Has anyone ever tried this?

| Philip Rowe | 03/12/2015 16:20:42 |

| 248 forum posts 33 photos | Sorting out some old files earlier today, I came across some notes that I had made as an apprentice more years ago than I care to admit to. Amongst lots of notes was one that I had completely forgotten about and which I don't even know is correct. Apparently a test for stainless steel is to coat it with copper sulphate solution, which some of us may remember was used as a marking out fluid. If the solution dries and sticks to the steel it is not stainless. If it simply wipes off after drying, then it is a stainless steel. I have never tried this and no longer have access to any copper sulphate to prove or disprove the idea, I wondered with all the vast wealth of knowledge and experience on this site if anybody could confirm or deny this. I vaguely recall sitting in a classroom during my apprenticeship at a division of G.E.C. during the early 60s and being fed all sorts of facts and figures, most of which I have forgotten, so I presume this is where my notes originated from. TIA Phil |

| Chris Evans 6 | 03/12/2015 16:52:18 |

2156 forum posts | Phillip, I can not answer your question but I also served my time at the GEC. Moulded Plastics Division toolroom from 1963 until 1970. Where where you ? I know they had sites all over the country. |

| Tractor man | 03/12/2015 16:57:41 |

| 426 forum posts 1 photos | Hi Phil, I was taught that trick by a Sheffield cutler to sort stainless out from carbon steel knife blanks. The actual indicator is if the metal becomes copper plated it is plain steel, if it stays bright then its stainless. The cutler just had a largish lump of copper sulphate crystal on his bench and if he needed to check if it was stainless he would just wet the steel and rub the crystal on it like a touchstone. Works really well. Stainless steel will actually rust if its not polished I was told, so lumps of raw steel could be indistinguishable from each other in the workshop. I still have a small bottle of copper sulphate solution made up to test steels if necessary. Regards Mick |

| Tim Stevens | 03/12/2015 16:58:47 |

1779 forum posts 1 photos | The surface of Stainless is certainly less reactive, in fact in most environments it is described as passive - which is why it does not rust etc. So, you may well be right, but I suggest it may depend rather on the grade of SS, and indeed on the nature of the CuSO4. if it is acidulated (with sulphuric acid usually) it might work differently from the blue vitriol on its own. Regards, Tim |

| Rik Shaw | 03/12/2015 17:01:13 |

1494 forum posts 403 photos | Phil - call me old fashioned but I still prefer copper sulphate as a marking out fluid but not for stainless as it just runs of without leaving a film of copper. I suppose its one of the reasons its called stainless! Just use a magnet - its less messy. Rik |

| Chris Evans 6 | 03/12/2015 17:05:26 |

2156 forum posts | "Just use a magnet it's less messy" but not for the 400 series stainless which is magnetic. |

| Rik Shaw | 03/12/2015 17:16:23 |

1494 forum posts 403 photos | .........and here's me thinking a four hundred series was a Rover. |

| I.M. OUTAHERE | 03/12/2015 17:37:39 |

| 1468 forum posts 3 photos | We used copper sulphate solution to check the hardchrome plating on rollers , if you wipe the roller down with a rag that had been dipped in copper sulphate solution it would react where the chrome had been ground off . There is a catch to using it for stainless and that is you could have a carbon steel bar or rod that has been plated so a magnet test would be useful as well . The next thing is to test if it is stainless or monel , from memory another acid test . I vaguely remember something about austenitic manganese steel not being magnetic either

Edited By XD 351 on 03/12/2015 17:38:46 |

| Philip Rowe | 03/12/2015 19:52:36 |

| 248 forum posts 33 photos | Interesting to see all the responses, seems that my notes were correct after all. Thanks to all for the information, it never ceases to amaze me the wealth of knowledge that can be found here. Chris, I did my time at MOV (Marconi Osram Valve) in Hammersmith, I see from Google earth that it is now a Tesco supermarket but nice to see that the original staircase and lift shaft tower with an ornate copper dome roof has been incorporated into the modern architecture. I suppose in the world of micro electronics, big glass cased valves and cathode ray tubes generating unwanted heat don't have much of a place, although presumably somebody must be making big transmitting valves. Maybe someone here can put me right? Phil |

