Correct Performance of Fixed Steadies

| martyn nutland | 16/12/2015 16:06:29 |

| 141 forum posts 10 photos |

A very basic question I'm afraid, but something about which I'm not sure. How 'steady' should a fixed steady be? I run a Chester Super B and a couple of years ago I bought a fixed steady and a traveling steady for my machine from Chester. Thus one can assume I have the right part for the model. But when I use the fixed steady I find it very difficult to get a solid set-up. I.e. the steady's fingers never grip the workpiece very firmly nor its feet the bed of the lathe. I use packing between the gybs on the steady and the underside of the bed and that does help but I'm never very happy with the arrangement. So, question very simply is, are we looking for 'solid' or is 'slop' what one would expect? Thanks in advance for any guidance. Martyn (and a reflective Christmas and a peaceful, safe, and above all, healthy 2016 from Paris and this troubled world of ours.)

|

| JasonB | 16/12/2015 16:24:58 |

25215 forum posts 3105 photos 1 articles | I suspect the biggest problem is that your lathe has a very high spindle height in relation to the bed width which will make the steady less stable than a wider bed machine. I had to clean a bit of stray paint off the bottom of my fixed steady but it does bolt solidly to the lathe bed now and the fingers are rigid.

J Edited By JasonB on 16/12/2015 16:45:16 |

| Andrew Johnston | 16/12/2015 16:26:31 |

7061 forum posts 719 photos | Rock steady! A good heave on the parts shouldn't move the steady on the bed, or the work in the steady. Cutting should be possible without chatter and as good a finish as normal turning: Andrew |

| martyn nutland | 16/12/2015 16:49:05 |

| 141 forum posts 10 photos |

Jason That's true. One reason I bought the Super B was the clearance bed to spindle. Enough to turn an Austin Seven flywheel! And Andrew. That's one 'helluva' steady. Not like you get from Chester! So we must go for 'rock'. Understood. Thank you. Martyn

|

| Neil Wyatt | 16/12/2015 19:04:06 |

19226 forum posts 749 photos 86 articles | My mini-lathe fixed steady is nice and solid - just a bit of a struggle to lock in place unless you use a stubby ring spanner Don't the fingers of your have locking nuts? |

| Andrew Johnston | 16/12/2015 19:09:32 |

7061 forum posts 719 photos | Posted by Neil Wyatt on 16/12/2015 19:04:06:

Don't the fingers of your have locking nuts? No, nor on the travelling steady. Andrew |

| Nigel McBurney 1 | 16/12/2015 19:37:35 |

1101 forum posts 3 photos | The steady shown is not up to the job,the lathe centre height is too high for the overall size of the machine,the only way to try to get a good performance would be to reduce the spindle speed far below the the usual speed and take your time.It may help to stiffen the steady by making a curved reinforcing steel strip between the top of the steady and the front so that the frame of the steady is a full circle,In the photo the steady looks very clean,with no oil stains,are you lubricating the pads with oil? When using a steady on some jobs i.e. large cylinder liners I rig up a drip feed oiler to keep the pads lubricated.I would also asked is the workpiece out of balance,if it is it will naturally affect the steady. |

| martyn nutland | 16/12/2015 19:40:14 |

| 141 forum posts 10 photos |

No...as Andrew says, or in my case, just hex drive cap screws for the three fingers and one, on the leg on one side, through the gyb So, as I see it, on the Chester (aka Chinese) design(!), you pull the one leg of the steady as tight as you can against the underside of the bed, then tighten the threaded gyn on the other side (with or without packing, but normally with, as otherwise it is extremely floppy) via the cap screw and an Allen key. Result, in my experience, overall floppy! As I also see it, all Neil's lock nuts would achieve is to lock the floppy set-up. Maybe I'm missing something. Martyn

|

| Emgee | 16/12/2015 20:07:05 |

| 2610 forum posts 312 photos | Another substantial fixed steady on a Denford Orac, modified base to suit this lathe, very sturdy. Emgee. |

| JasonB | 16/12/2015 20:12:50 |

25215 forum posts 3105 photos 1 articles | Posted by Nigel McBurney 1 on 16/12/2015 19:37:35:

