Files- best bang per buck

| MW | 13/07/2016 12:10:46 |

2052 forum posts 56 photos | Posted by Ajohnw on 13/07/2016 11:41:11:

Reduce pressure obviously but lift off ! No way. I have seen odd people doing that but never ever in training or in a toolroom.

I think thats mainly what they mean by not applying force to a backward stroke, presumably given enough time it will start to wear the teeth down and make each successive stroke that much harder. I've not actually seen this demonstrated however. Like you said, theatrically moving the file off the workpiece to show you're doing it is going to make it much longer to finish the job, i was once told about 50 strokes per minute was a reasonable average, and that a decent fitter could use the same file every day for 3 months and still be in good nick with care. Michael W

Edited By Michael Walters on 13/07/2016 12:14:24 |

| Ajohnw | 13/07/2016 13:25:06 |

| 3631 forum posts 160 photos | I'd say 3 months easily with correct use and a lot of metal removal. Some people reckon that they need a bit of use to cut cleanly and efficiently. I wouldn't argue about that at all. Filing flat and accurately is an odd process in some ways. Work needs to be at the correct height. At the 10 and 12" size the usual style of flat file with a safe edge should have a curve to it which tends to flattened in use. I reckon for truly accurate work purposefully lifting the file well off the work would mess it all up. There is also the point that a little bit of drag on the return stroke probably helps keep them sharp and maybe has something to do with them breaking in. Just a theory messed up by the curve but given that the pressure goes on after the stroke starts maybe not. Once people have the hang of say on a cube they check the error and then more or less change the angle of the file / play around the pressure on the file depending on the magnitude of the error. Done properly even with a large 2nd cut file the results will stand checking with blue, even the angles. Needs something smoother for a high quality finish. I'd guess there are other people on here that made the infamous square within a square and fitted an odd shaped template to a hole in a block of steel. In these cases for perfect results people are working to extremely fine limits. I'd guess that even a couple of 1/10,000" will mess the square within a square up. Mine was a 1 inch square. Aim being to get a firmish fit that is exactly the same when the square is rotated. Also when it's put in sideways anywhere. John -

Edited By Ajohnw on 13/07/2016 13:25:33 Edited By Ajohnw on 13/07/2016 13:26:47 |

| MW | 13/07/2016 15:57:04 |

2052 forum posts 56 photos | "I'd guess there are other people on here that made the infamous square within a square " When i was an apprentice those sadists gave me a piece of plate and asked me to get it square in all planes, it was a travesty to sort out and had the chief engineers scrutinizing every aspect of it, despite the fact they wouldn't imagine having to do these things themselves. As far as i could see i was the only one fiddling with metal to accurate sizes by hand whilst they're pushing buttons on their fancy machining centres. If they really made all their workers do this in the 19th century as a test i'm surprised nobody stuck two fingers up at them, i bet it happened, you're essentially asking someone to make an extremely awkward thing for it's own sake and then blaming them when it goes wrong, they can't seem to understand why someone would get angry? It might be a useful exercise but borderline construed antagonizing. I only wish i could see the look on their faces if i asked one of them to get a plate all nice and square for me, oh and by the way, it's going to have the full works of inspection, i'd analyse it to hell, not because it's important just because i want them to. Would show them the picture beyond their mirror maybe? Sounds ridiculous. I'd suspect that maybe during those days, there wasn't a separation between "basic" skills(i'd call good filing an art form) and proffesional demands. I think the top engineers then would be expected to do filing but these days you're not so they no longer practice what they preach. Michael W Edited By Michael Walters on 13/07/2016 16:15:43 |

| Jon | 15/07/2016 16:24:00 |

| 1001 forum posts 49 photos | Agree there Michael but that was when there were proper engineers employed who made this country great. All gone now anything will do. 50 strokes a miniute with a file and lifting off, top whack looking 20-25 with a 12" bastard which will generate heat quick in the part and file. |

| Ketan Swali | 26/07/2016 14:48:20 |

| 1481 forum posts 149 photos | After reading about Tomé from Dias Costas post, I asked him about them, discussed with our John S, and we decided to pay them a visit last Thursday. Here is a link with pictures and some factory footage of our day trip to Lisbon. Arc is hoping to carry a range of their products soon. Thank you Dias Costa for introducing us to Tomé. Ketan at ARC. |

| Michael Gilligan | 26/07/2016 18:10:45 |

23121 forum posts 1360 photos | Fantastic News, Ketan Thanks to all concerned. MichaelG. |

| MW | 26/07/2016 18:27:09 |

2052 forum posts 56 photos | How intriguing, I look forward to it. Michael W |

| Neil Wyatt | 26/07/2016 18:50:36 |

19226 forum posts 749 photos 86 articles | |

| Ajohnw | 28/07/2016 18:44:24 |

| 3631 forum posts 160 photos | I bought a couple of the files on ebay that I mentioned. They are very sharp. A bit heavily built for flat precision work but I suspect that is down to the style of file.

