The Workshop Progress Thread (2017)

Report your modeling and workshop progress here

| matt merchant | 17/05/2017 20:51:25 |

19 forum posts 2 photos | think this should be here rather than the do today thread. whoop took delivery today of a lovely little sieg sc2 lathe from Ketan and the team at arceurotrade really good service from them, 3 days from ordering to the well packed sturdy wooden crate being passed to my mucky dabs. ive not done much apart from unpack at the moment, tomorrows job after work will be cleaning off the packing grease and lubing her up Matt

|

| duncan webster | 17/05/2017 21:40:58 |

| 5307 forum posts 83 photos | Posted by JasonB on 10/05/2017 21:01:01:

For a bit of a break from the hit & miss engine carts I knocked this up over the last couple of weeks. About a 2/3rd size replica of the Alyn Foundry "CHUK" flame licker. Will do a build thread with drawings on MEM forum and probably post it here too. With thanks to Graham Corry (Alyn Foundry) and Andy over on MEM. Edited By JasonB on 10/05/2017 21:02:36 Like it, are flame lickers usually this loud? |

| JasonB | 18/05/2017 07:30:29 |

25215 forum posts 3105 photos 1 articles | Depends on the exhaust valve arrangement, this one has a large diaphram valve at the bottom of the cylinder and that is the farting sound you can hear. About 4 mins into this video of the vertical version Graham shows the valve and confirms it is the source of the noise, it is acutally the full dia of the bore and made from a 0.5mm disc parted off the end of a cast iron bar..

Edited By JasonB on 18/05/2017 08:01:33 Edited By JasonB on 18/05/2017 08:02:16 |

| mechman48 | 21/05/2017 12:15:21 |

2947 forum posts 468 photos | Nearing completion of my S50, sprayed up the castings, dried over a couple of days, then pre-trial assembly yesterday... |

