What is the difference between a face mill and a fly cutter?

| Mark Eisen | 25/06/2016 21:56:10 |

88 forum posts 68 photos | What is the difference between a face mill and a fly cutter? Will I need both? What type of face mills? Are Roughing end mills worth while getting these, if so what sizes? I have a Seig SX3L mill. More I read more confused I get. |

| Michael Gilligan | 25/06/2016 22:06:01 |

23121 forum posts 1360 photos | Posted by Mark Eisen on 25/06/2016 21:56:10:

What is the difference between a face mill and a fly cutter? . Easy answer for starters [others will surely be along with more]: A fly cutter typically has one cutting edge, and a face mill has several. ... Usage is similar, but you need to consider speeds 'n' feeds. MichaelG. |

| Paul Lousick | 26/06/2016 01:13:13 |

| 2276 forum posts 801 photos | Hi Mark, Either a face mill and a fly cutter can be used to machine the face of a plate. The face mill has a number of cutting teeth and is much faster than a fly cutter which only has one. Both can achieve the same finish. A fly cutter is inexpensive and could be home made. The SX3 mill is rated to use a 50mm face cutter but I have used a 75mm dia cutter using light cuts. You could probably fly cut at 150mm diameter. Fly cutting would leave a better finish. (You would not see the multiple cuts of a smaller diameter tool on a plate which is wider than the cutter) Roughing end mills are good for quickly removing metal when cutting on the side of the cutter. Use a normal end mill for the final cuts. I run a 12mm and 16mm roughing end mill in my SX3. Carbide cutters cost a bit more but last a lot longer. Paul Edited By Paul Lousick on 26/06/2016 01:14:39 |

| not done it yet | 26/06/2016 07:25:48 |

| 7517 forum posts 20 photos | Re the roughing and finishing end mills - think here that you can get a good finish with a standard end mill but the cuts will be much less. So the cutter gets worn more quickly for a given volume of metal removed and it takes more passes, so longer time. So your choice, when it comes to it. Often the roughing and finishing route is more cost effective in terms of time and cutter replacement.

Ask yourself if you would use a felling axe to split kindling. Nope! Easier to have an axe for cutting the tree down and a small chopper for the final splitting for kindling.

I always think that flycutters and face mills are the cheap alternative to a horizontal mill. You will always finish with a dished surface unless they are trammed in absolutely perfectly. Your choice of more small ridges or fewer ridges and possibly more 'concavity'. They are an acceptable solution for those with only a vertical mill. The perfectionists who use a vertical mill will likely surface grind for a truly flat finish?!

Of course, the suppliers will encourage you to buy both - won't they! |

| Tony Pratt 1 | 26/06/2016 08:00:28 |

| 2319 forum posts 13 photos | As all things in life no one M/C will do everything & perhaps a vertical mill is more versatile than a horizontal, you can get conversion attachments for both. Let the arguments begin Tony

Edited By Tony Pratt 1 on 26/06/2016 08:01:06 |

| JasonB | 26/06/2016 08:07:37 |

25215 forum posts 3105 photos 1 articles | As always the question of what will you need will depend a lot on what you intend to do. I tend to use a flycutter on my X3 for most metals as it gives a good finish, is easily sharpened and teh HSS blanks are cheap and last a long time. However for iron castings I will use a 40mm 3 tipped cutter as it copes better with any hardspots that may be present which would take the edge straight off a flycutter. I would say go with a flycutter first and then add a large indexable endmill or facemill if you find the need. For flycutting I have a set similar to the set of 3 with 12mm shanks that Arc sells which work fine, I also have a larger counterballanced one but don't use it much. Rougher/ripper cutters like Mark says will remove metal at a faster rate without putting so much load on the machine so can be useful if making things from solid stock. You will need to go back and make a finishing cut as they leave a more textured surface. As most castings tend to have 3mm to come off if you are lucky, less in a lot of cases there is often not much pount in us using rippers and then a second finishing cutter, may as well just use the finishing cutter. I have 10mm and 12mm roughers. If you are doing a lot of aluminium then its worth getting the dedicated ones for that, the lack of any coating and different helix angle help a lot. Edited By JasonB on 26/06/2016 08:11:45 |

| Vic | 26/06/2016 13:09:24 |

| 3453 forum posts 23 photos | I use carbide cutters in my Flycutter for hard stuff and HSS for softer stuff like aluminium alloy. |

| HOWARDT | 26/06/2016 15:13:56 |

| 1081 forum posts 39 photos | A fly cutter should have a single cutting edge that can be made to cover a large surface in one pass, then if the machine is properly setup it will produce a very flat surface. A face mill, having more than one cutting edge, will produce a more ridged surface as the cutting edges are not at all at the same height.

|

| Andrew Johnston | 26/06/2016 16:07:25 |

7061 forum posts 719 photos | Posted by not done it yet on 26/06/2016 07:25:48:

