The Workshop Progress Thread 2019

| Ron Laden | 15/11/2019 08:37:26 |

2320 forum posts 452 photos | Posted by JasonB on 11/11/2019 06:59:22:

No that's another one of his engine designs, a Type B

Jason, would I be correct in thinking you have a full set of castings for the engine and going by the picture did you bring them in from the US. |

| JasonB | 15/11/2019 09:11:13 |

25215 forum posts 3105 photos 1 articles | Morning Ron, yes I have the set of castings for the Type B, there are not that many but they

Nick Roland who is RMC had not been producing any engines for a few years but has started up again just getting small batches of 8-10 engines done and selling through e-bay. I spotted this one in February so ordered one. They are not badly priced but coming from the US cost about $70 postage and then you also have to pay VAT and fees on the total. Last week he put up a batch of the type D engines so I have just treated myself to a set of those castings for Christmas, as you can see about $100 postage on this as it is a bit heavier but he still has some available if anyone wants a set of castings while they are still hot. Very good quality ductile iron castings and cleanly cast though due to the nature of how the Type D frame is cast there is some flash on that. Some of the best plans and construction notes I have seen plus a CD with several hundred photos taken during construction as well as other helpful info. I have also got a type A that was recently completed but not running yet and I may have to do some mods to it as being originally designed to run on MAPP gas which you can't get now, it does not really run on other gasses. This was bought from a collector in the US who was thinning out his collection of unmade kits. Also have my name down for a set of plans for his SB2C when they become available.

J

PS if anyone knows of a set of type C or E castings looking for a new home I would be interested. Edited By JasonB on 15/11/2019 10:14:20 |

| Ron Laden | 15/11/2019 13:40:03 |

2320 forum posts 452 photos | One thing is for certain Jason, I dont think I would ever get tired of looking at those engines they are different to say the least. I can see that some of the parts may be a bit of a challenge to set up for machining but the end result makes it well worth it, the Type D I think looks amazing. Can I ask you keep us up to speed with progress it will be good to see them come together. Ron p.s. Forgot to say that watching the videos both the Type D and SB2C run very nicely indeed.