John - |

| dcosta | 28/07/2016 20:05:09 |

| 496 forum posts 207 photos | Hello Ketan, Ketan: Arc is hoping to carry a range of their products soon. Thank you Dias Costa for introducing us to Tomé. I was very happy to help you. Dias Costa

|

| Brian H | 28/07/2016 20:55:52 |

2312 forum posts 112 photos |

During my apprenticeship we were always instructed to break in new files and brass components or scrap brass before using them on cast iron or steel. I remember a fiendish test where we had to file out a 1" square hole in a plate and then file up a 1" cube so that it would fit without rattling in every possible way of fitting it.

|

| Tim Stevens | 28/07/2016 21:30:52 |

1779 forum posts 1 photos | How long before someone makes a model file cutting machine and demonstrates at a show how needle files are made? Cheers, Tim |

| Neil Wyatt | 29/07/2016 08:55:22 |

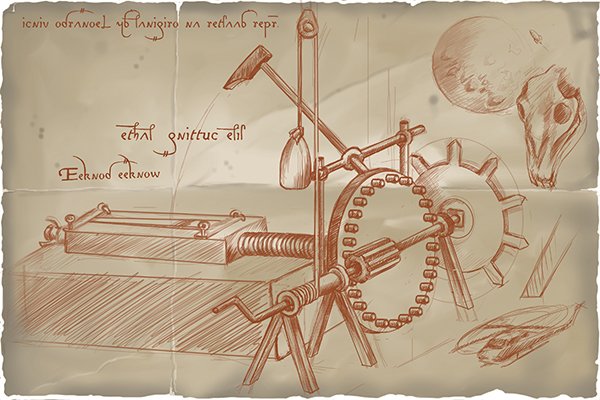

19226 forum posts 749 photos 86 articles | I wonder how many times this "Leonardo da Vinci" design has been mindlessly reproduced on the web by people who have not looked in the lower right hand corner

|

| Ajohnw | 29/07/2016 09:41:48 |

| 3631 forum posts 160 photos | Posted by Brian Hutchings on 28/07/2016 20:55:52:

During my apprenticeship we were always instructed to break in new files and brass components or scrap brass before using them on cast iron or steel. I remember a fiendish test where we had to file out a 1" square hole in a plate and then file up a 1" cube so that it would fit without rattling in every possible way of fitting it.

Brass. Lucky you. I was given rather large chunk of steel, a new 10" 2nd cut file, a surface plate, an angle plate, raddle and told to make a dice. Perfect 1.690" cube with the spots positioned by eye to 0.001" via boxes scribed with a height gauge. I can't remember how big the chunk of steel was really but I suspect 4" a side. It took some blisters and months to make it. From memory it was around 1 3/4 per side when they told us to finish it to size. The sizes used were historic and left people reasonably capable of fairly accurate work with a file. Then came the 1" square within a square that was about 3/8" thick followed by a bit of press tool work. Making a curiously shaped template on a shadow graph and then fitting that to a hole in a hefty block of steel. Also a number of oddments. Cold chisel, screw driver blade, odd leg callipers, a tap wrench and a tool makers cabinet out of folded sheet steel. Raddle is very fine red lead oxide mixed with a very light oil. John - |

| John Stevenson | 29/07/2016 09:50:25 |

5068 forum posts 3 photos | Posted by Neil Wyatt on 29/07/2016 08:55:22:

I wonder how many times this "Leonardo da Vinci" design has been mindlessly reproduced on the web by people who have not looked in the lower right hand corner

Is that your Mondayo Neil ? |

| Michael Gilligan | 29/07/2016 16:38:00 |

23121 forum posts 1360 photos | Posted by John Stevenson on 29/07/2016 09:50:25:

Is that your Mondayo Neil ? .

Nay Sir, 'tis an eckerplopter. MichaelG. |

| Ketan Swali | 17/10/2016 20:06:34 |

| 1481 forum posts 149 photos | Posted by dcosta on 28/07/2016 20:05:09:

Hello Ketan, Ketan: Arc is hoping to carry a range of their products soon. Thank you Dias Costa for introducing us to Tomé. I was very happy to help you. Dias Costa Finally put into stock this evening at ARC. Ketan at ARC. |

| Neil Wyatt | 17/10/2016 21:05:54 |

19226 forum posts 749 photos 86 articles | Looking closer at that pic again, there's a rocket at top right and try reading the text backwards Neil |

| Ian P | 17/10/2016 22:02:41 |

2747 forum posts 123 photos | Posted by Ketan Swali on 17/10/2016 20:06:34

Finally put into stock this evening at ARC. Ketan at ARC.

But when will they appear on the website so we can buy them? Ian P |

| Ketan Swali | 17/10/2016 23:12:01 |

| 1481 forum posts 149 photos | Posted by Ian Phillips on 17/10/2016 22:02:41:

Posted by Ketan Swali on 17/10/2016 20:06:34

Finally put into stock this evening at ARC. Ketan at ARC.

But when will they appear on the website so we can buy them? Ian P Hi Ian, They are on the website in the cutting tools section, link Ketan at ARC |

Please login to post a reply.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Mine was a very very slightly firmer in one orientation.

Mine was a very very slightly firmer in one orientation.

Register

Register Log-in

Log-in