Shapers (obsolete or not)

| John Stevenson | 25/07/2012 00:36:24 |

5068 forum posts 3 photos | Paul, I cheated when i did mine. I did them reversed so i only had to do two infernal ones and all the holders were just cut off an 18" slab that had been run down twice with a 60 degree side and face cutter on the horizontal. One pass either way. Currently have 43 holders between two lathes but could do with a few more to save swapping tools.

|

| _Paul_ | 25/07/2012 01:01:41 |

543 forum posts 31 photos | John

43 holders make my 15 or so look a bit sick My homemade ones are from chunks of unknown "scrapbinium" what material did you use any preference? Paul |

| John Olsen | 25/07/2012 03:35:39 |

| 1294 forum posts 108 photos 1 articles | Well shapers are certainly obsolete in industry, they are too slow. For amateurs...well, we are not usually concerned about time so much, and cheap tooling can make up for any extra time taken. If you have the space a shaper can be handy thing to have. If you don't have a lot of space, a lathe and a vertical mill is probably a more versatile setup than a lathe and a shaper. But you won't get the finish that a shaper can give you from a vertical mill, unless you can afford a good CNC machine, and that will be rather more expensive than any shaper would be. As far as the dovetails go, well, so far I have needed to do dovetails with 55 degree and 60 degree angles, so that would double the number of cutters needed. Wouldn't matter for production, where you are probably going to wear them out anyway, but for a one off it becomes a bit more questionable. I've also done T slots, although for some of those I do have the T slot cutter to fit the mill. They are a bit faster and less fiddly to do on a mill, but the shaper uses home made cutters which are certainly cheaper. When I find that the nearest piece of scrap is a bit oversize for the job needed...well, there is nothing like a shaper for ripping a bit of stock down to size. Shapers are good for work on stationary and marine type steam engines, where a lot of the work on the original would have been done on a planer. There is probably not so much work in a loco that a shaper would be useful for. But after all, it is a hobby, I enjoy my old shapers. If you don't happen to like them, feel free to use something else. Someone local has a $50,000 CNC machine at home...I am sure I would enjoy that too, if I had that sort of money to throw around. John |

| John Stevenson | 25/07/2012 07:19:23 |

5068 forum posts 3 photos | Paul, That design of mine was originally done in a smaller size for a ML7 years before cheap mports came out and I thought long and hard about it to make the production of the holders as easy as possibel given you only make one post but multiple holders.

The design was published in ME somewhere about 1987 but the design pre dates this by a while. The original is still alive and well and lives on Tony Jeffree's ML7 as he bought it from me.

My holders are just cold rolled steel as the design is based on a stock size, less machining. In fact only the dovetails, the tool slot / boring bar hole and clamp screw holes is all that is needed. As mentioned before the dovetails are milled in whist the holders are in an 18" long stick form on a horizontal mill, then sawn off.

Finla operation is to send them over the road to the heat treat plant and have them Tuftrided. It's a low temerature process, well low for heat treat, around 400 degrees but at this temperature you don't get any distorsion. This puts a hard black oxide coat on, only mirons thick but it's also rust resistant and stop the day to day dings and marks.

John S. |

| _Paul_ | 25/07/2012 16:19:51 |

543 forum posts 31 photos | Thanks John I'll have to have a dig through my old copies, having started to make the Aloris/PhaseII type I am now sort of commited but I can change that.