Edited By Ron Laden on 15/11/2019 14:02:37 |

| Ron Laden | 16/11/2019 06:28:45 |

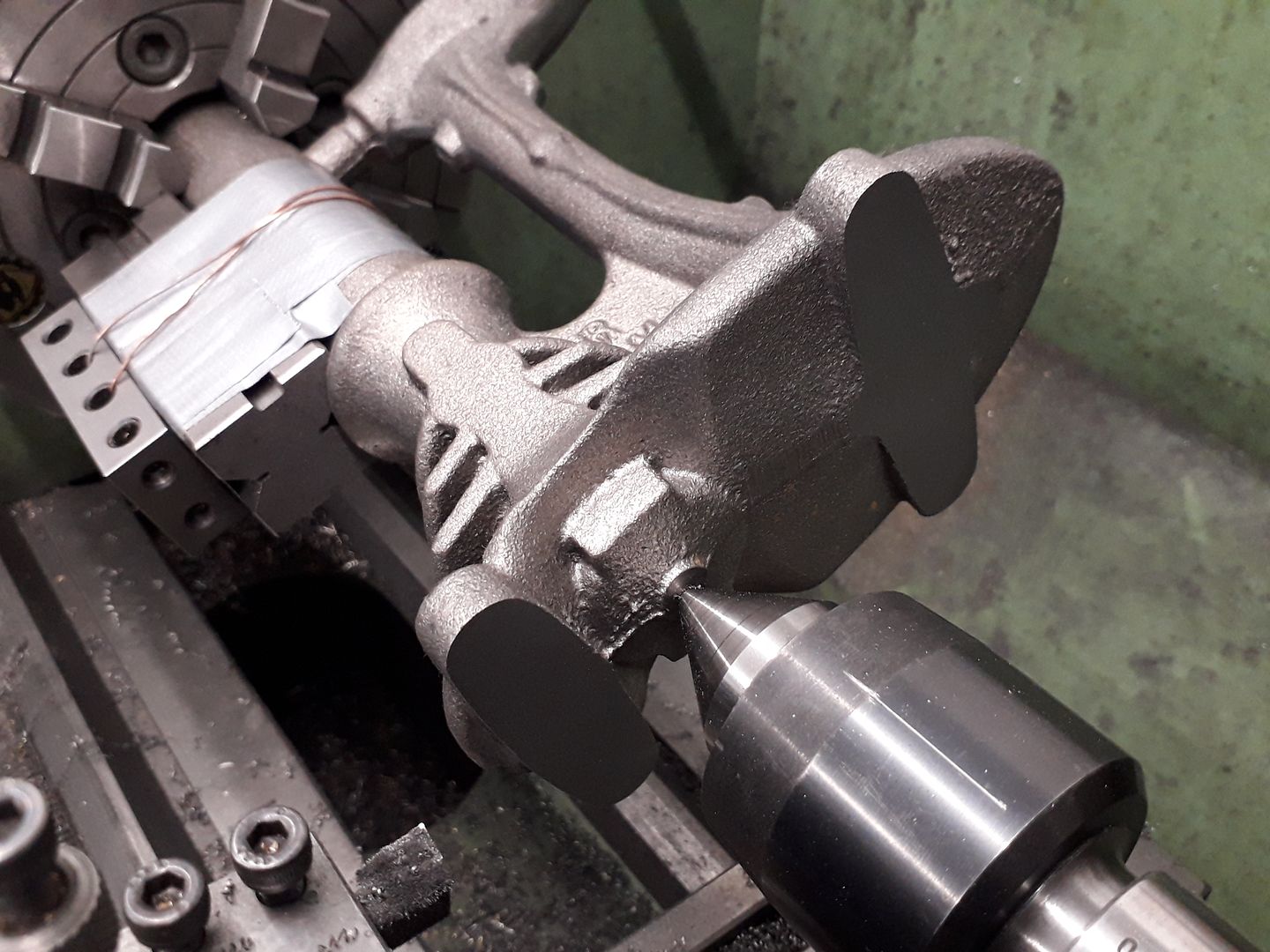

2320 forum posts 452 photos | Morning Jason The picture of the type B main frame set up in the lathe looks interesting I am guessing the V and 123 blocks are balancing out the bulk offset in the casting. Is the V taped on with 123 cross wired over the top..? Ron |

| JasonB | 16/11/2019 07:04:13 |

25215 forum posts 3105 photos 1 articles | Yes, two Vee blocks held with duct tape but they were not enough so added a 15-30-60 block and in the end also screwed a 10-20-40 to that when boring but 300rpm was about as fast as it was happy to run |

| Anthony Knights | 16/11/2019 11:06:12 |

| 681 forum posts 260 photos |

Got some brass strip to use for the gib. Clamped it to the dovetail to machine the top edge. Turned it over and packed it up with a hacksaw blade and cut the other edge. De-burred it and tried it for fit.

|

| JasonB | 17/11/2019 16:20:57 |

25215 forum posts 3105 photos 1 articles | Some good progress on the RMC Type B engine over the weekend. main casting complete and the pulley made from the now redundant chucking spigot, also got the two main bearings done so things could be slipped together.

The 3mm dia glass tube and 0.5mm tungsten electrode arrived yesterday so a bit of spark plug making may be next on this build though still waiting for the Loctite "Black Max" |

| Ian McVickers | 17/11/2019 17:14:44 |

| 261 forum posts 117 photos | Finally managed to get back into the shop and get the dro install finished on the Omnimill. I went down the pc based dro route seeing as I had a small pc and spare touch screen lying around. I had planned on using rotary encoders and rack I have as well but that idea didn't work out so I went for scales. The monitor is 21" wide screen so I don't have an excuse for miss-reading the dro now. So far it works well and I plan on fitting further scales on the vertical axis and quill. Edited By JasonB on 17/11/2019 17:17:24 |