| JasonB | 21/05/2017 17:57:14 |

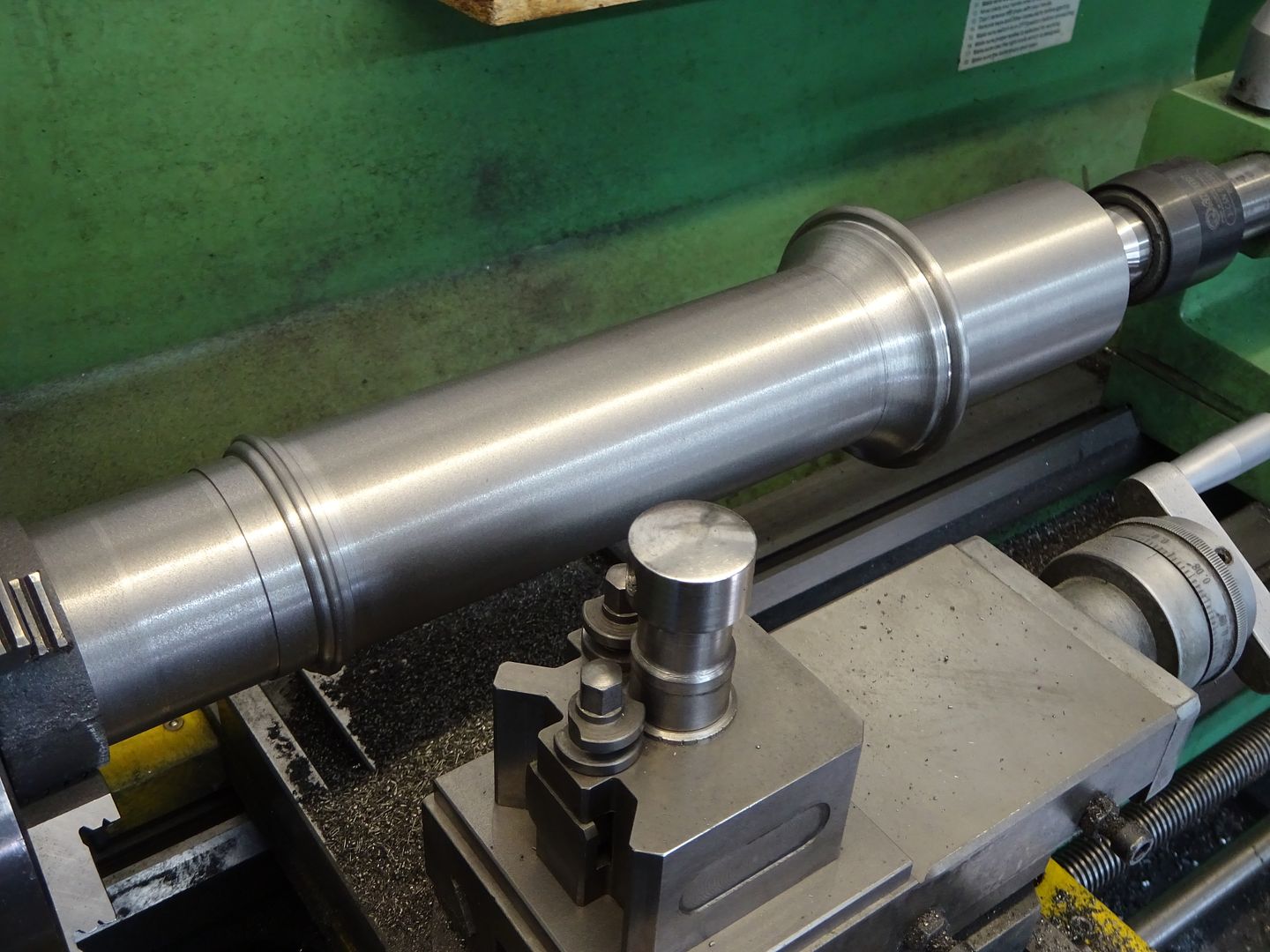

25215 forum posts 3105 photos 1 articles | A couple of weeks ago I picked up[ my set of casting sfor a 1/4 scale Otto Langen engine that I made the patterns for some time ago and thought I had best take a skim off them to make sure the castings were sound. Then I thought that while on the lateh it would be silly not to do a bit more work on them. Column so far, the long central area is still to be taper turned and fluted but has been left parallel to make things easier to hold as the 325mm long bore will hopefully be done with a between ctrs bar, for now I have bore dit with a toolpost bar in from either end and left 3mm under finished size.

