Sophie Beam Engine

| Brian John | 30/01/2016 10:04:58 |

| 1487 forum posts 582 photos | I am getting a bit ahead of myself here but this will be my next project after the Stirling engine is finished. 1. How do I make the main pillar ? Would you make this as one piece or three pieces ? 2. How to get the smooth taper on the flywheel/main beam connecting rod ?

Link to Bengs added by JasonB Edited By Brian John on 30/01/2016 10:05:33 Edited By JasonB on 30/01/2016 13:41:24 |

| JasonB | 30/01/2016 10:07:28 |

25215 forum posts 3105 photos 1 articles | The column is probably cast to shape but if not then its just a case of uurning various diameters. Have a search for "fishbelly" as I did a post about how to do them, may have been Garry's my little engine thread. |

| Brian John | 30/01/2016 11:18:09 |

| 1487 forum posts 582 photos | The column is not cast to shape. I cannot find ''fishbelly''. Is this done freehand ? Can you post a link please ? Edited By Brian John on 30/01/2016 11:20:46 |

| Circlip | 30/01/2016 12:00:14 |

| 1723 forum posts | You may find, the taper is two tapers joined end to end at the thick part with a radiused bit in the middle. Turn one taper and then flip end to end (Between centres), turn second at same setting and join with a file.

Regards Ian. |

| Michael Gilligan | 30/01/2016 12:07:44 |

23121 forum posts 1360 photos | Posted by Brian John on 30/01/2016 11:18:09:

I cannot find ''fishbelly''. .

