The Workshop Progress thread 2018

| Hopper | 22/06/2018 11:10:47 |

7881 forum posts 397 photos | Bit late I know, but maybe early for next time. An old painter's trick when prepping aluminium or galvanized steel etc. is to wipe it down with white vinegar. It cleans and etches the surface and helps the paint stick. |

| Jim Nic | 22/06/2018 14:06:34 |

406 forum posts 235 photos | Geoff To achieve the distinctly non prototypical polished rim on cast iron flywheels, after machining them to size and painting them, I mount them on a mandrel the same diameter as the crankshaft and chuck them up in a 3 jaw chuck on the lathe. Then it's a matter of turning it at a slowish speed (250 - 300 RPM ) and using a file and then progressively finer grades of abrasive paper until a smooth finish is obtained and finally finishing off on a buffing wheel. Before I made my buffing wheel I left them on the lathe and used Solvol Autosol automotive metal polish. This is not recommended, being a bit risky in the event the polishing cloth catches in the chuck. Jim Edited By Jim Nic on 22/06/2018 14:07:19 |

| JasonB | 22/06/2018 14:51:14 |

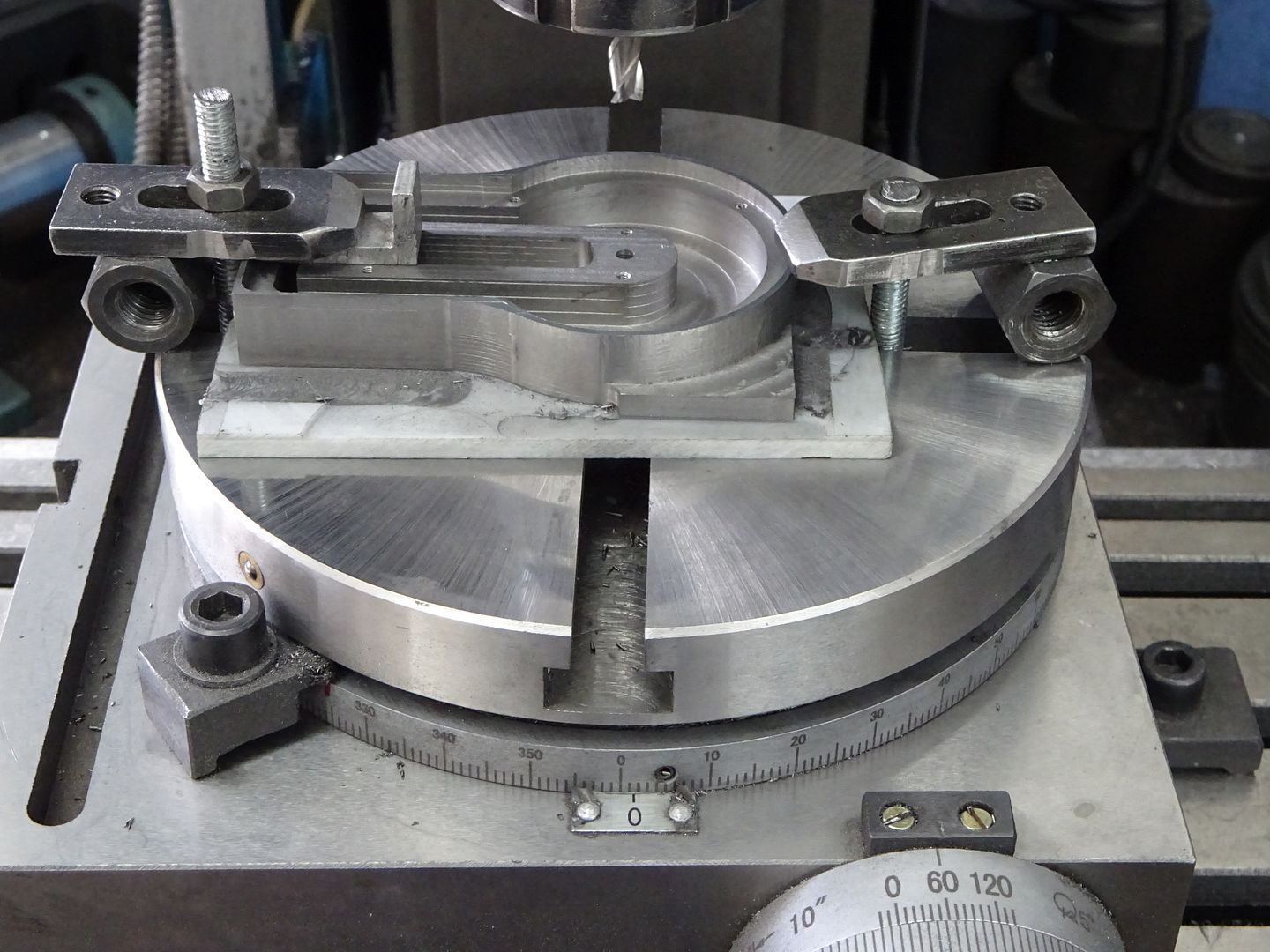

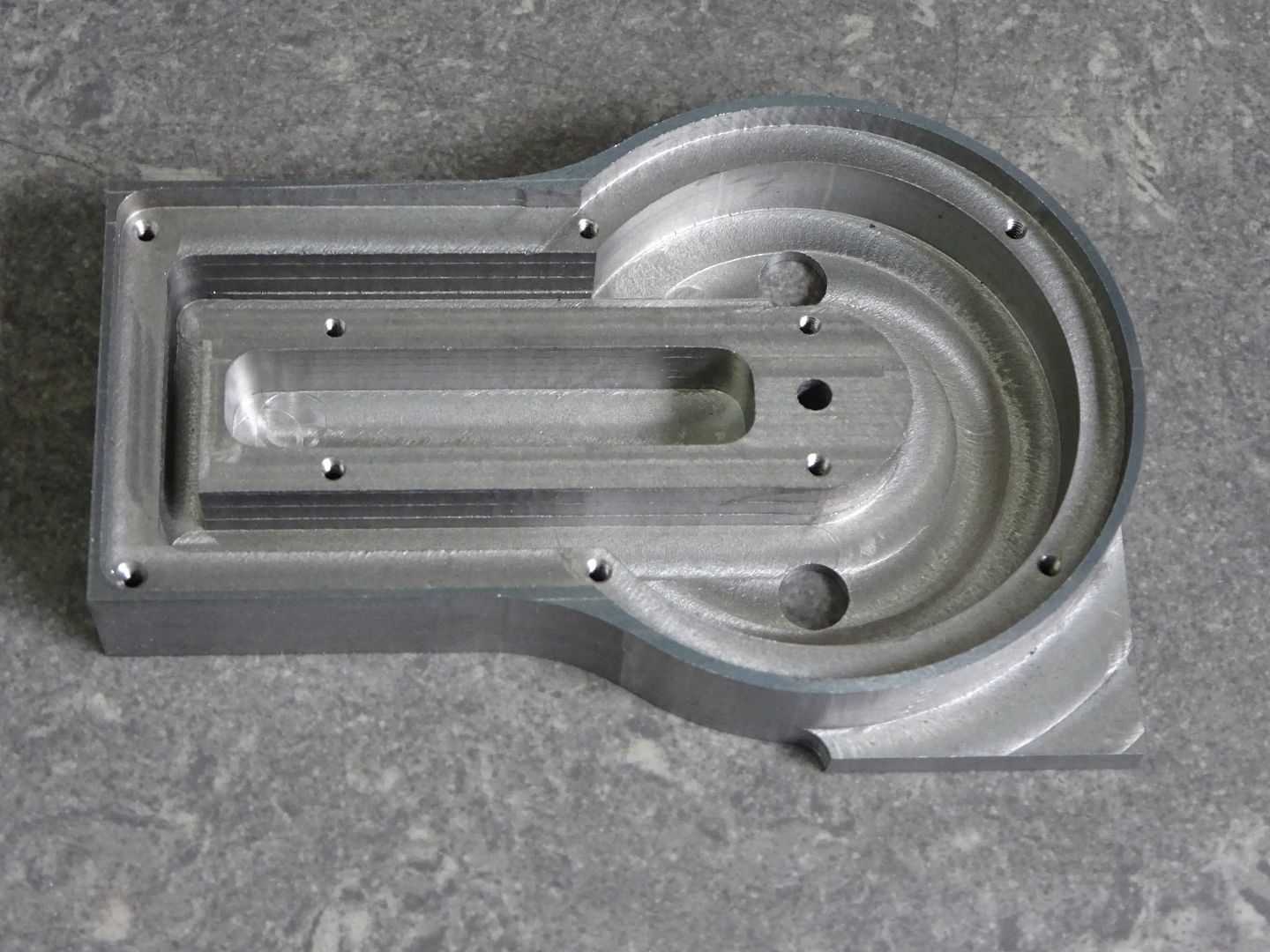

25215 forum posts 3105 photos 1 articles | Over the last week I have been doing the odd bit of machining on the Robinson hot air engine's base, started life as a slice off some 100mm dia bar

Then after a twirl or two on the rotary table and much swarf later it looks more the part. I'm quite liking the 150mm Rotary Table that ARC do, the 72:1 ratio makes for less handle turning and the ability to set the ring with 0-360 degree divisions anywhere around the table makes for easier setup, numbers are also easier to read than my Soba one.