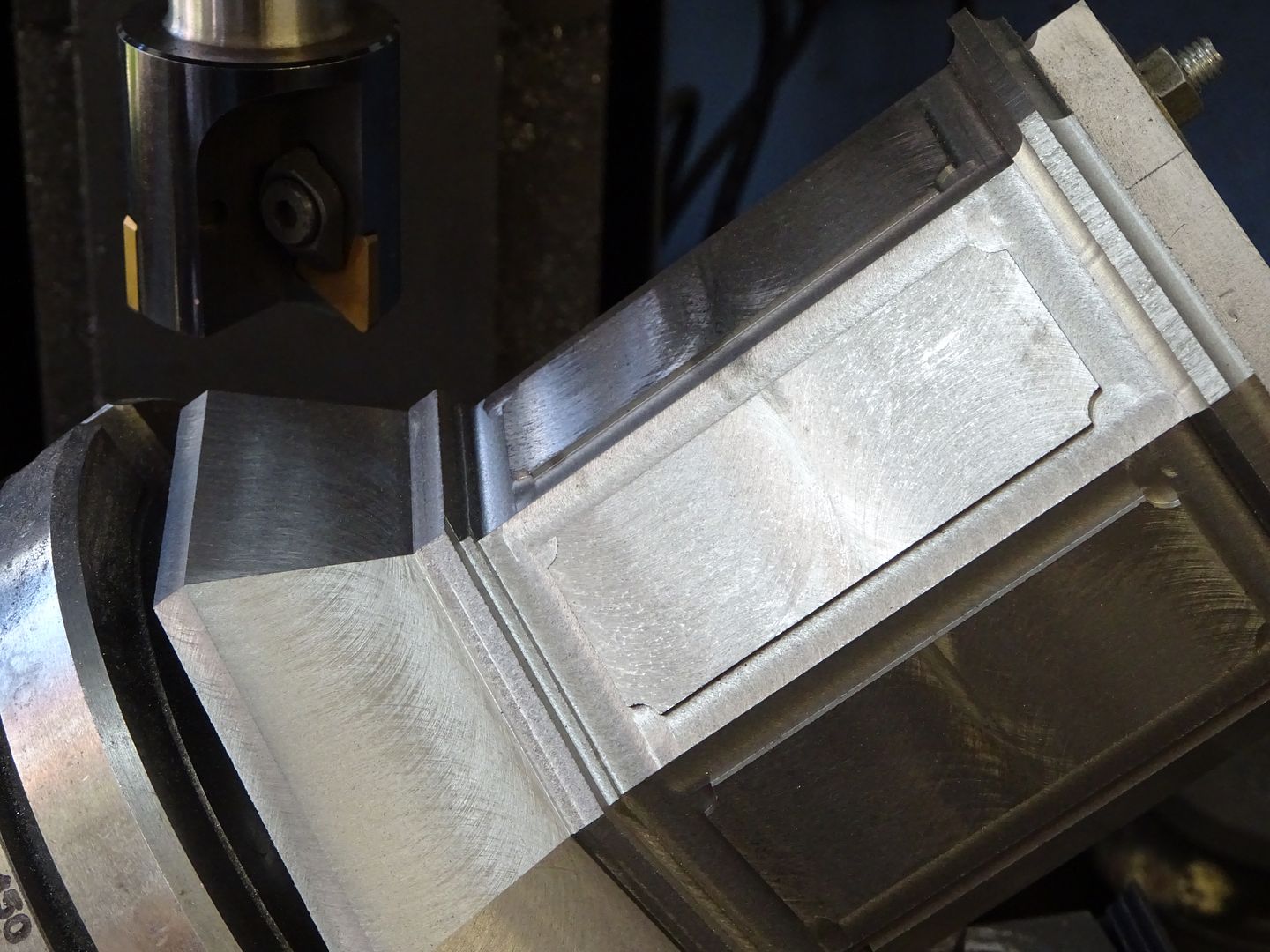

Same thing happend with the base, once it was on teh rotary table I could not see the point in taking it off until most of the machining was done.

|

| mechman48 | 24/05/2017 16:54:02 |

2947 forum posts 468 photos | Finished tweaking my S50 & gave it a final test run... runs nicely on 4 psi. Haven't decided on the cylinder lagging yet, maybe just leave as is

Edited By JasonB on 24/05/2017 17:08:53 |

| JasonB | 24/05/2017 17:09:34 |

25215 forum posts 3105 photos 1 articles | Very Nice |

| MW | 24/05/2017 18:42:37 |

2052 forum posts 56 photos | Posted by JasonB on 21/05/2017 17:57:14:

A couple of weeks ago I picked up[ my set of casting sfor a 1/4 scale Otto Langen engine that I made the patterns for some time ago and thought I had best take a skim off them to make sure the castings were sound. Then I thought that while on the lateh it would be silly not to do a bit more work on them. Column so far, the long central area is still to be taper turned and fluted but has been left parallel to make things easier to hold as the 325mm long bore will hopefully be done with a between ctrs bar, for now I have bore dit with a toolpost bar in from either end and left 3mm under finished size.