| Anthony Knights | 18/11/2019 08:43:47 |

| 681 forum posts 260 photos | Used the set up below to drill the holes for the gib strip adjusters. It was a bit tight and looks a bit precarious, but it's solid enough for drilling. I then clamped the gib strip in place and drilled through to put the dimples in the gib. I then removed the work piece from the milling machine and tapped the holes by hand. I haven't got any 3mm hex socket head screws so I've had to use pozi head screws as a temporary measure. |

| Anthony Knights | 20/11/2019 03:50:39 |

| 681 forum posts 260 photos | It's me again. I must be the only one braving the cold workshop. Made a plate to carry the lead screw. Then fitted the plate and lead screw to the table. |

| Mark Rand | 20/11/2019 21:29:46 |

| 1505 forum posts 56 photos | Posted by Anthony Knights on 20/11/2019 03:50:39:

It's me again. I must be the only one braving the cold workshop. Made a plate to carry the lead screw. I wasn't braving my cold workshop (which is quite warm, actually). I was on the roof of it replacing some damaged flashing. |

| Ian P | 20/11/2019 21:39:37 |

2747 forum posts 123 photos | Posted by Ian McVickers on 17/11/2019 17:14:44:

Finally managed to get back into the shop and get the dro install finished on the Omnimill. I went down the pc based dro route seeing as I had a small pc and spare touch screen lying around. I had planned on using rotary encoders and rack I have as well but that idea didn't work out so I went for scales.

The monitor is 21" wide screen so I don't have an excuse for miss-reading the dro now. So far it works well and I plan on fitting further scales on the vertical axis and quill. Edited By JasonB on 17/11/2019 17:17:24 I assume there is a PC with box of tricks driving the monitor, I have looked on the Machine DRO website and cannot see anything that resembles the equipment in the picture. Please could you post a link. Ian P

|

| JasonB | 21/11/2019 07:26:03 |

25215 forum posts 3105 photos 1 articles | First picture in Ian's post shows the PC interface sat on top of a small PC. The Main Machine-DRO site has none listed but M-DRO does? EDIT, found it on the main site now Edited By JasonB on 21/11/2019 07:34:11 |

| Michael Gilligan | 21/11/2019 08:48:22 |

23121 forum posts 1360 photos | Looks a good idea ... but: This product is now discontinued, please contact us for possible alternatives. MichaelG. |

| Ian McVickers | 21/11/2019 12:44:27 |

| 261 forum posts 117 photos | The DRO interface is indeed on top of the small pc. The older model is still on the website but I have one of the first new ones. Looks like they havent got everything finished off yet. Last time I spoke to Tony at M-DRO he said they were waiting on label plates I think. Worth giving him a call if your interested. |

| Ian McVickers | 21/11/2019 12:45:59 |

| 261 forum posts 117 photos | Forgot to add that mine has 4 input channels, the other one is on the back. Im sure Tony said that you can choose either 3 or 4 inputs. |

| JasonB | 24/11/2019 17:26:02 |

25215 forum posts 3105 photos 1 articles | I've remembered one of the reasons I'm not keen on casting kits - they don't take long to do

|

| Mark Rand | 24/11/2019 22:14:04 |

| 1505 forum posts 56 photos | Darn it, I take longer than that to clean up the mess in the shed |

| JasonB | 27/11/2019 07:29:12 |

25215 forum posts 3105 photos 1 articles | A bit of progress in the "virtual" workshop over the last couple of evenings and I have my next project. I had seen this engine on Preston's site several years ago and liked the look of it so copied the images to my "future projects" file. Size dictated by the offcut of 7" dia thickwall steel tube that I was given which will be used for the flywheel rim. Still a bit of tweaking needed to the design before I start cutting metal - cylinder may be a bit large in dia and circular base a bit small. Edited By JasonB on 27/11/2019 07:37:12 |

| Ron Laden | 27/11/2019 07:51:29 |

2320 forum posts 452 photos | Posted by JasonB on 24/11/2019 17:26:02:

I've remembered one of the reasons I'm not keen on casting kits - they don't take long to do

Excellent, I really like the look of it, look forward to seeing it run dont forget the video Jason. |

This thread is closed.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in