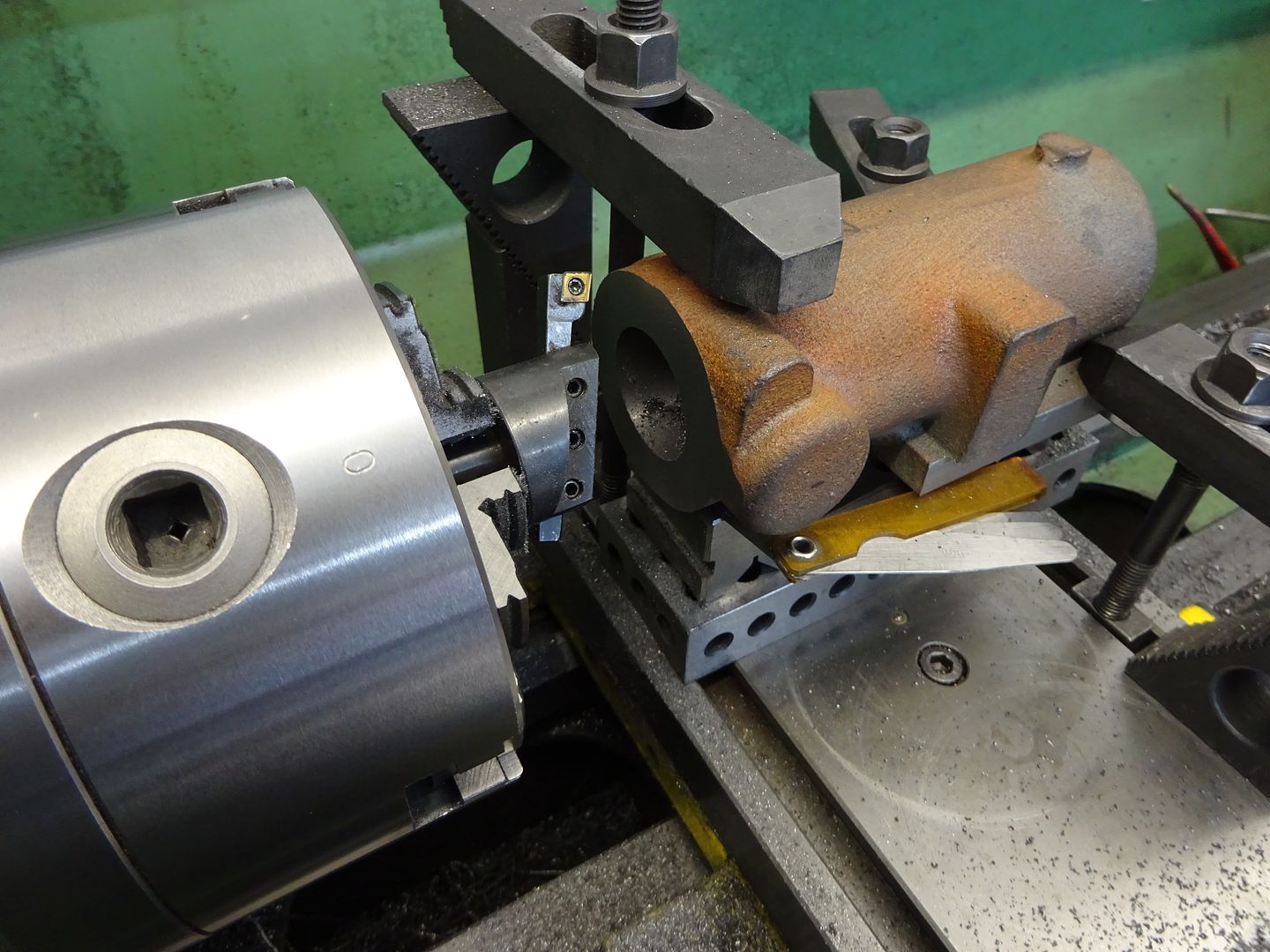

The perfectionists who use a vertical mill will likely surface grind for a truly flat finish?! Of course, what else would you do? In this picture the flycutter is on the left, and on the right is a face mill: Personally I don't like flycutters, and don't use them anymore. I rarely seem to get a good finish, especially when the vertical mill is properly trammed. They're slow, can only take shallow cuts and it is only too easy to forget the invisible spinning cutter and have an accident. I use the facemill on the horizontal mill as my vertical mill doesn't have the rigidity, or horsepower, to make use of it. As it happens the facemill cost twice what my horizontal mill cost, excluding delivery. Andrew |

| Vic | 26/06/2016 22:40:20 |

| 3453 forum posts 23 photos | Unless you use a carbide insert on a fly cutter many folks struggle at first to sharpen a HSS tool correctly. Most folks that know how to use a fly cutter properly swear by them. They are cheap to run and no other tool can traverse such a large area in one pass on a small mill. You can get some pretty fancy versions these days. Edited By Vic on 26/06/2016 22:40:55 |

| Vic | 26/06/2016 22:46:39 |

| 3453 forum posts 23 photos | He's right about the chips, that's about the only downside with a fly cutter! |