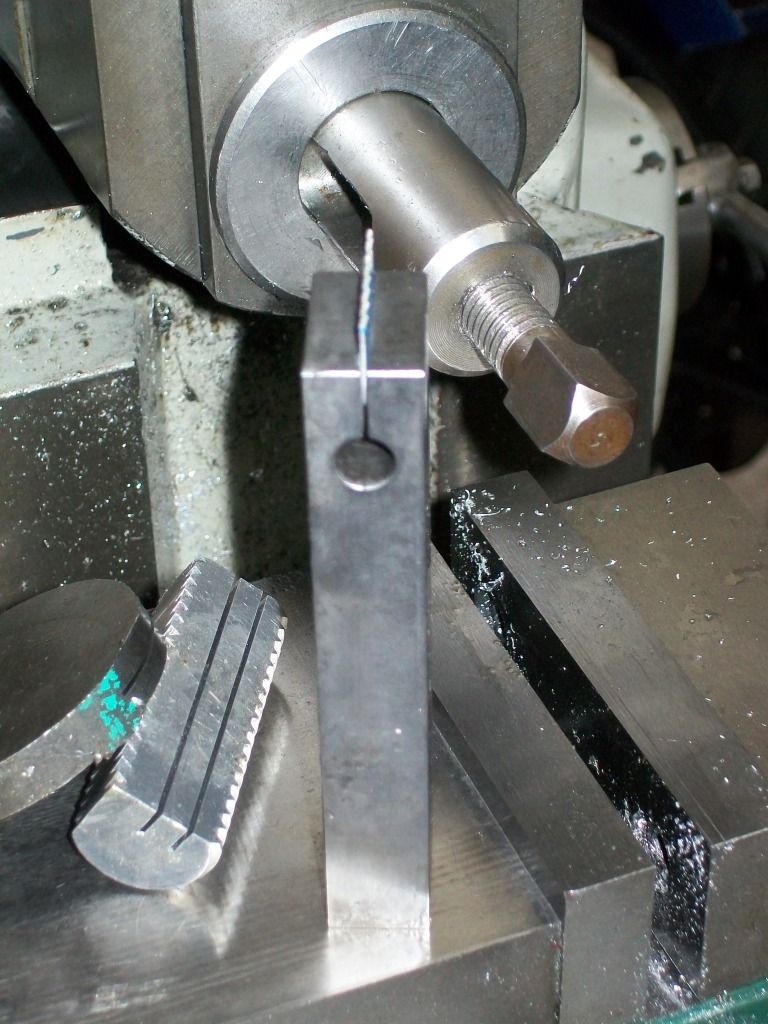

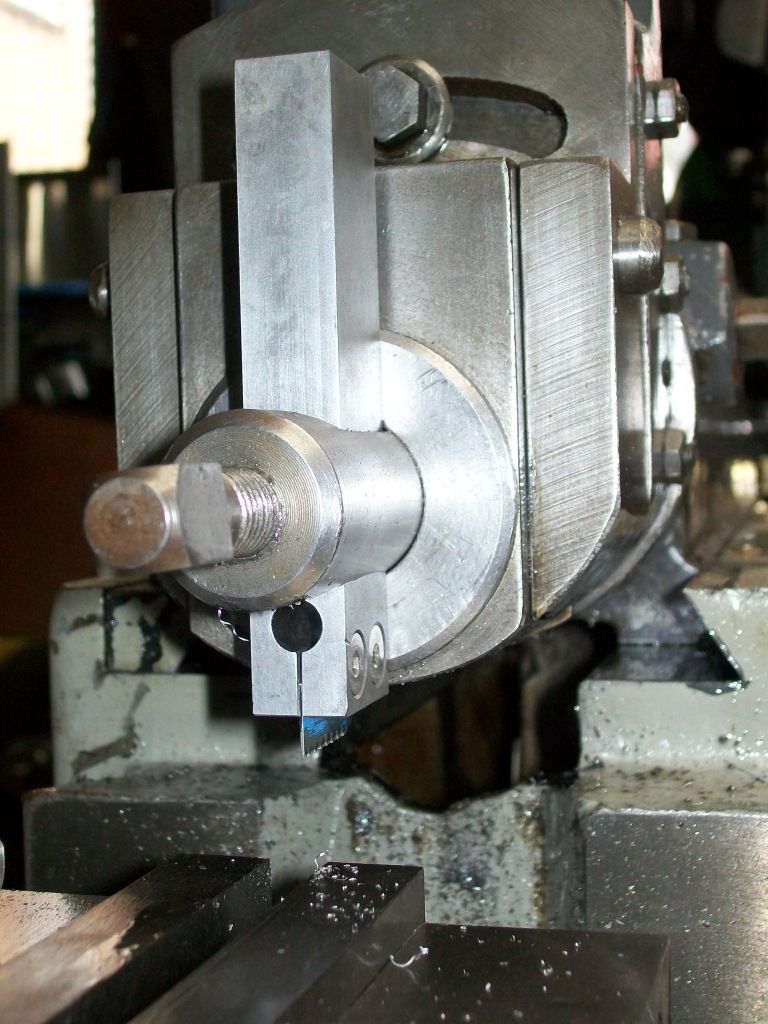

You make me quite envious any heat treat I have done is by yours truly and is never as good as I would like The Shaper can have some "diverse" uses I recently made this it's a slitting saw designed along the lines of Ian Bradley's (from his Shaping Machine book).

You may think this wouldnt have a great many uses but its great for slitting bushes and the like, uses scrap bits of old hacksaw blade as a cutter and unlike a thin lathe/shaper slitting blade it's 1" length means it dosent snap or shatter easily.