The steady shown is not up to the job,................... Where are you seeing this steady? Martyn has not put up a picture |

| martyn nutland | 16/12/2015 22:09:30 |

| 141 forum posts 10 photos | No Jason, I think Nigel means your steady is not 'up to the job'. My steady should be 'up to the job' because, as I was at pains to explain, I bought it from Chester as it was specifically for the Super B machine. Now I have to make a confession that I honestly, honestly did not think was relevant when I started this thread; but perhaps it is. I had a big row with Chester at the time over these items. They took ages to arrive and when they did they were very battered and had clearly been used (maybe abused) although I paid list price. I took this up with Chester, who I don't like as a supplier, and they said the steadies were in the state they were because they had been on the shelf for years. This was clearly a load of b-----ks. They had been using them at an exhibition, which explained the delay in despatch and they were in fact 'second hand'. This needn't have been said, but as everyone seems to have steadies that are as steady as a rock, I feel I must be totally honest. Martyn

|

| Bazyle | 16/12/2015 22:29:47 |

6956 forum posts 229 photos | You said at the beginning that it wasn't firmly fixed on the bed. You need to start by looking at the mounting. Perhaps the surfaces are not flat, parallel, there is paint on them etc. When you have it rock solid such that you can not feel any knock as you push it around then move onto stage two. We don't even know what it looks like so can't give much more advice. |

| Neil Wyatt | 16/12/2015 22:51:36 |

19226 forum posts 749 photos 86 articles | This is my steady, from Arc. It works just like the one on the Denford except it doesn't open up, and probably has even more meat in it..

This (from Machine Mart) is the steady for the Cl500M which I think is equivalent to the Chester B Super Multi.

It has screws to remove any play in the fingers. The locking mechanism looks OK to me, but it sounds like Martyn is running out of adjustment before it locks? Or maybe, as Jason suggests, paint needs to be removed from underneath. Other possibility would be a high spot on the contact surface, which should be easy to correct with a bit of blue. Neil |

| Michael Gilligan | 17/12/2015 00:15:50 |

23121 forum posts 1360 photos | Assuming the Chester Super B to be the item shown here Centre Height 210mm [forgive me if this is the wrong machine] Although a travelling steady should be viable; it would be quite difficult to engineer a decent fixed steady, and I would be interested to see an illustration of Chester's effort ... perhaps for good reason, this does not appear to be currently listed as an accessory. MichaelG.

Edited By Michael Gilligan on 17/12/2015 00:18:11 |

| John Stevenson | 17/12/2015 00:49:02 |

5068 forum posts 3 photos | Some points.

Andrews steady does have locking facilities, they are grub screws fitted to the 3 bosses facing rearwards in line with each finger.

Nothing wrong with Jason's steady, bet if truth be know it's done more work than the average OAP. The clue is in the name, STEADY, it steady's work. It not work holding, a chuck or a vise and is used accordingly.

The big, nay, read massive, crank grinders used to grind the Merlin cranks had steady's with wooden fingers and they did a sterling job.

Never having used a Chester B type steady but appreciating that it could have problems due to the centre hight then care must be taken to see that it does fit the bed as well as possible. May also help to plate the hight up to working hight with two thickish steel plates bolted front and back to make it more rigid. |

| Hopper | 17/12/2015 05:07:05 |

7881 forum posts 397 photos | Martyn, a picture of your steady/ies would save a thousand words. But for starters, you need to get rid of bits of shim between the steady and the bed. The steady needs to be locked solid to the ways. You may need to look at the length of thread on the clamping bolt, or some washers under the nut, or perhaps a piece of casting sticking out preventing full clamping movement. |

| martyn nutland | 17/12/2015 07:22:37 |

| 141 forum posts 10 photos | Good advice. I'll try these solutions. I think the Chester design is probably a 'dud' now I know things should be 'rock solid'. Thanks again. Martyn |