| Neil Wyatt | 03/12/2015 21:05:24 |

19226 forum posts 749 photos 86 articles | www.ampvalves.co.uk/product-category/valves/ My Vox Vt20 combines a digital sound processor with an EL81 that it uses to generate overdriven valve sounds - it is amazing the range of sounds it produces and you can even 'dial in' an artists rig and be reasonably confident of getting a fairly close sound that can be tweaked to a good representation. If only I could play as well as it sounds... Neil |

| Chris Evans 6 | 03/12/2015 21:56:15 |

2156 forum posts | Philip, you where a long way from me in Brum. Happy days and a very good training at the GEC. I did six years as an apprentice toolmaker and still can't see how modern apprenticeships can be done in three years. |

| Muzzer | 04/12/2015 08:37:17 |

2904 forum posts 448 photos | One of my student sponsorship / vacation jobs was with GEC EEV in Lincoln where they made microwave duplexer valves etc. On the same site they also made the last of the massive copper and glass thyrotrons. You could almost have climbed inside some of them, they were that big. Like the duplexers, they were manufactured using mechanical processes (bright brazing, mechanical fitting etc). Gone are those days - and its parent company of course.... |

| Geoff Theasby | 04/12/2015 08:50:30 |

| 615 forum posts 21 photos | Large transmitting valves (Well, large to radio amateurs) are still made in Russia, and marketed under the Svetlana name. I think EL34, KT66 vales etc., are still made new, to cater for the valve amplifier hi-fi enthusiasts. There are also oodles of 'new-old stock' left over from the 60s easily available. Geoff |