Really good turning and probably one of the best bits of metal work I've seen. How do you get so much done? is it just a little everyday? Michael W |

| JasonB | 24/05/2017 20:41:49 |

25215 forum posts 3105 photos 1 articles | I use my 3-jaw chuck and don't often work to 0.0001" or better Usually a couple of weekday evenings and some work at the weekends |

| MW | 24/05/2017 21:29:16 |

2052 forum posts 56 photos | Posted by JasonB on 24/05/2017 20:41:49:

I use my 3-jaw chuck and don't often work to 0.0001" or better Usually a couple of weekday evenings and some work at the weekends lol, 0.00254mm I think each unit of my DRO is 0.005mm! Those old timers really liked their fine fits you see. Guess it just goes to show what rank amateurs we are, what with our self centring nonsense chucks; it makes my 0.03mm max runout 3 jaw look very poor indeed. If I stopped offering to make things for other people maybe I could focus on making things for me! Really random question here, but since we're on the subject of accuracy is it possible to buy a dial clock finer than 0.01mm? every time I've looked it's always that finest unit. Michael W

|

| Michael Gilligan | 24/05/2017 22:13:49 |

23121 forum posts 1360 photos | Posted by Michael-w on 24/05/2017 21:29:16:

Really random question here, but since we're on the subject of accuracy is it possible to buy a dial clock finer than 0.01mm? every time I've looked it's always that finest unit. . http://www.mitutoyo.co.uk/small-tool-instruments-and-data-management/indicators/2900s-10 MichaelG. |

| MW | 24/05/2017 22:18:22 |

2052 forum posts 56 photos | Posted by Michael Gilligan on 24/05/2017 22:13:49:

MichaelG. Thank you! Michael W Edited By Michael-w on 24/05/2017 22:18:56 |

| Neil Wyatt | 24/05/2017 22:22:16 |

19226 forum posts 749 photos 86 articles | Good stuff, George. Neil |

| Joseph Noci 1 | 25/05/2017 06:59:13 |

| 1323 forum posts 1431 photos | Posted by Michael-w on 24/05/2017 21:29:16:

Really random question here, but since we're on the subject of accuracy is it possible to buy a dial clock finer than 0.01mm? every time I've looked it's always that finest unit. Michael W Hi Michael, I purchase one of these in the link, and it is actually very good indeed. -0.001mm indications - if seems reasonable in calibration, but then my reference is my DRO on the lathe, and it seems spot on in DRO steps of 0.0025mm. Was US $41.00 plus $7.00 expedited shipping - 3 weeks....(expedited??)

Joe |

| mechman48 | 25/05/2017 14:35:28 |

2947 forum posts 468 photos | JasonB

|

| Ian S C | 25/05/2017 14:35:42 |

7468 forum posts 230 photos | For setting up the lathe, don't go too fine, .001" is good enough(or metric equivalent), too fine and you will be for ever, trying to get zero while setting the 4 jaw chuck. Ian S C |

| JasonB | 25/05/2017 15:30:11 |

25215 forum posts 3105 photos 1 articles | George, when you are on the you tube screen a little bit below the video is a tab that says "share" if you click that it will cange to "share-Embed-Email" click embed and the box below will show a URL that starts <iframe..... Copy this url and then when you are posting here click the youtube icon along the top of the editing window and paste the URL there and say OK. It will look as though you have got it wrong as you will just get a big box with a red IFRAME written in tehemiddle but once you submit your reply that will change to the video. |

| mechman48 | 25/05/2017 20:10:42 |

2947 forum posts 468 photos | JasonB... thanks for the info'