| JasonB | 17/12/2015 07:46:45 |

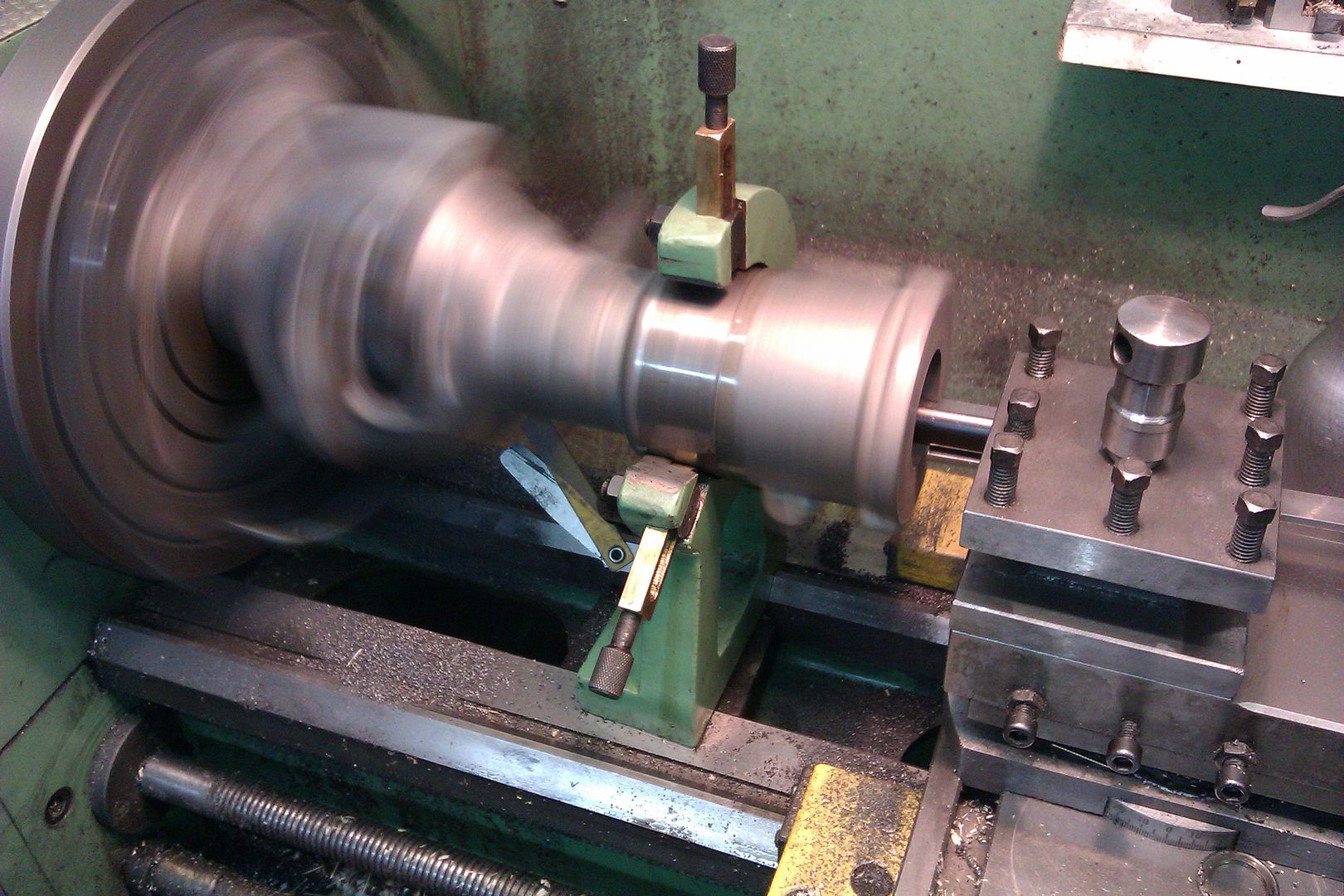

25215 forum posts 3105 photos 1 articles | The Centurion is basically the same lathe as you can see this IS a steady that is too tall for the bed width unlike mine which does the job perfectly well. Faced and bored 7" deep

Edited By JasonB on 17/12/2015 07:47:02 |

| Martin Kyte | 17/12/2015 08:48:40 |

3445 forum posts 62 photos | I apologise in advance if I am questioning your experience but you do understand that steadies are intended to run on portions of the work that are already truly circular and concentric with the spindle.? It's there to resist cutting forces not to centre the work. Sorry if you already know this but not everyone does when they first start out and I have no idea how long you have been at this. If you do understand just ignore me. regards Martin |

| Andrew Johnston | 17/12/2015 09:00:15 |

7061 forum posts 719 photos | Posted by John Stevenson on 17/12/2015 00:49:02:

Andrews steady does have locking facilities, they are grub screws fitted to the 3 bosses facing rearwards in line with each finger. Yep, noticed them last night, and just checked. They are indeed locking grubscrews; same on the travelling steady. One learns something every day, even if it's only that I'm a wally. Andrew |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in