Casting defect in cylinder wall

| JasonB | 19/10/2012 20:16:35 |

25215 forum posts 3105 photos 1 articles | If you reduce the bore by fitting a sleeve then yes the rings will need replacing, if you make the liner to a standard size eg 1.375" bore then you would have the choice of either making your own which is not hard or buying them off the shelf from the likes of Reeves or Stuarts If you were to skim a bit more out of the existing bore and take it upto 1.675" then you could make your liner bore to the original 1.5". However like I said on another forum this will depend on how close you can get without drastically cutting into the steam passages or getting close to the cylinder cover stud holes.

J |

| Stub Mandrel | 19/10/2012 21:39:40 |

4318 forum posts 291 photos 1 articles | Machinery's Handbook is great, but it's a refernce manual, not a how to guide. I recommend Peter Wrights Model Engineering a Foundation Course. Neil |

| David Haynes | 20/10/2012 07:19:51 |

| 168 forum posts 26 photos | What success have people had with machining these expoxy resins? Dave |

| JasonB | 20/10/2012 07:34:23 |

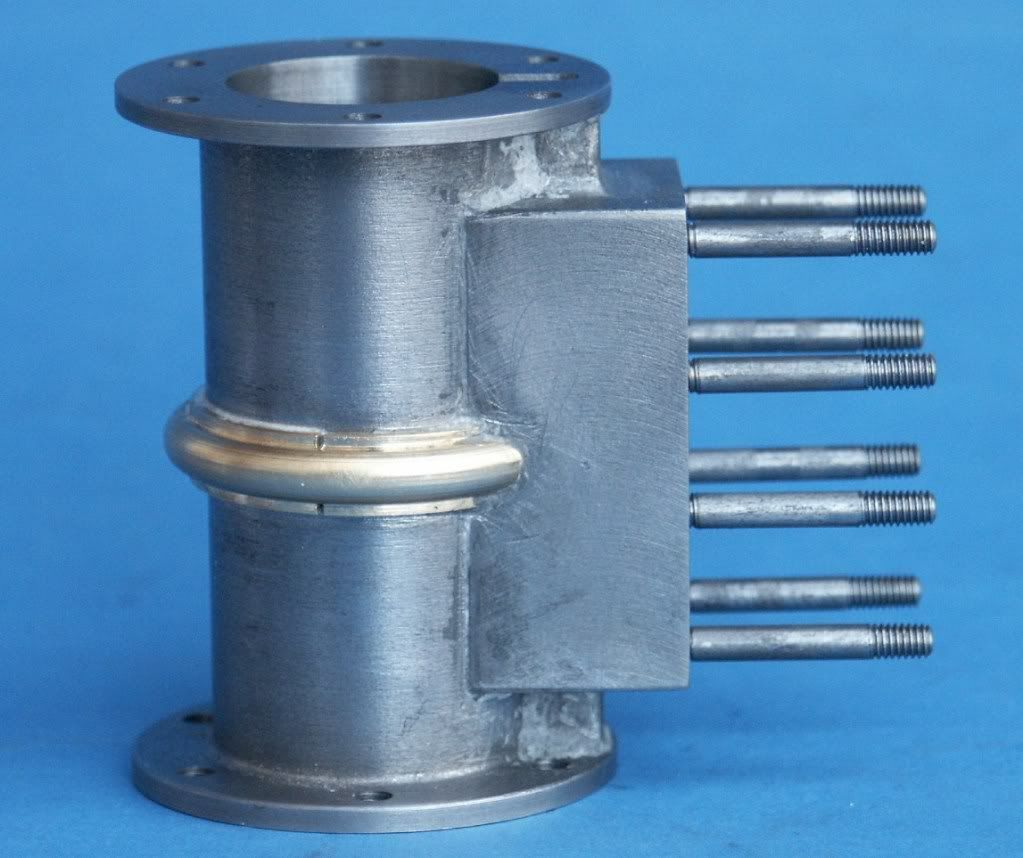

25215 forum posts 3105 photos 1 articles | I've not actually machined the JB Weld but have machined parts that are bonded together with it. For example the valve chest on this engine is bonded to the cylinder with the stuff and I was able to use a 40mm indexable endmill to machine the valve face with a fair depth of cut and it held up. I mostly use it to create fillets when fabricating "cast" parts and from whats required to blend it out I should think what they say about being able to machine it is true.

J |

| RICHARD GREEN 2 | 20/10/2012 09:08:18 |

| 329 forum posts 193 photos | Hello Sarah, Yes, my compound engine will have cast iron piston rings, I will make them myself to fit the new bore sizes, Piston rings are not too difficult to make, and are a very satisfying little project . Stub, I did state in my previous reply that "Machinerys Handbook" is a reference book, Sarah was asking about interference fits, "Machinerys Handbook" has got all the information on shrink fits, press fits, running fits and every other kind of "fit" that she will ever need. Richard. |

| Sarah | 20/10/2012 17:12:16 |

| 27 forum posts 4 photos | Hi Richard and Neil, Thank you both for the book recommendations, I'll have a look out for both of those. I have a couple of projects where I need to make some plugs with interference fits and I do need to do some research before I do this. I also want to find out dimensionally what is a good fit for crankshafts into brass bearing blocks. The No.4 engine does have too much play between round the bearing blocks and it would be nice to make the new bearing blocks to a specific size rather than just machine a bit then check, machine a bit then check etc.

I am learning a lot with the steam engines, but still a lot more go Many thanks for your help again, Sarah |

| Dusty | 20/10/2012 21:48:18 |

| 498 forum posts 9 photos | Sarah You say you don't know if the engine has ever run. If it has then the imperfection in the bore is probably contaminated by oil, if this is the case it will be almost impossible to clean the hole of oil in order to get the JB weld to adhere, as I suspect the cylinder is cast iron. In which case I would opt for the sleeve route. Edited By Dusty on 20/10/2012 21:49:41 |

| Jens Eirik Skogstad | 21/10/2012 08:02:20 |

400 forum posts 22 photos |

Posted by Terryd on 16/10/2012 14:03:47:

Hi Ian, It is common Stuart practice to have two rings in one groove. The Stuart Beam I'm refurbishing at the moment has this arrangement, Regards Terry Not all Stuart has 2 rings in one ring groove. I has Stuart compound steam engine, it has 1 ring in each ring groove, also 2 ring for each piston. And other to example no rings in piston in Stuart D10, it has bronze piston in cast iron cylinder. Some time can it be O-ring in bronze piston for reduced leakage (improved by model-engineer/hobby mechanic in case the piston is sloppy in cylinder). Sarah, the compound steam engine has cast iron rings, 2 rings for each pistons. Height of ring groove is 1/16". |

| Terryd | 21/10/2012 08:48:27 |

1946 forum posts 179 photos | Hi Jens, Sorry if I misled you and others by saying 'common Stuart practice'. That was a sloppy description, I should have said that Stuart designs often use two rings in one groove and it is common practice across several of their designs. I made both my 10H and 10V without rings. Just goes to show how easy it is to confuse by poor use of language and how difficult it is to clarify precisely what is intended. That is why we use drawings rather than text to describe components. best regards Terry |

| Ian S C | 22/10/2012 13:17:30 |

7468 forum posts 230 photos | Terry, Iwas going to use PTFE tape instead of rings, but as I had the cast iron, I though I would at least try Iron rings, I'll use the PTFE for the glands. Ian S C |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in