Regards

Paul |

| Shaun Trewinnard | 25/07/2012 19:45:25 |

| 9 forum posts | I bought a shaper some months ago and have been a little diffident about using it for fear of messing it up. Ian Bradley's book has been mentioned which might be just what I'm looking for. Any ideas where I could obtain a copy? Shaun T |

| Stub Mandrel | 25/07/2012 21:28:06 |

4318 forum posts 291 photos 1 articles | Saw a big shaper in action under steam power at Clay Mills Pumping Station. It was a delight to watch. Neil |

| Nobby | 25/07/2012 23:12:33 |

587 forum posts 113 photos |

Hi |

| colin hawes | 26/07/2012 11:27:42 |

| 570 forum posts 18 photos | My 10 inch shaper does frequent work on preparing the lumps of rusty steel, that lay on my scrapheap, for milling. It can machine wider flat surfaces than an average amateur's mill without leaving the overlapping cutter marks, is quick to set up,uses cheap tools and is very suitable for use on the tough steels and rust that soon ruin good milling cutters.I have recently thinned down pieces of car leaf springs that the milling cutters jibbed at ; some for a model and some to make a flypress tool. I have also used it as a slotter to cut internal splines ,keyways, gearteeth and various other profiles. So a shaper does have it's place in the amateur's workshop if you heve the space. I wonder if I could make it do hacksawing ? Colin |

| _Paul_ | 26/07/2012 12:20:35 |

543 forum posts 31 photos |

Posted by colin hawes on 26/07/2012 11:27:42:

I wonder if I could make it do hacksawing ? Colin There are a few ideas online here's one on the NEMES site I've not made one (apart from the slitting saw) but from what I read the issue centres around chip clearance, the working area of the saw blade would have to completely exit the work for the chips to clear so to cut a 5" lump of metal you would need a machine with at least a 10" stroke to clear the chips. It's the same principle as my old Donkey saws both have 14" blades but only have a 6" stroke. Paul Edited By _Paul_ on 26/07/2012 12:22:17 |

| colin hawes | 26/07/2012 14:36:29 |

| 570 forum posts 18 photos | Thanks for the info Paul .It seems that a shaper has more possibilities than is generally assumed. Too busy now to make a shaper hacksaw but is a future project. I like the bush splitting saw idea. It's a quick thing to make. Colin |

| _Paul_ | 26/07/2012 15:28:42 |

543 forum posts 31 photos |

Posted by Shaun Trewinnard on 25/07/2012 19:45:25:

I bought a shaper some months ago and have been a little diffident about using it for fear of messing it up. Ian Bradley's book has been mentioned which might be just what I'm looking for. Any ideas where I could obtain a copy? Shaun T Ian Bradley's book is OK but IMHO copies seem to be very overpriced, especially for the amount & type of content it also concentrates too heavily on the "Acorn" shaper (7" Atlas clone/copy). Here are some other tomes you may wish to consider:

Online you will find Machine Shop Operations & Setups (Chapter 7 I think) which is from "Cincinatti" tools and for a freebie it's very good. There are many others but I guess these are my favourites. Paul |

| Dunc | 29/07/2012 19:51:29 |

| 139 forum posts | I second the NEMES site. Many of the books noted above can be found by searching on: books.google.com Another site worth trying is: http://www.archive.org There are Yahoo groups: South Bend had How To Run a Shaper & Drill Press: my copy dates from c.1954 I have heard of a book/ME article (both?) that dates from the 1950s by Duplex. I expect that ME would have many posts but I am not a digital ME subscriber. MEW has a three-part article By Don Morris starting in MEW #22, Mar-Apr1994. Part 2 is in #24 & Part 3 in #25. The US magazines have some as well: Popular Mechanics How To Use, June 42; Know Your Shaper, Feb 54; How To Cut Contours, Oct 58.

Popular Science articles: How to Use, Aug 43; How To Cut Keyways, Apr 44.

Edited By David Clark 1 on 30/07/2012 09:35:52 |

| John Coates | 05/08/2012 00:11:15 |

558 forum posts 28 photos | Having just got back from 2 weeks holiday and missing this thread can I just say my Elliott 10M is now a much loved addition to my workshop. As previously stated it makes perfect flat planes which I found great for cleaning up my Keats angle plate castings from CES with none of those milling problems about getting beneath the cast iron crust. Cheap 1" x 5/8ths tool steel and I can make any number of useful cutters. I do like that slitting saw idea though - I'll be making one of those! |

| Martin Walsh 1 | 16/09/2012 12:57:36 |

| 113 forum posts 2 photos | I couldn't agree more I also have a elliott 10m great machine you get a much better surface finish than fly cutting on a milling machine also as the previous poster said If you are machining castings it is much more economic than using expensive milling cutters I love my shaper Best Wishes Martin ps Iam just going to try and cut a dovetail on mine Edited By Martin Walsh 1 on 16/09/2012 12:59:30 |

| _Paul_ | 17/09/2012 12:08:57 |

543 forum posts 31 photos | Rudy Kouhoupt did a couple of DVD's on using the shaper in one of them he shows how to cut a dovetail, I found both of his video's very helpful. I think Camden Miniatures stock most of Rudy's DVD's.

Paul |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in