| Anthony Kendall | 04/12/2015 09:33:36 |

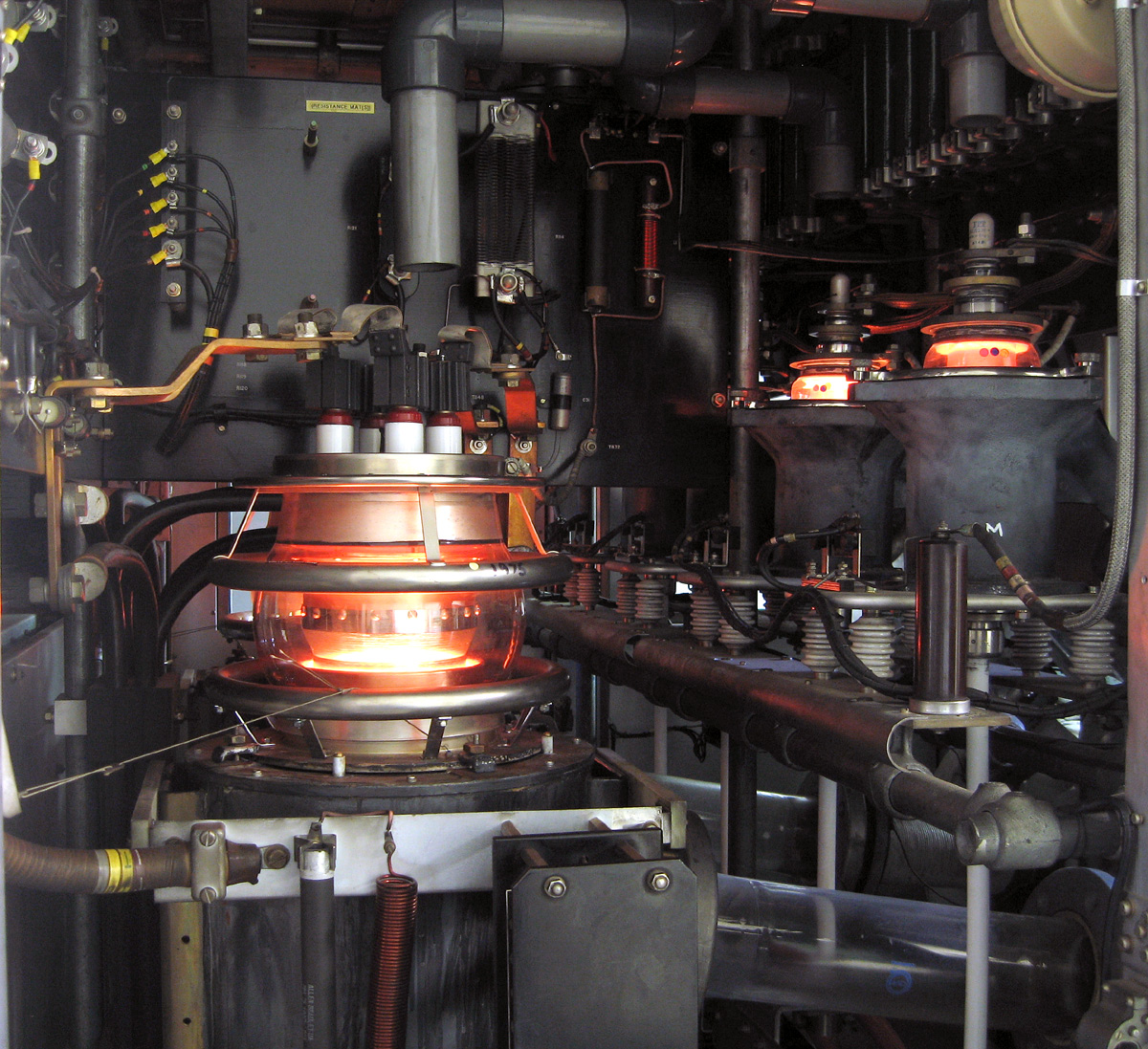

| 178 forum posts | Time to look at a real valve methinks - one with vapour cooling....

|

| hth | 04/12/2015 09:47:31 |

| 93 forum posts 22 photos | Hi

A ham friend of mine works for Eimac ? in California, where they still manufacture vacuum tubes to this day . He told me they do special stuff for the US military , Radar sets use Magnetrons I think thats right . But they also make and recondition tubes for commercial FM transmitters . Valve technology is still alive in various applications . |

| Muzzer | 04/12/2015 10:54:01 |

2904 forum posts 448 photos | Yes, magnetrons for microwave / radar. At EEV, I made a tester for evaluating the leakage of duplexers with a quick change fixture. The driving magnetron was something like 50kW pulsed maritime unit and there was no safety interlock. If I turned on the magnetron without a duplexer in the fixture, you could smell the ozone... The safety hazard from microwave and radar is surface heating of the skin and organs - no cancer hazard, as the energy is safely below that required for ionisation (eg X-rays etc). You might suffer skin burns and possible eye damage if you played your cards right. Duplexers are used to automatically connect / disconnect the shared waveguide / horn (aerial) between the transmitter and receiver. When transmitting, the energy due to the magnetron causes a spark gap in the receiver waveguide to break down. The resulting short circuit, carefully positioned a quarter of a wavelength from the junction, causes the receiver circuit to be seen as an open circuit and thus the sensitive receiver is protected. This work at EEV was years ago - around the time of the Fauklands conflict. IIRC, the Exocet missiles used EEV components. It was no place for a young engineer back then - I seemed to be the only one under 50. Retaining staff was challenging and they struggled to find new product concepts. They are now trendily called E2V (wow) but at least it appears they have a viable and sustainable business and the LIncoln site still makes microwave stuff.I expect the thyrotrons are long gone, mind... Murray |

| KWIL | 04/12/2015 11:05:59 |

| 3681 forum posts 70 photos | Happy days!! |

| Anthony Kendall | 04/12/2015 13:45:04 |

| 178 forum posts | Muzzer, the valve above is an EEV valve, built at Chelmsford. It produces 125kW of audio. |

| Muzzer | 04/12/2015 14:31:21 |

2904 forum posts 448 photos | Wow. An eighth of a megawatt of sound - that would make your ears bleed! What's that for - sports stadia etc? Psychops? I expect they will be replaced by Class D amplifiers now (soon?). When you say vapour cooling, do you mean some kind of phase change is involved or do you mean some form of inert gas circuit? I've used boiling Flourinert (boils at 70C at atmospheric pressure) for cooling power semis, which allows amazing power densities without heatsinks but my only experience of (fan-cooled) power valves was in a 1kW 2m linear amp back in the radio amateur days even before EEV. |

| Martin Kyte | 04/12/2015 15:08:47 |

3445 forum posts 62 photos | We used Traveling Wave Tubes for Radar Power Amplifiers and they did generate X-Rays. Martin |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in