| Mark Eisen | 28/06/2016 10:30:33 |

88 forum posts 68 photos | Thanks for you replies. After looking at links and you tube video I think buy a face mill and make a fly cutter. Looking at face mills at H&F. I was wondering if the more insert tips there are the better the finish? What is the difference between the 90° positive rake and the 45° super high rake? This has only 3 inserts but has MT arbor. https://www.machineryhouse.com.au/M529 Or is it better to buy an arbor and and face mill head separate They have 50 mm x 90° - 3 teeth 50 mm x 45°- 4 teeth 75 mm x 90° - 5 teeth or the head in this one has 7 teeth

https://www.machineryhouse.com.au/M530

Any where else to look for tooling?

|

| Paul Lousick | 28/06/2016 10:48:27 |

| 2276 forum posts 801 photos | Mark, Ausee Machine Tools is another site in Aust. Bargains also available on flee-bay Edited By Paul Lousick on 28/06/2016 10:50:25 |

| HOWARDT | 28/06/2016 11:11:24 |

| 1081 forum posts 39 photos | Depends on what you mean by a better finish. The finish is influenced by what ever machine and cutting tool you use. In days gone by we used to calculate feeds, speeds and cutter radius to give a particular Ra value. Having more cutting edges doesn't mean a better finish only a faster feed rate as cutting feeds are per tip. Also all tips won't be at the same height. If you have the luxury of power feed then it is easy to arrive at a decent finish, if you are doing it by hand then you are best to polish it up after cutting. |

| Vic | 28/06/2016 12:10:35 |

| 3453 forum posts 23 photos | It's worth mentioning that you can get a very nice finish on small items if the flycutter diameter is at least twice that of the length of the item to be cut and you don't mill past the axis of the cutter. I've also got what I regard as a nice slightly rigged finish by deliberately feeding too fast. Not to everyone's taste but I like it! |

| MW | 28/06/2016 12:17:30 |

2052 forum posts 56 photos | Posted by Vic on 26/06/2016 22:40:20:

Unless you use a carbide insert on a fly cutter many folks struggle at first to sharpen a HSS tool correctly. Most folks that know how to use a fly cutter properly swear by them. They are cheap to run and no other tool can traverse such a large area in one pass on a small mill. You can get some pretty fancy versions these days. Edited By Vic on 26/06/2016 22:40:55 That looks pretty cool, if i had 145 notes i'd consider it. Theres no reason why you couldn't make an indexable carbide fly cutter Michael W Edited By Michael Walters on 28/06/2016 12:22:22 |

| JasonB | 28/06/2016 12:40:27 |

25215 forum posts 3105 photos 1 articles | Dead easy to make, just put a lathe tool in the slot

|

| Vic | 28/06/2016 18:17:56 |

| 3453 forum posts 23 photos | Posted by Michael Walters on 28/06/2016 12:17:30:

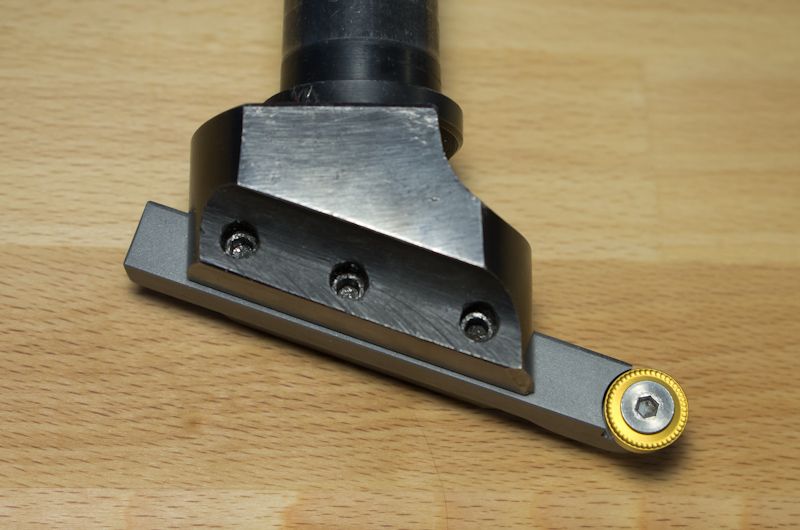

Theres no reason why you couldn't make an indexable carbide fly cutter Michael W Edited By Michael Walters on 28/06/2016 12:22:22 Absolutely. Not indexable but I made this for my fly cutter.

I should have added that as these inserts wear you can not only rotate them to provide a new edge you can also sharpen them on a diamond plate. Edited By Vic on 28/06/2016 18:30:40 |

| Roger Head | 29/06/2016 01:32:59 |

| 209 forum posts 7 photos | That's an interesting looking insert Vic. What is it? Roger

|

| JasonB | 29/06/2016 07:29:12 |

25215 forum posts 3105 photos 1 articles | Common or garden RCMT by the looks of it. |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in