|

| Joseph Noci 1 | 25/05/2017 21:35:20 |

| 1323 forum posts 1431 photos | Finally got to do the Rotary Encoder for my EMCO V10 X Axis. I have an old - 20 years - FAGOR DRO control unit with one working glass scale that I used on the V10 Z Axis, mounted behind the bed. The glass scale that used to be used on the X axis was smashed, and that's how I came to 'owning' this FAGOR unit - saved from the trash... I decided to try and make a rotary encoder fitted into the handwheel area of the cross slide, and adapting that encoder output to drive the FAGOR Unit. The encoder is a 1024 pulse/rev Quadrature encoder ( 2 pulse trains, one 90deg phase lagging the other). This gives in effect 4x1024 - 4096 edges per revolution. My leadscrews is a 2mm pitch, and the FAGOR unit glass scale gave 400 pulse per rev of the handwheel, ie, 400 pulse for 2mm movement ( 0.005mm resolution). So I used an Arduinio and some software to basically interpolate ( via Bresenhams, for those interested) the 4096 edges down to 400, and made the FAGOR display very happy..The whole thing is together, and works very nicely - Of course it does not measure axis movement, but leadscrew rotation, so does not take care of backlash, but on the cross slide, one tends to work in one direction anyway, even when using the handwheel dials.. milling the encoder housing to shape: The front cover plate - yucky stringy aluminium alloy this.. The Housing:

Trial fit of encoder wheel and optical sensor - also the extension to the leadscrew for the handwheel. Trial fit without the Cover/Housing: Coming together:

All fitted in place - Wires are routed in side two counter wound SSteel springs, and then down a brass tube, over the saddle to behind the bed, and then to a flexible armoured cable to the Arduino.

And the I looked out the workshop window... ....Joe

|

| David Standing 1 | 25/05/2017 23:37:23 |

| 1297 forum posts 50 photos | Joe Looks like you have been out and ironed your beach! I would expect nothing less of you |

This thread is closed.

Want the latest issue of Model Engineer or Model Engineers' Workshop? Use our magazine locator links to find your nearest stockist!

Sign up to our newsletter and get a free digital issue.

You can unsubscribe at anytime. View our privacy policy at www.mortons.co.uk/privacy

- hemingway ball turner

04/07/2025 14:40:26 - *Oct 2023: FORUM MIGRATION TIMELINE*

05/10/2023 07:57:11 - Making ER11 collet chuck

05/10/2023 07:56:24 - What did you do today? 2023

05/10/2023 07:25:01 - Orrery

05/10/2023 06:00:41 - Wera hand-tools

05/10/2023 05:47:07 - New member

05/10/2023 04:40:11 - Problems with external pot on at1 vfd

05/10/2023 00:06:32 - Drain plug

04/10/2023 23:36:17 - digi phase converter for 10 machines.....

04/10/2023 23:13:48 - More Latest Posts...

- View All Topics

- Reeves** - Rebuilt Royal Scot by Martin Evans

by John Broughton

£300.00 - BRITANNIA 5" GAUGE James Perrier

by Jon Seabright 1

£2,500.00 - Drill Grinder - for restoration

by Nigel Graham 2

£0.00 - WARCO WM18 MILLING MACHINE

by Alex Chudley

£1,200.00 - MYFORD SUPER 7 LATHE

by Alex Chudley

£2,000.00 - More "For Sale" Ads...

- D1-3 backplate

by Michael Horley

Price Not Specified - fixed steady for a Colchester bantam mark1 800

by George Jervis

Price Not Specified - lbsc pansy

by JACK SIDEBOTHAM

Price Not Specified - Pratt Burnerd multifit chuck key.

by Tim Riome

Price Not Specified - BANDSAW BLADE WELDER

by HUGH

Price Not Specified - More "Wanted" Ads...

Do you want to contact the Model Engineer and Model Engineers' Workshop team?

You can contact us by phone, mail or email about the magazines including becoming a contributor, submitting reader's letters or making queries about articles. You can also get in touch about this website, advertising or other general issues.

Click THIS LINK for full contact details.

For subscription issues please see THIS LINK.

Model Engineer Magazine

- Percival Marshall

- M.E. History

- LittleLEC

- M.E. Clock

ME Workshop

- An Adcock

- & Shipley

- Horizontal

- Mill

Subscribe Now

- Great savings

- Delivered to your door

Pre-order your copy!

- Delivered to your doorstep!

- Free UK delivery!

Register

Register Log-in

Log-in