|

| JasonB | 30/01/2016 13:27:41 |

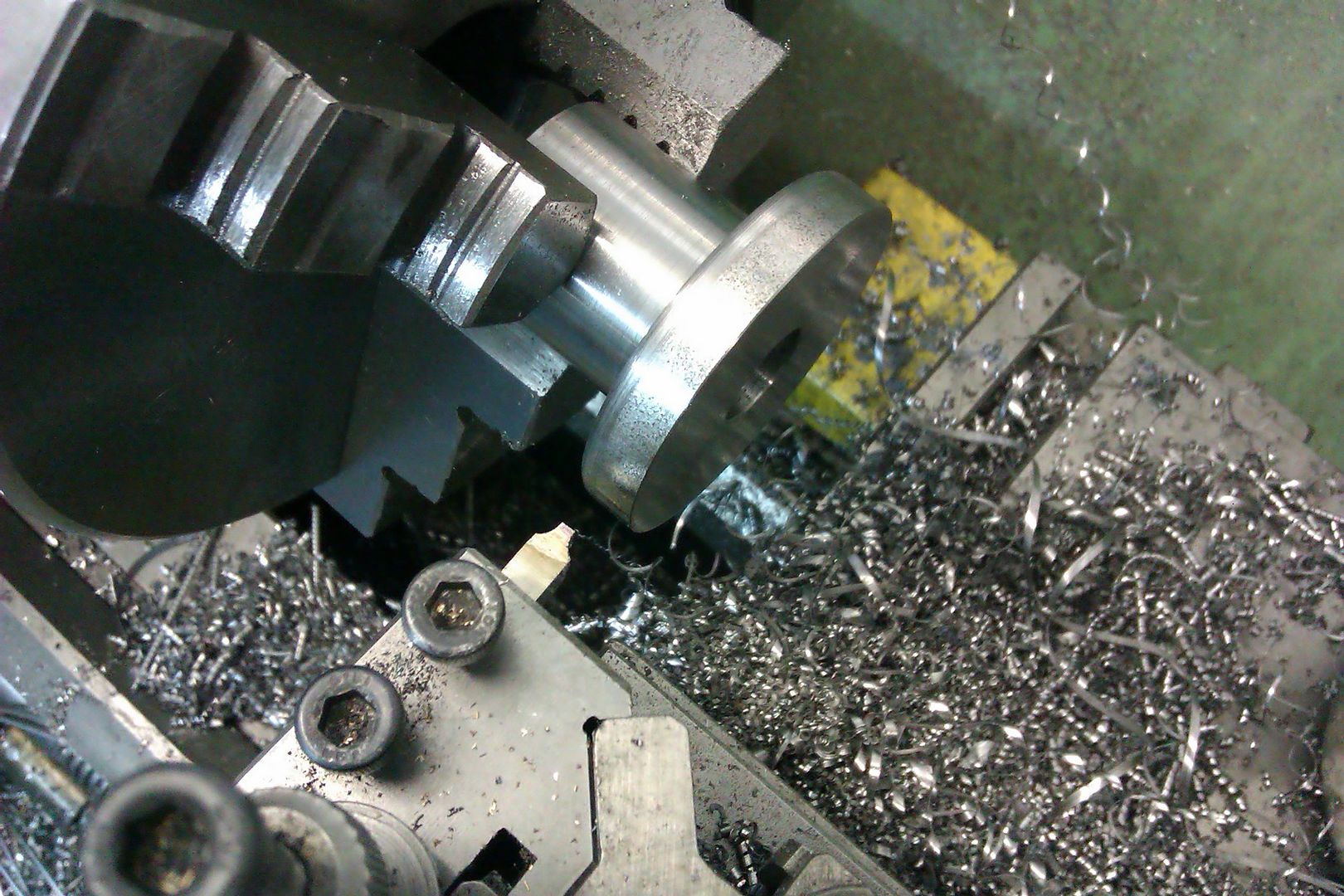

25215 forum posts 3105 photos 1 articles | Read the posts from 11-1-2014 in this thread I did some sketches to show the steps involved in fishbellying a rod. If the column is not cast then its just a case of holding a bit of round bar in your chuck with some tailstock support and turning the various diameters and then either using cocave or convex tools or eveb a file to add the mouldings This is one I did out of steel that is about 8" long, sorry no in progress photos.

I have also put a link to Bengs' site into your first post so people can see more details of teh kit.

Edited By JasonB on 30/01/2016 13:42:25 |

| Brian John | 31/01/2016 06:04:08 |

| 1487 forum posts 582 photos | Jason : So you used a file to add the mouldings ? I could not see how it might be done with a lathe tool. Thank you for the links. I now understand how the fishbelly is made : more freehand work. So I am going to have to buy a smooth single cut file from somewhere. Edited By Brian John on 31/01/2016 06:11:33 |

| JasonB | 31/01/2016 07:29:21 |

25215 forum posts 3105 photos 1 articles | IT could all be done with a file but better to do the basic shaping with a lateh tool first, think of it like a small version of that rounded piston end that you did. Its quite easy to grind up a shaped tool like this and if used on both sides would produce a half round and then just blend with a file. I don't have any single cut files but manage perfectly well so save your money.

|

| Brian John | 03/03/2016 06:19:40 |

| 1487 forum posts 582 photos | Having built one Stirling engine (''Laura'' from Bengs), I am interested in building another. How does this ''John'' Stirling engine compare in complexity with their Sophie Beam engine ie. which would appear to be the most difficult to build ?

Edited By Brian John on 03/03/2016 06:20:47 |

| pgk pgk | 03/03/2016 09:50:41 |

| 2661 forum posts 294 photos | It looks to me that Sophie would be the bigger challenge..so go for it..... and even better do it from bar stock to make it more of a challenge (specially without a mill lots of filing) |

| Ian S C | 03/03/2016 10:26:57 |

7468 forum posts 230 photos | Brian, I'd say go for it, it looks a nice little motor. From what I read on the link there's 10 pages of drawings, and 4 pages of instructions, in German, hope they have a translation. Ian S C |

| Ajohnw | 03/03/2016 12:50:11 |

| 3631 forum posts 160 photos | If you adapt a Peatol / Taig vertical slide to fit to your lathe Brian you will be able to mill lots of small things. It usually not too difficult to fit. It comes with a flat base and 2 holes running through it. That may allow it to be done as it comes. If not it's easy to fasten a bit of aluminium plate to the bottom. It's a very rigid vertical slide. Not sure if they do a metric version though but imperial would only be a minor inconvenience.

John - |

| Brian John | 04/03/2016 11:24:21 |

| 1487 forum posts 582 photos | You mean this ? Edited By Brian John on 04/03/2016 11:28:56 |

| Neil Wyatt | 04/03/2016 11:33:46 |

19226 forum posts 749 photos 86 articles | Posted by Ajohnw on 03/03/2016 12:50:11:

It's a very rigid vertical slide. - That I can vouch for! Neil

|

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in