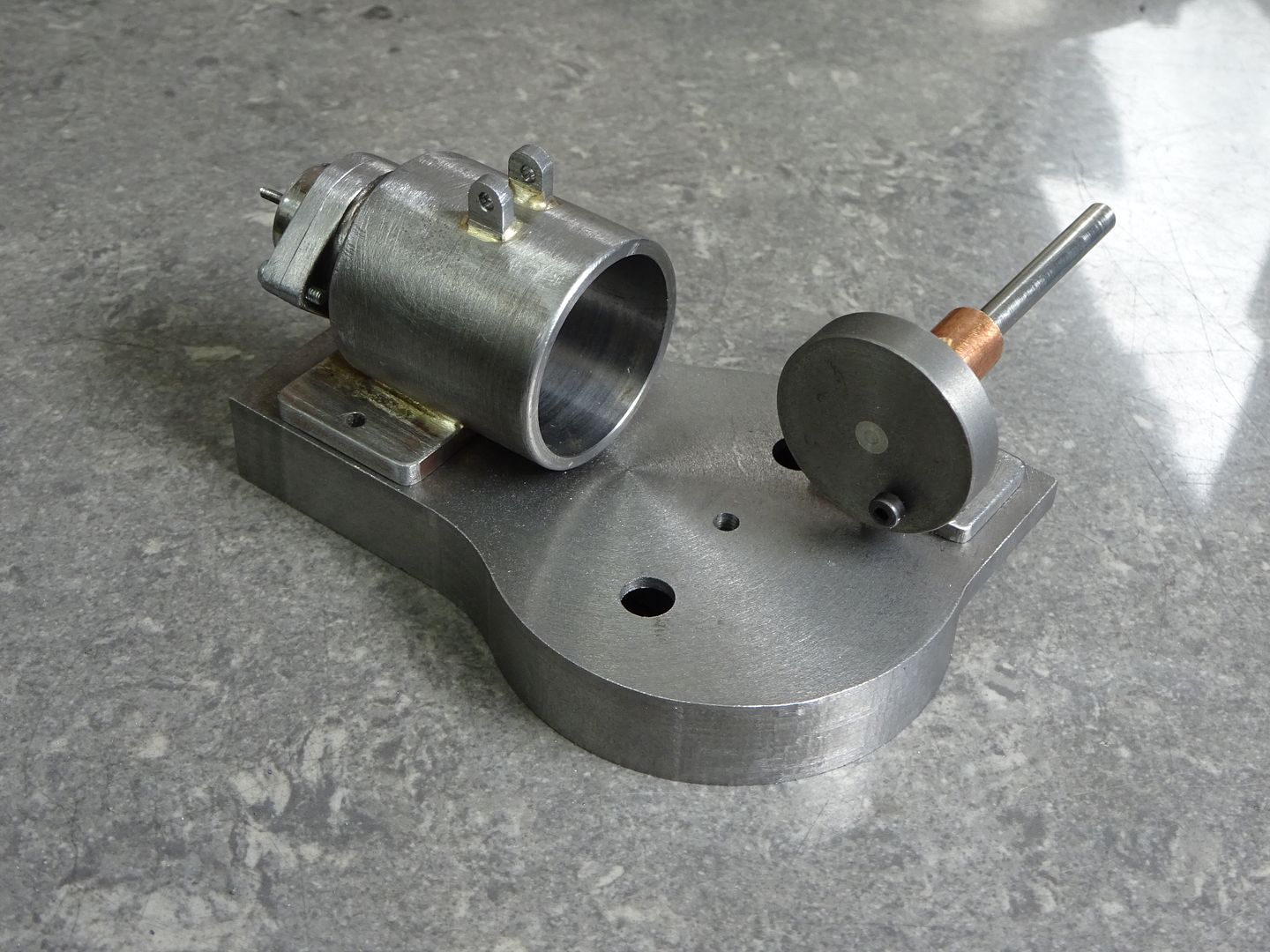

And with cylinder and crank/bearing in place

|

| Jim Nic | 22/06/2018 15:46:41 |

406 forum posts 235 photos | "A twirl or two on the rotary table". I really must read up and practice twirling if that's the kind of result possible. Jim |

| mechman48 | 23/06/2018 12:40:36 |

2947 forum posts 468 photos | Twirling or twerking?... ooh matron you are awful... |

