:49 |

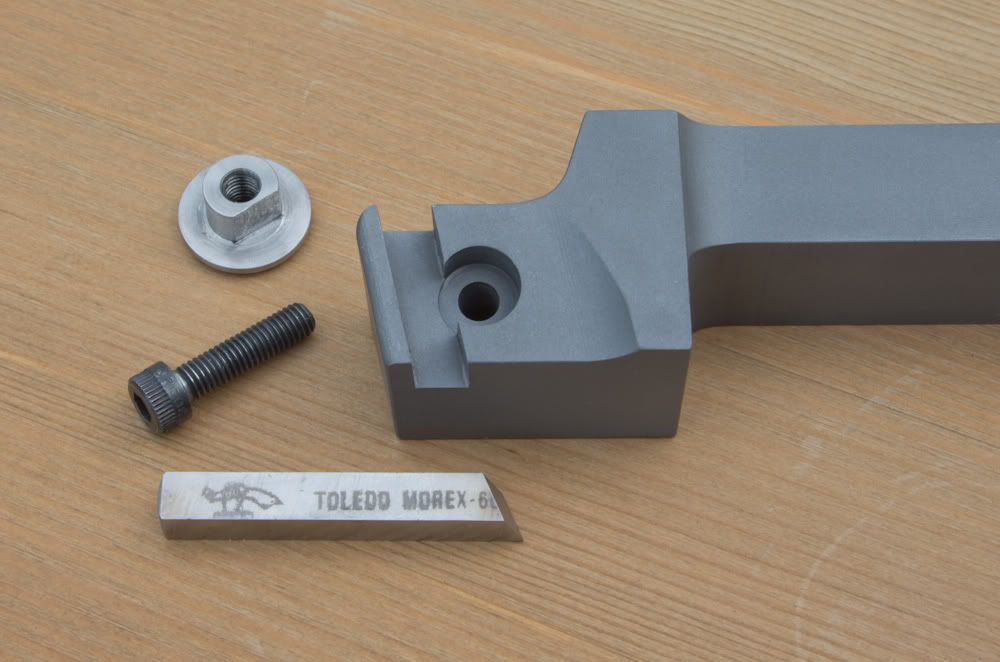

| 3453 forum posts 23 photos | Couple of pictures of mine in case it helps.

|

| Vic | 04/09/2016 10:21:22 |

| 3453 forum posts 23 photos |

|

| Rik Shaw | 04/09/2016 11:28:36 |

1494 forum posts 403 photos | If you follow the link to my album you will find pics and a rough sketch of mine. The tool bit clamp is hand profiled to avoid the tool fouling the work piece when facing and the two screws ensure no tool bit slippage whilst under load. A very useful and versatile tool with the tool bit (cobalt) easily sharpened in its simple jig against the vertical sanding disk on my linisher. Well worth making. PS Since the sharpening jig sketch was drawn I have added a simple strap clamp to hold the tool bit tight whilst sharpening. Rik **LINK** Edited By Rik Shaw on 04/09/2016 11:34:02 |

| Vic | 04/09/2016 11:57:57 |

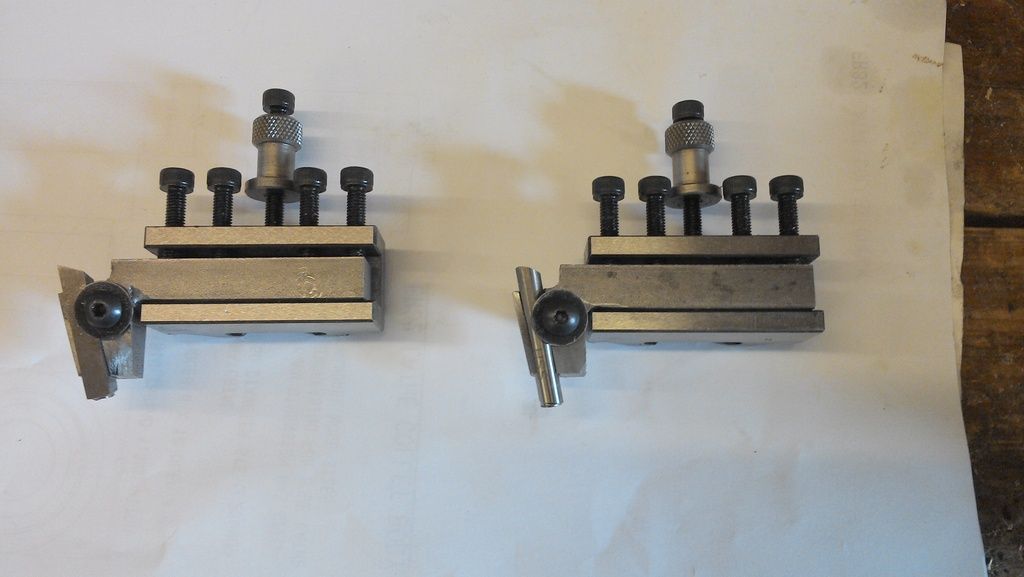

| 3453 forum posts 23 photos | Sharpening jigs. The alloy one is mine. The black one comes with the Eccentric tool.

|

| Thor 🇳🇴 | 04/09/2016 12:15:51 |

1766 forum posts 46 photos | HI Andy, Here is how I made mine. The first one I made for my smaller lathe, it uses 1/8" HSS tool bits since I had a box of them. I have since made another one for my larger lathe using 6mm HSS tool bits. They work very well, and as Vic has shown, it is easy to grind the tool bit. Thor Edited By Thor on 04/09/2016 12:16:14 |

| BW | 04/09/2016 12:18:02 |

| 249 forum posts 40 photos | This is a good thread http://www.modelenginemaker.com/index.php/topic,712.45.html When I made mine I remembered the 3 magic angles : incline 12 degrees towards headstock, 12 degrees towards lathe axis and grind the tool at 30 degrees. Set a piece of metal up in the mill vice accordingly and you can make something very ugly and primitive but it will work.