| duncan webster | 24/06/2018 00:02:31 |

| 5307 forum posts 83 photos | Today I set about making blow down valve for my stationary boiler, and while I'm at it a second one, for the loco I'm building (very slowly) at the same time. I know the thread in the boiler is 5/16*32 so no need to check. Wrong, it's 3/8*32, so I'm now making 3 off. It takes surprisingly little extra time to make 3, finding all the right drills, taps etc takes most of the time. Artificial intelligence is no match for natural stupididty! Edited By duncan webster on 24/06/2018 00:03:08 |

| Michael Briggs | 24/06/2018 00:37:23 |

| 221 forum posts 12 photos | Arc 150mm rotary table, £389, ouch ! 😳 |

| Nige | 24/06/2018 08:22:18 |

370 forum posts 65 photos | Mmm, WARCO do a 150mm rotary table for £149 but I'm not experienced enough to make anything other than a 'cost' comparison though the Arc one certainly looks a more expensive job. Just thought this might not be the right thread to kick off a comparison of rotary tables, would a moderator please move if necessary. Edited By Nige on 24/06/2018 08:24:01 |

| mechman48 | 24/06/2018 11:25:22 |

2947 forum posts 468 photos | A little more done on my Vertical Cross, cladding & banding... may have to trim banding a little more, it clears the inlet flange ok, possibly trim the length a touch more, I leave the masking tape on to ensure paintwork has hardened up plus allowing for any touch ups... looks ok with the light blue... |

| geoff walker 1 | 24/06/2018 12:28:09 |

| 521 forum posts 217 photos | Hi Jim, To achieve the distinctly non prototypical polished rim on cast iron flywheels, after machining them to size and painting them, I mount them on a mandrel the same diameter as the crankshaft and chuck them up in a 3 jaw chuck on the lathe. Then it's a matter of turning it at a slowish speed (250 - 300 RPM ) and using a file and then progressively finer grades of abrasive paper until a smooth finish is obtained and finally finishing off on a buffing wheel. Yes this method was great Jim. I've just done a stuart flywheel finishing with 1200 grade wet or dry using light oil as a lubricant. A final buff and it's come up a treat. cheers Geoff |

| mechman48 | 27/06/2018 17:59:24 |

2947 forum posts 468 photos | ... 'Yes this method was great Jim. I've just done a Stuart flywheel finishing with 1200 grade wet or dry using light oil as a lubricant.' ... |

| Neil Wyatt | 27/06/2018 21:17:51 |

19226 forum posts 749 photos 86 articles | Hey Gerge, I like the Origami bird... I have one of the 150mm Warco tables, strictly far too huge for my X2, but I needed a big one and it just about lets me get away with it. Very smooth and nicely made, I thought a lot for the price. I know Jason is very chuffed with his Arc one which is a lot more 'modern'. |

| mechman48 | 28/06/2018 15:26:16 |

2947 forum posts 468 photos | ... Hey George, I like the Origami bird... |

| mechman48 | 29/06/2018 09:44:59 |

2947 forum posts 468 photos | Did a pre-run reassembly, looks ok if I say so mesel', just need to reset timing & bit clean up... |

| Johnboy25 | 29/06/2018 11:13:45 |

260 forum posts 3 photos | It’s been a little too warm in the workshop lately to get serious work done.😕 Yesterday my max/min thermometer indicated 31 Centigrade. As much as I like this time of year I seem to more done when it cooler. So it’s evenings and mornings being the best times at the moment. A good time perhaps to draw up plans for an insulated replacement workshop! John |

| Jim Nic | 29/06/2018 13:54:58 |

406 forum posts 235 photos | Certainly looks good George, do she run yet? Jim |

| mechman48 | 29/06/2018 17:05:02 |

2947 forum posts 468 photos | Posted by Jim Nic on 29/06/2018 13:54:58:

Certainly looks good George, do she run yet? Jim

|

| geoff walker 1 | 29/06/2018 19:55:39 |

| 521 forum posts 217 photos | Yes, very nice George. Do you run on steam or compressed air. Could I ask a general question here. A lot of "older" designs have a crank arm which is very simple and not balanced with a web the opposite side to the crank pin. Why is that, do some engines just not need it? Geoff |

| mechman48 | 29/06/2018 22:37:03 |

2947 forum posts 468 photos | Re-assembled & trial run... hopefully it has embedded her ok. Still need a tidy up & clean up but she's working... |

| JasonB | 30/06/2018 07:01:07 |

25215 forum posts 3105 photos 1 articles | Looking good George but does sound like you are leaking air which would be one reason your compressor is kicking in so soon.

J |

This thread is closed.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - Winter Storage Of Locomotives

04/10/2023 21:02:11 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in