A lesser known property of these tools is that if yoiu turn the tool around 90 degrees you then get a shear tool for doing a fine finish.

http://metalworkforums.com/f65/t180275-tangential-trickery?highlight=tangential

|

| Andy Sproule | 04/09/2016 15:26:23 |

| 122 forum posts 35 photos | Thank's for the replies guys plenty of ideas.Is it important to use a particular type of steel would it need hardened when finished? |

| Thor 🇳🇴 | 04/09/2016 15:30:33 |

1766 forum posts 46 photos | Hi Andy, When I made mine I used a steel with a bit more carbon than you usually find in mild steel - about 0.3% to 0.4% IIRC. Mild steel would probably work Ok, a harder steel might last longer though. I have not hardened any of my tool holders. Thor Edited By Thor on 04/09/2016 15:35:20 |

| Neil Wyatt | 04/09/2016 19:33:52 |

19226 forum posts 749 photos 86 articles | Vic, Did you 'parkerize' that and if so what's your technique? Neil |

| Rik Shaw | 04/09/2016 19:58:09 |

1494 forum posts 403 photos | "Did you 'parkerize' that and if so what's your technique? It was just sand blasted if I remember right. Rik |

| Vic | 04/09/2016 20:28:16 |

| 3453 forum posts 23 photos | Yes quite right. It was just sand blasted and then wiped over with WD40 or Renwax. |

| Michael Horner | 04/09/2016 21:43:25 |

| 229 forum posts 63 photos | Hi Andy How about this one made by Michael Cox **LINK** It uses a parallelogram to get one of the 12 degrees. This means you don't have to cut a compound angle. Cheers Michael. |

| Vic | 05/09/2016 09:41:27 |

| 3453 forum posts 23 photos | I don't have a tilting or a swivelling vice. All I did to make mine was to swing my 4" vice round 12° to the table then mount a 2" vice in it at 12°. The work piece was then clamped in the smaller vice. Once the slot was cut and the hole drilled, tapped and counterbored the work piece was remounted in the straightened 4" vice and milled to size.

Edited By Vic on 05/09/2016 09:55:18 |

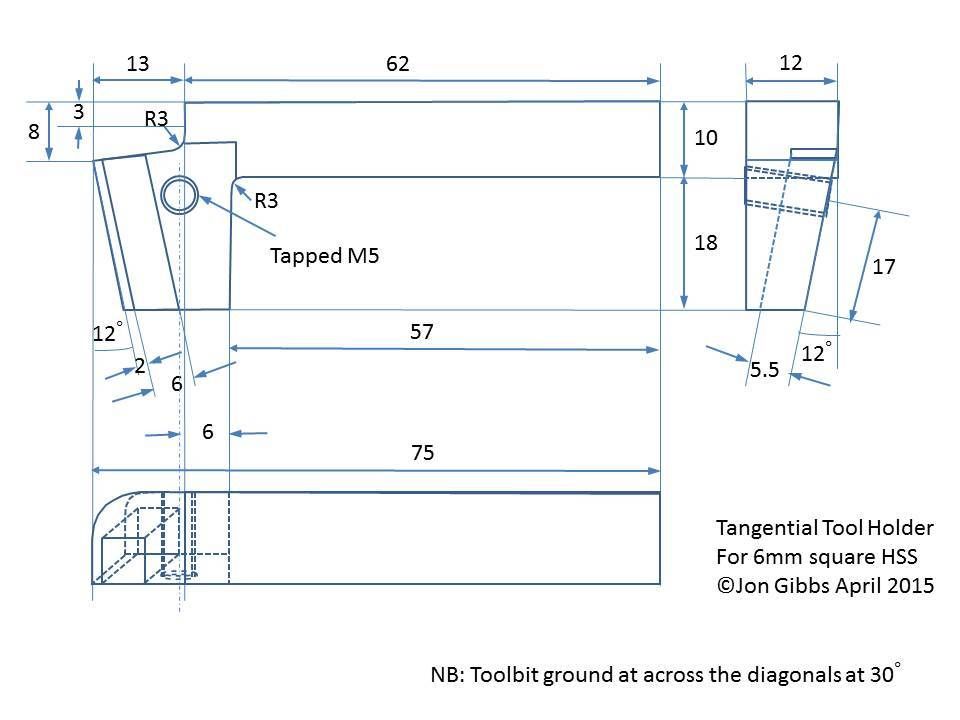

| Jon Gibbs | 05/09/2016 10:11:51 |

| 750 forum posts | I made mine a while ago...

...but I'm currently investigating the Wimberley which I think has some advantages particular as a right hand hogger of material. It doesn't need to hang below the bottom of the bottom of the tool-holder and the flank wear of the cutting bit is naturally ground off in sharpening. If you get any flank wear with the tangential toolholder you sometimes need to grind off quite a lot of the tool tip to get below it. HTH Jon Edited By Jon Gibbs on 05/09/2016 10:44:01 |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in